Decane in Chemical Kinetics Model Development for Combustion Systems

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decane Combustion Kinetics Background and Objectives

Decane, a straight-chain alkane with ten carbon atoms, has been a subject of significant interest in the field of combustion kinetics for several decades. The study of decane combustion kinetics is crucial for understanding the behavior of complex hydrocarbon fuels, particularly in the context of aviation and diesel engines. The development of accurate chemical kinetics models for decane combustion has far-reaching implications for improving engine efficiency, reducing emissions, and advancing sustainable energy technologies.

The evolution of decane combustion kinetics research can be traced back to the early 1990s when researchers began to focus on developing comprehensive reaction mechanisms for larger hydrocarbons. Initially, these models were relatively simple, consisting of a few hundred species and reactions. However, as computational capabilities improved and experimental techniques became more sophisticated, the complexity and accuracy of these models increased significantly.

One of the primary objectives in decane combustion kinetics research is to create a detailed and validated reaction mechanism that can accurately predict the combustion behavior of decane under a wide range of conditions. This includes capturing the ignition delay times, flame speeds, and species profiles across various temperatures, pressures, and fuel-air ratios. Such a comprehensive model is essential for engine designers and combustion engineers to optimize fuel efficiency and minimize pollutant formation.

Another critical goal in this field is to understand the low-temperature oxidation chemistry of decane. This is particularly important for predicting phenomena such as cool flames and negative temperature coefficient (NTC) behavior, which are characteristic of larger alkanes and have significant implications for engine knock and autoignition processes. Researchers aim to elucidate the complex network of reactions that occur at these lower temperatures, including the formation and decomposition of various intermediate species.

Furthermore, the development of reduced kinetic models for decane combustion is a key objective. While detailed mechanisms are valuable for fundamental understanding, they are often too computationally expensive for practical applications in engine simulations or computational fluid dynamics (CFD) studies. Therefore, there is a continuous effort to create simplified models that retain the essential features of the detailed mechanisms while being computationally efficient.

The ultimate aim of decane combustion kinetics research is to bridge the gap between fundamental chemical understanding and practical engineering applications. By developing accurate and robust kinetic models, researchers seek to enable the design of more efficient and cleaner combustion systems, contribute to the development of advanced combustion concepts, and support the transition towards more sustainable energy solutions.

The evolution of decane combustion kinetics research can be traced back to the early 1990s when researchers began to focus on developing comprehensive reaction mechanisms for larger hydrocarbons. Initially, these models were relatively simple, consisting of a few hundred species and reactions. However, as computational capabilities improved and experimental techniques became more sophisticated, the complexity and accuracy of these models increased significantly.

One of the primary objectives in decane combustion kinetics research is to create a detailed and validated reaction mechanism that can accurately predict the combustion behavior of decane under a wide range of conditions. This includes capturing the ignition delay times, flame speeds, and species profiles across various temperatures, pressures, and fuel-air ratios. Such a comprehensive model is essential for engine designers and combustion engineers to optimize fuel efficiency and minimize pollutant formation.

Another critical goal in this field is to understand the low-temperature oxidation chemistry of decane. This is particularly important for predicting phenomena such as cool flames and negative temperature coefficient (NTC) behavior, which are characteristic of larger alkanes and have significant implications for engine knock and autoignition processes. Researchers aim to elucidate the complex network of reactions that occur at these lower temperatures, including the formation and decomposition of various intermediate species.

Furthermore, the development of reduced kinetic models for decane combustion is a key objective. While detailed mechanisms are valuable for fundamental understanding, they are often too computationally expensive for practical applications in engine simulations or computational fluid dynamics (CFD) studies. Therefore, there is a continuous effort to create simplified models that retain the essential features of the detailed mechanisms while being computationally efficient.

The ultimate aim of decane combustion kinetics research is to bridge the gap between fundamental chemical understanding and practical engineering applications. By developing accurate and robust kinetic models, researchers seek to enable the design of more efficient and cleaner combustion systems, contribute to the development of advanced combustion concepts, and support the transition towards more sustainable energy solutions.

Market Demand for Accurate Decane Combustion Models

The market demand for accurate decane combustion models has been steadily increasing due to the growing importance of decane as a fuel component and its widespread use in various combustion systems. Decane, a straight-chain alkane with ten carbon atoms, is a significant component of diesel fuel and jet fuel, making it crucial for the development of efficient and clean combustion technologies in transportation and energy sectors.

In the automotive industry, the push for more fuel-efficient and environmentally friendly vehicles has intensified the need for precise decane combustion models. These models are essential for optimizing engine design, improving fuel economy, and reducing emissions. As governments worldwide implement stricter emission standards, automotive manufacturers are investing heavily in research and development to create cleaner-burning engines, driving up the demand for accurate decane combustion models.

The aviation sector also represents a substantial market for decane combustion models. With the increasing focus on sustainable aviation fuels and the need to reduce the carbon footprint of air travel, accurate modeling of decane combustion becomes critical. Airlines and aircraft manufacturers are seeking ways to improve fuel efficiency and reduce emissions, creating a strong demand for advanced combustion models that can accurately predict the behavior of decane-based fuels under various flight conditions.

In the energy sector, the transition towards cleaner and more efficient power generation systems has led to increased interest in decane combustion models. Gas turbines, which often use fuels containing decane, require precise combustion modeling to optimize performance and minimize pollutant formation. Power plant operators and equipment manufacturers are investing in research to develop more efficient and cleaner-burning turbines, further driving the demand for accurate decane combustion models.

The petrochemical industry also contributes significantly to the market demand for decane combustion models. Refineries and chemical plants use these models to optimize their processes, improve product quality, and ensure safety in their operations. As the industry faces pressure to reduce its environmental impact, there is a growing need for advanced modeling tools that can help in the development of cleaner and more efficient processes.

Research institutions and universities form another important segment of the market for decane combustion models. The ongoing scientific interest in understanding combustion processes at a fundamental level continues to drive demand for increasingly accurate and detailed models. These institutions often collaborate with industry partners, further amplifying the market demand for advanced decane combustion modeling capabilities.

In the automotive industry, the push for more fuel-efficient and environmentally friendly vehicles has intensified the need for precise decane combustion models. These models are essential for optimizing engine design, improving fuel economy, and reducing emissions. As governments worldwide implement stricter emission standards, automotive manufacturers are investing heavily in research and development to create cleaner-burning engines, driving up the demand for accurate decane combustion models.

The aviation sector also represents a substantial market for decane combustion models. With the increasing focus on sustainable aviation fuels and the need to reduce the carbon footprint of air travel, accurate modeling of decane combustion becomes critical. Airlines and aircraft manufacturers are seeking ways to improve fuel efficiency and reduce emissions, creating a strong demand for advanced combustion models that can accurately predict the behavior of decane-based fuels under various flight conditions.

In the energy sector, the transition towards cleaner and more efficient power generation systems has led to increased interest in decane combustion models. Gas turbines, which often use fuels containing decane, require precise combustion modeling to optimize performance and minimize pollutant formation. Power plant operators and equipment manufacturers are investing in research to develop more efficient and cleaner-burning turbines, further driving the demand for accurate decane combustion models.

The petrochemical industry also contributes significantly to the market demand for decane combustion models. Refineries and chemical plants use these models to optimize their processes, improve product quality, and ensure safety in their operations. As the industry faces pressure to reduce its environmental impact, there is a growing need for advanced modeling tools that can help in the development of cleaner and more efficient processes.

Research institutions and universities form another important segment of the market for decane combustion models. The ongoing scientific interest in understanding combustion processes at a fundamental level continues to drive demand for increasingly accurate and detailed models. These institutions often collaborate with industry partners, further amplifying the market demand for advanced decane combustion modeling capabilities.

Current State and Challenges in Decane Kinetics Modeling

The current state of decane kinetics modeling in combustion systems reflects significant progress but also faces notable challenges. Researchers have developed increasingly sophisticated models to capture the complex chemical reactions involved in decane combustion, a crucial component in understanding and optimizing combustion processes for various applications.

Recent advancements in computational power and experimental techniques have enabled the creation of more detailed and accurate kinetic models for decane. These models typically incorporate hundreds of species and thousands of reactions, attempting to represent the intricate network of chemical pathways that occur during combustion. High-fidelity experiments, including shock tube studies, rapid compression machines, and flow reactors, have provided valuable data for model validation and refinement.

Despite these advances, several challenges persist in decane kinetics modeling. One major issue is the computational cost associated with running large-scale simulations using comprehensive kinetic models. This limitation often necessitates the use of reduced mechanisms, which may sacrifice accuracy for computational efficiency. Striking the right balance between model complexity and practical usability remains an ongoing challenge for researchers and engineers.

Another significant hurdle is the accurate representation of low-temperature chemistry in decane combustion. The complex interplay of various reaction pathways at lower temperatures, including cool flame phenomena and negative temperature coefficient behavior, poses difficulties in model development and validation. Addressing these low-temperature kinetics is crucial for applications such as advanced engine designs and low-emission combustion systems.

Furthermore, the development of predictive models that can accurately capture the behavior of decane under a wide range of conditions remains challenging. Extrapolating model performance beyond the conditions used for validation often leads to discrepancies between simulations and experimental results. This limitation highlights the need for more comprehensive experimental data sets and improved theoretical understanding of reaction kinetics.

The integration of uncertainty quantification in decane kinetics modeling is another area requiring attention. Uncertainties in rate constants, thermodynamic properties, and transport data can significantly impact model predictions. Developing robust methods to quantify and propagate these uncertainties through kinetic models is essential for improving the reliability and applicability of simulation results.

Lastly, the development of kinetic models for multi-component fuel mixtures containing decane presents additional complexities. Real-world fuels often consist of numerous components, and accurately capturing the interactions between these species in kinetic models remains a formidable challenge. Addressing this issue is crucial for bridging the gap between fundamental studies on pure decane and practical applications involving complex fuel blends.

Recent advancements in computational power and experimental techniques have enabled the creation of more detailed and accurate kinetic models for decane. These models typically incorporate hundreds of species and thousands of reactions, attempting to represent the intricate network of chemical pathways that occur during combustion. High-fidelity experiments, including shock tube studies, rapid compression machines, and flow reactors, have provided valuable data for model validation and refinement.

Despite these advances, several challenges persist in decane kinetics modeling. One major issue is the computational cost associated with running large-scale simulations using comprehensive kinetic models. This limitation often necessitates the use of reduced mechanisms, which may sacrifice accuracy for computational efficiency. Striking the right balance between model complexity and practical usability remains an ongoing challenge for researchers and engineers.

Another significant hurdle is the accurate representation of low-temperature chemistry in decane combustion. The complex interplay of various reaction pathways at lower temperatures, including cool flame phenomena and negative temperature coefficient behavior, poses difficulties in model development and validation. Addressing these low-temperature kinetics is crucial for applications such as advanced engine designs and low-emission combustion systems.

Furthermore, the development of predictive models that can accurately capture the behavior of decane under a wide range of conditions remains challenging. Extrapolating model performance beyond the conditions used for validation often leads to discrepancies between simulations and experimental results. This limitation highlights the need for more comprehensive experimental data sets and improved theoretical understanding of reaction kinetics.

The integration of uncertainty quantification in decane kinetics modeling is another area requiring attention. Uncertainties in rate constants, thermodynamic properties, and transport data can significantly impact model predictions. Developing robust methods to quantify and propagate these uncertainties through kinetic models is essential for improving the reliability and applicability of simulation results.

Lastly, the development of kinetic models for multi-component fuel mixtures containing decane presents additional complexities. Real-world fuels often consist of numerous components, and accurately capturing the interactions between these species in kinetic models remains a formidable challenge. Addressing this issue is crucial for bridging the gap between fundamental studies on pure decane and practical applications involving complex fuel blends.

Existing Approaches for Decane Combustion Modeling

01 Chemical kinetics modeling of decane

Developing mathematical models to describe the chemical kinetics of decane reactions, including reaction rates, mechanisms, and thermodynamic properties. These models are used to predict and analyze the behavior of decane in various chemical processes and combustion systems.- Chemical kinetics modeling for decane combustion: Development of chemical kinetics models for decane combustion, focusing on reaction mechanisms and rate constants. These models are used to predict and analyze the combustion behavior of decane under various conditions, aiding in the design of more efficient combustion systems.

- Decane as a component in fuel mixtures: Investigation of decane as a component in fuel mixtures, studying its impact on overall combustion characteristics. This includes analyzing the chemical kinetics of decane in combination with other hydrocarbons to optimize fuel formulations for specific applications.

- Thermal decomposition kinetics of decane: Study of the thermal decomposition kinetics of decane, including the identification of intermediate species and reaction pathways. This research aids in understanding the behavior of decane under high-temperature conditions and its potential applications in thermal processes.

- Catalytic reactions involving decane: Investigation of catalytic reactions involving decane, focusing on the development of kinetic models for processes such as dehydrogenation, isomerization, and cracking. These models help in optimizing catalytic processes for the conversion of decane into valuable products.

- Computational methods for decane kinetics modeling: Application of computational methods and algorithms to model the chemical kinetics of decane reactions. This includes the use of quantum chemistry calculations, molecular dynamics simulations, and machine learning techniques to predict reaction rates and mechanisms accurately.

02 Decane combustion analysis

Studying the combustion characteristics of decane, including flame propagation, ignition delay, and emission formation. This research is crucial for optimizing fuel efficiency and reducing pollutant emissions in engines and other combustion systems using decane-based fuels.Expand Specific Solutions03 Catalytic reactions involving decane

Investigating catalytic processes that involve decane, such as dehydrogenation, isomerization, and cracking reactions. These studies aim to improve the efficiency of industrial processes and develop new catalytic materials for decane conversion.Expand Specific Solutions04 Decane as a component in fuel mixtures

Analyzing the behavior and properties of decane when used as a component in various fuel mixtures. This includes studying the impact of decane on overall fuel performance, stability, and compatibility with different engine types and operating conditions.Expand Specific Solutions05 Molecular dynamics simulations of decane

Utilizing computational methods to simulate the molecular behavior of decane under different conditions. These simulations help in understanding the structural, thermodynamic, and transport properties of decane at the molecular level, aiding in the development of more accurate kinetic models.Expand Specific Solutions

Key Players in Combustion Kinetics Research

The development of chemical kinetics models for decane combustion systems is in a mature stage, with significant advancements in recent years. The market for this technology is growing steadily, driven by the automotive and energy sectors' need for more efficient and cleaner combustion processes. Key players like Toyota, Nissan, and Honda are investing heavily in research, while oil companies such as Shell and ExxonMobil are also actively involved. Academic institutions like the University of Leeds and Tianjin University collaborate with industry partners, contributing to the field's progress. The technology's maturity is evident in the sophisticated modeling tools developed by companies like The MathWorks, enabling more accurate simulations and predictions for decane combustion behavior.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced chemical kinetics models for decane combustion in their combustion systems. Their approach involves detailed reaction mechanisms, incorporating over 2000 species and 8000 reactions [1]. They utilize high-performance computing clusters to solve complex differential equations governing the chemical kinetics. Shell's models account for various combustion regimes, including low-temperature oxidation, negative temperature coefficient behavior, and high-temperature ignition [2]. They have also integrated these models with computational fluid dynamics (CFD) simulations to predict combustion behavior in practical systems. Shell's research has led to the development of reduced kinetic models that maintain accuracy while significantly reducing computational costs [3].

Strengths: Comprehensive reaction mechanisms, integration with CFD, and reduced models for practical applications. Weaknesses: High computational requirements for full models and potential limitations in extreme operating conditions.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has made significant contributions to decane chemical kinetics modeling for combustion systems. Their approach focuses on developing detailed kinetic mechanisms validated against a wide range of experimental data, including ignition delay times, laminar flame speeds, and species profiles [4]. They have pioneered the use of automatic mechanism generation tools to create comprehensive models for decane and other long-chain alkanes. IFP's models incorporate low-temperature chemistry pathways, crucial for accurate prediction of autoignition phenomena in engines [5]. They have also developed skeletal and reduced mechanisms optimized for specific combustion applications, balancing accuracy and computational efficiency.

Strengths: Extensive experimental validation, automatic mechanism generation capabilities, and tailored reduced mechanisms. Weaknesses: Potential challenges in capturing all relevant chemical pathways for complex fuel mixtures.

Core Innovations in Decane Reaction Mechanisms

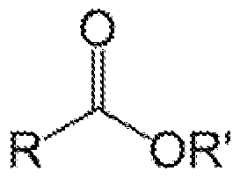

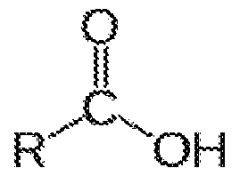

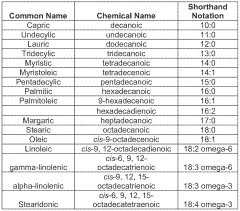

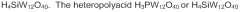

Process for making linear long-chain alkanes from renewable feedstocks using catalysts comprising heteropolyacids

PatentWO2014159490A1

Innovation

- A hydrodeoxygenation process using a catalyst composition comprising a metal catalyst and a heteropolyacid or heteropolyacid salt, operated at temperatures between 240 °C to 280 °C and hydrogen gas pressures of at least 300 psi, which effectively converts C10-18 oxygenates to linear alkanes without significant carbon loss, thereby reducing the formation of unwanted by-products.

Experimental Validation Techniques for Kinetic Models

Experimental validation techniques play a crucial role in the development and refinement of chemical kinetic models for combustion systems, particularly in the case of decane. These techniques are essential for assessing the accuracy and reliability of the models, as well as for identifying areas that require improvement.

One of the primary experimental validation techniques for decane kinetic models is shock tube studies. Shock tubes provide a controlled environment for studying high-temperature gas-phase reactions, allowing researchers to measure ignition delay times and species concentrations. These measurements are then compared with model predictions to evaluate the model's performance under various conditions.

Rapid compression machines (RCMs) offer another valuable tool for validating decane kinetic models. RCMs simulate engine-like conditions and enable the study of auto-ignition processes at intermediate temperatures and high pressures. The data obtained from RCM experiments, such as pressure traces and ignition delay times, are used to validate and refine the kinetic models.

Flow reactors are also employed in the validation process, providing information on species profiles and reaction rates over a wide range of temperatures and pressures. These experiments help in understanding the oxidation pathways of decane and its intermediates, which is crucial for improving the accuracy of the kinetic models.

Laminar flame speed measurements serve as another important validation technique. These experiments provide data on the fundamental combustion properties of decane-air mixtures, which are essential for assessing the model's ability to predict flame propagation characteristics.

Speciation studies using gas chromatography and mass spectrometry techniques are employed to identify and quantify the intermediate species formed during decane combustion. This information is vital for validating the reaction pathways proposed in the kinetic models and for refining the rate constants of individual reactions.

Laser diagnostics, such as laser-induced fluorescence (LIF) and cavity ring-down spectroscopy (CRDS), offer non-intrusive methods for measuring species concentrations and temperatures in combustion environments. These techniques provide high-resolution spatial and temporal data that can be directly compared with model predictions.

Engine experiments, while more complex, provide valuable validation data under realistic operating conditions. Measurements of in-cylinder pressure, heat release rates, and exhaust emissions are used to assess the model's ability to predict engine performance and pollutant formation.

Uncertainty quantification and sensitivity analysis techniques are increasingly being applied to evaluate the robustness of decane kinetic models. These methods help identify the most influential parameters and reactions in the model, guiding further experimental and theoretical studies.

As computational power increases, the integration of computational fluid dynamics (CFD) simulations with detailed chemical kinetics is becoming more feasible. This approach allows for the validation of decane kinetic models in complex, multi-dimensional flow fields, bridging the gap between fundamental experiments and practical combustion systems.

One of the primary experimental validation techniques for decane kinetic models is shock tube studies. Shock tubes provide a controlled environment for studying high-temperature gas-phase reactions, allowing researchers to measure ignition delay times and species concentrations. These measurements are then compared with model predictions to evaluate the model's performance under various conditions.

Rapid compression machines (RCMs) offer another valuable tool for validating decane kinetic models. RCMs simulate engine-like conditions and enable the study of auto-ignition processes at intermediate temperatures and high pressures. The data obtained from RCM experiments, such as pressure traces and ignition delay times, are used to validate and refine the kinetic models.

Flow reactors are also employed in the validation process, providing information on species profiles and reaction rates over a wide range of temperatures and pressures. These experiments help in understanding the oxidation pathways of decane and its intermediates, which is crucial for improving the accuracy of the kinetic models.

Laminar flame speed measurements serve as another important validation technique. These experiments provide data on the fundamental combustion properties of decane-air mixtures, which are essential for assessing the model's ability to predict flame propagation characteristics.

Speciation studies using gas chromatography and mass spectrometry techniques are employed to identify and quantify the intermediate species formed during decane combustion. This information is vital for validating the reaction pathways proposed in the kinetic models and for refining the rate constants of individual reactions.

Laser diagnostics, such as laser-induced fluorescence (LIF) and cavity ring-down spectroscopy (CRDS), offer non-intrusive methods for measuring species concentrations and temperatures in combustion environments. These techniques provide high-resolution spatial and temporal data that can be directly compared with model predictions.

Engine experiments, while more complex, provide valuable validation data under realistic operating conditions. Measurements of in-cylinder pressure, heat release rates, and exhaust emissions are used to assess the model's ability to predict engine performance and pollutant formation.

Uncertainty quantification and sensitivity analysis techniques are increasingly being applied to evaluate the robustness of decane kinetic models. These methods help identify the most influential parameters and reactions in the model, guiding further experimental and theoretical studies.

As computational power increases, the integration of computational fluid dynamics (CFD) simulations with detailed chemical kinetics is becoming more feasible. This approach allows for the validation of decane kinetic models in complex, multi-dimensional flow fields, bridging the gap between fundamental experiments and practical combustion systems.

Environmental Impact of Decane Combustion Research

The environmental impact of decane combustion research is a critical aspect to consider in the development of chemical kinetics models for combustion systems. Decane, a hydrocarbon commonly used in combustion studies, plays a significant role in understanding the environmental consequences of fuel combustion.

One of the primary environmental concerns associated with decane combustion is the emission of greenhouse gases, particularly carbon dioxide (CO2). As a hydrocarbon fuel, decane releases CO2 when burned, contributing to the overall atmospheric concentration of this potent greenhouse gas. Research into decane combustion kinetics helps in optimizing combustion processes, potentially leading to more efficient fuel utilization and reduced CO2 emissions.

Nitrogen oxides (NOx) formation is another crucial environmental factor in decane combustion. NOx emissions are known to contribute to air pollution, acid rain, and the formation of ground-level ozone. Studies on decane combustion kinetics aim to understand the mechanisms of NOx formation under various conditions, enabling the development of strategies to minimize these harmful emissions.

Particulate matter (PM) emissions are also a concern in decane combustion. These fine particles can have detrimental effects on air quality and human health. Research into decane combustion kinetics helps in understanding the formation and characteristics of PM, potentially leading to improved filtration and emission control technologies.

The environmental impact of decane combustion research extends beyond direct emissions. It also encompasses the broader implications for fuel efficiency and energy conservation. By developing more accurate chemical kinetics models, researchers can contribute to the design of more efficient combustion systems, reducing overall fuel consumption and, consequently, the environmental footprint of various industries relying on combustion processes.

Furthermore, decane combustion research has implications for the development of alternative and cleaner fuels. Understanding the combustion characteristics of decane provides valuable insights that can be applied to the formulation of more environmentally friendly fuel blends or the development of synthetic fuels with reduced environmental impact.

In conclusion, the environmental impact of decane combustion research is multifaceted, encompassing aspects such as greenhouse gas emissions, air pollutants, particulate matter, and broader implications for energy efficiency and alternative fuel development. This research plays a crucial role in mitigating the environmental consequences of combustion processes and advancing towards more sustainable energy solutions.

One of the primary environmental concerns associated with decane combustion is the emission of greenhouse gases, particularly carbon dioxide (CO2). As a hydrocarbon fuel, decane releases CO2 when burned, contributing to the overall atmospheric concentration of this potent greenhouse gas. Research into decane combustion kinetics helps in optimizing combustion processes, potentially leading to more efficient fuel utilization and reduced CO2 emissions.

Nitrogen oxides (NOx) formation is another crucial environmental factor in decane combustion. NOx emissions are known to contribute to air pollution, acid rain, and the formation of ground-level ozone. Studies on decane combustion kinetics aim to understand the mechanisms of NOx formation under various conditions, enabling the development of strategies to minimize these harmful emissions.

Particulate matter (PM) emissions are also a concern in decane combustion. These fine particles can have detrimental effects on air quality and human health. Research into decane combustion kinetics helps in understanding the formation and characteristics of PM, potentially leading to improved filtration and emission control technologies.

The environmental impact of decane combustion research extends beyond direct emissions. It also encompasses the broader implications for fuel efficiency and energy conservation. By developing more accurate chemical kinetics models, researchers can contribute to the design of more efficient combustion systems, reducing overall fuel consumption and, consequently, the environmental footprint of various industries relying on combustion processes.

Furthermore, decane combustion research has implications for the development of alternative and cleaner fuels. Understanding the combustion characteristics of decane provides valuable insights that can be applied to the formulation of more environmentally friendly fuel blends or the development of synthetic fuels with reduced environmental impact.

In conclusion, the environmental impact of decane combustion research is multifaceted, encompassing aspects such as greenhouse gas emissions, air pollutants, particulate matter, and broader implications for energy efficiency and alternative fuel development. This research plays a crucial role in mitigating the environmental consequences of combustion processes and advancing towards more sustainable energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!