Conductive Polymer Inks in the Aerospace Industry

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Conductive Polymer Inks Background and Objectives

Conductive polymer inks represent a significant technological advancement in materials science, emerging from the convergence of polymer chemistry and electronic engineering. These specialized materials have evolved from basic conductive polymers discovered in the 1970s to sophisticated formulations capable of meeting the demanding requirements of aerospace applications. The evolution trajectory shows a clear shift from rigid, metal-based conductors to flexible, lightweight polymer alternatives that maintain electrical performance while adding new functionalities.

The aerospace industry has historically relied on conventional metallic conductors for electrical systems, but weight reduction imperatives and increasing electronic complexity have driven the search for alternatives. Conductive polymer inks emerged as promising candidates due to their unique combination of electrical conductivity, mechanical flexibility, and reduced weight compared to traditional metal-based solutions. This technological evolution aligns with broader aerospace trends toward lightweighting, miniaturization, and enhanced functionality.

Recent advancements in polymer chemistry have significantly improved the performance characteristics of conductive inks, particularly in terms of conductivity, adhesion, and environmental stability. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles has further enhanced their electrical properties, pushing conductivity levels closer to those of traditional metals while maintaining the inherent advantages of polymers.

The primary technical objectives for conductive polymer inks in aerospace applications include achieving conductivity levels suitable for replacing metal wiring in non-critical systems, ensuring long-term stability under extreme environmental conditions, developing manufacturing processes compatible with complex aerospace components, and meeting stringent safety and certification requirements. Additionally, there is a focus on developing formulations that can be applied through additive manufacturing techniques, enabling the creation of conformal electronics directly on structural components.

Future development goals include enhancing temperature resistance to withstand the extreme conditions experienced in aerospace environments, improving durability against UV radiation and atomic oxygen exposure in space applications, and developing self-healing capabilities to address microcracks that may develop during service. Research is also directed toward creating multi-functional inks that can simultaneously provide conductivity, electromagnetic interference shielding, and structural health monitoring capabilities.

The convergence of these technological developments with aerospace industry needs presents a significant opportunity for innovation, potentially enabling new design paradigms for aircraft and spacecraft electrical systems that are lighter, more resilient, and more integrated with structural components than current solutions permit.

The aerospace industry has historically relied on conventional metallic conductors for electrical systems, but weight reduction imperatives and increasing electronic complexity have driven the search for alternatives. Conductive polymer inks emerged as promising candidates due to their unique combination of electrical conductivity, mechanical flexibility, and reduced weight compared to traditional metal-based solutions. This technological evolution aligns with broader aerospace trends toward lightweighting, miniaturization, and enhanced functionality.

Recent advancements in polymer chemistry have significantly improved the performance characteristics of conductive inks, particularly in terms of conductivity, adhesion, and environmental stability. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles has further enhanced their electrical properties, pushing conductivity levels closer to those of traditional metals while maintaining the inherent advantages of polymers.

The primary technical objectives for conductive polymer inks in aerospace applications include achieving conductivity levels suitable for replacing metal wiring in non-critical systems, ensuring long-term stability under extreme environmental conditions, developing manufacturing processes compatible with complex aerospace components, and meeting stringent safety and certification requirements. Additionally, there is a focus on developing formulations that can be applied through additive manufacturing techniques, enabling the creation of conformal electronics directly on structural components.

Future development goals include enhancing temperature resistance to withstand the extreme conditions experienced in aerospace environments, improving durability against UV radiation and atomic oxygen exposure in space applications, and developing self-healing capabilities to address microcracks that may develop during service. Research is also directed toward creating multi-functional inks that can simultaneously provide conductivity, electromagnetic interference shielding, and structural health monitoring capabilities.

The convergence of these technological developments with aerospace industry needs presents a significant opportunity for innovation, potentially enabling new design paradigms for aircraft and spacecraft electrical systems that are lighter, more resilient, and more integrated with structural components than current solutions permit.

Market Demand Analysis for Aerospace Polymer Inks

The aerospace industry is witnessing a significant surge in demand for conductive polymer inks, driven primarily by the sector's increasing focus on lightweight components, flexible electronics, and advanced sensing systems. Market research indicates that the global aerospace conductive polymer inks market is projected to grow at a compound annual growth rate of 9.7% from 2023 to 2030, reaching a market value of 1.8 billion USD by the end of the forecast period.

This growth is largely attributed to the aerospace industry's continuous pursuit of weight reduction in aircraft components. With fuel efficiency remaining a critical concern for commercial aviation, manufacturers are actively seeking materials that can replace traditional metal conductors while maintaining electrical performance. Conductive polymer inks offer weight savings of up to 70% compared to conventional copper wiring in certain applications, translating to substantial fuel savings over an aircraft's operational lifetime.

The military and defense segment represents the largest market share for aerospace polymer inks, accounting for approximately 42% of the total demand. This is primarily due to the increasing integration of electronic warfare systems, advanced avionics, and unmanned aerial vehicles (UAVs) that require lightweight, durable electronic components capable of withstanding extreme operational conditions.

Commercial aviation follows closely, with a market share of 37%, driven by the growing adoption of in-flight entertainment systems, structural health monitoring sensors, and smart cabin technologies. The space segment, though smaller at 21% market share, is showing the fastest growth rate at 12.3% annually, fueled by the expanding small satellite market and commercial space initiatives.

Regionally, North America dominates the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade due to increasing aerospace manufacturing activities in China, Japan, and India.

Key application areas driving demand include printed circuit boards for avionics (31% of applications), flexible sensors for structural health monitoring (27%), heating elements for anti-icing systems (18%), electromagnetic interference (EMI) shielding (14%), and other applications such as antennas and RFID tags (10%). The demand for these applications is expected to grow as the industry continues to embrace more electric aircraft architectures and digital transformation initiatives.

Customer requirements are increasingly focused on performance metrics such as conductivity stability under extreme temperature variations (-65°C to +150°C), resistance to vibration and mechanical stress, and long-term reliability in high-altitude environments. Additionally, there is growing demand for polymer inks that comply with stringent aerospace safety standards and environmental regulations, particularly regarding flame retardancy and low outgassing properties.

This growth is largely attributed to the aerospace industry's continuous pursuit of weight reduction in aircraft components. With fuel efficiency remaining a critical concern for commercial aviation, manufacturers are actively seeking materials that can replace traditional metal conductors while maintaining electrical performance. Conductive polymer inks offer weight savings of up to 70% compared to conventional copper wiring in certain applications, translating to substantial fuel savings over an aircraft's operational lifetime.

The military and defense segment represents the largest market share for aerospace polymer inks, accounting for approximately 42% of the total demand. This is primarily due to the increasing integration of electronic warfare systems, advanced avionics, and unmanned aerial vehicles (UAVs) that require lightweight, durable electronic components capable of withstanding extreme operational conditions.

Commercial aviation follows closely, with a market share of 37%, driven by the growing adoption of in-flight entertainment systems, structural health monitoring sensors, and smart cabin technologies. The space segment, though smaller at 21% market share, is showing the fastest growth rate at 12.3% annually, fueled by the expanding small satellite market and commercial space initiatives.

Regionally, North America dominates the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next decade due to increasing aerospace manufacturing activities in China, Japan, and India.

Key application areas driving demand include printed circuit boards for avionics (31% of applications), flexible sensors for structural health monitoring (27%), heating elements for anti-icing systems (18%), electromagnetic interference (EMI) shielding (14%), and other applications such as antennas and RFID tags (10%). The demand for these applications is expected to grow as the industry continues to embrace more electric aircraft architectures and digital transformation initiatives.

Customer requirements are increasingly focused on performance metrics such as conductivity stability under extreme temperature variations (-65°C to +150°C), resistance to vibration and mechanical stress, and long-term reliability in high-altitude environments. Additionally, there is growing demand for polymer inks that comply with stringent aerospace safety standards and environmental regulations, particularly regarding flame retardancy and low outgassing properties.

Current Status and Technical Challenges in Conductive Polymer Inks

Conductive polymer inks have emerged as a transformative technology in the aerospace industry, offering significant advantages over traditional metallic conductors. Currently, these inks are primarily based on PEDOT:PSS, polyaniline, and polypyrrole formulations, with varying levels of conductivity ranging from 1-1000 S/cm depending on composition and processing methods. The global market for these materials in aerospace applications reached approximately $78 million in 2022, with a projected CAGR of 11.3% through 2028.

Despite promising developments, several technical challenges impede widespread adoption. Conductivity levels remain significantly lower than traditional metal conductors, with the best polymer inks achieving only 5-10% of copper's conductivity. This limitation restricts their use in high-power or high-frequency applications critical to aerospace systems. Additionally, environmental stability presents a major hurdle, as many conductive polymers exhibit degradation when exposed to UV radiation, oxygen, and moisture—conditions routinely encountered in aerospace environments.

Adhesion to aerospace-grade substrates poses another significant challenge. Current formulations often demonstrate insufficient adhesion to specialized composite materials and metal alloys used in aircraft construction, leading to reliability concerns during thermal cycling and mechanical stress. The aerospace industry's stringent certification requirements further complicate adoption, as new materials must undergo extensive qualification testing to meet safety standards.

Manufacturing scalability remains problematic, with inconsistent batch-to-batch properties and limited production capacity hindering industrial-scale implementation. Most production methods are laboratory-scale, with few suppliers capable of delivering aerospace-grade materials in quantities sufficient for large aircraft components. This supply chain constraint has slowed integration efforts at major aerospace manufacturers.

Geographically, research and development in this field is concentrated in North America (35%), Europe (30%), and East Asia (25%), with emerging contributions from research institutions in India and Brazil. Leading aerospace nations like the United States, France, Germany, and Japan have established specialized research centers focused on conductive polymer applications, often through public-private partnerships.

Recent technical breakthroughs include the development of hybrid metal-polymer composites that achieve conductivities of up to 2000 S/cm while maintaining flexibility, and novel encapsulation techniques that extend environmental stability to over 5000 hours in accelerated weathering tests. However, these advances have yet to be fully validated in actual aerospace operating conditions, representing a critical gap between laboratory success and practical implementation.

Despite promising developments, several technical challenges impede widespread adoption. Conductivity levels remain significantly lower than traditional metal conductors, with the best polymer inks achieving only 5-10% of copper's conductivity. This limitation restricts their use in high-power or high-frequency applications critical to aerospace systems. Additionally, environmental stability presents a major hurdle, as many conductive polymers exhibit degradation when exposed to UV radiation, oxygen, and moisture—conditions routinely encountered in aerospace environments.

Adhesion to aerospace-grade substrates poses another significant challenge. Current formulations often demonstrate insufficient adhesion to specialized composite materials and metal alloys used in aircraft construction, leading to reliability concerns during thermal cycling and mechanical stress. The aerospace industry's stringent certification requirements further complicate adoption, as new materials must undergo extensive qualification testing to meet safety standards.

Manufacturing scalability remains problematic, with inconsistent batch-to-batch properties and limited production capacity hindering industrial-scale implementation. Most production methods are laboratory-scale, with few suppliers capable of delivering aerospace-grade materials in quantities sufficient for large aircraft components. This supply chain constraint has slowed integration efforts at major aerospace manufacturers.

Geographically, research and development in this field is concentrated in North America (35%), Europe (30%), and East Asia (25%), with emerging contributions from research institutions in India and Brazil. Leading aerospace nations like the United States, France, Germany, and Japan have established specialized research centers focused on conductive polymer applications, often through public-private partnerships.

Recent technical breakthroughs include the development of hybrid metal-polymer composites that achieve conductivities of up to 2000 S/cm while maintaining flexibility, and novel encapsulation techniques that extend environmental stability to over 5000 hours in accelerated weathering tests. However, these advances have yet to be fully validated in actual aerospace operating conditions, representing a critical gap between laboratory success and practical implementation.

Current Technical Solutions for Conductive Polymer Applications

01 Conductive polymer compositions for printable electronics

Conductive polymer inks can be formulated with specific polymers like PEDOT:PSS, polyaniline, or polythiophene derivatives to create printable electronic components. These formulations typically include solvents, binders, and additives that enhance conductivity while maintaining printability. The resulting inks can be used for flexible electronics, sensors, and printed circuit applications where traditional metal conductors may not be suitable.- Composition of conductive polymer inks: Conductive polymer inks typically consist of conductive polymers such as PEDOT:PSS, polyaniline, or polypyrrole combined with solvents and additives to enhance conductivity and printability. These formulations often include stabilizers to prevent aggregation and improve shelf life. The composition can be tailored to achieve specific electrical properties while maintaining suitable viscosity and surface tension for various printing methods.

- Manufacturing processes for conductive polymer inks: Manufacturing processes for conductive polymer inks involve polymerization techniques, dispersion methods, and formulation procedures to ensure uniform particle distribution and optimal electrical performance. These processes may include in-situ polymerization, solution blending, or emulsion techniques. Post-processing treatments such as filtering and sonication are often employed to achieve desired particle size distribution and prevent nozzle clogging in printing applications.

- Applications of conductive polymer inks: Conductive polymer inks find applications in printed electronics, flexible displays, sensors, photovoltaic devices, and wearable technology. They enable the fabrication of transparent conductive films, RFID tags, and organic light-emitting diodes. These inks are particularly valuable in applications requiring mechanical flexibility, lightweight properties, and low-temperature processing, making them suitable for roll-to-roll manufacturing and additive fabrication techniques.

- Performance enhancement additives: Various additives are incorporated into conductive polymer inks to enhance their performance characteristics. These include conductivity enhancers like metal nanoparticles, carbon materials (graphene, carbon nanotubes), and ionic compounds. Surfactants improve wetting properties and adhesion to substrates, while cross-linking agents enhance mechanical durability. Specialized additives can also improve thermal stability, environmental resistance, and long-term reliability of the printed conductive patterns.

- Substrate compatibility and curing methods: Conductive polymer inks are formulated for compatibility with various substrates including paper, plastic films, textiles, and glass. Different curing methods such as thermal annealing, UV curing, or infrared treatment are employed to achieve optimal conductivity and adhesion. The curing process facilitates solvent evaporation, polymer chain alignment, and cross-linking reactions that significantly impact the final electrical and mechanical properties of the printed patterns.

02 Nanoparticle-enhanced conductive polymer inks

Incorporating conductive nanoparticles such as carbon nanotubes, graphene, or metal nanoparticles into polymer matrices significantly enhances the electrical conductivity of printing inks. These hybrid formulations combine the flexibility and processability of polymers with the superior conductivity of nanomaterials. The resulting inks exhibit improved performance for applications requiring high conductivity while maintaining the mechanical properties of polymers.Expand Specific Solutions03 Processing techniques for conductive polymer inks

Various processing methods can be employed to optimize the performance of conductive polymer inks, including solvent selection, curing conditions, and post-treatment processes. Techniques such as thermal annealing, UV curing, or chemical treatments can significantly enhance conductivity by improving polymer chain alignment or removing insulating components. These processing approaches are crucial for achieving the desired electrical properties in the final printed structures.Expand Specific Solutions04 Substrate compatibility and adhesion enhancement

Formulating conductive polymer inks with appropriate adhesion promoters and surface modifiers enables compatibility with various substrates including plastics, paper, textiles, and glass. These additives improve wetting, adhesion, and film formation while maintaining electrical conductivity. Proper substrate interaction is essential for creating durable printed electronic components that maintain performance under mechanical stress and environmental conditions.Expand Specific Solutions05 Environmental stability and durability improvements

Enhancing the environmental stability of conductive polymer inks through specialized additives and encapsulation techniques protects against degradation from moisture, oxygen, UV light, and temperature fluctuations. Stabilizers, antioxidants, and cross-linking agents can be incorporated to extend the functional lifetime of printed electronic components. These formulation strategies are critical for applications requiring long-term reliability in various environmental conditions.Expand Specific Solutions

Key Industry Players in Aerospace Polymer Ink Development

The conductive polymer inks market in the aerospace industry is currently in a growth phase, with increasing adoption driven by demands for lightweight, flexible electronics in aircraft systems. The global market size is estimated to reach approximately $500 million by 2025, expanding at a CAGR of 8-10%. Regarding technical maturity, established players like Henkel AG, 3M Innovative Properties, and TE Connectivity lead with advanced formulations offering superior conductivity and durability in extreme aerospace environments. LG Chem and BYD are advancing battery-related applications, while specialized players like InkTec and Intrinsiq Materials focus on niche aerospace printing solutions. Research institutions including NASA, Clemson University, and Tianjin University are driving innovation through collaborative projects with industry partners, particularly in developing high-performance inks that meet stringent aerospace requirements for thermal stability and reliability.

Leidos Holdings, Inc.

Technical Solution: Leidos has developed specialized conductive polymer ink technologies through their advanced materials division specifically targeting aerospace applications. Their proprietary formulations combine PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) with carbon nanotubes and silver nanowires to achieve conductivity values of 103-104 S/m while maintaining flexibility and adhesion on aerospace-grade composite materials[9]. Leidos' aerospace conductive inks feature exceptional radiation resistance, maintaining over 90% of their electrical performance after exposure to 500 kRad, making them suitable for satellite and high-altitude aircraft applications. The company has pioneered inkjet-printable formulations that enable direct digital manufacturing of conductive traces on complex aerospace components without requiring masks or screens. Their inks incorporate proprietary additives that enhance resistance to atomic oxygen and vacuum environments encountered in space applications[10]. Leidos has implemented these materials in defense aerospace programs for conformal sensors, lightweight antennas, and de-icing systems that can be directly printed onto aircraft structures, reducing weight and installation complexity compared to traditional approaches.

Strengths: Exceptional radiation resistance makes these inks ideal for space applications, digital printing compatibility enables rapid prototyping and complex designs, and proven performance in defense aerospace programs provides established qualification data. Weaknesses: Moderate conductivity values compared to metal-based systems require careful circuit design, and specialized formulations can have limited shelf life requiring careful inventory management.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed LOCTITE ABLESTIK conductive polymer ink systems specifically engineered for aerospace applications. These formulations combine silver nanoparticles with proprietary polymer matrices to achieve conductivity values exceeding 105 S/m while maintaining flexibility and adhesion on aerospace-grade substrates[5]. Henkel's aerospace conductive inks feature exceptional thermal stability (-65°C to +230°C) and can withstand over 1,000 thermal cycles without significant degradation in electrical performance. Their formulations incorporate proprietary additives that enhance resistance to humidity, salt spray, and aviation fluids, meeting stringent aerospace environmental testing requirements including RTCA DO-160[6]. Henkel has pioneered hybrid conductive polymer systems that combine the processability of screen printing with the performance of traditional solder connections, enabling the creation of complex, multi-layer flexible circuits that can be integrated directly into aircraft structural components. These solutions have been implemented in commercial aircraft for de-icing systems, structural health monitoring sensors, and lightweight antenna arrays.

Strengths: Exceptional environmental resistance particularly to aviation fluids and humidity, excellent adhesion to multiple substrate types including composites, and established aerospace qualification history with major aircraft manufacturers. Weaknesses: Relatively high viscosity limits application in some fine-feature printing processes, and some formulations require specialized curing equipment that increases implementation costs.

Critical Patents and Innovations in Aerospace Polymer Inks

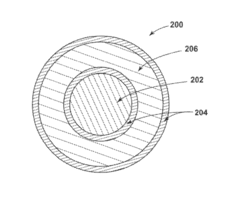

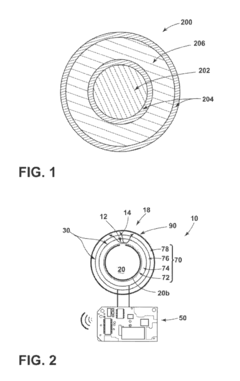

Electrically conductive polymers as sensing media to detect leaks in aerospace pneumatic ducts

PatentActiveUS9989435B2

Innovation

- A leak detection system comprising a rigid metal duct coated with an electrically conductive polymer that melts upon a high-temperature fluid leak, monitored by sensors measuring electrical characteristics, with insulation layers to manage thermal exposure and facilitate faster detection.

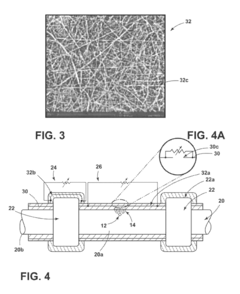

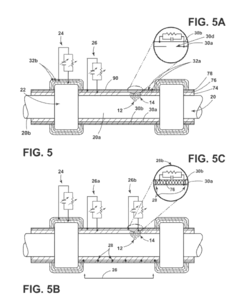

Conducting polymer ink

PatentActiveUS8691116B2

Innovation

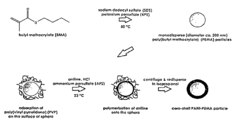

- Development of conductive polymer inks with a dispersion of core/shell polymeric particles, where the core is insulative and has a low glass transition temperature, and the shell is conductive, allowing for high-speed printing without hazardous solvents, and the core acts as a binder, enabling high conductivity.

Environmental Impact and Sustainability Considerations

The aerospace industry's adoption of conductive polymer inks presents significant environmental and sustainability implications that warrant careful consideration. Traditional electronic manufacturing processes often involve hazardous materials and energy-intensive production methods, creating substantial environmental burdens. Conductive polymer inks offer a promising alternative with potentially reduced environmental footprints through lower processing temperatures, decreased solvent usage, and minimized waste generation.

A key environmental advantage of conductive polymer inks is their compatibility with additive manufacturing techniques. Unlike subtractive manufacturing processes that remove material to create components, additive approaches deposit material only where needed, significantly reducing material waste. This resource efficiency is particularly valuable in aerospace applications where specialized, high-value materials are common.

Many conductive polymer formulations utilize water-based systems rather than volatile organic compounds (VOCs), addressing concerns about air quality and worker exposure to harmful chemicals. The reduction in VOCs aligns with increasingly stringent environmental regulations worldwide and contributes to healthier manufacturing environments. However, some polymer ink systems still rely on organic solvents, presenting ongoing challenges for complete environmental optimization.

End-of-life considerations represent another critical sustainability aspect. The aerospace industry faces unique challenges regarding component disposal and recycling due to strict performance and safety requirements. Research into biodegradable conductive polymers and recyclable composite structures incorporating these materials shows promise for improving the lifecycle impact of aerospace electronics.

Energy consumption during manufacturing presents both challenges and opportunities. While polymer inks typically require less energy for processing compared to traditional metal-based electronics, the aerospace industry's demanding performance requirements may necessitate additional processing steps that partially offset these gains. Ongoing research focuses on optimizing curing processes to maintain performance while minimizing energy inputs.

Supply chain sustainability also merits attention as the industry scales up polymer ink adoption. The sourcing of raw materials, particularly rare elements sometimes used in high-performance formulations, raises questions about resource depletion and geopolitical dependencies. Efforts to develop formulations using abundant, renewable resources could enhance long-term sustainability while reducing supply vulnerabilities.

Carbon footprint assessments comparing traditional aerospace electronic manufacturing with polymer ink-based approaches indicate potential for significant greenhouse gas reductions, particularly when considering the entire lifecycle from material extraction through disposal. These environmental benefits, coupled with potential weight reductions in aircraft components, could contribute to reduced fuel consumption and emissions during operation.

A key environmental advantage of conductive polymer inks is their compatibility with additive manufacturing techniques. Unlike subtractive manufacturing processes that remove material to create components, additive approaches deposit material only where needed, significantly reducing material waste. This resource efficiency is particularly valuable in aerospace applications where specialized, high-value materials are common.

Many conductive polymer formulations utilize water-based systems rather than volatile organic compounds (VOCs), addressing concerns about air quality and worker exposure to harmful chemicals. The reduction in VOCs aligns with increasingly stringent environmental regulations worldwide and contributes to healthier manufacturing environments. However, some polymer ink systems still rely on organic solvents, presenting ongoing challenges for complete environmental optimization.

End-of-life considerations represent another critical sustainability aspect. The aerospace industry faces unique challenges regarding component disposal and recycling due to strict performance and safety requirements. Research into biodegradable conductive polymers and recyclable composite structures incorporating these materials shows promise for improving the lifecycle impact of aerospace electronics.

Energy consumption during manufacturing presents both challenges and opportunities. While polymer inks typically require less energy for processing compared to traditional metal-based electronics, the aerospace industry's demanding performance requirements may necessitate additional processing steps that partially offset these gains. Ongoing research focuses on optimizing curing processes to maintain performance while minimizing energy inputs.

Supply chain sustainability also merits attention as the industry scales up polymer ink adoption. The sourcing of raw materials, particularly rare elements sometimes used in high-performance formulations, raises questions about resource depletion and geopolitical dependencies. Efforts to develop formulations using abundant, renewable resources could enhance long-term sustainability while reducing supply vulnerabilities.

Carbon footprint assessments comparing traditional aerospace electronic manufacturing with polymer ink-based approaches indicate potential for significant greenhouse gas reductions, particularly when considering the entire lifecycle from material extraction through disposal. These environmental benefits, coupled with potential weight reductions in aircraft components, could contribute to reduced fuel consumption and emissions during operation.

Aerospace Certification and Regulatory Requirements

The aerospace industry maintains exceptionally stringent certification and regulatory requirements for all materials and components used in aircraft and spacecraft manufacturing. Conductive polymer inks must navigate this complex regulatory landscape before widespread adoption can occur. The Federal Aviation Administration (FAA) in the United States, the European Union Aviation Safety Agency (EASA), and similar authorities worldwide have established comprehensive frameworks that govern the certification of materials for aerospace applications.

These regulatory bodies require extensive testing and validation of conductive polymer inks to ensure they meet safety standards for flammability, toxicity, and electromagnetic compatibility. FAA regulations such as 14 CFR Part 25 specifically address the airworthiness standards for transport category aircraft, including requirements for materials used in electrical systems. Similarly, EASA's CS-25 certification specifications outline comparable requirements for European aircraft certification.

Material qualification processes for aerospace applications typically follow standards established by organizations like SAE International, ASTM International, and the International Electrotechnical Commission (IEC). For conductive polymer inks, relevant standards include ASTM F3301 for printed electronics and IEC 62137 for reliability testing of electronic interconnections. These standards define testing methodologies for properties such as adhesion, electrical conductivity under environmental stress, and long-term reliability.

Environmental testing represents another critical aspect of aerospace certification. Conductive polymer inks must demonstrate resilience to extreme temperature fluctuations (-55°C to +125°C), low atmospheric pressure, humidity cycling, and resistance to fluids commonly encountered in aerospace environments. The RTCA DO-160 standard specifically addresses environmental conditions and test procedures for airborne equipment, providing guidelines that manufacturers of conductive polymer ink systems must follow.

Electromagnetic interference (EMI) and compatibility testing are particularly important for conductive materials in aerospace applications. Regulations require that printed electronic circuits created with conductive inks neither emit unacceptable levels of electromagnetic radiation nor be susceptible to interference from other systems. This is governed by standards such as MIL-STD-461 for electromagnetic compatibility.

The certification process also includes production quality control requirements. Manufacturers must implement quality management systems compliant with AS9100, the aerospace-specific extension of ISO 9001, ensuring consistent production quality and traceability. This includes documentation of material sources, manufacturing processes, and batch testing results for conductive polymer ink formulations.

These regulatory bodies require extensive testing and validation of conductive polymer inks to ensure they meet safety standards for flammability, toxicity, and electromagnetic compatibility. FAA regulations such as 14 CFR Part 25 specifically address the airworthiness standards for transport category aircraft, including requirements for materials used in electrical systems. Similarly, EASA's CS-25 certification specifications outline comparable requirements for European aircraft certification.

Material qualification processes for aerospace applications typically follow standards established by organizations like SAE International, ASTM International, and the International Electrotechnical Commission (IEC). For conductive polymer inks, relevant standards include ASTM F3301 for printed electronics and IEC 62137 for reliability testing of electronic interconnections. These standards define testing methodologies for properties such as adhesion, electrical conductivity under environmental stress, and long-term reliability.

Environmental testing represents another critical aspect of aerospace certification. Conductive polymer inks must demonstrate resilience to extreme temperature fluctuations (-55°C to +125°C), low atmospheric pressure, humidity cycling, and resistance to fluids commonly encountered in aerospace environments. The RTCA DO-160 standard specifically addresses environmental conditions and test procedures for airborne equipment, providing guidelines that manufacturers of conductive polymer ink systems must follow.

Electromagnetic interference (EMI) and compatibility testing are particularly important for conductive materials in aerospace applications. Regulations require that printed electronic circuits created with conductive inks neither emit unacceptable levels of electromagnetic radiation nor be susceptible to interference from other systems. This is governed by standards such as MIL-STD-461 for electromagnetic compatibility.

The certification process also includes production quality control requirements. Manufacturers must implement quality management systems compliant with AS9100, the aerospace-specific extension of ISO 9001, ensuring consistent production quality and traceability. This includes documentation of material sources, manufacturing processes, and batch testing results for conductive polymer ink formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!