Methods for homogenizing performance in second-life battery arrays

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Technology Background and Objectives

Second-life battery technology has emerged as a critical solution for sustainable energy management, evolving significantly over the past decade. Initially, lithium-ion batteries from electric vehicles (EVs) were considered waste after reaching 70-80% of their original capacity. However, research has demonstrated these batteries retain substantial utility for less demanding applications such as stationary energy storage systems (ESS), creating a viable second-life pathway.

The evolution of this technology has been driven by the exponential growth in EV adoption globally, with projections indicating that by 2030, over 145 GWh of used EV batteries will become available for repurposing. This trend has catalyzed research into effective methods for battery assessment, refurbishment, and performance homogenization to ensure reliable operation in second-life applications.

A significant technical challenge in this domain involves addressing the inherent variability in aged battery cells. After primary use in EVs, individual cells within battery packs develop unique degradation profiles based on their operational history, temperature exposure, and charging patterns. This heterogeneity creates substantial obstacles when integrating these cells into new array configurations for second-life applications.

The primary technical objective in this field is to develop robust methodologies for homogenizing performance across second-life battery arrays. This includes advanced diagnostic techniques to accurately assess remaining capacity and internal resistance, sorting algorithms to optimize cell grouping, and adaptive battery management systems capable of balancing performance disparities during operation.

Recent technological advancements have focused on non-invasive testing protocols that can rapidly evaluate large quantities of used cells, machine learning algorithms that predict future degradation patterns, and innovative circuit designs that compensate for cell-to-cell variations. These developments aim to maximize the usable capacity of repurposed battery arrays while ensuring safety and reliability.

The environmental and economic implications of this technology are substantial. Extending battery life through second-use applications can reduce the carbon footprint of battery production by up to 70% while creating a circular economy model for energy storage components. Additionally, second-life batteries offer cost advantages, typically priced at 30-70% below new batteries for stationary storage applications.

Looking forward, the technology trajectory points toward increasingly sophisticated battery management systems with cell-level monitoring and control, standardized testing protocols across manufacturers, and automated refurbishment processes to scale second-life battery deployment. These developments align with global sustainability goals and represent a critical pathway toward maximizing the value of energy storage resources.

The evolution of this technology has been driven by the exponential growth in EV adoption globally, with projections indicating that by 2030, over 145 GWh of used EV batteries will become available for repurposing. This trend has catalyzed research into effective methods for battery assessment, refurbishment, and performance homogenization to ensure reliable operation in second-life applications.

A significant technical challenge in this domain involves addressing the inherent variability in aged battery cells. After primary use in EVs, individual cells within battery packs develop unique degradation profiles based on their operational history, temperature exposure, and charging patterns. This heterogeneity creates substantial obstacles when integrating these cells into new array configurations for second-life applications.

The primary technical objective in this field is to develop robust methodologies for homogenizing performance across second-life battery arrays. This includes advanced diagnostic techniques to accurately assess remaining capacity and internal resistance, sorting algorithms to optimize cell grouping, and adaptive battery management systems capable of balancing performance disparities during operation.

Recent technological advancements have focused on non-invasive testing protocols that can rapidly evaluate large quantities of used cells, machine learning algorithms that predict future degradation patterns, and innovative circuit designs that compensate for cell-to-cell variations. These developments aim to maximize the usable capacity of repurposed battery arrays while ensuring safety and reliability.

The environmental and economic implications of this technology are substantial. Extending battery life through second-use applications can reduce the carbon footprint of battery production by up to 70% while creating a circular economy model for energy storage components. Additionally, second-life batteries offer cost advantages, typically priced at 30-70% below new batteries for stationary storage applications.

Looking forward, the technology trajectory points toward increasingly sophisticated battery management systems with cell-level monitoring and control, standardized testing protocols across manufacturers, and automated refurbishment processes to scale second-life battery deployment. These developments align with global sustainability goals and represent a critical pathway toward maximizing the value of energy storage resources.

Market Analysis for Repurposed Battery Systems

The second-life battery market is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need for sustainable battery disposal solutions. As EV batteries typically retain 70-80% of their original capacity after their automotive life cycle, they present substantial value for repurposing in less demanding applications. The global market for second-life EV batteries was valued at approximately $430 million in 2022 and is projected to reach $2.3 billion by 2030, representing a compound annual growth rate of 23.1%.

Energy storage systems constitute the largest application segment for repurposed batteries, accounting for nearly 55% of the market share. This dominance is attributed to the growing integration of renewable energy sources into power grids, which necessitates efficient energy storage solutions to address intermittency issues. Commercial and industrial backup power systems represent the second-largest market segment at 25%, followed by residential energy storage at 15%.

Regional analysis reveals that Asia Pacific currently leads the market with a 45% share, primarily due to the strong presence of battery manufacturers and recycling facilities in China, Japan, and South Korea. Europe follows with a 30% market share, driven by stringent environmental regulations and ambitious renewable energy targets. North America accounts for 20% of the market, with growth accelerated by increasing investments in grid modernization and energy storage projects.

The customer landscape for repurposed battery systems is diverse, encompassing utility companies, commercial building operators, telecommunications providers, and residential consumers. Utility companies are particularly interested in large-scale energy storage solutions for grid stabilization and peak shaving applications. Meanwhile, commercial entities are adopting these systems for reducing energy costs and ensuring operational continuity during power outages.

Key market drivers include declining costs of battery storage systems, supportive government policies promoting circular economy initiatives, and increasing corporate sustainability commitments. The cost of repurposed battery systems is approximately 30-50% lower than new battery systems, making them an economically attractive option for various applications.

However, several challenges impede market growth, including technical barriers related to performance homogenization, lack of standardized testing protocols, and uncertain regulatory frameworks regarding battery reuse. The variability in battery performance characteristics presents a significant technical challenge that requires innovative solutions to ensure reliable operation in second-life applications.

Energy storage systems constitute the largest application segment for repurposed batteries, accounting for nearly 55% of the market share. This dominance is attributed to the growing integration of renewable energy sources into power grids, which necessitates efficient energy storage solutions to address intermittency issues. Commercial and industrial backup power systems represent the second-largest market segment at 25%, followed by residential energy storage at 15%.

Regional analysis reveals that Asia Pacific currently leads the market with a 45% share, primarily due to the strong presence of battery manufacturers and recycling facilities in China, Japan, and South Korea. Europe follows with a 30% market share, driven by stringent environmental regulations and ambitious renewable energy targets. North America accounts for 20% of the market, with growth accelerated by increasing investments in grid modernization and energy storage projects.

The customer landscape for repurposed battery systems is diverse, encompassing utility companies, commercial building operators, telecommunications providers, and residential consumers. Utility companies are particularly interested in large-scale energy storage solutions for grid stabilization and peak shaving applications. Meanwhile, commercial entities are adopting these systems for reducing energy costs and ensuring operational continuity during power outages.

Key market drivers include declining costs of battery storage systems, supportive government policies promoting circular economy initiatives, and increasing corporate sustainability commitments. The cost of repurposed battery systems is approximately 30-50% lower than new battery systems, making them an economically attractive option for various applications.

However, several challenges impede market growth, including technical barriers related to performance homogenization, lack of standardized testing protocols, and uncertain regulatory frameworks regarding battery reuse. The variability in battery performance characteristics presents a significant technical challenge that requires innovative solutions to ensure reliable operation in second-life applications.

Technical Challenges in Battery Array Homogenization

The homogenization of second-life battery arrays presents significant technical challenges that must be addressed to enable widespread adoption of these repurposed energy storage systems. The fundamental issue stems from the inherent variability in degradation patterns across batteries that have completed their primary use cycle, typically in electric vehicles. These batteries exhibit diverse capacity retention levels, internal resistance variations, and thermal characteristics, making their integration into cohesive arrays problematic.

Cell-to-cell variations represent the most immediate challenge, with capacity differences often exceeding 20% within a single batch of second-life cells. This heterogeneity creates imbalances during charging and discharging cycles, leading to premature system failures and reduced overall efficiency. The weakest cells effectively become bottlenecks for the entire array, limiting total energy throughput and operational lifespan.

State of health (SOH) estimation presents another significant hurdle. Unlike new batteries with predictable characteristics, second-life batteries require sophisticated diagnostic algorithms to accurately determine their remaining useful capacity and performance parameters. Current methodologies often rely on simplified models that fail to capture the complex electrochemical changes resulting from years of varied usage patterns, environmental exposures, and charging histories.

Thermal management complications arise from inconsistent heat generation across cells with different internal resistance profiles. These thermal gradients accelerate degradation in hotter cells while potentially underutilizing cooler ones, creating a negative feedback loop that exacerbates performance divergence over time. Conventional cooling systems designed for homogeneous new battery arrays prove inadequate for these variable thermal loads.

Battery management systems (BMS) face unprecedented complexity when handling second-life arrays. Traditional BMS architectures assume relatively uniform cell characteristics and employ standardized control parameters. However, second-life applications require adaptive, cell-specific management strategies capable of continuously optimizing performance across widely varying components. The computational demands of such systems often exceed practical implementation constraints.

Aging trajectory prediction represents perhaps the most challenging aspect of second-life battery homogenization. While new batteries follow relatively predictable degradation curves, second-life cells exhibit highly individualized aging patterns influenced by their unique histories. This unpredictability complicates system design and lifecycle planning, as engineers must account for accelerated failure modes that may emerge unexpectedly in certain cells.

Electrical balancing techniques must also evolve beyond conventional approaches. Active balancing systems capable of significant energy redistribution between cells become necessary, rather than the simpler passive balancing methods sufficient for new battery arrays. These systems add cost, complexity, and potential points of failure to second-life implementations.

Cell-to-cell variations represent the most immediate challenge, with capacity differences often exceeding 20% within a single batch of second-life cells. This heterogeneity creates imbalances during charging and discharging cycles, leading to premature system failures and reduced overall efficiency. The weakest cells effectively become bottlenecks for the entire array, limiting total energy throughput and operational lifespan.

State of health (SOH) estimation presents another significant hurdle. Unlike new batteries with predictable characteristics, second-life batteries require sophisticated diagnostic algorithms to accurately determine their remaining useful capacity and performance parameters. Current methodologies often rely on simplified models that fail to capture the complex electrochemical changes resulting from years of varied usage patterns, environmental exposures, and charging histories.

Thermal management complications arise from inconsistent heat generation across cells with different internal resistance profiles. These thermal gradients accelerate degradation in hotter cells while potentially underutilizing cooler ones, creating a negative feedback loop that exacerbates performance divergence over time. Conventional cooling systems designed for homogeneous new battery arrays prove inadequate for these variable thermal loads.

Battery management systems (BMS) face unprecedented complexity when handling second-life arrays. Traditional BMS architectures assume relatively uniform cell characteristics and employ standardized control parameters. However, second-life applications require adaptive, cell-specific management strategies capable of continuously optimizing performance across widely varying components. The computational demands of such systems often exceed practical implementation constraints.

Aging trajectory prediction represents perhaps the most challenging aspect of second-life battery homogenization. While new batteries follow relatively predictable degradation curves, second-life cells exhibit highly individualized aging patterns influenced by their unique histories. This unpredictability complicates system design and lifecycle planning, as engineers must account for accelerated failure modes that may emerge unexpectedly in certain cells.

Electrical balancing techniques must also evolve beyond conventional approaches. Active balancing systems capable of significant energy redistribution between cells become necessary, rather than the simpler passive balancing methods sufficient for new battery arrays. These systems add cost, complexity, and potential points of failure to second-life implementations.

Current Homogenization Methods and Solutions

01 Battery cell selection and matching techniques

Second-life battery arrays can be optimized by implementing advanced selection and matching techniques for individual cells. This involves sorting and grouping batteries with similar characteristics such as capacity, internal resistance, and degradation levels. By ensuring homogeneity among cells within a battery pack, performance variations are minimized, leading to improved overall efficiency and extended service life of repurposed battery systems.- Battery cell balancing and equalization techniques: Various methods for balancing and equalizing second-life battery cells to ensure uniform performance across the array. These techniques include active and passive balancing circuits, state-of-charge equalization, and voltage/current regulation systems that compensate for differences between individual cells. By homogenizing the electrical characteristics of repurposed batteries, these methods extend the useful life of battery arrays and improve overall system reliability.

- Battery health monitoring and diagnostics: Advanced monitoring systems that assess the health and performance of second-life batteries in real-time. These solutions incorporate sensors, data analytics, and predictive algorithms to evaluate battery degradation patterns, remaining useful life, and performance variations. By identifying underperforming cells and providing early warning of potential failures, these systems enable proactive maintenance and optimization of battery arrays to maintain homogeneous performance.

- Adaptive control systems for battery arrays: Intelligent control systems that dynamically adjust operating parameters based on the condition of individual batteries within an array. These systems implement adaptive algorithms that modify charging/discharging profiles, thermal management, and load distribution to compensate for performance variations between cells. By continuously optimizing operational parameters, these control systems ensure consistent performance across heterogeneous second-life battery arrays.

- Battery sorting and matching methodologies: Systematic approaches for categorizing and grouping second-life batteries based on their electrical characteristics, degradation levels, and performance metrics. These methodologies employ testing protocols, statistical analysis, and machine learning algorithms to identify batteries with similar properties. By creating homogeneous groups before assembling arrays, these techniques minimize initial performance variations and simplify subsequent management of the battery system.

- Thermal management for performance uniformity: Specialized thermal regulation systems designed to maintain consistent temperature across second-life battery arrays. These solutions include active cooling mechanisms, heat distribution systems, and thermal isolation techniques that prevent temperature gradients within the battery pack. By ensuring uniform thermal conditions, these systems minimize performance variations caused by temperature differences and extend the operational lifespan of repurposed batteries.

02 Battery management systems for performance equalization

Specialized battery management systems (BMS) can be implemented to actively balance and equalize the performance of second-life battery arrays. These systems continuously monitor individual cell parameters and apply adaptive control strategies to compensate for variations between cells. Advanced algorithms enable real-time adjustment of charging and discharging patterns, ensuring uniform energy distribution across the array and preventing premature failure of weaker cells.Expand Specific Solutions03 Thermal management for performance homogenization

Thermal management solutions play a crucial role in homogenizing the performance of second-life battery arrays. Temperature variations between cells can significantly impact their behavior and accelerate degradation. Implementing effective cooling systems, thermal insulation, and heat distribution mechanisms helps maintain uniform operating temperatures across the battery array, resulting in more consistent performance characteristics and extended operational lifetime.Expand Specific Solutions04 Predictive modeling and simulation techniques

Advanced predictive modeling and simulation techniques enable better understanding and optimization of second-life battery array performance. By analyzing historical data and creating digital twins of battery systems, these approaches can forecast performance variations and identify optimal configurations for homogenization. Machine learning algorithms can detect patterns in battery behavior, allowing for proactive adjustments to maintain consistent performance across the array.Expand Specific Solutions05 Adaptive charging protocols for performance uniformity

Implementing adaptive charging protocols specifically designed for second-life battery arrays can significantly improve performance homogeneity. These protocols adjust charging parameters based on the unique characteristics of each repurposed cell, compensating for variations in capacity and internal resistance. By customizing the charging process for individual cells while maintaining system-level coordination, these methods ensure more uniform state-of-charge distribution and consistent performance across the entire battery array.Expand Specific Solutions

Key Industry Players in Battery Repurposing

The second-life battery market is currently in its growth phase, with increasing adoption driven by sustainability initiatives and economic incentives. The global market size for repurposed EV batteries is projected to reach significant scale as major automotive and energy companies develop standardized solutions for performance homogenization. Leading players like LG Energy Solution, CATL, and Panasonic are advancing technologies to address battery degradation variability, while Toyota, Honda, and Kyocera focus on integrated battery management systems. Research institutions including CEA and Commonwealth Scientific & Industrial Research Organisation are developing algorithms for state-of-health estimation. The technology is approaching commercial maturity with companies like Nilar and EaglePicher implementing innovative cell balancing and thermal management techniques to ensure consistent performance across repurposed battery arrays.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated "Hierarchical Equalization Framework" (HEF) specifically designed for second-life battery applications. Their approach begins with a comprehensive cell characterization process that evaluates capacity retention, internal resistance, self-discharge rates, and thermal behavior. Based on these parameters, Toyota's system implements a multi-level equalization strategy that operates at both the cell and module levels. At the cell level, the HEF employs active balancing circuits with bidirectional energy transfer capabilities, allowing energy to be redistributed from stronger to weaker cells during operation. At the module level, Toyota's proprietary "Adaptive Load Distribution" algorithm dynamically adjusts the power demands placed on different modules based on their performance capabilities. The system incorporates a thermal management solution that strategically distributes cooling resources to maintain consistent temperature profiles across the battery array. Additionally, Toyota has implemented a machine learning algorithm that continuously analyzes performance data to optimize the equalization parameters and predict future degradation patterns.

Strengths: The hierarchical approach provides exceptional flexibility in managing performance variations at multiple levels within the battery system. The machine learning component allows the system to adapt to changing battery conditions over time, maximizing performance consistency. Weaknesses: The multi-level equalization strategy requires complex control systems and additional hardware, increasing overall system cost. The sophisticated algorithms may require significant computational resources for real-time operation.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced Battery Management System (BMS) specifically designed for second-life battery applications. Their approach combines hardware sorting mechanisms with proprietary algorithms to group cells with similar capacity, internal resistance, and degradation patterns. The system employs a dynamic resistance balancing technique that continuously adjusts the current flow through individual cells based on their real-time performance characteristics. This allows for more uniform discharge/charge rates across cells with varying degradation levels. Additionally, LG Chem implements a thermal management solution that strategically distributes cooling resources to maintain consistent temperature profiles across the entire battery array, preventing thermal gradients that could exacerbate performance variations. Their system also incorporates predictive analytics to forecast future degradation patterns and proactively adjust balancing parameters accordingly.

Strengths: Comprehensive approach combining hardware sorting, dynamic resistance balancing, and predictive analytics provides excellent homogenization results. The system's ability to adapt to changing battery conditions over time ensures sustained performance. Weaknesses: Implementation requires sophisticated electronics and control systems, increasing overall system cost and complexity. The solution may be less effective for extremely degraded cells with significant capacity differences.

Critical Patents and Research in Battery Balancing

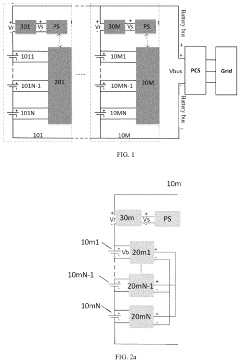

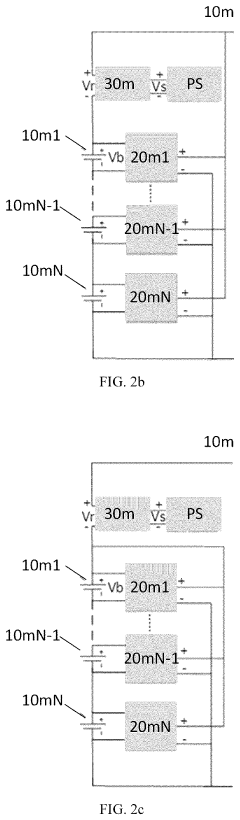

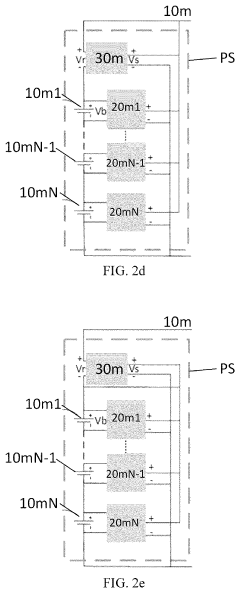

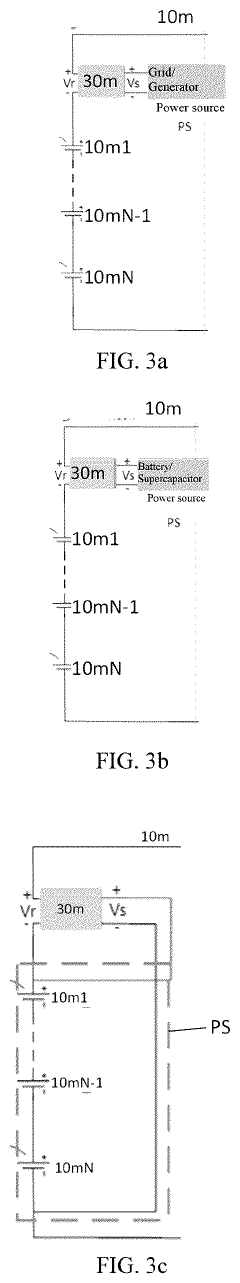

Secondary battery system

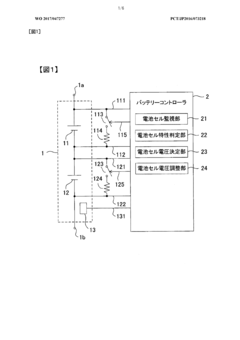

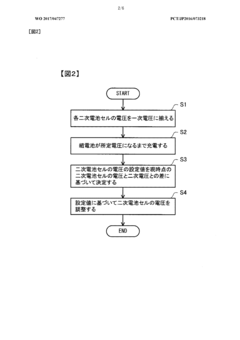

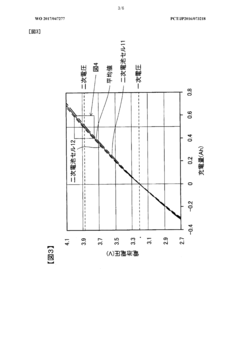

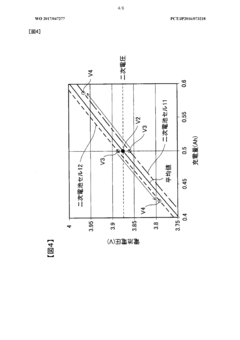

PatentWO2017047277A1

Innovation

- A secondary battery system that includes a battery cell monitoring section, a characteristic determination unit, and a voltage adjustment mechanism to monitor and adjust the voltage of each battery cell based on its deterioration state, using temperature data to equalize cell characteristics and maintain optimal voltage levels.

Battery system and equalization management method therefor

PatentPendingUS20240136825A1

Innovation

- A battery system utilizing low-voltage semiconductor devices for both pack and cluster equalizers, connected in series and parallel configurations, respectively, to achieve simultaneous inter-cluster and pack equalization, with a control module managing charge and discharge logic to regulate states of charge and voltage.

Environmental Impact and Sustainability Benefits

The implementation of second-life battery homogenization methods delivers substantial environmental benefits that extend far beyond the immediate technical advantages. By extending the useful life of batteries that would otherwise be discarded, these homogenization techniques significantly reduce the environmental burden associated with battery production and disposal.

Primary among these benefits is the reduction in raw material extraction requirements. The mining of lithium, cobalt, nickel, and other battery materials creates considerable environmental disruption, including habitat destruction, water pollution, and carbon emissions. Each kilogram of lithium-ion battery material repurposed through second-life applications potentially prevents 5-15 kg of CO2 emissions associated with new battery production.

Waste reduction represents another critical environmental advantage. Current global battery waste is projected to reach 11 million tonnes annually by 2030, with only 5% being recycled in many regions. Homogenization methods that enable effective second-life applications could divert up to 70% of these batteries from waste streams, dramatically reducing landfill usage and potential toxic leachate.

The carbon footprint reduction achieved through battery repurposing is substantial. Life cycle assessments indicate that homogenized second-life battery systems can achieve 50-70% lower carbon emissions compared to new battery production when accounting for manufacturing, transportation, and end-of-life processing. This translates to approximately 50-150 kg CO2e savings per kWh of repurposed battery capacity.

From a circular economy perspective, performance homogenization techniques enable more efficient resource utilization by creating standardized, reliable second-life battery products. This standardization facilitates easier integration into energy storage systems and promotes the development of specialized recycling processes for eventual end-of-life management.

Water conservation benefits are also significant, as battery manufacturing is water-intensive. Repurposing one tonne of lithium-ion batteries can save approximately 40-85 cubic meters of water that would otherwise be required for new battery production. Additionally, the reduced need for raw material extraction decreases water pollution risks in mining regions.

The sustainability advantages extend to economic dimensions as well. By creating viable markets for used batteries, homogenization methods help establish circular business models that generate value from what was previously considered waste, potentially creating new green jobs in battery testing, refurbishment, and system integration sectors.

Primary among these benefits is the reduction in raw material extraction requirements. The mining of lithium, cobalt, nickel, and other battery materials creates considerable environmental disruption, including habitat destruction, water pollution, and carbon emissions. Each kilogram of lithium-ion battery material repurposed through second-life applications potentially prevents 5-15 kg of CO2 emissions associated with new battery production.

Waste reduction represents another critical environmental advantage. Current global battery waste is projected to reach 11 million tonnes annually by 2030, with only 5% being recycled in many regions. Homogenization methods that enable effective second-life applications could divert up to 70% of these batteries from waste streams, dramatically reducing landfill usage and potential toxic leachate.

The carbon footprint reduction achieved through battery repurposing is substantial. Life cycle assessments indicate that homogenized second-life battery systems can achieve 50-70% lower carbon emissions compared to new battery production when accounting for manufacturing, transportation, and end-of-life processing. This translates to approximately 50-150 kg CO2e savings per kWh of repurposed battery capacity.

From a circular economy perspective, performance homogenization techniques enable more efficient resource utilization by creating standardized, reliable second-life battery products. This standardization facilitates easier integration into energy storage systems and promotes the development of specialized recycling processes for eventual end-of-life management.

Water conservation benefits are also significant, as battery manufacturing is water-intensive. Repurposing one tonne of lithium-ion batteries can save approximately 40-85 cubic meters of water that would otherwise be required for new battery production. Additionally, the reduced need for raw material extraction decreases water pollution risks in mining regions.

The sustainability advantages extend to economic dimensions as well. By creating viable markets for used batteries, homogenization methods help establish circular business models that generate value from what was previously considered waste, potentially creating new green jobs in battery testing, refurbishment, and system integration sectors.

Standardization and Safety Protocols

The standardization of second-life battery arrays represents a critical foundation for ensuring consistent performance and safety across repurposed energy storage systems. Currently, the industry faces significant challenges due to the lack of unified protocols for testing, grading, and deploying batteries that have completed their primary use cycle. Organizations including IEEE, IEC, and UL are actively developing frameworks that address these gaps, with recent progress in establishing testing methodologies for capacity measurement, internal resistance evaluation, and cycle life prediction specifically tailored for second-life applications.

Safety protocols for homogenizing performance must address the unique risks associated with repurposed batteries, including thermal runaway prevention, electrical isolation standards, and environmental protection measures. The Battery Passport initiative, gaining traction in Europe and North America, provides a comprehensive documentation system tracking battery history, performance metrics, and safety parameters throughout its lifecycle. This standardized information exchange facilitates more accurate performance matching and risk assessment when integrating diverse battery units into cohesive arrays.

Thermal management standardization has emerged as a particularly crucial aspect of homogenization protocols. Recent research demonstrates that uniform temperature distribution across battery modules can reduce performance variation by up to 30% in second-life applications. Standardized cooling system requirements, temperature monitoring protocols, and thermal runaway prevention measures are being incorporated into emerging guidelines from organizations like SAE International and the National Fire Protection Association.

Electrical safety standards specifically addressing second-life battery arrays have evolved to include specialized requirements for battery management systems (BMS). These standards mandate capabilities for cell balancing, state-of-health monitoring, and fault detection tailored to the unique characteristics of aged cells. The implementation of standardized communication protocols between BMS units enables more effective performance homogenization across diverse battery modules, with CAN-based systems emerging as the preferred industry standard.

Testing certification processes are increasingly incorporating accelerated aging protocols designed to predict long-term performance consistency in heterogeneous battery arrays. These standardized methodologies enable more accurate classification of second-life batteries and facilitate optimal grouping strategies based on remaining capacity, internal resistance, and degradation patterns. The development of internationally recognized certification marks for second-life batteries represents a significant step toward market acceptance and regulatory compliance.

Safety protocols for homogenizing performance must address the unique risks associated with repurposed batteries, including thermal runaway prevention, electrical isolation standards, and environmental protection measures. The Battery Passport initiative, gaining traction in Europe and North America, provides a comprehensive documentation system tracking battery history, performance metrics, and safety parameters throughout its lifecycle. This standardized information exchange facilitates more accurate performance matching and risk assessment when integrating diverse battery units into cohesive arrays.

Thermal management standardization has emerged as a particularly crucial aspect of homogenization protocols. Recent research demonstrates that uniform temperature distribution across battery modules can reduce performance variation by up to 30% in second-life applications. Standardized cooling system requirements, temperature monitoring protocols, and thermal runaway prevention measures are being incorporated into emerging guidelines from organizations like SAE International and the National Fire Protection Association.

Electrical safety standards specifically addressing second-life battery arrays have evolved to include specialized requirements for battery management systems (BMS). These standards mandate capabilities for cell balancing, state-of-health monitoring, and fault detection tailored to the unique characteristics of aged cells. The implementation of standardized communication protocols between BMS units enables more effective performance homogenization across diverse battery modules, with CAN-based systems emerging as the preferred industry standard.

Testing certification processes are increasingly incorporating accelerated aging protocols designed to predict long-term performance consistency in heterogeneous battery arrays. These standardized methodologies enable more accurate classification of second-life batteries and facilitate optimal grouping strategies based on remaining capacity, internal resistance, and degradation patterns. The development of internationally recognized certification marks for second-life batteries represents a significant step toward market acceptance and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!