Design of adaptive control systems for second-life battery packs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Adaptive Control Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decade, with lithium-ion batteries becoming the predominant energy storage solution across various industries. As electric vehicles (EVs) gain market share globally, a critical challenge emerges: managing the growing volume of batteries that no longer meet the rigorous performance requirements for automotive applications but retain 70-80% of their original capacity.

Second-life battery utilization represents a sustainable approach to extend battery lifecycle, reducing environmental impact while creating additional economic value. These batteries, repurposed from EVs, can serve effectively in less demanding applications such as stationary energy storage systems, grid stabilization, and renewable energy integration. However, the technical complexity of managing these batteries presents significant challenges due to their heterogeneous nature, varying degradation patterns, and uncertain remaining useful life.

Adaptive control systems for second-life battery packs aim to address these challenges by implementing intelligent management strategies that can dynamically adjust to changing battery conditions. The primary objective is to develop control algorithms capable of optimizing performance, extending operational lifespan, and ensuring safety despite the inherent variability and uncertainty in second-life battery characteristics.

The historical development of battery management systems has primarily focused on new, homogeneous battery packs with predictable behavior patterns. Traditional control approaches rely on predetermined models and parameters that become inadequate when applied to second-life batteries with diverse histories, chemistries, and degradation states. This technological gap necessitates innovative adaptive control solutions.

Current research trends indicate growing interest in machine learning-based approaches, real-time parameter estimation techniques, and robust control methodologies that can accommodate uncertainty. These developments align with broader industry movements toward circular economy principles and sustainable resource utilization.

The technical objectives for adaptive control systems in this context include: developing accurate state estimation algorithms for heterogeneous battery cells; implementing dynamic power allocation strategies to optimize performance while minimizing further degradation; creating fault detection and safety mechanisms adapted to the unique risk profiles of second-life batteries; and designing scalable architectures that can accommodate various battery configurations and applications.

Achieving these objectives requires interdisciplinary expertise spanning electrochemistry, control theory, machine learning, and systems engineering. The successful development of adaptive control systems for second-life battery packs would not only solve a pressing technical challenge but also contribute significantly to sustainability goals by extending battery lifecycles and reducing resource consumption.

Second-life battery utilization represents a sustainable approach to extend battery lifecycle, reducing environmental impact while creating additional economic value. These batteries, repurposed from EVs, can serve effectively in less demanding applications such as stationary energy storage systems, grid stabilization, and renewable energy integration. However, the technical complexity of managing these batteries presents significant challenges due to their heterogeneous nature, varying degradation patterns, and uncertain remaining useful life.

Adaptive control systems for second-life battery packs aim to address these challenges by implementing intelligent management strategies that can dynamically adjust to changing battery conditions. The primary objective is to develop control algorithms capable of optimizing performance, extending operational lifespan, and ensuring safety despite the inherent variability and uncertainty in second-life battery characteristics.

The historical development of battery management systems has primarily focused on new, homogeneous battery packs with predictable behavior patterns. Traditional control approaches rely on predetermined models and parameters that become inadequate when applied to second-life batteries with diverse histories, chemistries, and degradation states. This technological gap necessitates innovative adaptive control solutions.

Current research trends indicate growing interest in machine learning-based approaches, real-time parameter estimation techniques, and robust control methodologies that can accommodate uncertainty. These developments align with broader industry movements toward circular economy principles and sustainable resource utilization.

The technical objectives for adaptive control systems in this context include: developing accurate state estimation algorithms for heterogeneous battery cells; implementing dynamic power allocation strategies to optimize performance while minimizing further degradation; creating fault detection and safety mechanisms adapted to the unique risk profiles of second-life batteries; and designing scalable architectures that can accommodate various battery configurations and applications.

Achieving these objectives requires interdisciplinary expertise spanning electrochemistry, control theory, machine learning, and systems engineering. The successful development of adaptive control systems for second-life battery packs would not only solve a pressing technical challenge but also contribute significantly to sustainability goals by extending battery lifecycles and reducing resource consumption.

Market Analysis for Second-Life Battery Applications

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need to manage end-of-life batteries. By 2030, the global second-life battery market is projected to reach $4.2 billion, with a compound annual growth rate of 23.1% from 2023. This growth is primarily fueled by the expanding EV market, which is creating a substantial pipeline of batteries that will eventually reach their automotive end-of-life but retain 70-80% of their original capacity.

The utility sector represents the largest application segment for second-life batteries, accounting for approximately 45% of the market. Energy storage systems for grid stabilization, peak shaving, and renewable energy integration are driving this demand. Commercial and industrial applications follow at 30%, where second-life batteries are increasingly deployed for backup power, demand charge reduction, and energy cost optimization.

Residential applications currently comprise about 15% of the market but are expected to grow faster than other segments due to increasing distributed energy resources and home energy management systems. The remaining 10% is distributed across specialized applications including telecommunications, remote power systems, and mobile charging infrastructure.

Geographically, Asia Pacific dominates the market with 40% share, led by China, Japan, and South Korea, where EV adoption is high and supportive regulatory frameworks exist. Europe follows with 35%, driven by stringent sustainability regulations and ambitious renewable energy targets. North America accounts for 20%, while the rest of the world makes up the remaining 5%.

Key market drivers include decreasing costs of repurposing technologies, growing environmental regulations mandating battery recycling and reuse, and the economic value proposition of extending battery life. The cost of repurposing has decreased by approximately 60% over the past five years, making second-life applications increasingly competitive with new battery systems.

Market challenges include the lack of standardization across battery designs, uncertainty regarding long-term performance and reliability, and competition from declining prices of new lithium-ion batteries. The absence of unified testing protocols and quality standards for second-life batteries also creates market barriers.

Customer requirements are evolving toward more sophisticated battery management systems that can adapt to the variable conditions of second-life batteries. There is growing demand for predictive analytics capabilities, remote monitoring, and adaptive control systems that can optimize performance based on the unique characteristics of repurposed battery packs.

The utility sector represents the largest application segment for second-life batteries, accounting for approximately 45% of the market. Energy storage systems for grid stabilization, peak shaving, and renewable energy integration are driving this demand. Commercial and industrial applications follow at 30%, where second-life batteries are increasingly deployed for backup power, demand charge reduction, and energy cost optimization.

Residential applications currently comprise about 15% of the market but are expected to grow faster than other segments due to increasing distributed energy resources and home energy management systems. The remaining 10% is distributed across specialized applications including telecommunications, remote power systems, and mobile charging infrastructure.

Geographically, Asia Pacific dominates the market with 40% share, led by China, Japan, and South Korea, where EV adoption is high and supportive regulatory frameworks exist. Europe follows with 35%, driven by stringent sustainability regulations and ambitious renewable energy targets. North America accounts for 20%, while the rest of the world makes up the remaining 5%.

Key market drivers include decreasing costs of repurposing technologies, growing environmental regulations mandating battery recycling and reuse, and the economic value proposition of extending battery life. The cost of repurposing has decreased by approximately 60% over the past five years, making second-life applications increasingly competitive with new battery systems.

Market challenges include the lack of standardization across battery designs, uncertainty regarding long-term performance and reliability, and competition from declining prices of new lithium-ion batteries. The absence of unified testing protocols and quality standards for second-life batteries also creates market barriers.

Customer requirements are evolving toward more sophisticated battery management systems that can adapt to the variable conditions of second-life batteries. There is growing demand for predictive analytics capabilities, remote monitoring, and adaptive control systems that can optimize performance based on the unique characteristics of repurposed battery packs.

Technical Challenges in Second-Life Battery Management

The management of second-life battery packs presents significant technical challenges due to the inherent variability and degradation of used batteries. Unlike new batteries with predictable characteristics, second-life batteries exhibit diverse degradation patterns influenced by their previous usage conditions, charging cycles, and environmental exposures. This heterogeneity complicates the development of standardized management systems, requiring more sophisticated approaches to ensure safe and efficient operation.

Battery state estimation represents one of the most critical challenges in second-life applications. Traditional methods for State of Charge (SoC) and State of Health (SoH) estimation often rely on models calibrated for new batteries with consistent properties. When applied to aged batteries with varying degradation levels, these models can produce significant errors, potentially leading to suboptimal performance or safety risks. Advanced estimation techniques incorporating machine learning algorithms and adaptive models are being explored, but they require extensive validation across diverse battery conditions.

Thermal management presents another significant hurdle in second-life battery systems. Used batteries often exhibit increased internal resistance, leading to higher heat generation during operation. This thermal behavior varies considerably between individual cells based on their degradation history, creating potential hotspots within battery packs. Designing cooling systems that can adapt to these non-uniform thermal characteristics while maintaining optimal operating temperatures remains challenging.

Safety concerns are amplified in second-life applications due to the increased risk of cell failure. Degraded batteries may be more susceptible to thermal runaway, especially when subjected to conditions outside their diminished safe operating windows. Developing robust fault detection algorithms and protective measures that can identify potential failures before they occur is essential but technically demanding given the variable nature of aged cells.

System integration challenges arise when combining batteries with different histories into a unified pack. Variations in capacity, internal resistance, and degradation rates can lead to electrical imbalances, reducing overall system efficiency and accelerating further degradation. Advanced cell balancing techniques and adaptive power electronics are required to mitigate these effects, but implementing such systems cost-effectively remains difficult.

Longevity prediction represents perhaps the most complex challenge. Forecasting the remaining useful life of second-life battery packs requires models that can account for both historical degradation and future usage patterns. Current predictive models struggle with the compounded uncertainties of varied past usage and the additional degradation mechanisms that may emerge in second-life applications.

Battery state estimation represents one of the most critical challenges in second-life applications. Traditional methods for State of Charge (SoC) and State of Health (SoH) estimation often rely on models calibrated for new batteries with consistent properties. When applied to aged batteries with varying degradation levels, these models can produce significant errors, potentially leading to suboptimal performance or safety risks. Advanced estimation techniques incorporating machine learning algorithms and adaptive models are being explored, but they require extensive validation across diverse battery conditions.

Thermal management presents another significant hurdle in second-life battery systems. Used batteries often exhibit increased internal resistance, leading to higher heat generation during operation. This thermal behavior varies considerably between individual cells based on their degradation history, creating potential hotspots within battery packs. Designing cooling systems that can adapt to these non-uniform thermal characteristics while maintaining optimal operating temperatures remains challenging.

Safety concerns are amplified in second-life applications due to the increased risk of cell failure. Degraded batteries may be more susceptible to thermal runaway, especially when subjected to conditions outside their diminished safe operating windows. Developing robust fault detection algorithms and protective measures that can identify potential failures before they occur is essential but technically demanding given the variable nature of aged cells.

System integration challenges arise when combining batteries with different histories into a unified pack. Variations in capacity, internal resistance, and degradation rates can lead to electrical imbalances, reducing overall system efficiency and accelerating further degradation. Advanced cell balancing techniques and adaptive power electronics are required to mitigate these effects, but implementing such systems cost-effectively remains difficult.

Longevity prediction represents perhaps the most complex challenge. Forecasting the remaining useful life of second-life battery packs requires models that can account for both historical degradation and future usage patterns. Current predictive models struggle with the compounded uncertainties of varied past usage and the additional degradation mechanisms that may emerge in second-life applications.

Current Adaptive Control Solutions for Repurposed Batteries

01 Battery management systems for second-life batteries

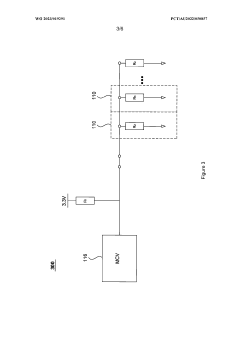

Advanced battery management systems (BMS) specifically designed for second-life batteries that monitor and control various parameters such as state of charge, state of health, and temperature. These systems adapt to the degraded characteristics of used batteries and optimize their performance in secondary applications. The BMS employs algorithms that account for the history and current condition of repurposed batteries to ensure safe and efficient operation.- Battery management systems for second-life applications: Battery management systems specifically designed for second-life battery applications focus on monitoring and controlling repurposed batteries that have completed their primary use cycle. These systems incorporate specialized algorithms to assess the health and performance of aged cells, manage their charging and discharging processes, and optimize their operation within new applications. The control systems account for the degraded capacity and altered characteristics of second-life batteries while ensuring safe and efficient operation.

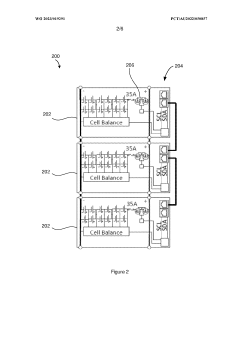

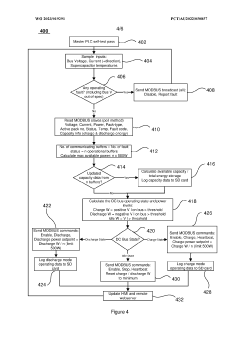

- Adaptive control algorithms for heterogeneous battery packs: Adaptive control algorithms are developed to manage heterogeneous battery packs composed of cells with varying states of health, capacities, and degradation levels. These algorithms dynamically adjust charging parameters, power distribution, and operational limits based on real-time performance data. The control systems continuously learn and adapt to changing battery characteristics, optimizing the overall performance of mixed battery assemblies while preventing damage to weaker cells.

- Thermal management and safety control systems: Specialized thermal management and safety control systems for second-life battery packs monitor temperature distribution, prevent thermal runaway, and implement protective measures against abnormal conditions. These systems incorporate temperature sensors, cooling mechanisms, and emergency shutdown protocols tailored to the unique risk profiles of aged batteries. The control architecture prioritizes safety while balancing performance requirements, implementing predictive models to anticipate thermal issues before they become critical.

- State estimation and predictive control techniques: Advanced state estimation and predictive control techniques are employed to accurately determine the state of charge, state of health, and remaining useful life of second-life batteries. These systems utilize machine learning algorithms, electrochemical models, and historical performance data to predict battery behavior under various operating conditions. The control systems make proactive adjustments based on these predictions, optimizing charging profiles and operational parameters to extend battery life while maintaining reliable performance.

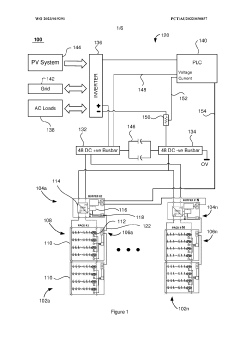

- Grid integration and energy management systems: Control systems designed for grid integration of second-life battery storage systems enable these repurposed batteries to participate in grid services and energy management applications. These systems coordinate charging and discharging based on grid demands, electricity pricing, and renewable energy availability. The adaptive controls optimize the economic value of second-life batteries while managing their technical limitations, implementing communication protocols for interaction with smart grid infrastructure and energy management systems.

02 Adaptive charging and discharging control strategies

Control systems that dynamically adjust charging and discharging parameters based on the unique characteristics of second-life battery packs. These systems implement adaptive algorithms that modify current rates, voltage limits, and power profiles according to the degradation level of repurposed batteries. By tailoring the charging and discharging processes to the specific condition of each battery or module, these control strategies extend the useful life of second-life batteries while maintaining safety.Expand Specific Solutions03 Cell balancing and pack configuration management

Control systems that manage the configuration of second-life battery packs by actively balancing cells with different degradation levels. These systems can dynamically reconfigure the electrical connections between cells or modules to optimize overall pack performance. Advanced cell balancing techniques compensate for the varying capacities and internal resistances found in repurposed batteries, ensuring more uniform operation across the pack and preventing individual cells from experiencing harmful operating conditions.Expand Specific Solutions04 Predictive maintenance and fault detection systems

Intelligent control systems that employ predictive analytics to anticipate potential failures in second-life battery packs. These systems continuously monitor battery parameters and use machine learning algorithms to identify patterns indicative of developing issues. By detecting anomalies before they lead to failures, these control systems enable proactive maintenance interventions. This approach is particularly valuable for second-life batteries, which may have less predictable behavior than new batteries due to their varied usage history.Expand Specific Solutions05 Grid integration and energy management for second-life battery systems

Control systems designed to optimize the integration of second-life battery storage with power grids or renewable energy sources. These systems manage energy flows between the battery pack, power sources, and loads while accounting for the specific limitations of repurposed batteries. Advanced algorithms determine optimal charging and discharging schedules based on electricity prices, renewable energy availability, and battery condition. These control systems enable second-life batteries to provide valuable grid services such as peak shaving, frequency regulation, and backup power despite their degraded performance characteristics.Expand Specific Solutions

Key Industry Players in Second-Life Battery Technology

The adaptive control systems for second-life battery packs market is in its early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is expanding rapidly, driven by sustainability initiatives and the growing electric vehicle sector. Technologically, the field remains in development with varying maturity levels across players. Leading companies like Contemporary Amperex Technology, LG Energy Solution, and Samsung SDI are advancing commercial solutions, while Toyota, Panasonic Energy, and Sony are leveraging their battery expertise to develop sophisticated control systems. Research institutions like Fuzhou University and Commonwealth Scientific & Industrial Research Organisation are contributing fundamental innovations. Japanese electronics manufacturers including NEC, Toshiba, and Hitachi are applying their control systems expertise to this emerging field, creating a competitive landscape balanced between established battery manufacturers and technology companies.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered an adaptive control system for second-life battery packs that utilizes a hierarchical control architecture. Their system employs a dual-layer approach with a master controller managing overall pack performance while subordinate controllers optimize individual module operation. The technology incorporates real-time electrochemical impedance spectroscopy (EIS) to continuously characterize battery cells and detect subtle changes in internal resistance and capacity. LG's adaptive algorithm dynamically adjusts charge/discharge profiles based on the identified state of health variations across repurposed cells. The system features thermal management controls that adapt to the unique thermal characteristics of aged cells, preventing hotspots and ensuring uniform temperature distribution. Their Battery Management System (BMS) includes predictive modeling capabilities that forecast capacity fade trajectories and adjust operational parameters to maximize remaining useful life while maintaining safety parameters within established thresholds.

Strengths: Sophisticated EIS implementation provides highly accurate cell characterization without expensive additional hardware. The hierarchical control architecture efficiently manages complexity in heterogeneous battery packs. Weaknesses: The system requires initial calibration periods when deployed with new second-life batteries, potentially delaying optimal performance during early operation.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive adaptive control system for second-life battery applications that centers on their proprietary "Adaptive Cell Balancing" technology. Their system employs a sophisticated state estimation algorithm that accurately determines the varying states of health across repurposed cells with different usage histories. The control architecture utilizes a model predictive control (MPC) framework that continuously updates internal resistance and capacity models based on real-time measurements. Samsung's approach incorporates dynamic power allocation strategies that distribute load demands optimally across modules with heterogeneous performance characteristics. Their BMS features adaptive thermal management that adjusts cooling/heating parameters based on the unique thermal response of aged cells under various load conditions. The system includes a self-diagnostic capability that identifies potential failure modes specific to second-life applications and implements preventive control measures to extend operational lifespan while maintaining safety parameters.

Strengths: Advanced model predictive control framework enables optimal performance even with highly heterogeneous cell populations. Sophisticated power allocation algorithms maximize overall system efficiency despite varying cell capabilities. Weaknesses: The complex modeling requirements demand significant computational resources and extensive characterization data for optimal performance.

Core Technologies for Battery State Estimation and Control

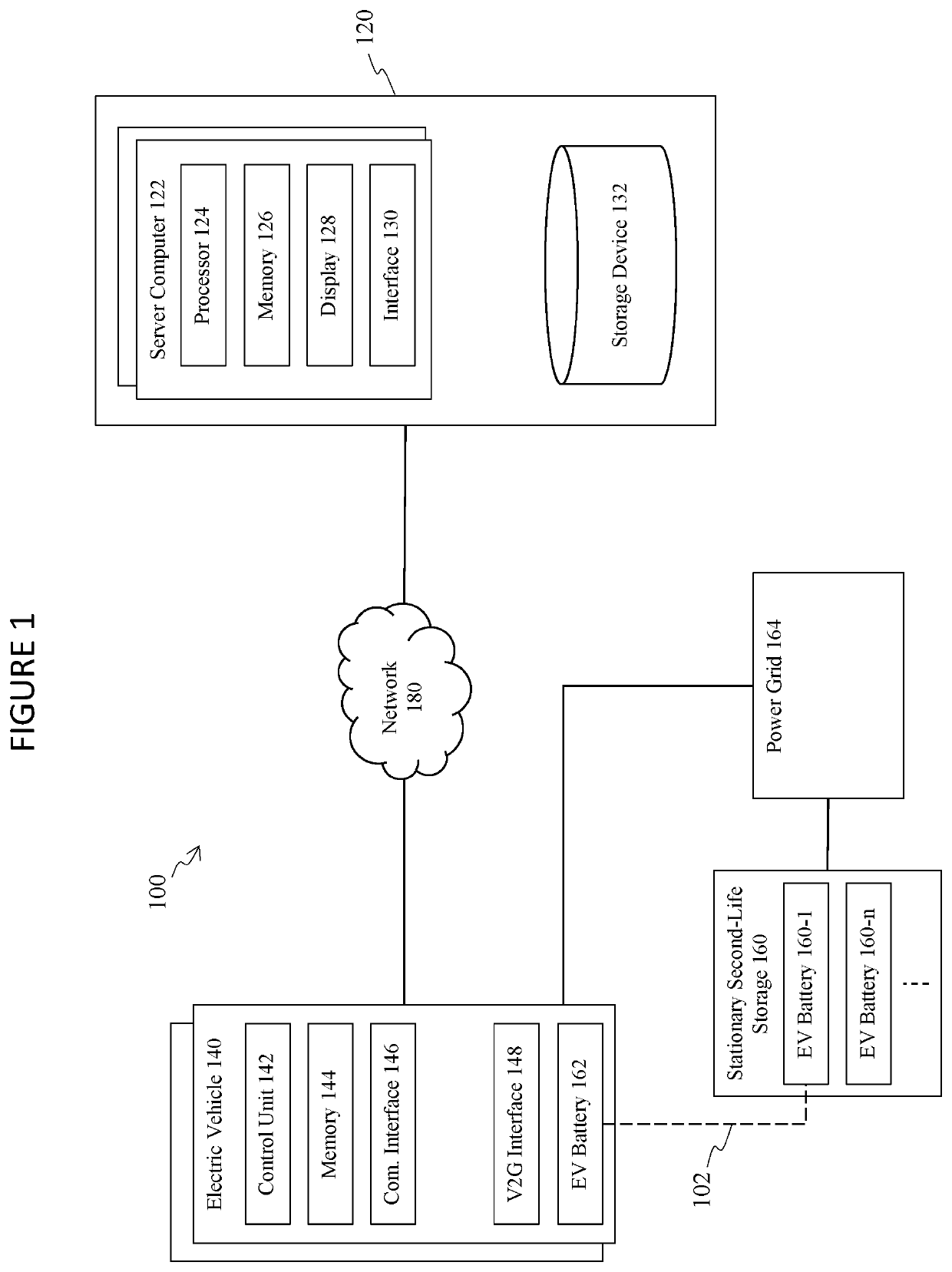

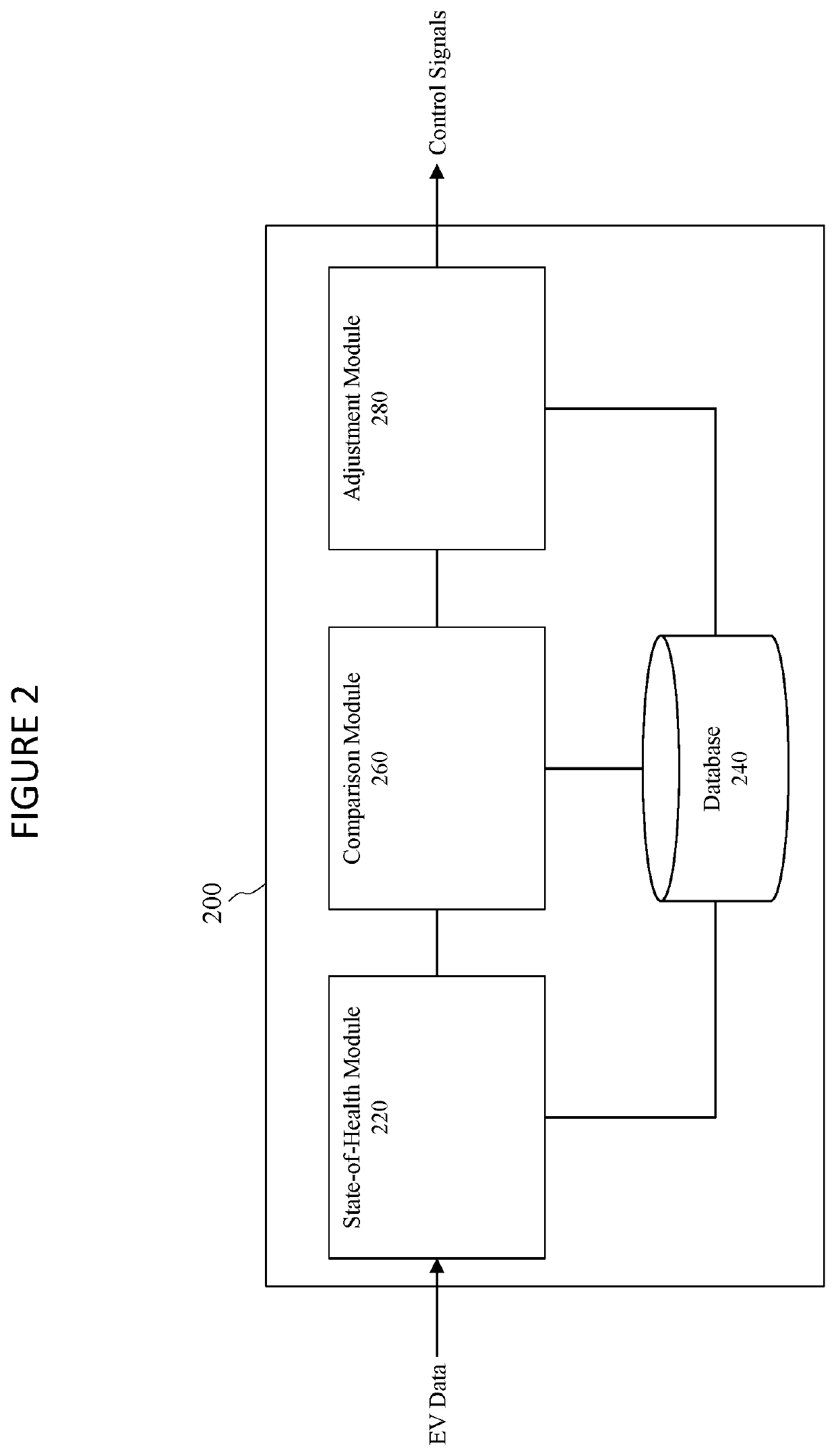

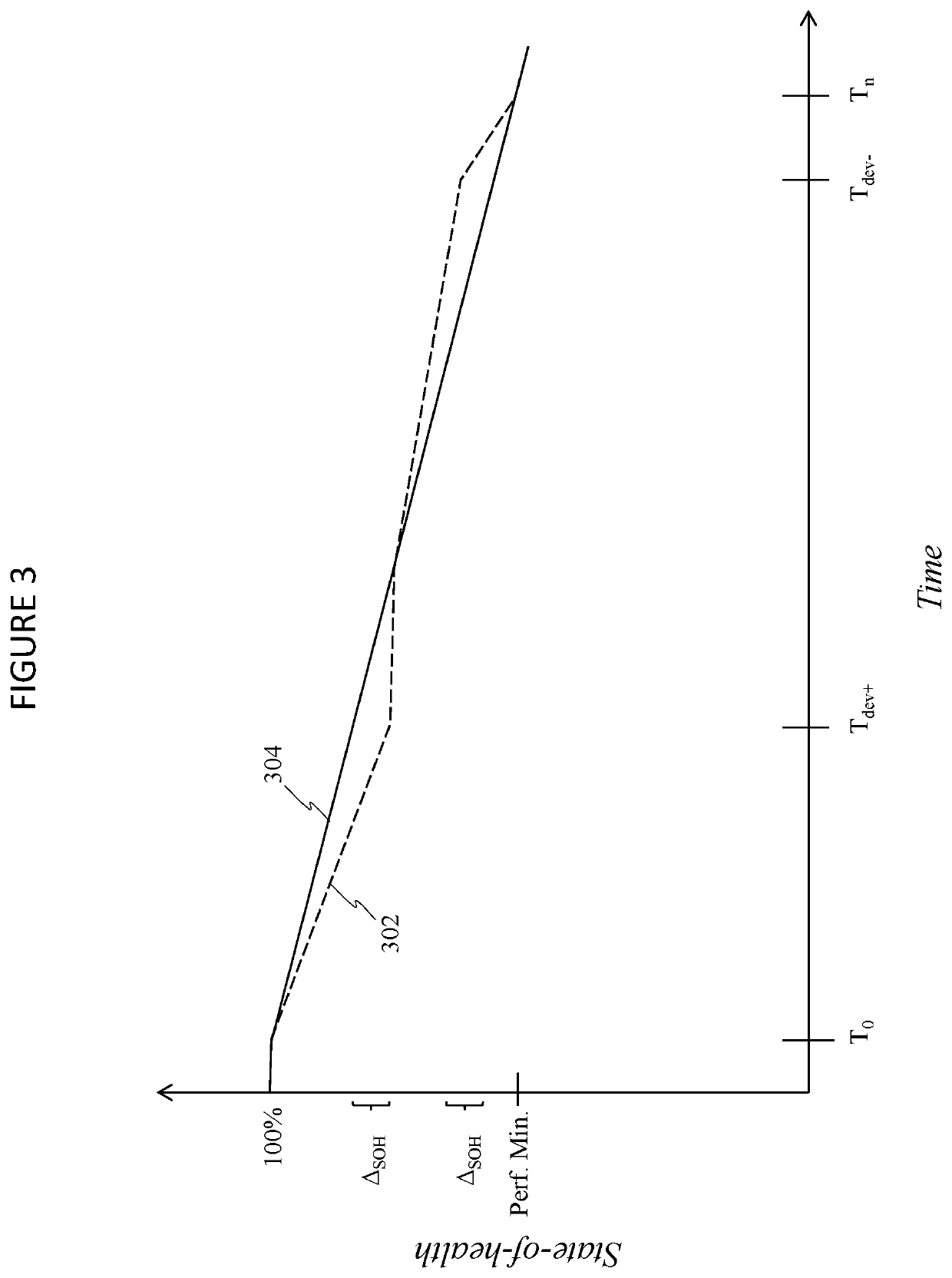

Systems and method for EV battery second-life management

PatentActiveUS10752128B1

Innovation

- A system and method for managing the state-of-health of EV batteries by determining individual deviance values from a reference state and controlling vehicle-to-grid operations to ensure all batteries have similar states-of-health, forming a stationary second-life unit for bi-directional power exchange with the grid.

A battery management system

PatentWO2023019291A1

Innovation

- A battery management system that includes buffer modules capable of automatically detecting the type of battery pack and dynamically controlling charge and discharge cycles, using bi-directional DC-to-DC converters or micro-inverters to integrate multiple battery packs with varying chemistries into a single system, eliminating the need for pre-testing and matching.

Safety and Reliability Standards for Second-Life Batteries

The safety and reliability standards for second-life batteries represent a critical framework for ensuring the successful implementation of adaptive control systems in repurposed battery packs. As these batteries transition from electric vehicles to stationary energy storage applications, they must comply with stringent regulations that differ significantly from their original use case. Currently, the primary standards governing second-life batteries include IEC 62619 for industrial applications, UL 1973 for stationary grid applications, and ISO 6469 for safety specifications in electric vehicles.

These standards establish minimum requirements for thermal management, electrical safety, and mechanical integrity that adaptive control systems must maintain throughout the battery's second life. The Battery Directive 2006/66/EC in Europe and similar regulations in other regions further mandate proper handling, labeling, and end-of-life management considerations that control systems must accommodate through appropriate monitoring and reporting functions.

A significant challenge in standardization arises from the heterogeneous nature of second-life batteries. Unlike new batteries, these units have varied degradation patterns, usage histories, and remaining capacities. Adaptive control systems must therefore incorporate robust diagnostic capabilities to assess and continuously monitor these parameters against established safety thresholds. The IEEE 1881 standard for battery management systems provides guidance on the minimum data collection and analysis requirements that such adaptive systems should implement.

Testing protocols for second-life battery applications have evolved to include accelerated aging tests, thermal runaway resistance assessments, and cycle life predictions under various operational conditions. Adaptive control systems must demonstrate compliance with these protocols through extensive validation testing. The IEC 62660 series specifically addresses the performance and reliability testing methodologies that control systems should incorporate into their operational parameters.

Emerging standards are increasingly focusing on the dynamic nature of second-life applications. The development of UL 9540A for test methods for evaluating thermal runaway fire propagation and NFPA 855 for the installation of stationary energy storage systems are particularly relevant for adaptive control system design. These standards emphasize the importance of real-time monitoring and responsive control algorithms that can prevent cascading failures in repurposed battery packs.

Certification processes for second-life battery systems require comprehensive documentation of the adaptive control system's response to various failure modes. This includes verification of fault detection capabilities, emergency shutdown procedures, and communication protocols with broader energy management systems. The IEC 63056 standard specifically addresses these safety requirements for secondary batteries in stationary applications, providing essential guidance for adaptive control system designers.

These standards establish minimum requirements for thermal management, electrical safety, and mechanical integrity that adaptive control systems must maintain throughout the battery's second life. The Battery Directive 2006/66/EC in Europe and similar regulations in other regions further mandate proper handling, labeling, and end-of-life management considerations that control systems must accommodate through appropriate monitoring and reporting functions.

A significant challenge in standardization arises from the heterogeneous nature of second-life batteries. Unlike new batteries, these units have varied degradation patterns, usage histories, and remaining capacities. Adaptive control systems must therefore incorporate robust diagnostic capabilities to assess and continuously monitor these parameters against established safety thresholds. The IEEE 1881 standard for battery management systems provides guidance on the minimum data collection and analysis requirements that such adaptive systems should implement.

Testing protocols for second-life battery applications have evolved to include accelerated aging tests, thermal runaway resistance assessments, and cycle life predictions under various operational conditions. Adaptive control systems must demonstrate compliance with these protocols through extensive validation testing. The IEC 62660 series specifically addresses the performance and reliability testing methodologies that control systems should incorporate into their operational parameters.

Emerging standards are increasingly focusing on the dynamic nature of second-life applications. The development of UL 9540A for test methods for evaluating thermal runaway fire propagation and NFPA 855 for the installation of stationary energy storage systems are particularly relevant for adaptive control system design. These standards emphasize the importance of real-time monitoring and responsive control algorithms that can prevent cascading failures in repurposed battery packs.

Certification processes for second-life battery systems require comprehensive documentation of the adaptive control system's response to various failure modes. This includes verification of fault detection capabilities, emergency shutdown procedures, and communication protocols with broader energy management systems. The IEC 63056 standard specifically addresses these safety requirements for secondary batteries in stationary applications, providing essential guidance for adaptive control system designers.

Environmental Impact and Sustainability Assessment

The implementation of adaptive control systems for second-life battery packs represents a significant opportunity to address environmental challenges associated with battery waste. The repurposing of electric vehicle (EV) batteries for secondary applications can extend their useful life by 5-10 years, substantially reducing the environmental footprint associated with battery production and disposal. Life cycle assessment (LCA) studies indicate that repurposing EV batteries can reduce carbon emissions by 15-25% compared to manufacturing new batteries for stationary storage applications, while simultaneously decreasing the demand for raw materials extraction.

The environmental benefits extend beyond carbon reduction. Mining operations for critical battery materials like lithium, cobalt, and nickel cause significant ecological disruption, including habitat destruction, water pollution, and soil contamination. By extending battery lifecycles through adaptive control systems, the mining pressure can be alleviated by approximately 20-30% for these materials, according to recent industry analyses. Furthermore, water conservation benefits are substantial, with estimates suggesting that each repurposed 60kWh battery pack saves approximately 3,000-5,000 gallons of water that would otherwise be consumed in new battery production.

Waste reduction represents another crucial environmental advantage. Currently, less than 5% of lithium-ion batteries are effectively recycled globally, with the majority ending in landfills where they pose contamination risks. Adaptive control systems that optimize second-life battery performance can delay this waste generation while providing valuable energy storage services. This circular economy approach aligns with sustainable development goals and increasingly stringent environmental regulations in major markets.

Energy efficiency improvements through sophisticated adaptive control algorithms further enhance the sustainability profile of second-life battery systems. These algorithms can optimize charging and discharging patterns based on real-time battery health metrics, potentially improving overall system efficiency by 10-15% compared to conventional control methods. This translates to reduced energy consumption during operation, multiplying the environmental benefits throughout the extended service life.

The sustainability assessment must also consider end-of-life scenarios after second use. Advanced adaptive control systems can incorporate predictive maintenance capabilities that maximize useful life while providing valuable data for eventual recycling processes. This data-driven approach can improve recycling efficiency by helping recyclers target specific battery components based on their degradation patterns, potentially increasing material recovery rates by 15-20% compared to current recycling methods.

The environmental benefits extend beyond carbon reduction. Mining operations for critical battery materials like lithium, cobalt, and nickel cause significant ecological disruption, including habitat destruction, water pollution, and soil contamination. By extending battery lifecycles through adaptive control systems, the mining pressure can be alleviated by approximately 20-30% for these materials, according to recent industry analyses. Furthermore, water conservation benefits are substantial, with estimates suggesting that each repurposed 60kWh battery pack saves approximately 3,000-5,000 gallons of water that would otherwise be consumed in new battery production.

Waste reduction represents another crucial environmental advantage. Currently, less than 5% of lithium-ion batteries are effectively recycled globally, with the majority ending in landfills where they pose contamination risks. Adaptive control systems that optimize second-life battery performance can delay this waste generation while providing valuable energy storage services. This circular economy approach aligns with sustainable development goals and increasingly stringent environmental regulations in major markets.

Energy efficiency improvements through sophisticated adaptive control algorithms further enhance the sustainability profile of second-life battery systems. These algorithms can optimize charging and discharging patterns based on real-time battery health metrics, potentially improving overall system efficiency by 10-15% compared to conventional control methods. This translates to reduced energy consumption during operation, multiplying the environmental benefits throughout the extended service life.

The sustainability assessment must also consider end-of-life scenarios after second use. Advanced adaptive control systems can incorporate predictive maintenance capabilities that maximize useful life while providing valuable data for eventual recycling processes. This data-driven approach can improve recycling efficiency by helping recyclers target specific battery components based on their degradation patterns, potentially increasing material recovery rates by 15-20% compared to current recycling methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!