Residual life estimation for warranty modeling of second-life batteries

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries becoming the dominant energy storage solution across various applications, particularly in electric vehicles (EVs). As the first-life applications of these batteries approach their end-of-life phase, typically when capacity degrades to 70-80% of original capacity, a substantial opportunity emerges for repurposing these batteries for second-life applications.

Second-life battery technology refers to the repurposing and redeployment of EV batteries that no longer meet the stringent requirements of automotive applications but retain sufficient capacity for less demanding applications. This technology domain has gained prominence due to the increasing adoption of EVs globally and the subsequent accumulation of retired batteries, creating both environmental challenges and economic opportunities.

The historical development of second-life battery technology can be traced back to early 2010s when pioneering research began exploring the feasibility of repurposing retired EV batteries. Initial efforts focused primarily on technical feasibility studies, with limited commercial applications. By mid-2010s, several automakers initiated pilot projects to demonstrate the viability of second-life applications, primarily in stationary energy storage systems.

Current technological trends indicate a growing sophistication in battery management systems (BMS) specifically designed for second-life applications, advanced diagnostic tools for battery health assessment, and standardized protocols for battery repurposing. The integration of artificial intelligence and machine learning algorithms for more accurate state-of-health estimation represents the cutting edge of this technological evolution.

The primary objective of residual life estimation for warranty modeling of second-life batteries is to develop reliable methodologies that can accurately predict the remaining useful life of repurposed batteries under various operating conditions. This involves creating robust mathematical models that account for the unique degradation patterns of previously used batteries, considering their first-life usage history and heterogeneous aging characteristics.

Additional objectives include establishing standardized testing protocols for second-life batteries, developing cost-effective screening methods to identify suitable candidates for repurposing, and creating warranty frameworks that balance risk mitigation for manufacturers with attractive value propositions for consumers. These objectives collectively aim to enhance the economic viability of the second-life battery ecosystem while addressing technical uncertainties associated with previously used energy storage systems.

The successful achievement of these objectives would significantly contribute to circular economy principles in the battery value chain, reduce the environmental impact of battery disposal, and potentially lower the total cost of ownership for EVs by creating additional value recovery opportunities.

Second-life battery technology refers to the repurposing and redeployment of EV batteries that no longer meet the stringent requirements of automotive applications but retain sufficient capacity for less demanding applications. This technology domain has gained prominence due to the increasing adoption of EVs globally and the subsequent accumulation of retired batteries, creating both environmental challenges and economic opportunities.

The historical development of second-life battery technology can be traced back to early 2010s when pioneering research began exploring the feasibility of repurposing retired EV batteries. Initial efforts focused primarily on technical feasibility studies, with limited commercial applications. By mid-2010s, several automakers initiated pilot projects to demonstrate the viability of second-life applications, primarily in stationary energy storage systems.

Current technological trends indicate a growing sophistication in battery management systems (BMS) specifically designed for second-life applications, advanced diagnostic tools for battery health assessment, and standardized protocols for battery repurposing. The integration of artificial intelligence and machine learning algorithms for more accurate state-of-health estimation represents the cutting edge of this technological evolution.

The primary objective of residual life estimation for warranty modeling of second-life batteries is to develop reliable methodologies that can accurately predict the remaining useful life of repurposed batteries under various operating conditions. This involves creating robust mathematical models that account for the unique degradation patterns of previously used batteries, considering their first-life usage history and heterogeneous aging characteristics.

Additional objectives include establishing standardized testing protocols for second-life batteries, developing cost-effective screening methods to identify suitable candidates for repurposing, and creating warranty frameworks that balance risk mitigation for manufacturers with attractive value propositions for consumers. These objectives collectively aim to enhance the economic viability of the second-life battery ecosystem while addressing technical uncertainties associated with previously used energy storage systems.

The successful achievement of these objectives would significantly contribute to circular economy principles in the battery value chain, reduce the environmental impact of battery disposal, and potentially lower the total cost of ownership for EVs by creating additional value recovery opportunities.

Market Analysis for Second-Life Battery Applications

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need for sustainable battery lifecycle management. As EV batteries typically retain 70-80% of their original capacity after their automotive service life, they present substantial value for repurposing in less demanding applications.

The global market for second-life batteries was valued at approximately $1.6 billion in 2022 and is projected to reach $9.1 billion by 2030, representing a compound annual growth rate (CAGR) of 24.2%. This remarkable growth trajectory is supported by several key market drivers, including increasing environmental regulations, rising raw material costs for new battery production, and growing demand for sustainable energy storage solutions.

Energy storage applications currently dominate the second-life battery market, accounting for roughly 60% of deployments. These applications include residential and commercial energy storage systems, grid stabilization, and renewable energy integration. The telecommunications sector represents another significant market segment at 15%, utilizing second-life batteries for backup power systems. Additional applications include industrial equipment (10%), mobility solutions (8%), and other miscellaneous uses (7%).

Geographically, Asia-Pacific leads the market with 45% share, driven by China's massive EV fleet and supportive government policies. Europe follows at 30%, with particularly strong growth in Germany, France, and the Netherlands due to aggressive renewable energy targets. North America accounts for 20% of the market, with the remaining 5% distributed across other regions.

A critical factor influencing market dynamics is the warranty modeling challenge for second-life batteries. Current warranty structures typically offer 2-5 years of coverage, significantly shorter than the 8-10 years common for new batteries. This discrepancy reflects the uncertainty in residual life estimation, which directly impacts pricing strategies, risk management, and customer confidence.

Market research indicates that improved residual life estimation technologies could expand the second-life battery market by an additional 30-40% by 2028, as enhanced reliability predictions would enable more competitive warranty offerings and open new application segments. Particularly, sectors with mission-critical operations that currently avoid second-life batteries due to reliability concerns could become viable markets with advanced estimation techniques.

Consumer surveys reveal that 78% of potential commercial customers cite warranty concerns as a primary barrier to second-life battery adoption, highlighting the strategic importance of residual life estimation in market development. As estimation technologies improve, the market is expected to see both expansion in volume and diversification in application scope.

The global market for second-life batteries was valued at approximately $1.6 billion in 2022 and is projected to reach $9.1 billion by 2030, representing a compound annual growth rate (CAGR) of 24.2%. This remarkable growth trajectory is supported by several key market drivers, including increasing environmental regulations, rising raw material costs for new battery production, and growing demand for sustainable energy storage solutions.

Energy storage applications currently dominate the second-life battery market, accounting for roughly 60% of deployments. These applications include residential and commercial energy storage systems, grid stabilization, and renewable energy integration. The telecommunications sector represents another significant market segment at 15%, utilizing second-life batteries for backup power systems. Additional applications include industrial equipment (10%), mobility solutions (8%), and other miscellaneous uses (7%).

Geographically, Asia-Pacific leads the market with 45% share, driven by China's massive EV fleet and supportive government policies. Europe follows at 30%, with particularly strong growth in Germany, France, and the Netherlands due to aggressive renewable energy targets. North America accounts for 20% of the market, with the remaining 5% distributed across other regions.

A critical factor influencing market dynamics is the warranty modeling challenge for second-life batteries. Current warranty structures typically offer 2-5 years of coverage, significantly shorter than the 8-10 years common for new batteries. This discrepancy reflects the uncertainty in residual life estimation, which directly impacts pricing strategies, risk management, and customer confidence.

Market research indicates that improved residual life estimation technologies could expand the second-life battery market by an additional 30-40% by 2028, as enhanced reliability predictions would enable more competitive warranty offerings and open new application segments. Particularly, sectors with mission-critical operations that currently avoid second-life batteries due to reliability concerns could become viable markets with advanced estimation techniques.

Consumer surveys reveal that 78% of potential commercial customers cite warranty concerns as a primary barrier to second-life battery adoption, highlighting the strategic importance of residual life estimation in market development. As estimation technologies improve, the market is expected to see both expansion in volume and diversification in application scope.

Technical Challenges in Battery Residual Life Estimation

Estimating the residual life of second-life batteries presents significant technical challenges due to the complex nature of battery degradation mechanisms and the unique history of each used battery. The primary difficulty lies in accurately quantifying the state of health (SOH) of batteries that have already undergone varying degrees of degradation during their first life applications, typically in electric vehicles.

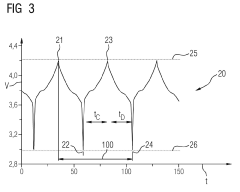

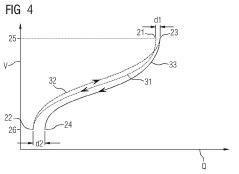

Battery degradation follows non-linear patterns influenced by multiple factors including charge-discharge cycles, depth of discharge, temperature exposure, and calendar aging. These factors create complex interdependencies that traditional linear models struggle to capture accurately. Furthermore, the lack of complete historical data for second-life batteries compounds this challenge, as information about previous usage conditions and stress factors is often incomplete or unavailable.

Current diagnostic methods face limitations in accurately assessing internal chemical and physical changes within battery cells. Non-invasive techniques such as electrochemical impedance spectroscopy (EIS) and differential voltage analysis (DVA) provide valuable insights but cannot fully characterize all degradation mechanisms. This creates uncertainty in establishing the true starting point for residual life estimation.

The heterogeneity of second-life battery populations presents another significant challenge. Batteries sourced from different vehicles, manufacturers, and usage environments exhibit varying degradation patterns and remaining capacities. This heterogeneity makes it difficult to develop standardized models that can be applied across diverse battery populations, necessitating more adaptive and individualized approaches.

Accelerated aging tests, commonly used to predict battery life, may not accurately represent real-world degradation in second-life applications. The correlation between laboratory testing conditions and actual operational environments remains imperfect, leading to potential discrepancies between predicted and actual residual life.

The transition from first to second life introduces additional uncertainties. Repurposing processes, including disassembly, testing, and reconfiguration, may impact battery performance in ways that are difficult to quantify. Moreover, second-life applications often have different operational requirements and stress profiles compared to first-life use, further complicating the transferability of existing degradation models.

Data-driven approaches using machine learning show promise but require extensive training datasets that are currently limited for second-life batteries. The lack of comprehensive field data spanning the entire lifecycle of repurposed batteries creates significant gaps in model validation and refinement capabilities.

Battery degradation follows non-linear patterns influenced by multiple factors including charge-discharge cycles, depth of discharge, temperature exposure, and calendar aging. These factors create complex interdependencies that traditional linear models struggle to capture accurately. Furthermore, the lack of complete historical data for second-life batteries compounds this challenge, as information about previous usage conditions and stress factors is often incomplete or unavailable.

Current diagnostic methods face limitations in accurately assessing internal chemical and physical changes within battery cells. Non-invasive techniques such as electrochemical impedance spectroscopy (EIS) and differential voltage analysis (DVA) provide valuable insights but cannot fully characterize all degradation mechanisms. This creates uncertainty in establishing the true starting point for residual life estimation.

The heterogeneity of second-life battery populations presents another significant challenge. Batteries sourced from different vehicles, manufacturers, and usage environments exhibit varying degradation patterns and remaining capacities. This heterogeneity makes it difficult to develop standardized models that can be applied across diverse battery populations, necessitating more adaptive and individualized approaches.

Accelerated aging tests, commonly used to predict battery life, may not accurately represent real-world degradation in second-life applications. The correlation between laboratory testing conditions and actual operational environments remains imperfect, leading to potential discrepancies between predicted and actual residual life.

The transition from first to second life introduces additional uncertainties. Repurposing processes, including disassembly, testing, and reconfiguration, may impact battery performance in ways that are difficult to quantify. Moreover, second-life applications often have different operational requirements and stress profiles compared to first-life use, further complicating the transferability of existing degradation models.

Data-driven approaches using machine learning show promise but require extensive training datasets that are currently limited for second-life batteries. The lack of comprehensive field data spanning the entire lifecycle of repurposed batteries creates significant gaps in model validation and refinement capabilities.

Current Warranty Modeling Approaches for Used Batteries

01 Battery residual life estimation methods

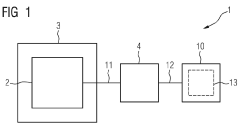

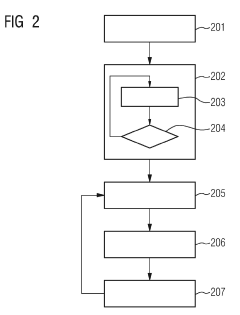

Various methods are employed to estimate the residual life of second-life batteries, including algorithmic approaches, machine learning models, and statistical analysis. These methods analyze battery performance data such as charge-discharge cycles, voltage curves, and internal resistance to predict remaining useful life. Advanced estimation techniques help determine whether batteries are suitable for second-life applications by providing accurate assessments of their remaining capacity and performance potential.- Battery residual life estimation methods: Various methods are employed to estimate the remaining useful life of batteries, including algorithmic approaches, machine learning models, and statistical analysis. These methods analyze parameters such as voltage, current, temperature, and charge-discharge cycles to predict how much longer a battery can function effectively before requiring replacement. Accurate estimation is crucial for determining whether batteries are suitable for second-life applications.

- Second-life battery repurposing technologies: Technologies for repurposing used batteries focus on evaluating, refurbishing, and reconfiguring batteries for secondary applications. This includes sorting and grading systems that categorize batteries based on their remaining capacity and performance characteristics. Specialized equipment and processes are developed to prepare batteries from electric vehicles and other primary applications for use in less demanding secondary applications such as stationary energy storage.

- Battery health monitoring systems: Monitoring systems continuously track battery health parameters to assess residual life in real-time. These systems incorporate sensors and diagnostic tools that measure key indicators such as internal resistance, capacity fade, and self-discharge rates. The collected data helps in making informed decisions about when to transition batteries from primary to secondary applications, ensuring optimal utilization throughout their extended lifecycle.

- Energy storage applications for second-life batteries: Second-life batteries with sufficient residual capacity can be integrated into various energy storage applications. These include grid support systems, renewable energy storage, backup power supplies, and residential energy storage units. The applications are designed to match the performance capabilities of aged batteries, taking advantage of their remaining useful life while accommodating their reduced capacity and efficiency compared to new batteries.

- Battery degradation prediction and management: Advanced techniques for predicting battery degradation patterns help in managing second-life applications more effectively. These include accelerated aging tests, electrochemical modeling, and comparative analysis of similar battery types. By understanding how batteries degrade over time under different conditions, systems can be designed to optimize the use of second-life batteries, extending their total service life and improving the economic and environmental benefits of battery reuse.

02 Battery management systems for second-life applications

Specialized battery management systems (BMS) are designed to monitor and control second-life batteries, optimizing their performance and extending their useful life. These systems continuously track battery parameters, manage thermal conditions, and implement protective measures against overcharging or deep discharging. The BMS can adapt to the degraded characteristics of used batteries and implement specific algorithms tailored for second-life applications, ensuring safe and efficient operation despite the batteries' history.Expand Specific Solutions03 Testing and classification protocols for repurposed batteries

Standardized testing and classification protocols are essential for evaluating second-life batteries. These protocols include capacity testing, impedance measurements, cycle life assessment, and safety validation. Based on test results, batteries are classified according to their performance capabilities and suitable applications. This systematic approach ensures that repurposed batteries meet safety standards and performance requirements for their intended second-life use cases.Expand Specific Solutions04 Energy storage applications for second-life batteries

Second-life batteries find valuable applications in stationary energy storage systems, including grid support, renewable energy integration, and backup power solutions. These applications typically have less demanding performance requirements than electric vehicles, making them suitable for batteries with reduced capacity. By repurposing batteries for energy storage, their useful life can be extended by several years, improving the overall sustainability and economic value of the original battery investment.Expand Specific Solutions05 Battery degradation analysis and prediction

Understanding the degradation mechanisms of batteries is crucial for accurately predicting their residual life in second-life applications. Research focuses on analyzing factors such as calendar aging, cycling stress, temperature effects, and usage patterns that contribute to capacity fade and power loss. Advanced diagnostic techniques can identify specific degradation modes and their progression rates, enabling more precise predictions of how long repurposed batteries will continue to function effectively in their second-life roles.Expand Specific Solutions

Key Industry Players in Second-Life Battery Market

The second-life battery warranty modeling market is currently in its growth phase, with increasing adoption driven by sustainability initiatives and circular economy principles. The market size is expanding rapidly as electric vehicle batteries reach end-of-life status and require repurposing solutions. From a technical maturity perspective, the landscape shows varied development levels. Industry leaders like Toyota, BYD, and Panasonic have established advanced predictive modeling capabilities for residual life estimation, while companies such as LG Energy Solution, Samsung Electronics, and Hitachi are investing heavily in battery management systems with sophisticated diagnostic algorithms. Academic institutions including Harbin Institute of Technology and Shandong University are contributing fundamental research, creating a competitive ecosystem where collaboration between automotive manufacturers, battery producers, and research institutions is driving innovation in warranty modeling methodologies.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive Battery Health Check system that utilizes machine learning algorithms to estimate the residual life of second-life EV batteries. Their approach combines real-time battery monitoring with historical performance data to create predictive models that account for various degradation factors. Toyota's system incorporates multiple parameters including charge-discharge cycles, temperature exposure history, and voltage characteristics to generate accurate remaining useful life (RUL) predictions. The company has implemented this technology in their battery reuse programs, where retired vehicle batteries are repurposed for stationary energy storage applications. Their warranty modeling framework includes confidence intervals for failure probability, allowing for more precise warranty terms based on the specific condition of each second-life battery rather than applying generic warranty periods.

Strengths: Extensive real-world data from millions of vehicles enables highly accurate prediction models; integrated approach combining hardware monitoring and software analytics. Weaknesses: System complexity requires significant computational resources; model accuracy depends heavily on the quality of historical usage data which may not always be available for older batteries.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the "Battery Second Life" (BSL) program with advanced residual life estimation technology specifically designed for their Blade Battery architecture. Their approach utilizes a multi-level health assessment framework that evaluates both cell-level and pack-level degradation patterns. BYD's system employs electrochemical impedance spectroscopy (EIS) combined with machine learning algorithms to detect subtle changes in battery internal resistance and capacity fade. The company has developed proprietary algorithms that can distinguish between reversible and irreversible capacity loss, enabling more accurate end-of-life predictions. Their warranty modeling incorporates stress factors such as depth of discharge patterns, temperature extremes, and charging rates to create customized warranty terms for second-life applications. BYD's system also features adaptive modeling that continuously refines predictions as new operational data becomes available from deployed second-life systems.

Strengths: Proprietary battery chemistry knowledge allows for highly specific degradation modeling; vertical integration from cell manufacturing to second-life applications provides complete data visibility. Weaknesses: Models are optimized primarily for BYD's specific battery chemistry and may require significant adaptation for other battery types; system requires specialized testing equipment for initial assessment.

Core Estimation Methodologies and Algorithms

Method, apparatus and computer program product for calculating residual value of storage batteries

PatentActiveJP2023016708A

Innovation

- A method involving precise temperature control and multiple load cycles using high-precision coulometry to measure and calculate discharge capacity, combined with data from battery management systems, to assess the battery's remaining useful life and degradation rate, ensuring accurate classification for energy storage suitability.

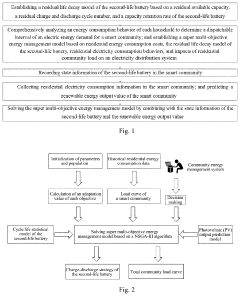

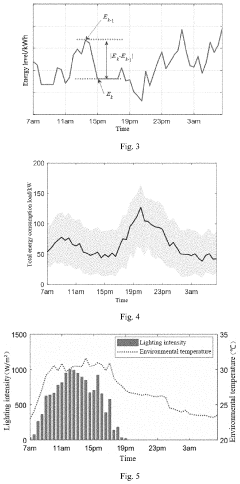

Hierarchical energy management for community microgrids with integration of second-life battery energy storage systems and photovoltaic solar energy

PatentPendingUS20230070151A1

Innovation

- A second-life battery-based super multi-objective energy management method is introduced, which establishes a residual life decay model and a comprehensive energy management model using non-dominated sorting genetic algorithm-III (NSGA-III) to determine charge and discharge quantities, minimizing energy consumption costs, life loss, and peak-to-average ratios, while considering residential energy habits and battery capacity retention.

Regulatory Framework for Second-Life Battery Deployment

The regulatory landscape for second-life battery deployment presents a complex framework that significantly impacts warranty modeling and residual life estimation practices. Currently, regulations governing second-life batteries remain fragmented across different jurisdictions, creating challenges for standardized warranty approaches. In the European Union, the Battery Directive (2006/66/EC) and its proposed revision under the European Green Deal establish end-of-life management requirements but lack specific provisions for second-life applications. This regulatory gap creates uncertainty regarding liability transfer when batteries transition from automotive to stationary storage applications.

In the United States, regulations vary by state, with California leading through its Advanced Clean Cars Program and battery recycling requirements. However, federal guidelines specifically addressing second-life battery warranties remain underdeveloped. The Environmental Protection Agency (EPA) and Department of Energy (DOE) have issued guidance documents rather than binding regulations, leaving warranty modeling in a state of regulatory ambiguity.

Asian markets demonstrate varying approaches, with China implementing strict regulations through GB/T 34014-2017 standards that establish technical requirements for repurposed EV batteries. Japan's regulatory framework focuses on safety certification through their JIS standards, while South Korea has developed a certification system specifically for second-life batteries that includes warranty requirements based on residual capacity assessments.

International standards organizations are actively working to address these regulatory gaps. The International Electrotechnical Commission (IEC) has developed IEC 63330, which provides guidelines for testing and evaluating second-life batteries. Similarly, ISO/TC 197 is developing standards for determining the state of health and remaining useful life of lithium-ion batteries, which will directly impact warranty modeling methodologies.

The regulatory challenges extend to liability considerations, as current frameworks often fail to clearly delineate responsibility between original manufacturers and second-life battery refurbishers. This creates significant warranty modeling complexities, as estimating residual life must account for potential regulatory changes that could alter testing requirements, performance standards, or liability assignments.

For effective warranty modeling, organizations must incorporate regulatory compliance costs into their financial projections. These include testing expenses to meet certification requirements, potential extended producer responsibility obligations, and insurance costs associated with liability uncertainties. Additionally, warranty models must be adaptable to evolving regulations, particularly as governments worldwide increasingly focus on circular economy principles and sustainable battery management.

In the United States, regulations vary by state, with California leading through its Advanced Clean Cars Program and battery recycling requirements. However, federal guidelines specifically addressing second-life battery warranties remain underdeveloped. The Environmental Protection Agency (EPA) and Department of Energy (DOE) have issued guidance documents rather than binding regulations, leaving warranty modeling in a state of regulatory ambiguity.

Asian markets demonstrate varying approaches, with China implementing strict regulations through GB/T 34014-2017 standards that establish technical requirements for repurposed EV batteries. Japan's regulatory framework focuses on safety certification through their JIS standards, while South Korea has developed a certification system specifically for second-life batteries that includes warranty requirements based on residual capacity assessments.

International standards organizations are actively working to address these regulatory gaps. The International Electrotechnical Commission (IEC) has developed IEC 63330, which provides guidelines for testing and evaluating second-life batteries. Similarly, ISO/TC 197 is developing standards for determining the state of health and remaining useful life of lithium-ion batteries, which will directly impact warranty modeling methodologies.

The regulatory challenges extend to liability considerations, as current frameworks often fail to clearly delineate responsibility between original manufacturers and second-life battery refurbishers. This creates significant warranty modeling complexities, as estimating residual life must account for potential regulatory changes that could alter testing requirements, performance standards, or liability assignments.

For effective warranty modeling, organizations must incorporate regulatory compliance costs into their financial projections. These include testing expenses to meet certification requirements, potential extended producer responsibility obligations, and insurance costs associated with liability uncertainties. Additionally, warranty models must be adaptable to evolving regulations, particularly as governments worldwide increasingly focus on circular economy principles and sustainable battery management.

Economic Viability Assessment of Battery Repurposing

The economic viability of battery repurposing represents a critical factor in the development of second-life battery markets. When evaluating the residual life estimation for warranty modeling, financial considerations become paramount for stakeholders across the value chain. Current market analyses indicate that repurposed electric vehicle (EV) batteries can be offered at 30-70% of the cost of new batteries, creating significant economic incentives for repurposing rather than recycling.

Cost structures for battery repurposing operations include collection, transportation, testing, disassembly, reconfiguration, and certification processes. These operational expenses must be balanced against the projected revenue from second-life applications to determine profitability thresholds. Research indicates that transportation costs alone can account for 10-15% of total repurposing expenses, highlighting the importance of regional processing centers to minimize these costs.

Warranty modeling for second-life batteries introduces unique economic challenges compared to new battery systems. The uncertainty in residual life estimation directly impacts warranty reserve calculations and pricing strategies. Companies must develop sophisticated financial models that account for this uncertainty while remaining competitive in the marketplace. Data suggests that accurate residual life estimation can reduce warranty reserve requirements by 15-25%, significantly improving profit margins for repurposers.

The economic value proposition varies considerably across different second-life applications. Stationary energy storage applications typically offer the highest economic returns due to less stringent performance requirements and longer acceptable service lives. Market research indicates that grid stabilization and renewable energy integration applications can generate 30-40% higher returns compared to backup power applications, influencing warranty structure decisions.

Regulatory frameworks and incentive programs significantly impact the economic equation. In regions with favorable policies for battery reuse, such as the European Union's Battery Directive revisions, the economic viability improves through reduced compliance costs and potential subsidies. These regulatory advantages can improve profit margins by 5-15% depending on the jurisdiction, directly affecting warranty pricing strategies.

The timing of market entry represents another critical economic consideration. Early market entrants face higher technology risks but potentially greater profit margins, while later entrants benefit from established testing protocols and more accurate residual life estimation methodologies. This timing consideration affects warranty modeling approaches, with early entrants typically requiring larger warranty reserves to account for greater uncertainty.

Cost structures for battery repurposing operations include collection, transportation, testing, disassembly, reconfiguration, and certification processes. These operational expenses must be balanced against the projected revenue from second-life applications to determine profitability thresholds. Research indicates that transportation costs alone can account for 10-15% of total repurposing expenses, highlighting the importance of regional processing centers to minimize these costs.

Warranty modeling for second-life batteries introduces unique economic challenges compared to new battery systems. The uncertainty in residual life estimation directly impacts warranty reserve calculations and pricing strategies. Companies must develop sophisticated financial models that account for this uncertainty while remaining competitive in the marketplace. Data suggests that accurate residual life estimation can reduce warranty reserve requirements by 15-25%, significantly improving profit margins for repurposers.

The economic value proposition varies considerably across different second-life applications. Stationary energy storage applications typically offer the highest economic returns due to less stringent performance requirements and longer acceptable service lives. Market research indicates that grid stabilization and renewable energy integration applications can generate 30-40% higher returns compared to backup power applications, influencing warranty structure decisions.

Regulatory frameworks and incentive programs significantly impact the economic equation. In regions with favorable policies for battery reuse, such as the European Union's Battery Directive revisions, the economic viability improves through reduced compliance costs and potential subsidies. These regulatory advantages can improve profit margins by 5-15% depending on the jurisdiction, directly affecting warranty pricing strategies.

The timing of market entry represents another critical economic consideration. Early market entrants face higher technology risks but potentially greater profit margins, while later entrants benefit from established testing protocols and more accurate residual life estimation methodologies. This timing consideration affects warranty modeling approaches, with early entrants typically requiring larger warranty reserves to account for greater uncertainty.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!