Low-temperature performance optimization of second-life lithium-ion cells

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Technology Background and Objectives

The concept of second-life lithium-ion batteries has emerged as a sustainable solution to address the growing concerns of battery waste management and resource utilization. These batteries, which have completed their primary service life in electric vehicles (EVs) but retain 70-80% of their original capacity, present significant potential for repurposing in less demanding applications such as stationary energy storage systems. The evolution of this technology has been driven by the rapid growth of the EV market, creating an inevitable surge in retired batteries that still possess considerable value.

Low-temperature performance has been identified as a critical challenge for second-life lithium-ion cells. Historically, lithium-ion batteries have exhibited significant capacity fade, power loss, and efficiency reduction at temperatures below 0°C. This limitation stems from the fundamental electrochemical processes that govern battery operation, including reduced electrolyte conductivity, increased charge-transfer resistance, and slower lithium-ion diffusion kinetics at lower temperatures.

The technological trajectory of second-life battery applications has progressed from simple proof-of-concept demonstrations to sophisticated battery management systems capable of handling heterogeneous aged cells. Early research focused primarily on characterization and sorting methodologies, while recent developments have shifted toward adaptive control strategies and performance optimization techniques specifically designed for second-life contexts.

The primary technical objectives for low-temperature performance optimization of second-life lithium-ion cells include: extending operational temperature range to at least -20°C without significant performance degradation; developing advanced thermal management solutions tailored to the unique characteristics of aged cells; creating predictive models that accurately forecast performance under varying temperature conditions; and establishing standardized testing protocols to evaluate low-temperature behavior consistently across different second-life battery systems.

Additionally, research aims to understand the complex interplay between aging mechanisms and low-temperature performance, as previous degradation patterns from first-life usage significantly influence how these batteries respond to thermal challenges in their second life. The heterogeneity of aged cells further complicates this relationship, necessitating sophisticated characterization and management approaches.

The ultimate goal of this technological development is to transform what was once considered waste into valuable energy storage assets, thereby creating a circular economy for lithium-ion batteries. By addressing the low-temperature performance limitations, second-life batteries can expand their application scope to regions with cold climates and seasonal temperature variations, significantly enhancing their economic viability and environmental benefits.

Low-temperature performance has been identified as a critical challenge for second-life lithium-ion cells. Historically, lithium-ion batteries have exhibited significant capacity fade, power loss, and efficiency reduction at temperatures below 0°C. This limitation stems from the fundamental electrochemical processes that govern battery operation, including reduced electrolyte conductivity, increased charge-transfer resistance, and slower lithium-ion diffusion kinetics at lower temperatures.

The technological trajectory of second-life battery applications has progressed from simple proof-of-concept demonstrations to sophisticated battery management systems capable of handling heterogeneous aged cells. Early research focused primarily on characterization and sorting methodologies, while recent developments have shifted toward adaptive control strategies and performance optimization techniques specifically designed for second-life contexts.

The primary technical objectives for low-temperature performance optimization of second-life lithium-ion cells include: extending operational temperature range to at least -20°C without significant performance degradation; developing advanced thermal management solutions tailored to the unique characteristics of aged cells; creating predictive models that accurately forecast performance under varying temperature conditions; and establishing standardized testing protocols to evaluate low-temperature behavior consistently across different second-life battery systems.

Additionally, research aims to understand the complex interplay between aging mechanisms and low-temperature performance, as previous degradation patterns from first-life usage significantly influence how these batteries respond to thermal challenges in their second life. The heterogeneity of aged cells further complicates this relationship, necessitating sophisticated characterization and management approaches.

The ultimate goal of this technological development is to transform what was once considered waste into valuable energy storage assets, thereby creating a circular economy for lithium-ion batteries. By addressing the low-temperature performance limitations, second-life batteries can expand their application scope to regions with cold climates and seasonal temperature variations, significantly enhancing their economic viability and environmental benefits.

Market Analysis for Repurposed Lithium-ion Batteries

The second-life battery market has experienced significant growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the subsequent need for battery disposal solutions. By 2030, the global market for repurposed lithium-ion batteries is projected to reach $7.8 billion, growing at a CAGR of 23.1% from 2023. This growth is primarily fueled by the expanding EV market, with an estimated 145 million EVs expected on roads by 2030, creating a substantial supply of retired batteries.

The market segmentation for second-life batteries reveals diverse application opportunities. Stationary energy storage represents the largest segment, accounting for approximately 45% of the market, followed by industrial applications (25%), backup power systems (15%), and other emerging applications (15%). Geographically, Asia-Pacific dominates with 40% market share, followed by Europe (30%), North America (20%), and other regions (10%).

Low-temperature performance optimization of second-life lithium-ion cells addresses a critical market need, as performance degradation in cold environments remains a significant barrier to widespread adoption. Studies indicate that lithium-ion batteries can lose up to 50% of their capacity at temperatures below 0°C, severely limiting their utility in regions with cold climates.

Consumer demand analysis reveals strong interest in repurposed batteries with enhanced cold-weather performance. A recent industry survey showed that 78% of potential commercial customers cited improved low-temperature operation as a "very important" or "critical" factor in their purchasing decisions for energy storage systems.

The economic value proposition is compelling. Repurposed batteries typically cost 40-60% less than new batteries, while still retaining 70-80% of their original capacity. With optimized low-temperature performance, these cost advantages can be maintained even in challenging environmental conditions, expanding the addressable market significantly.

Regulatory trends are increasingly favorable for the second-life battery market. The European Union's Battery Directive revision, China's policy on EV battery recycling, and similar initiatives in North America are creating a structured framework for battery repurposing. These regulations are expected to increase the supply of retired batteries by mandating proper end-of-life management.

Market challenges persist, including standardization issues, warranty concerns, and competition from declining new battery prices. However, technological innovations specifically addressing low-temperature performance could create significant competitive advantages and premium pricing opportunities in this growing market.

The market segmentation for second-life batteries reveals diverse application opportunities. Stationary energy storage represents the largest segment, accounting for approximately 45% of the market, followed by industrial applications (25%), backup power systems (15%), and other emerging applications (15%). Geographically, Asia-Pacific dominates with 40% market share, followed by Europe (30%), North America (20%), and other regions (10%).

Low-temperature performance optimization of second-life lithium-ion cells addresses a critical market need, as performance degradation in cold environments remains a significant barrier to widespread adoption. Studies indicate that lithium-ion batteries can lose up to 50% of their capacity at temperatures below 0°C, severely limiting their utility in regions with cold climates.

Consumer demand analysis reveals strong interest in repurposed batteries with enhanced cold-weather performance. A recent industry survey showed that 78% of potential commercial customers cited improved low-temperature operation as a "very important" or "critical" factor in their purchasing decisions for energy storage systems.

The economic value proposition is compelling. Repurposed batteries typically cost 40-60% less than new batteries, while still retaining 70-80% of their original capacity. With optimized low-temperature performance, these cost advantages can be maintained even in challenging environmental conditions, expanding the addressable market significantly.

Regulatory trends are increasingly favorable for the second-life battery market. The European Union's Battery Directive revision, China's policy on EV battery recycling, and similar initiatives in North America are creating a structured framework for battery repurposing. These regulations are expected to increase the supply of retired batteries by mandating proper end-of-life management.

Market challenges persist, including standardization issues, warranty concerns, and competition from declining new battery prices. However, technological innovations specifically addressing low-temperature performance could create significant competitive advantages and premium pricing opportunities in this growing market.

Low-Temperature Challenges in Second-Life Batteries

Second-life lithium-ion batteries face significant performance degradation at low temperatures, primarily due to the reduced kinetics of electrochemical reactions. When temperatures drop below 0°C, the electrolyte viscosity increases dramatically, leading to decreased ion mobility and conductivity. This results in higher internal resistance, which manifests as reduced capacity, power capability, and accelerated aging compared to operation at ambient temperatures.

The severity of these challenges is often amplified in second-life applications because these cells have already experienced capacity fade and increased impedance during their first life. The solid-electrolyte interphase (SEI) layer, which grows during the initial battery life, becomes thicker and less permeable at low temperatures, further hindering lithium-ion transport. This creates a compounding effect where aged cells suffer disproportionately more severe performance losses at low temperatures than new cells.

Lithium plating represents another critical concern for second-life batteries operating in cold environments. The reduced intercalation kinetics at the graphite anode can cause lithium ions to plate as metallic lithium rather than intercalating properly. This irreversible process not only consumes active lithium but also creates dendrites that may penetrate the separator, potentially causing internal short circuits and safety hazards.

The heterogeneity among second-life cells compounds these challenges. Batteries collected from first-life applications typically show varying degrees of degradation, even within the same batch. This non-uniform aging creates cells with different low-temperature behaviors, making it difficult to implement standardized optimization strategies across repurposed battery packs.

Energy management systems face particular difficulties when operating second-life batteries in cold conditions. The state-of-charge (SOC) and state-of-health (SOH) estimation algorithms become less accurate at low temperatures due to the non-linear relationship between voltage, current, and actual capacity. This reduced accuracy compromises the effectiveness of battery management systems, potentially leading to over-discharge or overcharge conditions.

Self-heating effects during discharge can partially mitigate cold temperature issues, but second-life batteries generate less heat due to their reduced power capability, creating a negative feedback loop. Additionally, the thermal management systems designed for first-life applications may not be optimized for the altered thermal characteristics of aged cells, resulting in uneven temperature distribution and localized hotspots.

These challenges necessitate specialized approaches for low-temperature applications of second-life batteries, including advanced thermal management strategies, modified charging protocols, and enhanced battery management systems capable of adapting to the unique characteristics of aged cells in cold environments.

The severity of these challenges is often amplified in second-life applications because these cells have already experienced capacity fade and increased impedance during their first life. The solid-electrolyte interphase (SEI) layer, which grows during the initial battery life, becomes thicker and less permeable at low temperatures, further hindering lithium-ion transport. This creates a compounding effect where aged cells suffer disproportionately more severe performance losses at low temperatures than new cells.

Lithium plating represents another critical concern for second-life batteries operating in cold environments. The reduced intercalation kinetics at the graphite anode can cause lithium ions to plate as metallic lithium rather than intercalating properly. This irreversible process not only consumes active lithium but also creates dendrites that may penetrate the separator, potentially causing internal short circuits and safety hazards.

The heterogeneity among second-life cells compounds these challenges. Batteries collected from first-life applications typically show varying degrees of degradation, even within the same batch. This non-uniform aging creates cells with different low-temperature behaviors, making it difficult to implement standardized optimization strategies across repurposed battery packs.

Energy management systems face particular difficulties when operating second-life batteries in cold conditions. The state-of-charge (SOC) and state-of-health (SOH) estimation algorithms become less accurate at low temperatures due to the non-linear relationship between voltage, current, and actual capacity. This reduced accuracy compromises the effectiveness of battery management systems, potentially leading to over-discharge or overcharge conditions.

Self-heating effects during discharge can partially mitigate cold temperature issues, but second-life batteries generate less heat due to their reduced power capability, creating a negative feedback loop. Additionally, the thermal management systems designed for first-life applications may not be optimized for the altered thermal characteristics of aged cells, resulting in uneven temperature distribution and localized hotspots.

These challenges necessitate specialized approaches for low-temperature applications of second-life batteries, including advanced thermal management strategies, modified charging protocols, and enhanced battery management systems capable of adapting to the unique characteristics of aged cells in cold environments.

Current Low-Temperature Performance Solutions

01 Electrolyte modifications for low-temperature performance

Modifying the electrolyte composition can significantly improve the low-temperature performance of second-life lithium-ion cells. This includes using electrolyte additives, adjusting solvent ratios, or incorporating low-freezing-point components that maintain ionic conductivity at low temperatures. These modifications help reduce electrolyte viscosity and improve ion transport, which are critical factors affecting battery performance in cold conditions.- Electrolyte modifications for low-temperature performance: Modifying the electrolyte composition can significantly improve the low-temperature performance of second-life lithium-ion cells. This includes using electrolyte additives, adjusting the concentration of lithium salts, and incorporating low-freezing-point solvents. These modifications help to reduce the viscosity of the electrolyte at low temperatures, improve ion conductivity, and prevent lithium plating, which are critical for maintaining cell performance in cold conditions.

- Electrode material optimization for second-life applications: Optimizing electrode materials is essential for enhancing the low-temperature performance of second-life lithium-ion cells. This involves selecting cathode and anode materials with superior low-temperature characteristics, modifying the particle size and morphology of active materials, and incorporating conductive additives. These optimizations help to reduce charge transfer resistance and improve the kinetics of electrochemical reactions at low temperatures.

- Thermal management systems for cold environments: Implementing effective thermal management systems is crucial for maintaining the performance of second-life lithium-ion cells in low-temperature environments. This includes battery preheating mechanisms, insulation techniques, and temperature control systems. These approaches help to keep the battery at an optimal operating temperature range, preventing capacity loss and power fade that typically occur in cold conditions.

- Cell screening and sorting methods for second-life applications: Developing effective screening and sorting methods is important for selecting suitable cells for second-life applications with good low-temperature performance. This involves assessing capacity retention at low temperatures, internal resistance measurements, and cycle life testing under cold conditions. These methods help to identify cells that maintain acceptable performance levels in low-temperature environments after their first life cycle.

- Battery management system adaptations for low temperatures: Adapting battery management systems (BMS) specifically for low-temperature operation of second-life cells is essential for optimizing performance. This includes implementing specialized charging protocols, state-of-charge estimation algorithms calibrated for cold conditions, and adaptive control strategies. These BMS adaptations help to prevent lithium plating during charging at low temperatures and optimize the available capacity of aged cells in cold environments.

02 Electrode material optimization for second-life applications

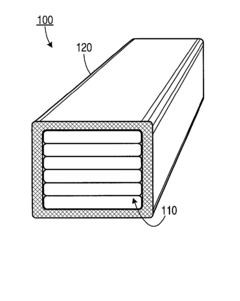

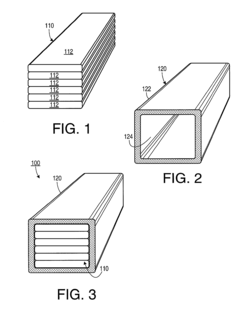

Specific electrode materials can be selected or modified to enhance low-temperature performance in second-life lithium-ion cells. This includes using doped cathode materials, nanostructured anodes, or composite electrodes that maintain their structural integrity and electrochemical properties at low temperatures. These optimized materials facilitate faster charge transfer and reduce performance degradation when operating in cold environments.Expand Specific Solutions03 Thermal management systems for cold environments

Implementing specialized thermal management systems can help maintain optimal operating temperatures for second-life lithium-ion cells in cold environments. These systems may include insulation materials, heating elements, or phase-change materials that provide thermal regulation. Effective thermal management prevents excessive capacity loss and power fade at low temperatures by keeping the cells within their ideal operating temperature range.Expand Specific Solutions04 Battery management system adaptations

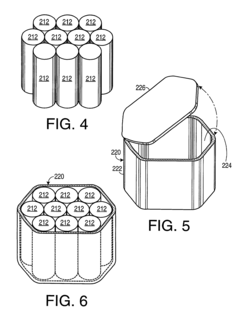

Advanced battery management systems (BMS) can be specifically programmed to optimize the performance of second-life lithium-ion cells at low temperatures. These systems may include adaptive charging algorithms, state-of-health monitoring, and predictive models that adjust operating parameters based on temperature conditions. The BMS can implement preheating strategies, adjust current limits, or modify voltage thresholds to protect the battery while maximizing available capacity in cold conditions.Expand Specific Solutions05 Cell selection and matching techniques

Careful selection and matching of cells for second-life applications can improve overall low-temperature performance. This involves screening used cells based on their capacity retention at low temperatures, internal resistance characteristics, and aging patterns. By grouping cells with similar properties and performance metrics, battery packs can be assembled that maintain better balance and efficiency when operating in cold environments, extending their useful second life.Expand Specific Solutions

Key Industry Players in Second-Life Battery Market

The low-temperature performance optimization of second-life lithium-ion cells market is in its growth phase, with increasing interest driven by sustainability goals and energy storage demands. The global market for second-life batteries is projected to expand significantly as major automotive manufacturers like Toyota, BYD, and NIO seek to extend battery value chains. Technical maturity varies across players, with established companies such as LG Energy Solution, CATL, and Toyota leading research efforts through advanced thermal management systems and electrolyte modifications. Battery manufacturers including GS Yuasa and Wildcat Discovery Technologies are developing specialized low-temperature additives, while academic institutions like California Institute of Technology and University of Michigan contribute fundamental research to address crystallization and ion transport challenges at low temperatures.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-faceted approach to low-temperature performance optimization in second-life lithium-ion cells. Their technology centers on a proprietary electrolyte system containing fluoroethylene carbonate and lithium difluoro(oxalato)borate additives that significantly reduce the activation energy for lithium-ion transport at sub-zero temperatures. For second-life applications, they've developed a cell-sorting algorithm that identifies batteries with complementary degradation patterns, allowing for optimized pack configuration. Their thermal management solution incorporates thin-film heating elements directly integrated into the cell structure, enabling rapid and uniform warming even in heavily degraded cells. LG's system also features adaptive charging protocols that automatically adjust C-rates based on both temperature and the specific degradation history of the repurposed cells, maintaining 80% of room temperature capacity at -20°C in cells that have already completed their first-life cycle.

Strengths: Highly effective electrolyte formulations specifically designed for aged cells; sophisticated cell matching system that optimizes pack-level performance; integrated heating solution with minimal energy consumption. Weaknesses: Complex implementation requiring detailed battery history data; higher manufacturing costs for the integrated heating elements; system optimization heavily dependent on accurate degradation modeling.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive low-temperature optimization system for second-life lithium-ion cells that combines advanced electrolyte formulations with intelligent battery management. Their solution utilizes ethylene carbonate-based electrolytes with low-freezing point additives and proprietary lithium salt mixtures that maintain ionic conductivity down to -30°C. The company's battery management system employs machine learning algorithms to predict performance degradation patterns specific to aged cells and adjusts charging protocols accordingly. CATL's approach includes a pre-heating strategy using internal resistance heating that requires minimal external energy input, making it particularly suitable for electric vehicle applications in cold climates. Their technology also incorporates silicon-graphite composite anodes that demonstrate improved lithium-ion diffusion at low temperatures compared to conventional graphite anodes used in first-life applications.

Strengths: Superior electrolyte formulations specifically engineered for aged cells; advanced BMS with predictive analytics for second-life applications; minimal external energy requirements for pre-heating. Weaknesses: Higher implementation costs compared to simpler solutions; requires sophisticated control systems that may be challenging to integrate with existing infrastructure.

Critical Patents in Cold-Weather Battery Operation

System for enhanced lithium-ion battery performance at low temperatures

PatentInactiveUS20030031922A1

Innovation

- A phase change material sleeve that acts as an insulator at low temperatures and a conductor at high temperatures, allowing for efficient heat retention and dissipation, enabling optimal performance across varying temperature environments.

Lithium ion secondary battery

PatentWO2015037451A1

Innovation

- A lithium-ion secondary battery design incorporating a negative electrode with a mixture of carbon materials like natural graphite, artificial graphite, and non-graphitizable carbon, combined with an electrolyte solution containing a cyclic disulfonate ester compound and an acid anhydride, which forms a low-resistance film on the electrode surface, enhancing low-temperature rate characteristics and storage performance.

Environmental Impact and Sustainability Assessment

The environmental impact of second-life lithium-ion cells represents a critical dimension in sustainable energy storage solutions. Repurposing batteries that have reached the end of their first-life applications (typically electric vehicles) significantly extends their useful lifespan, thereby reducing the demand for new battery production. This practice substantially decreases the environmental footprint associated with resource extraction, manufacturing processes, and waste management.

Low-temperature optimization of these second-life cells further enhances their sustainability profile. By improving cold-weather performance, these batteries become viable in a broader range of applications and geographical locations, maximizing their utilization potential. This optimization directly contributes to circular economy principles by ensuring that valuable materials remain in productive use for extended periods rather than entering waste streams prematurely.

The carbon footprint reduction achieved through second-life applications is substantial. Research indicates that repurposing lithium-ion batteries can reduce greenhouse gas emissions by 15-70% compared to manufacturing new batteries, depending on the application and optimization level. Low-temperature performance improvements specifically reduce the need for energy-intensive heating systems in cold climates, further decreasing operational emissions.

Material conservation represents another significant environmental benefit. Each repurposed battery reduces the demand for critical raw materials including lithium, cobalt, nickel, and copper. These resources face increasing supply constraints and their extraction often involves significant environmental disruption, including habitat destruction, water pollution, and energy-intensive processing.

Waste reduction outcomes are equally important. Globally, lithium-ion battery waste is projected to reach 2 million metric tons annually by 2030. Effective second-life utilization, particularly when optimized for challenging conditions like low temperatures, could divert up to 60% of this waste from landfills or resource-intensive recycling processes.

The sustainability assessment must also consider potential trade-offs. Chemical additives or structural modifications used to enhance low-temperature performance may introduce new environmental concerns or complicate eventual recycling processes. Life cycle assessment studies indicate that optimization techniques involving minimal additional materials or those using bio-based alternatives offer the most favorable environmental profiles.

Policy implications are significant as regulatory frameworks increasingly incorporate extended producer responsibility and circular economy principles. Low-temperature optimized second-life batteries align with these emerging requirements while potentially qualifying for incentives designed to promote sustainable technology solutions.

Low-temperature optimization of these second-life cells further enhances their sustainability profile. By improving cold-weather performance, these batteries become viable in a broader range of applications and geographical locations, maximizing their utilization potential. This optimization directly contributes to circular economy principles by ensuring that valuable materials remain in productive use for extended periods rather than entering waste streams prematurely.

The carbon footprint reduction achieved through second-life applications is substantial. Research indicates that repurposing lithium-ion batteries can reduce greenhouse gas emissions by 15-70% compared to manufacturing new batteries, depending on the application and optimization level. Low-temperature performance improvements specifically reduce the need for energy-intensive heating systems in cold climates, further decreasing operational emissions.

Material conservation represents another significant environmental benefit. Each repurposed battery reduces the demand for critical raw materials including lithium, cobalt, nickel, and copper. These resources face increasing supply constraints and their extraction often involves significant environmental disruption, including habitat destruction, water pollution, and energy-intensive processing.

Waste reduction outcomes are equally important. Globally, lithium-ion battery waste is projected to reach 2 million metric tons annually by 2030. Effective second-life utilization, particularly when optimized for challenging conditions like low temperatures, could divert up to 60% of this waste from landfills or resource-intensive recycling processes.

The sustainability assessment must also consider potential trade-offs. Chemical additives or structural modifications used to enhance low-temperature performance may introduce new environmental concerns or complicate eventual recycling processes. Life cycle assessment studies indicate that optimization techniques involving minimal additional materials or those using bio-based alternatives offer the most favorable environmental profiles.

Policy implications are significant as regulatory frameworks increasingly incorporate extended producer responsibility and circular economy principles. Low-temperature optimized second-life batteries align with these emerging requirements while potentially qualifying for incentives designed to promote sustainable technology solutions.

Safety Standards and Certification Requirements

The safety standards and certification requirements for second-life lithium-ion cells operating at low temperatures represent a critical regulatory framework that manufacturers and integrators must navigate. These standards have evolved significantly in response to the unique challenges posed by repurposing batteries that have completed their first life cycle, typically in electric vehicles, for secondary applications such as stationary energy storage systems.

International standards organizations including IEC, ISO, UL, and IEEE have established specific protocols for testing and certifying second-life batteries under low-temperature conditions. The IEC 62619 standard, for instance, outlines safety requirements for secondary lithium cells and batteries for use in industrial applications, with specific provisions for thermal cycling and low-temperature performance assessment. Similarly, UL 1973 addresses batteries for use in stationary applications, with rigorous testing requirements for operation in sub-zero environments.

Certification processes typically require extensive testing of cell performance at temperature ranges from -20°C to -40°C, depending on the intended application. These tests evaluate capacity retention, internal resistance changes, and most critically, safety performance including thermal runaway resistance at low temperatures. The certification requirements are particularly stringent for second-life cells due to their unknown degradation history and potentially inconsistent performance characteristics.

Regulatory frameworks across different regions show notable variations. The European Union, through its Battery Directive (2006/66/EC) and upcoming Battery Regulation, imposes specific requirements for second-life battery certification, including enhanced safety testing for low-temperature applications. In North America, UL and CSA standards predominate, while China has developed GB/T standards that address the unique challenges of repurposed lithium-ion cells.

Transportation regulations present additional compliance challenges, particularly for cells intended for cold-climate applications. UN 38.3 testing requirements include mandatory low-temperature cycling and vibration tests that second-life cells must pass before being transported, adding complexity to the supply chain for these products.

Insurance requirements represent another layer of compliance considerations. Many insurers require additional certifications beyond the minimum regulatory standards, particularly for low-temperature applications where the risk profile of second-life cells remains less understood than that of new cells. These requirements often include more extensive cycle life testing at low temperatures and enhanced battery management system capabilities for monitoring cell behavior in cold conditions.

Emerging standards are beginning to address the specific challenges of second-life batteries more comprehensively, with organizations like SAE International developing guidelines specifically for repurposed automotive batteries in their J2997 standard, including detailed protocols for low-temperature performance validation and safety assessment.

International standards organizations including IEC, ISO, UL, and IEEE have established specific protocols for testing and certifying second-life batteries under low-temperature conditions. The IEC 62619 standard, for instance, outlines safety requirements for secondary lithium cells and batteries for use in industrial applications, with specific provisions for thermal cycling and low-temperature performance assessment. Similarly, UL 1973 addresses batteries for use in stationary applications, with rigorous testing requirements for operation in sub-zero environments.

Certification processes typically require extensive testing of cell performance at temperature ranges from -20°C to -40°C, depending on the intended application. These tests evaluate capacity retention, internal resistance changes, and most critically, safety performance including thermal runaway resistance at low temperatures. The certification requirements are particularly stringent for second-life cells due to their unknown degradation history and potentially inconsistent performance characteristics.

Regulatory frameworks across different regions show notable variations. The European Union, through its Battery Directive (2006/66/EC) and upcoming Battery Regulation, imposes specific requirements for second-life battery certification, including enhanced safety testing for low-temperature applications. In North America, UL and CSA standards predominate, while China has developed GB/T standards that address the unique challenges of repurposed lithium-ion cells.

Transportation regulations present additional compliance challenges, particularly for cells intended for cold-climate applications. UN 38.3 testing requirements include mandatory low-temperature cycling and vibration tests that second-life cells must pass before being transported, adding complexity to the supply chain for these products.

Insurance requirements represent another layer of compliance considerations. Many insurers require additional certifications beyond the minimum regulatory standards, particularly for low-temperature applications where the risk profile of second-life cells remains less understood than that of new cells. These requirements often include more extensive cycle life testing at low temperatures and enhanced battery management system capabilities for monitoring cell behavior in cold conditions.

Emerging standards are beginning to address the specific challenges of second-life batteries more comprehensively, with organizations like SAE International developing guidelines specifically for repurposed automotive batteries in their J2997 standard, including detailed protocols for low-temperature performance validation and safety assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!