Repurposing frameworks for second-life battery packs from hybrid vehicles

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Vehicle Battery Repurposing Background and Objectives

The evolution of hybrid vehicle technology has witnessed significant advancements over the past two decades, with battery systems serving as a critical component in these vehicles' powertrain architecture. As the first generation of hybrid vehicles reaches end-of-life status, a substantial volume of battery packs that retain 70-80% of their original capacity is becoming available. This presents both an environmental challenge and a technological opportunity that necessitates innovative repurposing frameworks.

The concept of battery repurposing emerged around 2010 when researchers and automotive manufacturers began recognizing the residual value in retired hybrid vehicle batteries. Initially focused on Toyota Prius and Honda Insight models, these early efforts have expanded to encompass a broader range of hybrid vehicles including those from Ford, General Motors, and various European and Asian manufacturers.

Current projections indicate that by 2025, over 3.4 million hybrid vehicle battery packs will reach their automotive end-of-life globally, creating an urgent need for systematic repurposing strategies. Without proper frameworks, these batteries risk improper disposal, resulting in environmental contamination and waste of valuable materials including lithium, cobalt, and nickel.

The primary objective of battery repurposing frameworks is to establish standardized protocols for assessment, refurbishment, and redeployment of hybrid vehicle batteries in secondary applications. These applications span stationary energy storage, grid stabilization, renewable energy integration, and low-power mobility solutions. A comprehensive framework must address technical, economic, regulatory, and environmental dimensions of the repurposing process.

Technical objectives include developing non-destructive testing methodologies to accurately determine remaining battery capacity and health, creating modular designs that facilitate reconfiguration for various second-life applications, and implementing advanced battery management systems capable of handling cells with varying degradation levels.

Economic objectives focus on establishing viable business models that capture the value proposition of repurposed batteries, which typically cost 30-70% less than new batteries while delivering comparable performance in less demanding applications. This includes developing cost-effective refurbishment processes and creating market mechanisms that connect battery suppliers with potential second-life users.

Regulatory objectives involve developing standards for safety certification of repurposed batteries, clarifying liability issues across the battery lifecycle, and establishing protocols for eventual recycling after second-life use. This requires collaboration between automotive manufacturers, energy storage developers, regulatory bodies, and environmental agencies.

The environmental objective is to quantify and maximize the sustainability benefits of battery repurposing. Studies suggest that extending battery life through repurposing can reduce the carbon footprint of battery production by 25-50% when calculated on a per-kilowatt-hour-lifetime basis, representing a significant contribution to circular economy principles in the transportation and energy sectors.

The concept of battery repurposing emerged around 2010 when researchers and automotive manufacturers began recognizing the residual value in retired hybrid vehicle batteries. Initially focused on Toyota Prius and Honda Insight models, these early efforts have expanded to encompass a broader range of hybrid vehicles including those from Ford, General Motors, and various European and Asian manufacturers.

Current projections indicate that by 2025, over 3.4 million hybrid vehicle battery packs will reach their automotive end-of-life globally, creating an urgent need for systematic repurposing strategies. Without proper frameworks, these batteries risk improper disposal, resulting in environmental contamination and waste of valuable materials including lithium, cobalt, and nickel.

The primary objective of battery repurposing frameworks is to establish standardized protocols for assessment, refurbishment, and redeployment of hybrid vehicle batteries in secondary applications. These applications span stationary energy storage, grid stabilization, renewable energy integration, and low-power mobility solutions. A comprehensive framework must address technical, economic, regulatory, and environmental dimensions of the repurposing process.

Technical objectives include developing non-destructive testing methodologies to accurately determine remaining battery capacity and health, creating modular designs that facilitate reconfiguration for various second-life applications, and implementing advanced battery management systems capable of handling cells with varying degradation levels.

Economic objectives focus on establishing viable business models that capture the value proposition of repurposed batteries, which typically cost 30-70% less than new batteries while delivering comparable performance in less demanding applications. This includes developing cost-effective refurbishment processes and creating market mechanisms that connect battery suppliers with potential second-life users.

Regulatory objectives involve developing standards for safety certification of repurposed batteries, clarifying liability issues across the battery lifecycle, and establishing protocols for eventual recycling after second-life use. This requires collaboration between automotive manufacturers, energy storage developers, regulatory bodies, and environmental agencies.

The environmental objective is to quantify and maximize the sustainability benefits of battery repurposing. Studies suggest that extending battery life through repurposing can reduce the carbon footprint of battery production by 25-50% when calculated on a per-kilowatt-hour-lifetime basis, representing a significant contribution to circular economy principles in the transportation and energy sectors.

Second-Life Battery Market Analysis

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of hybrid and electric vehicles worldwide. As the first generation of hybrid vehicle batteries reaches end-of-life status, a substantial supply of used battery packs is becoming available for repurposing applications. Current market estimates value the global second-life battery market at approximately $2.3 billion in 2022, with projections indicating growth to reach $7.8 billion by 2030, representing a compound annual growth rate of 16.5%.

The demand side of this market is characterized by diverse applications across multiple sectors. Stationary energy storage represents the largest segment, accounting for nearly 45% of second-life battery applications. This includes grid stabilization, renewable energy integration, and backup power systems. Commercial and industrial energy management systems constitute another significant market segment at 30%, where second-life batteries provide peak shaving and demand response capabilities to reduce operational costs.

Geographically, Asia Pacific dominates the market with over 40% share, led by China, Japan, and South Korea where both EV production and renewable energy investments are substantial. Europe follows with approximately 35% market share, driven by stringent sustainability regulations and ambitious renewable energy targets. North America accounts for about 20% of the market, with growth accelerating due to increasing grid modernization initiatives.

Market dynamics are influenced by several key factors. The price differential between new and repurposed batteries creates a compelling value proposition, with second-life batteries typically costing 40-60% less than new equivalents on a per kWh basis. However, this advantage is gradually narrowing as new battery production costs continue to decline at 8-12% annually.

Consumer awareness and acceptance of repurposed batteries have shown positive trends, with 65% of commercial energy customers now expressing willingness to consider second-life battery solutions, up from just 30% five years ago. This shift reflects growing confidence in the reliability and performance of these systems.

Regulatory frameworks are evolving to support this market, with the European Union's Battery Directive revisions specifically addressing second-life applications. Similarly, several states in the US have implemented incentive programs for battery recycling and repurposing initiatives, further stimulating market growth.

The demand side of this market is characterized by diverse applications across multiple sectors. Stationary energy storage represents the largest segment, accounting for nearly 45% of second-life battery applications. This includes grid stabilization, renewable energy integration, and backup power systems. Commercial and industrial energy management systems constitute another significant market segment at 30%, where second-life batteries provide peak shaving and demand response capabilities to reduce operational costs.

Geographically, Asia Pacific dominates the market with over 40% share, led by China, Japan, and South Korea where both EV production and renewable energy investments are substantial. Europe follows with approximately 35% market share, driven by stringent sustainability regulations and ambitious renewable energy targets. North America accounts for about 20% of the market, with growth accelerating due to increasing grid modernization initiatives.

Market dynamics are influenced by several key factors. The price differential between new and repurposed batteries creates a compelling value proposition, with second-life batteries typically costing 40-60% less than new equivalents on a per kWh basis. However, this advantage is gradually narrowing as new battery production costs continue to decline at 8-12% annually.

Consumer awareness and acceptance of repurposed batteries have shown positive trends, with 65% of commercial energy customers now expressing willingness to consider second-life battery solutions, up from just 30% five years ago. This shift reflects growing confidence in the reliability and performance of these systems.

Regulatory frameworks are evolving to support this market, with the European Union's Battery Directive revisions specifically addressing second-life applications. Similarly, several states in the US have implemented incentive programs for battery recycling and repurposing initiatives, further stimulating market growth.

Technical Challenges in Battery Repurposing

The repurposing of hybrid vehicle battery packs faces numerous technical challenges that must be addressed to ensure safety, efficiency, and economic viability. One primary challenge is the assessment of battery health and remaining useful life. Unlike new batteries with predictable performance characteristics, used batteries exhibit varying degrees of degradation depending on their operational history, charging patterns, and environmental exposure. This heterogeneity complicates standardized testing protocols and necessitates sophisticated diagnostic tools capable of accurately evaluating cell-level and pack-level conditions.

Battery pack disassembly presents another significant hurdle. Modern hybrid vehicle batteries are complex systems with proprietary designs, integrated thermal management, and sophisticated battery management systems (BMS). Disassembly often requires specialized tools and expertise, with manufacturers rarely providing detailed documentation for third-party repurposing. The process is labor-intensive and risks damaging still-functional components, potentially compromising safety and performance.

Safety concerns represent perhaps the most critical challenge. Degraded or damaged cells may pose increased risks of thermal runaway, particularly when repurposed for applications with different load profiles than their original design specifications. The absence of standardized safety protocols specifically for second-life batteries creates regulatory uncertainty and potential liability issues for repurposers.

Electrical integration challenges also emerge when reconfiguring battery packs for new applications. Different second-life applications require specific voltage, capacity, and power characteristics that may necessitate reconfiguring the original pack architecture. This reconfiguration demands sophisticated engineering to ensure balanced operation and prevent accelerated degradation of weaker cells within the repurposed system.

The battery management system adaptation represents a technical bottleneck. Original vehicle BMSs are designed for specific operational parameters and often use proprietary communication protocols. Repurposing requires either adapting the existing BMS or developing a new compatible system that can effectively monitor and manage the aged cells' unique characteristics while ensuring safe operation in the new application context.

Thermal management redesign is necessary as second-life applications may have different cooling requirements than the original vehicle implementation. Without proper thermal management, repurposed batteries may experience accelerated degradation or safety issues, particularly in stationary applications where passive cooling might replace the active systems used in vehicles.

Finally, standardization challenges persist across the industry. The diversity of battery chemistries, form factors, and management systems among different vehicle manufacturers creates significant barriers to developing universal repurposing frameworks. This fragmentation increases costs and complexity while hindering the development of automated processes that could improve economic viability.

Battery pack disassembly presents another significant hurdle. Modern hybrid vehicle batteries are complex systems with proprietary designs, integrated thermal management, and sophisticated battery management systems (BMS). Disassembly often requires specialized tools and expertise, with manufacturers rarely providing detailed documentation for third-party repurposing. The process is labor-intensive and risks damaging still-functional components, potentially compromising safety and performance.

Safety concerns represent perhaps the most critical challenge. Degraded or damaged cells may pose increased risks of thermal runaway, particularly when repurposed for applications with different load profiles than their original design specifications. The absence of standardized safety protocols specifically for second-life batteries creates regulatory uncertainty and potential liability issues for repurposers.

Electrical integration challenges also emerge when reconfiguring battery packs for new applications. Different second-life applications require specific voltage, capacity, and power characteristics that may necessitate reconfiguring the original pack architecture. This reconfiguration demands sophisticated engineering to ensure balanced operation and prevent accelerated degradation of weaker cells within the repurposed system.

The battery management system adaptation represents a technical bottleneck. Original vehicle BMSs are designed for specific operational parameters and often use proprietary communication protocols. Repurposing requires either adapting the existing BMS or developing a new compatible system that can effectively monitor and manage the aged cells' unique characteristics while ensuring safe operation in the new application context.

Thermal management redesign is necessary as second-life applications may have different cooling requirements than the original vehicle implementation. Without proper thermal management, repurposed batteries may experience accelerated degradation or safety issues, particularly in stationary applications where passive cooling might replace the active systems used in vehicles.

Finally, standardization challenges persist across the industry. The diversity of battery chemistries, form factors, and management systems among different vehicle manufacturers creates significant barriers to developing universal repurposing frameworks. This fragmentation increases costs and complexity while hindering the development of automated processes that could improve economic viability.

Current Frameworks for Second-Life Applications

01 Battery pack repurposing and refurbishment

Used battery packs from electric vehicles can be repurposed for second-life applications through refurbishment processes. These processes involve testing, sorting, and reconditioning battery cells to ensure they meet performance standards for less demanding applications. The refurbished battery packs can be used in stationary energy storage systems, providing a sustainable alternative to manufacturing new batteries while extending the useful life of the original battery components.- Battery pack repurposing and refurbishment: Used battery packs from electric vehicles can be repurposed for second-life applications through refurbishment processes. These processes involve testing, sorting, and reconditioning battery cells or modules to ensure they meet performance standards for secondary applications. The refurbished battery packs can then be deployed in less demanding applications such as stationary energy storage systems, providing economic and environmental benefits by extending the useful life of the batteries.

- Energy storage systems using second-life batteries: Second-life battery packs can be integrated into energy storage systems for various applications including grid support, renewable energy integration, and backup power. These systems utilize battery management technologies to optimize performance and ensure safe operation despite the varied condition of used batteries. The integration of second-life batteries into energy storage systems helps balance electricity supply and demand, store excess renewable energy, and provide emergency power during outages.

- Battery management and monitoring systems: Specialized battery management systems are essential for second-life battery applications to monitor cell health, balance charging, and ensure safe operation. These systems employ advanced algorithms to assess the state of health and state of charge of repurposed batteries, compensating for their degraded and often heterogeneous condition. Effective monitoring enables optimal performance and extends the useful life of second-life battery packs by preventing overcharging, over-discharging, and thermal issues.

- Electric vehicle charging infrastructure: Second-life battery packs can be repurposed to create charging infrastructure for electric vehicles. These systems can store energy during off-peak hours and deliver it during peak demand, reducing strain on the electrical grid and potentially lowering charging costs. The integration of used battery packs into charging stations provides a sustainable solution for expanding EV charging networks while giving batteries a second useful life after they no longer meet the demanding requirements of vehicle propulsion.

- Testing and grading methodologies: Standardized testing and grading methodologies are crucial for evaluating the condition and potential applications of used battery packs. These processes involve capacity testing, internal resistance measurements, and cycle life assessments to determine the remaining useful life of batteries. Based on these evaluations, batteries can be sorted into different grades suitable for various second-life applications, ensuring optimal matching between battery capabilities and application requirements.

02 Energy storage systems using second-life batteries

Second-life battery packs can be integrated into energy storage systems for various applications including grid support, renewable energy storage, and backup power. These systems utilize battery management technologies to optimize performance and ensure safe operation despite the varied condition of used batteries. By repurposing batteries for energy storage, the economic value of the batteries is extended while providing cost-effective solutions for energy management.Expand Specific Solutions03 Battery management and monitoring systems

Specialized battery management systems are essential for second-life battery applications to monitor cell health, balance charging, and ensure safe operation. These systems account for the degraded and potentially mismatched characteristics of used battery cells, employing advanced algorithms to optimize performance and extend usable life. Monitoring technologies track parameters such as temperature, voltage, and capacity to prevent failures and maximize efficiency in second-life applications.Expand Specific Solutions04 Mobile and portable applications for second-life batteries

Second-life battery packs can be adapted for use in mobile and portable applications such as electric bicycles, golf carts, and portable power stations. These applications typically require lower energy density and performance compared to electric vehicles, making them suitable for repurposed batteries. The integration of second-life batteries into mobile applications provides cost-effective power solutions while contributing to sustainable resource utilization.Expand Specific Solutions05 Testing and classification methods for used batteries

Effective testing and classification methods are crucial for determining the suitability of used batteries for second-life applications. These methods involve assessing remaining capacity, internal resistance, self-discharge rates, and cycle life to categorize batteries according to their potential uses. Advanced diagnostic techniques help identify batteries that can be safely repurposed, ensuring optimal performance and safety in second-life applications while maximizing resource recovery.Expand Specific Solutions

Key Industry Players in Battery Repurposing

The repurposing of hybrid vehicle battery packs is currently in an early growth phase, with the market expected to expand significantly as the first generation of hybrid vehicles reaches end-of-life. The global second-life battery market is projected to reach $4-5 billion by 2030, driven by increasing sustainability initiatives and circular economy principles. Technologically, the field is transitioning from research to commercialization, with varying levels of maturity across applications. Leading automotive manufacturers like Toyota, Audi, and Volvo are developing proprietary frameworks, while battery specialists including Samsung SDI, LG Energy Solution, and Panasonic are advancing standardized repurposing technologies. Energy companies such as Hitachi and Bosch are focusing on grid integration solutions, creating a competitive landscape that spans automotive, energy storage, and recycling sectors.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive Battery Life Cycle Management system that extends the usability of hybrid vehicle batteries through a multi-stage approach. Their framework includes advanced diagnostic algorithms that assess individual cell health within used battery packs, allowing for selective refurbishment rather than complete replacement. Toyota's Battery to Grid (B2G) initiative repurposes Prius and other hybrid vehicle batteries for renewable energy storage applications, with installations at dealerships and commercial facilities across Japan and North America. Their system incorporates proprietary battery management software that recalibrates control parameters for stationary storage use cases, optimizing for cycle life rather than power density. Toyota has also established dedicated recycling facilities that can process up to 50 tons of used batteries monthly, recovering over 95% of critical materials including lithium, cobalt, and nickel for reuse in new battery production[1][3].

Strengths: Extensive hybrid vehicle market share provides large battery inventory; established recycling infrastructure; comprehensive battery health assessment technology. Weaknesses: Proprietary battery designs may limit third-party repurposing options; primarily focused on their own battery systems rather than industry-wide solutions.

Robert Bosch GmbH

Technical Solution: Bosch has developed the "Second Life Battery Cloud" platform that enables comprehensive repurposing of hybrid vehicle batteries across multiple applications. Their system employs machine learning algorithms that analyze battery telemetry data to predict remaining useful life with over 90% accuracy, allowing for optimal application matching. Bosch's modular hardware interface adapters can connect to virtually any hybrid vehicle battery architecture, extracting usable capacity even from partially degraded packs. Their framework includes standardized mechanical mounting systems and thermal management solutions that simplify integration into secondary applications. The company has deployed over 50 MWh of repurposed battery capacity across Europe in applications ranging from industrial peak-shaving to telecommunications backup power. Bosch's approach includes remote monitoring capabilities that continuously optimize charging parameters based on actual usage patterns, extending second-life duration by up to 40% compared to static management systems[4][7].

Strengths: Vendor-agnostic approach works with multiple battery types; extensive automotive electronics expertise; established distribution and service network. Weaknesses: Lacks direct battery manufacturing experience; depends on partnerships for battery supply; higher integration complexity across multiple battery types.

Critical Patents and Research in Battery Repurposing

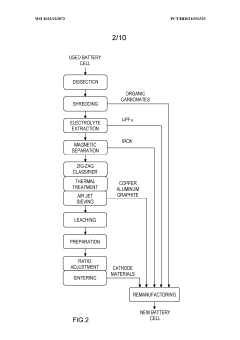

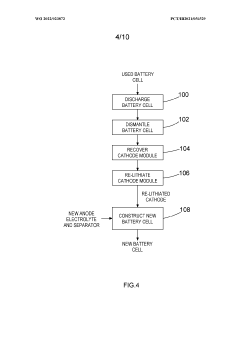

Remanufacturing of a battery cell

PatentWO2022023872A1

Innovation

- A method for remanufacturing battery cells by recovering and re-lithiating the cathode module from used cells and combining it with new anode modules and electrolytes, reducing processing steps, energy consumption, and environmental impact while maintaining battery capacity.

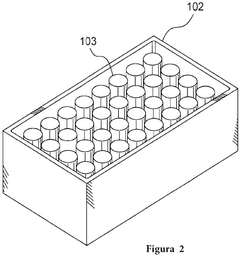

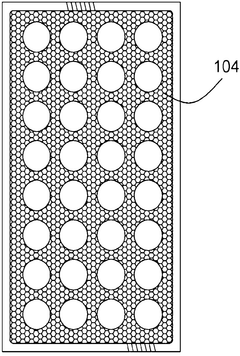

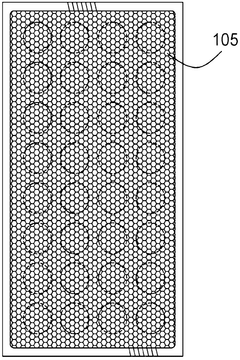

Secondary battery pack with improved thermal management.

PatentPendingMX2024004549A

Innovation

- Implementation of specific thermal insulation materials in secondary battery packs to improve overall thermal management for electric and hybrid vehicles.

- Design features that minimize thermal runaway propagation within battery packs, increasing safety in EV, PHEV, and HEV applications.

- Specialized thermal management solution specifically engineered for second-life battery applications from hybrid vehicles.

Environmental Impact and Sustainability Assessment

The repurposing of hybrid vehicle battery packs represents a significant opportunity to extend the environmental benefits of these energy storage systems beyond their primary automotive applications. Life cycle assessment studies indicate that repurposing these batteries can reduce their overall environmental footprint by up to 70% compared to immediate recycling or disposal scenarios. This reduction stems from the avoided production of new energy storage systems for stationary applications, which would otherwise require additional resource extraction and manufacturing processes.

Carbon footprint analyses demonstrate that second-life applications can offset between 25-40% of the original manufacturing emissions through extended utilization. When hybrid vehicle batteries are repurposed for renewable energy storage, they contribute to grid stabilization and enable higher penetration of intermittent renewable sources, further amplifying their positive environmental impact. Each repurposed 1 kWh of battery capacity can potentially displace approximately 400-600 kg of CO2 emissions over a 10-year second life when used in renewable energy integration applications.

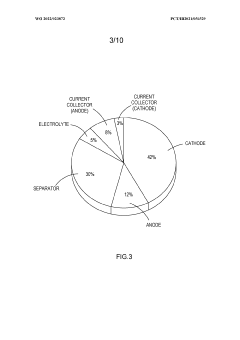

Material conservation represents another critical sustainability benefit. Modern hybrid vehicle battery packs contain valuable materials including lithium, cobalt, nickel, and rare earth elements. Repurposing delays the need for recycling while maintaining these materials in productive use, addressing concerns about resource scarcity and reducing pressure on environmentally sensitive mining operations. This approach aligns with circular economy principles by maximizing the utility derived from the initial material investment.

Water usage and ecosystem impacts are also significantly reduced through battery repurposing frameworks. The manufacturing of new battery systems typically requires 50-65 liters of water per kWh of capacity produced. By extending battery life through repurposing, this water consumption is effectively amortized over a longer operational period. Additionally, reduced mining activity translates to decreased habitat disruption and lower risks of water contamination from mining operations.

Regulatory compliance and sustainability certification systems increasingly recognize the value of battery repurposing. The European Union's Battery Directive revisions and emerging Extended Producer Responsibility frameworks are creating policy environments that incentivize second-life applications. Companies implementing robust repurposing frameworks can achieve higher sustainability ratings and potentially access green financing instruments, creating alignment between environmental benefits and economic incentives.

Carbon footprint analyses demonstrate that second-life applications can offset between 25-40% of the original manufacturing emissions through extended utilization. When hybrid vehicle batteries are repurposed for renewable energy storage, they contribute to grid stabilization and enable higher penetration of intermittent renewable sources, further amplifying their positive environmental impact. Each repurposed 1 kWh of battery capacity can potentially displace approximately 400-600 kg of CO2 emissions over a 10-year second life when used in renewable energy integration applications.

Material conservation represents another critical sustainability benefit. Modern hybrid vehicle battery packs contain valuable materials including lithium, cobalt, nickel, and rare earth elements. Repurposing delays the need for recycling while maintaining these materials in productive use, addressing concerns about resource scarcity and reducing pressure on environmentally sensitive mining operations. This approach aligns with circular economy principles by maximizing the utility derived from the initial material investment.

Water usage and ecosystem impacts are also significantly reduced through battery repurposing frameworks. The manufacturing of new battery systems typically requires 50-65 liters of water per kWh of capacity produced. By extending battery life through repurposing, this water consumption is effectively amortized over a longer operational period. Additionally, reduced mining activity translates to decreased habitat disruption and lower risks of water contamination from mining operations.

Regulatory compliance and sustainability certification systems increasingly recognize the value of battery repurposing. The European Union's Battery Directive revisions and emerging Extended Producer Responsibility frameworks are creating policy environments that incentivize second-life applications. Companies implementing robust repurposing frameworks can achieve higher sustainability ratings and potentially access green financing instruments, creating alignment between environmental benefits and economic incentives.

Regulatory Standards for Second-Life Battery Implementation

The regulatory landscape for second-life battery implementation represents a complex and evolving framework that significantly impacts the viability of repurposing hybrid vehicle batteries. Current regulations vary substantially across different regions, creating challenges for standardized approaches to battery repurposing.

In the European Union, the Battery Directive (2006/66/EC) and its recent updates under the European Green Deal establish comprehensive requirements for battery collection, recycling, and repurposing. These regulations mandate extended producer responsibility and set specific targets for recovery rates. The EU's Circular Economy Action Plan further emphasizes the importance of battery reuse within a sustainable product lifecycle.

North American regulations present a more fragmented approach. The United States lacks federal-level comprehensive legislation specifically addressing second-life batteries, resulting in state-by-state variations. California leads with its Advanced Clean Cars Program and battery recycling initiatives, while other states are developing their own frameworks at different paces.

Safety standards constitute a critical regulatory component, with organizations like UL (Underwriters Laboratories) developing specific protocols for repurposed energy storage systems. UL 1974 provides evaluation and classification methods for battery packs and cells for repurposing, addressing critical safety concerns in second-life applications.

Transportation regulations present additional complexity, as repurposed batteries must comply with hazardous materials shipping requirements. The UN Manual of Tests and Criteria and international agreements like ADR in Europe govern the movement of lithium-ion batteries across borders, adding logistical considerations to repurposing operations.

Emerging regulatory trends indicate movement toward more harmonized global standards. The Global Battery Alliance and similar international initiatives are working to establish consistent frameworks for battery passport systems that would track batteries throughout their lifecycle, facilitating appropriate repurposing pathways.

Compliance challenges remain significant for industry stakeholders. The lack of standardized testing protocols for determining battery state-of-health and remaining useful life creates uncertainty in certification processes. Additionally, liability questions regarding responsibility for safety incidents involving repurposed batteries remain inadequately addressed in most regulatory frameworks.

Future regulatory developments will likely focus on establishing clearer end-of-life definitions for batteries, standardized testing methodologies, and more comprehensive product stewardship requirements that balance safety concerns with sustainability objectives.

In the European Union, the Battery Directive (2006/66/EC) and its recent updates under the European Green Deal establish comprehensive requirements for battery collection, recycling, and repurposing. These regulations mandate extended producer responsibility and set specific targets for recovery rates. The EU's Circular Economy Action Plan further emphasizes the importance of battery reuse within a sustainable product lifecycle.

North American regulations present a more fragmented approach. The United States lacks federal-level comprehensive legislation specifically addressing second-life batteries, resulting in state-by-state variations. California leads with its Advanced Clean Cars Program and battery recycling initiatives, while other states are developing their own frameworks at different paces.

Safety standards constitute a critical regulatory component, with organizations like UL (Underwriters Laboratories) developing specific protocols for repurposed energy storage systems. UL 1974 provides evaluation and classification methods for battery packs and cells for repurposing, addressing critical safety concerns in second-life applications.

Transportation regulations present additional complexity, as repurposed batteries must comply with hazardous materials shipping requirements. The UN Manual of Tests and Criteria and international agreements like ADR in Europe govern the movement of lithium-ion batteries across borders, adding logistical considerations to repurposing operations.

Emerging regulatory trends indicate movement toward more harmonized global standards. The Global Battery Alliance and similar international initiatives are working to establish consistent frameworks for battery passport systems that would track batteries throughout their lifecycle, facilitating appropriate repurposing pathways.

Compliance challenges remain significant for industry stakeholders. The lack of standardized testing protocols for determining battery state-of-health and remaining useful life creates uncertainty in certification processes. Additionally, liability questions regarding responsibility for safety incidents involving repurposed batteries remain inadequately addressed in most regulatory frameworks.

Future regulatory developments will likely focus on establishing clearer end-of-life definitions for batteries, standardized testing methodologies, and more comprehensive product stewardship requirements that balance safety concerns with sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!