Conductive Polymer Inks for Low-voltage Flexible Electronics

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Inks Background and Objectives

Conductive polymer inks have emerged as a transformative technology in the field of flexible electronics over the past three decades. Initially developed in the 1970s with the discovery of electrically conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa (Nobel Prize in Chemistry, 2000), these materials have evolved from laboratory curiosities to commercially viable solutions for next-generation electronic devices.

The evolution of conductive polymer inks has been driven by the increasing demand for lightweight, flexible, and low-cost electronic components that can operate at low voltages. Traditional metallic conductors, while offering excellent conductivity, lack the mechanical flexibility and processing advantages that polymer-based materials provide. The development trajectory has moved from rigid silicon-based electronics toward more adaptable platforms that can conform to various surfaces and withstand mechanical deformation.

Recent advancements in polymer chemistry and ink formulation techniques have significantly improved the electrical properties, stability, and processability of conductive polymer inks. Materials such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), polyaniline, and polypyrrole have been extensively studied and optimized for various applications. The incorporation of nanomaterials like carbon nanotubes and graphene has further enhanced their performance characteristics.

The primary objective of current research in conductive polymer inks is to achieve a balance between electrical conductivity, mechanical flexibility, and environmental stability while maintaining compatibility with low-cost, large-area manufacturing processes. Specifically, researchers aim to develop formulations that can operate efficiently at voltages below 5V, making them suitable for battery-powered and energy-harvesting applications.

Another critical goal is to improve the long-term reliability of these materials under various environmental conditions, including humidity, temperature fluctuations, and mechanical stress. This is particularly important for wearable electronics and IoT devices that must function reliably in diverse environments.

From an industrial perspective, the objectives include scaling up production methods, standardizing formulation processes, and reducing manufacturing costs to enable mass adoption. The development of printing techniques compatible with these inks, such as inkjet, screen, and gravure printing, represents another significant focus area.

Looking forward, the field is moving toward multifunctional conductive polymer inks that can simultaneously serve as conductors, sensors, and energy storage components. The integration of these materials with biodegradable substrates also aligns with growing sustainability concerns, potentially enabling fully recyclable or biodegradable electronic systems.

The evolution of conductive polymer inks has been driven by the increasing demand for lightweight, flexible, and low-cost electronic components that can operate at low voltages. Traditional metallic conductors, while offering excellent conductivity, lack the mechanical flexibility and processing advantages that polymer-based materials provide. The development trajectory has moved from rigid silicon-based electronics toward more adaptable platforms that can conform to various surfaces and withstand mechanical deformation.

Recent advancements in polymer chemistry and ink formulation techniques have significantly improved the electrical properties, stability, and processability of conductive polymer inks. Materials such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), polyaniline, and polypyrrole have been extensively studied and optimized for various applications. The incorporation of nanomaterials like carbon nanotubes and graphene has further enhanced their performance characteristics.

The primary objective of current research in conductive polymer inks is to achieve a balance between electrical conductivity, mechanical flexibility, and environmental stability while maintaining compatibility with low-cost, large-area manufacturing processes. Specifically, researchers aim to develop formulations that can operate efficiently at voltages below 5V, making them suitable for battery-powered and energy-harvesting applications.

Another critical goal is to improve the long-term reliability of these materials under various environmental conditions, including humidity, temperature fluctuations, and mechanical stress. This is particularly important for wearable electronics and IoT devices that must function reliably in diverse environments.

From an industrial perspective, the objectives include scaling up production methods, standardizing formulation processes, and reducing manufacturing costs to enable mass adoption. The development of printing techniques compatible with these inks, such as inkjet, screen, and gravure printing, represents another significant focus area.

Looking forward, the field is moving toward multifunctional conductive polymer inks that can simultaneously serve as conductors, sensors, and energy storage components. The integration of these materials with biodegradable substrates also aligns with growing sustainability concerns, potentially enabling fully recyclable or biodegradable electronic systems.

Market Analysis for Low-voltage Flexible Electronics

The global market for low-voltage flexible electronics is experiencing unprecedented growth, driven by increasing demand for wearable devices, IoT applications, and portable consumer electronics. Current market valuations indicate that the flexible electronics sector is projected to reach approximately $40 billion by 2026, with conductive polymer inks representing a significant segment within this ecosystem. The compound annual growth rate (CAGR) for this specific technology is outpacing traditional electronics at 15-18%, highlighting the shift toward more adaptable and energy-efficient electronic solutions.

Consumer electronics remains the dominant application sector, accounting for nearly 40% of the market share. However, healthcare applications are showing the fastest growth trajectory as medical device manufacturers increasingly adopt flexible, low-voltage components for patient monitoring systems, smart bandages, and implantable devices. The automotive industry has also emerged as a significant market, incorporating flexible displays and sensors into next-generation vehicle designs.

Regional analysis reveals that Asia-Pacific currently leads manufacturing capacity, with South Korea, Japan, and Taiwan hosting major production facilities. North America and Europe, meanwhile, maintain leadership in research and development, particularly in advanced materials science related to conductive polymer formulations. Emerging markets in India and Brazil are showing accelerated adoption rates, primarily in consumer electronics applications.

Market drivers for conductive polymer inks in low-voltage applications include decreasing power consumption requirements, growing environmental regulations limiting traditional electronic materials, and increasing consumer demand for longer battery life in portable devices. The ability of these materials to function at voltages below 5V provides significant energy efficiency advantages over conventional electronics.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, particularly for specialized monomers and additives required in high-performance conductive polymer formulations. This has prompted increased vertical integration among leading manufacturers and strategic partnerships with chemical suppliers to ensure consistent material quality and availability.

Price sensitivity varies significantly by application sector. Consumer electronics manufacturers demonstrate high price sensitivity due to competitive pressures, while medical and industrial applications prioritize performance and reliability over cost considerations. Current pricing trends show gradual reduction in cost-per-unit as manufacturing processes mature and economies of scale are realized.

Market penetration barriers include technical challenges in achieving consistent conductivity across large surface areas, integration complexities with existing manufacturing processes, and regulatory hurdles in certain application sectors. Despite these challenges, market forecasts remain highly positive, with conductive polymer inks positioned to become a cornerstone technology in the expanding low-voltage flexible electronics ecosystem.

Consumer electronics remains the dominant application sector, accounting for nearly 40% of the market share. However, healthcare applications are showing the fastest growth trajectory as medical device manufacturers increasingly adopt flexible, low-voltage components for patient monitoring systems, smart bandages, and implantable devices. The automotive industry has also emerged as a significant market, incorporating flexible displays and sensors into next-generation vehicle designs.

Regional analysis reveals that Asia-Pacific currently leads manufacturing capacity, with South Korea, Japan, and Taiwan hosting major production facilities. North America and Europe, meanwhile, maintain leadership in research and development, particularly in advanced materials science related to conductive polymer formulations. Emerging markets in India and Brazil are showing accelerated adoption rates, primarily in consumer electronics applications.

Market drivers for conductive polymer inks in low-voltage applications include decreasing power consumption requirements, growing environmental regulations limiting traditional electronic materials, and increasing consumer demand for longer battery life in portable devices. The ability of these materials to function at voltages below 5V provides significant energy efficiency advantages over conventional electronics.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing, particularly for specialized monomers and additives required in high-performance conductive polymer formulations. This has prompted increased vertical integration among leading manufacturers and strategic partnerships with chemical suppliers to ensure consistent material quality and availability.

Price sensitivity varies significantly by application sector. Consumer electronics manufacturers demonstrate high price sensitivity due to competitive pressures, while medical and industrial applications prioritize performance and reliability over cost considerations. Current pricing trends show gradual reduction in cost-per-unit as manufacturing processes mature and economies of scale are realized.

Market penetration barriers include technical challenges in achieving consistent conductivity across large surface areas, integration complexities with existing manufacturing processes, and regulatory hurdles in certain application sectors. Despite these challenges, market forecasts remain highly positive, with conductive polymer inks positioned to become a cornerstone technology in the expanding low-voltage flexible electronics ecosystem.

Current Status and Challenges in Conductive Polymer Technology

Conductive polymer technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Currently, the field has reached a stage where several conductive polymer inks demonstrate electrical conductivity ranging from 1,000 to 10,000 S/cm, approaching the lower end of metallic conductors while maintaining flexibility advantages critical for flexible electronics applications.

The market has seen commercial availability of PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) formulations achieving conductivities up to 4,000 S/cm through secondary doping techniques. Polyaniline and polypyrrole-based inks have also gained traction, though their conductivity values typically remain lower, in the range of 100-1,000 S/cm. These materials have enabled initial commercial applications in transparent electrodes, OLED displays, and certain wearable electronics.

Despite these achievements, several significant challenges persist in conductive polymer technology for low-voltage flexible electronics. Stability remains a primary concern, with many formulations exhibiting performance degradation under ambient conditions, particularly when exposed to oxygen and moisture. Long-term reliability testing indicates conductivity losses of 30-50% over extended periods in unencapsulated devices, necessitating improved barrier technologies or intrinsically stable polymer structures.

Processing limitations constitute another major hurdle. Current ink formulations often require toxic solvents or complex post-processing steps like thermal annealing at temperatures exceeding 150°C, which restricts compatibility with temperature-sensitive substrates such as PET or paper. Additionally, achieving uniform film morphology at industrial scales remains problematic, with thickness variations leading to inconsistent electrical properties across large-area applications.

The cost-performance ratio presents an ongoing challenge, as high-performance conductive polymers typically require expensive dopants or complex synthesis routes. Production scaling has been limited, with current manufacturing capabilities generally restricted to small or medium batch sizes, driving costs significantly higher than traditional metallic alternatives.

Interface engineering represents another critical technical barrier. Contact resistance between conductive polymer layers and other device components often limits overall performance in integrated systems. Research indicates that this interfacial resistance can dominate device characteristics in low-voltage applications, where operating voltages below 1V are desired.

Standardization across the industry remains insufficient, with varying testing protocols and performance metrics making direct comparisons between different materials challenging. This fragmentation has slowed adoption in conservative industries like automotive and medical electronics, where reliability standards are particularly stringent.

The market has seen commercial availability of PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) formulations achieving conductivities up to 4,000 S/cm through secondary doping techniques. Polyaniline and polypyrrole-based inks have also gained traction, though their conductivity values typically remain lower, in the range of 100-1,000 S/cm. These materials have enabled initial commercial applications in transparent electrodes, OLED displays, and certain wearable electronics.

Despite these achievements, several significant challenges persist in conductive polymer technology for low-voltage flexible electronics. Stability remains a primary concern, with many formulations exhibiting performance degradation under ambient conditions, particularly when exposed to oxygen and moisture. Long-term reliability testing indicates conductivity losses of 30-50% over extended periods in unencapsulated devices, necessitating improved barrier technologies or intrinsically stable polymer structures.

Processing limitations constitute another major hurdle. Current ink formulations often require toxic solvents or complex post-processing steps like thermal annealing at temperatures exceeding 150°C, which restricts compatibility with temperature-sensitive substrates such as PET or paper. Additionally, achieving uniform film morphology at industrial scales remains problematic, with thickness variations leading to inconsistent electrical properties across large-area applications.

The cost-performance ratio presents an ongoing challenge, as high-performance conductive polymers typically require expensive dopants or complex synthesis routes. Production scaling has been limited, with current manufacturing capabilities generally restricted to small or medium batch sizes, driving costs significantly higher than traditional metallic alternatives.

Interface engineering represents another critical technical barrier. Contact resistance between conductive polymer layers and other device components often limits overall performance in integrated systems. Research indicates that this interfacial resistance can dominate device characteristics in low-voltage applications, where operating voltages below 1V are desired.

Standardization across the industry remains insufficient, with varying testing protocols and performance metrics making direct comparisons between different materials challenging. This fragmentation has slowed adoption in conservative industries like automotive and medical electronics, where reliability standards are particularly stringent.

Current Technical Solutions for Conductive Polymer Inks

01 Conductive polymer compositions for low-voltage applications

Various conductive polymer compositions have been developed specifically for low-voltage electronic applications. These formulations typically combine conductive polymers with additives that enhance conductivity while maintaining processability at low operating voltages. The compositions are designed to provide stable electrical performance with minimal power requirements, making them suitable for portable and energy-efficient devices.- Conductive polymer compositions for low-voltage applications: Specific conductive polymer compositions have been developed for low-voltage electronic applications. These formulations typically include conjugated polymers like PEDOT:PSS, polyaniline, or polythiophene derivatives that offer high conductivity at low operating voltages. The inks are engineered with precise dopant concentrations and additives to enhance charge transport properties while maintaining processability for various printing methods.

- Printing techniques for conductive polymer inks: Various printing methods have been optimized for depositing conductive polymer inks in low-voltage electronic devices. These techniques include inkjet printing, screen printing, gravure printing, and flexographic printing, each offering different advantages in terms of resolution, throughput, and compatibility with specific ink formulations. The printing parameters are carefully controlled to ensure uniform film formation and optimal electrical performance in the final devices.

- Additives and nanoparticles for enhanced conductivity: Incorporating specific additives and nanoparticles into conductive polymer inks can significantly improve their electrical properties for low-voltage applications. Common additives include metal nanoparticles (silver, gold, copper), carbon nanomaterials (graphene, carbon nanotubes), and conductivity enhancers like dimethyl sulfoxide or ethylene glycol. These materials create conductive pathways within the polymer matrix, reducing the operational voltage requirements while maintaining flexibility and processability.

- Substrate interactions and adhesion mechanisms: The interaction between conductive polymer inks and various substrates plays a crucial role in low-voltage device performance. Surface treatments and adhesion promoters are incorporated into ink formulations to improve wetting, adhesion, and electrical contact with substrates ranging from flexible polymers to rigid inorganic materials. These formulations often include functional groups that can form chemical or physical bonds with the substrate surface, ensuring stable electrical connections even at low operating voltages.

- Post-processing treatments for performance optimization: Various post-processing techniques are employed to optimize the performance of printed conductive polymer inks in low-voltage applications. These include thermal annealing, solvent vapor treatment, UV curing, and plasma treatment. Such processes help remove residual solvents, improve polymer chain alignment, enhance cross-linking, and optimize the morphology of the conductive network. These treatments can significantly reduce the operational voltage requirements while improving conductivity, stability, and device lifetime.

02 Printable conductive polymer ink formulations

Specialized ink formulations containing conductive polymers have been developed for printing electronic components. These inks are engineered with specific viscosity, surface tension, and particle size distribution to enable various printing techniques including inkjet, screen, and flexographic printing. The formulations often include solvents, binders, and dispersants that facilitate uniform deposition while maintaining electrical conductivity at low operating voltages.Expand Specific Solutions03 Low-voltage polymer electronic devices and applications

Conductive polymer inks have been utilized to create various low-voltage electronic devices including thin-film transistors, sensors, displays, and flexible circuits. These applications leverage the unique properties of conductive polymers to operate efficiently at reduced voltages compared to traditional electronics. The devices often feature multilayer structures where conductive polymer layers serve as electrodes, semiconductors, or interface materials.Expand Specific Solutions04 Doping strategies for enhanced low-voltage performance

Various doping techniques have been developed to improve the conductivity of polymer inks at low voltages. These methods include chemical doping with electron donors or acceptors, incorporation of metal nanoparticles, and addition of ionic compounds. Controlled doping enables precise tuning of electrical properties, reducing activation thresholds and improving charge transport efficiency in low-voltage operating conditions.Expand Specific Solutions05 Manufacturing processes for low-voltage conductive polymer components

Specialized manufacturing techniques have been developed for producing low-voltage conductive polymer components. These processes include solution processing, thermal annealing, photolithography, and various deposition methods optimized for conductive polymer inks. The manufacturing approaches focus on achieving uniform film formation, precise patterning, and good interfacial contact between layers, which are critical for reliable low-voltage operation.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The conductive polymer inks market for low-voltage flexible electronics is currently in a growth phase, with increasing adoption across multiple industries. The market is projected to expand significantly due to rising demand for flexible, lightweight electronic devices. Technologically, the field shows varying maturity levels, with companies like Henkel, Wacker Chemie, and Nanotech Energy leading commercial development through established product lines. Academic institutions including Tianjin University and Karlsruhe Institute of Technology are advancing fundamental research, while specialized players like PolyIC and E Ink focus on application-specific innovations. The competitive landscape features both chemical conglomerates (LG Chem, DIC Corp) and specialized materials startups, indicating a market transitioning from research to commercialization with significant growth potential in consumer electronics, automotive, and healthcare sectors.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed LOCTITE ECI 8000 series, a portfolio of conductive polymer inks specifically designed for low-voltage flexible electronics applications. Their technology utilizes a proprietary blend of conductive polymers (primarily PEDOT:PSS) modified with additives that enhance conductivity while maintaining flexibility. The formulation includes stabilizers that prevent degradation under bending stress, allowing for over 10,000 flex cycles without significant resistance changes. Henkel's approach incorporates nano-sized conductive fillers that create efficient electron pathways while requiring minimal loading, resulting in inks that can operate effectively at voltages below 5V. Their manufacturing process employs a controlled polymerization technique that ensures consistent particle size distribution and uniform electrical properties across production batches.

Strengths: Excellent adhesion to multiple substrate materials including PET, PI, and TPU; maintains conductivity after repeated flexing; environmentally stable with minimal performance degradation in varying humidity conditions. Weaknesses: Higher cost compared to traditional silver-based inks; limited shelf life requiring refrigerated storage; processing window requires precise temperature control during curing.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has pioneered graphene-based conductive polymer ink systems specifically engineered for low-voltage flexible electronic applications. Their proprietary technology combines functionalized graphene with conductive polymers to create highly conductive, ultra-flexible inks that maintain performance at operating voltages as low as 1.5V. The company's patented process involves chemical modification of graphene oxide sheets with conductive polymer chains, creating strong interfacial bonding that enhances electron mobility across material interfaces. Their formulations achieve sheet resistances below 10 ohms/square while maintaining transparency above 80% for certain variants. Nanotech's manufacturing approach uses environmentally friendly water-based systems that eliminate the need for harmful solvents, making their inks suitable for direct printing on temperature-sensitive substrates. Recent advancements have incorporated self-healing properties into their inks, allowing micro-cracks formed during flexing to reconnect and maintain circuit integrity.

Strengths: Exceptional conductivity-to-flexibility ratio; environmentally friendly water-based formulations; compatible with various printing techniques including inkjet, screen and gravure printing. Weaknesses: Higher production costs compared to traditional conductive inks; requires specialized handling during the manufacturing process; limited long-term stability data in extreme environmental conditions.

Core Patents and Technical Literature Analysis

Conducting polymer ink

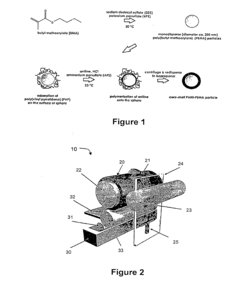

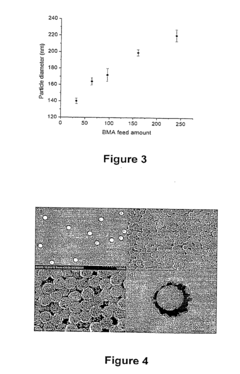

PatentActiveUS20110048772A1

Innovation

- Development of conductive polymer inks with a dispersion of core/shell polymeric particles, where the core is insulative and has a low glass transition temperature, and the shell is conductive, allowing for formulation with environmentally friendly carrier liquids and additives to control viscosity and electrical characteristics, enabling high-speed printing and high conductivity.

Conductive polymeric ink composition and organic solar cell containing same

PatentWO2013169087A1

Innovation

- A conductive polymer ink composition is developed, incorporating an aqueous dispersion solution with a conductive polymer, a conductivity enhancer, a solvent, and a fluorine-based surfactant with a hydrophilic-lipophilic balance (HLB) of 12 or more, improving surface energy and jetting properties to enhance spreadability and coating capabilities.

Manufacturing Scalability and Process Integration

The scalability of conductive polymer ink manufacturing represents a critical factor in the commercial viability of low-voltage flexible electronics. Current laboratory-scale synthesis methods face significant challenges when transitioning to industrial production volumes. Batch-to-batch consistency remains problematic, with variations in molecular weight distribution and doping levels affecting electrical performance across production runs.

Process integration presents another dimension of complexity, as conductive polymer inks must seamlessly interface with existing manufacturing infrastructure. Roll-to-roll (R2R) processing shows particular promise, enabling continuous production of flexible electronic components at high throughput rates. However, the rheological properties of polymer inks must be precisely engineered to ensure compatibility with R2R deposition techniques such as gravure, flexographic, and screen printing.

Thermal budget constraints pose additional challenges for integration. Many substrate materials used in flexible electronics (PET, PEN, paper) cannot withstand high processing temperatures. This necessitates the development of polymer ink formulations that achieve optimal conductivity at low curing temperatures (<150°C), often requiring innovative approaches such as photonic curing or chemical additives that promote conductivity without thermal annealing.

Environmental considerations increasingly influence manufacturing scalability. Traditional conductive polymer synthesis often involves hazardous solvents and reagents that present regulatory hurdles for large-scale production. Recent advances in green chemistry approaches have yielded water-based formulations and environmentally benign processing routes, though these typically exhibit lower conductivity than their conventional counterparts.

Equipment compatibility represents another integration challenge. Existing industrial printing equipment requires specific viscosity ranges and surface tension properties that may conflict with optimal electrical performance. Manufacturers must balance these competing requirements through careful formulation engineering, often incorporating rheology modifiers and surfactants that maintain electrical properties while ensuring printability.

Quality control methodologies must evolve alongside manufacturing scale-up. In-line monitoring techniques capable of detecting conductivity variations, thickness inconsistencies, and defects at production speeds remain underdeveloped. Advanced spectroscopic and electrical testing protocols integrated directly into manufacturing lines will be essential for maintaining quality standards at industrial scales.

Cross-contamination prevention becomes increasingly important as production volumes increase. Dedicated manufacturing lines or thorough cleaning protocols must be established to prevent performance degradation from trace contaminants, particularly for high-sensitivity, low-voltage applications where minor impurities can significantly impact device performance.

Process integration presents another dimension of complexity, as conductive polymer inks must seamlessly interface with existing manufacturing infrastructure. Roll-to-roll (R2R) processing shows particular promise, enabling continuous production of flexible electronic components at high throughput rates. However, the rheological properties of polymer inks must be precisely engineered to ensure compatibility with R2R deposition techniques such as gravure, flexographic, and screen printing.

Thermal budget constraints pose additional challenges for integration. Many substrate materials used in flexible electronics (PET, PEN, paper) cannot withstand high processing temperatures. This necessitates the development of polymer ink formulations that achieve optimal conductivity at low curing temperatures (<150°C), often requiring innovative approaches such as photonic curing or chemical additives that promote conductivity without thermal annealing.

Environmental considerations increasingly influence manufacturing scalability. Traditional conductive polymer synthesis often involves hazardous solvents and reagents that present regulatory hurdles for large-scale production. Recent advances in green chemistry approaches have yielded water-based formulations and environmentally benign processing routes, though these typically exhibit lower conductivity than their conventional counterparts.

Equipment compatibility represents another integration challenge. Existing industrial printing equipment requires specific viscosity ranges and surface tension properties that may conflict with optimal electrical performance. Manufacturers must balance these competing requirements through careful formulation engineering, often incorporating rheology modifiers and surfactants that maintain electrical properties while ensuring printability.

Quality control methodologies must evolve alongside manufacturing scale-up. In-line monitoring techniques capable of detecting conductivity variations, thickness inconsistencies, and defects at production speeds remain underdeveloped. Advanced spectroscopic and electrical testing protocols integrated directly into manufacturing lines will be essential for maintaining quality standards at industrial scales.

Cross-contamination prevention becomes increasingly important as production volumes increase. Dedicated manufacturing lines or thorough cleaning protocols must be established to prevent performance degradation from trace contaminants, particularly for high-sensitivity, low-voltage applications where minor impurities can significantly impact device performance.

Environmental Impact and Sustainability Considerations

The environmental footprint of conductive polymer inks represents a critical consideration in the development of low-voltage flexible electronics. Traditional electronic manufacturing processes often involve toxic chemicals, heavy metals, and energy-intensive procedures that generate significant waste. Conductive polymer inks offer promising alternatives with potentially lower environmental impact, particularly when derived from sustainable sources or designed with end-of-life considerations.

Many conductive polymer formulations utilize water-based systems that reduce the need for harmful volatile organic compounds (VOCs) commonly found in conventional metal-based inks. This shift significantly decreases air pollution during manufacturing and improves workplace safety. Additionally, the lower processing temperatures required for polymer inks compared to metal alternatives translate to reduced energy consumption during production, contributing to lower carbon emissions across the manufacturing lifecycle.

Biodegradability presents both an opportunity and challenge for conductive polymer technologies. While some polymers can be engineered to degrade under specific environmental conditions, this characteristic must be carefully balanced against performance requirements and longevity expectations. Research into bio-derived conductive polymers from renewable feedstocks shows promise for reducing dependence on petroleum-based materials, though commercial viability remains limited by cost and performance constraints.

The recyclability of flexible electronics incorporating conductive polymer inks demands particular attention. Current electronic waste recycling infrastructure is poorly equipped to handle hybrid materials combining polymers, substrates, and other electronic components. Designing for disassembly and material recovery represents an emerging focus area, with potential for significant sustainability improvements through modular approaches and compatible material selections that facilitate separation at end-of-life.

Life cycle assessment (LCA) studies comparing conductive polymer inks to traditional metal-based conductors reveal complex sustainability tradeoffs. While polymers may offer advantages in production energy and toxicity, questions remain regarding durability, replacement frequency, and end-of-life management. Comprehensive cradle-to-grave analyses are needed to fully quantify environmental benefits across different application scenarios and usage patterns.

Regulatory frameworks increasingly influence material selection and design approaches for flexible electronics. Restrictions on hazardous substances (like RoHS in Europe) and extended producer responsibility policies create incentives for developing more environmentally benign conductive materials. Forward-thinking manufacturers are proactively addressing these considerations through green chemistry principles and circular economy approaches that minimize waste and maximize resource efficiency throughout the product lifecycle.

Many conductive polymer formulations utilize water-based systems that reduce the need for harmful volatile organic compounds (VOCs) commonly found in conventional metal-based inks. This shift significantly decreases air pollution during manufacturing and improves workplace safety. Additionally, the lower processing temperatures required for polymer inks compared to metal alternatives translate to reduced energy consumption during production, contributing to lower carbon emissions across the manufacturing lifecycle.

Biodegradability presents both an opportunity and challenge for conductive polymer technologies. While some polymers can be engineered to degrade under specific environmental conditions, this characteristic must be carefully balanced against performance requirements and longevity expectations. Research into bio-derived conductive polymers from renewable feedstocks shows promise for reducing dependence on petroleum-based materials, though commercial viability remains limited by cost and performance constraints.

The recyclability of flexible electronics incorporating conductive polymer inks demands particular attention. Current electronic waste recycling infrastructure is poorly equipped to handle hybrid materials combining polymers, substrates, and other electronic components. Designing for disassembly and material recovery represents an emerging focus area, with potential for significant sustainability improvements through modular approaches and compatible material selections that facilitate separation at end-of-life.

Life cycle assessment (LCA) studies comparing conductive polymer inks to traditional metal-based conductors reveal complex sustainability tradeoffs. While polymers may offer advantages in production energy and toxicity, questions remain regarding durability, replacement frequency, and end-of-life management. Comprehensive cradle-to-grave analyses are needed to fully quantify environmental benefits across different application scenarios and usage patterns.

Regulatory frameworks increasingly influence material selection and design approaches for flexible electronics. Restrictions on hazardous substances (like RoHS in Europe) and extended producer responsibility policies create incentives for developing more environmentally benign conductive materials. Forward-thinking manufacturers are proactively addressing these considerations through green chemistry principles and circular economy approaches that minimize waste and maximize resource efficiency throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!