Large-scale second-life battery deployment in industrial microgrids

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Second-Life Battery Technology Background and Objectives

Second-life battery technology has evolved significantly over the past decade, emerging as a sustainable solution to address the growing concerns of battery waste management and resource utilization. Initially, these batteries were primarily sourced from electric vehicles (EVs) where they are typically replaced after reaching 70-80% of their original capacity, despite retaining substantial functionality for less demanding applications. This technological evolution represents a circular economy approach to energy storage, extending battery lifecycle beyond their primary automotive use.

The development trajectory of second-life batteries has been accelerated by the rapid growth in the EV market, with global sales increasing from approximately 450,000 units in 2015 to over 6.6 million in 2021. This expansion has created a substantial pipeline of batteries that will become available for second-life applications in the coming years, with projections suggesting availability of over 200 GWh of second-life capacity by 2030.

Technical advancements in battery management systems (BMS) have been crucial in enabling effective repurposing. Modern BMS technologies can accurately assess individual cell health, predict remaining useful life, and optimize performance in second-life applications. These systems have evolved from simple voltage monitoring to sophisticated predictive analytics incorporating machine learning algorithms that continuously improve battery utilization efficiency.

The integration of second-life batteries into industrial microgrids represents a convergence of two significant technological trends: the rise of distributed energy resources and the circular economy approach to battery lifecycle management. Industrial microgrids, which operate as localized energy systems capable of functioning independently from the main grid, provide an ideal application environment for second-life batteries due to their more predictable load profiles and professional management capabilities.

The primary technical objectives for large-scale second-life battery deployment in industrial microgrids include developing standardized assessment protocols for battery condition evaluation, creating adaptive management systems that can handle heterogeneous battery arrays, and establishing cost-effective refurbishment processes. Additionally, there are aims to achieve integration with renewable energy sources to enhance grid stability and reduce peak demand charges for industrial facilities.

Research objectives also focus on extending the useful life of these repurposed batteries through advanced thermal management, optimized charging strategies, and improved state-of-health monitoring. The ultimate goal is to establish a technically viable, economically attractive, and environmentally sustainable model for second-life battery utilization that can be scaled across various industrial settings globally.

The development trajectory of second-life batteries has been accelerated by the rapid growth in the EV market, with global sales increasing from approximately 450,000 units in 2015 to over 6.6 million in 2021. This expansion has created a substantial pipeline of batteries that will become available for second-life applications in the coming years, with projections suggesting availability of over 200 GWh of second-life capacity by 2030.

Technical advancements in battery management systems (BMS) have been crucial in enabling effective repurposing. Modern BMS technologies can accurately assess individual cell health, predict remaining useful life, and optimize performance in second-life applications. These systems have evolved from simple voltage monitoring to sophisticated predictive analytics incorporating machine learning algorithms that continuously improve battery utilization efficiency.

The integration of second-life batteries into industrial microgrids represents a convergence of two significant technological trends: the rise of distributed energy resources and the circular economy approach to battery lifecycle management. Industrial microgrids, which operate as localized energy systems capable of functioning independently from the main grid, provide an ideal application environment for second-life batteries due to their more predictable load profiles and professional management capabilities.

The primary technical objectives for large-scale second-life battery deployment in industrial microgrids include developing standardized assessment protocols for battery condition evaluation, creating adaptive management systems that can handle heterogeneous battery arrays, and establishing cost-effective refurbishment processes. Additionally, there are aims to achieve integration with renewable energy sources to enhance grid stability and reduce peak demand charges for industrial facilities.

Research objectives also focus on extending the useful life of these repurposed batteries through advanced thermal management, optimized charging strategies, and improved state-of-health monitoring. The ultimate goal is to establish a technically viable, economically attractive, and environmentally sustainable model for second-life battery utilization that can be scaled across various industrial settings globally.

Market Analysis for Industrial Microgrid Battery Storage

The industrial microgrid battery storage market is experiencing significant growth, driven by increasing energy costs, grid reliability concerns, and sustainability initiatives. Current market valuations place the global industrial microgrid sector at approximately $21 billion in 2023, with projections indicating growth to reach $46 billion by 2030, representing a compound annual growth rate of 11.8%. Battery storage components specifically account for roughly 30% of this market value, highlighting their critical role in microgrid functionality.

Second-life battery deployment represents a rapidly expanding segment within this market. With electric vehicle battery production increasing exponentially, the volume of batteries reaching their end-of-first-life stage is creating a substantial supply pipeline for industrial applications. Industry analysts estimate that by 2025, over 200 GWh of EV batteries will become available for second-life applications, with industrial microgrids positioned as a primary deployment channel.

Demand drivers for industrial microgrid battery storage include energy cost management, with facilities reporting 15-30% reductions in energy expenses through peak shaving and time-of-use optimization. Additionally, manufacturing facilities implementing battery storage solutions have demonstrated improved power quality metrics, with voltage sag incidents reduced by up to 95% in documented case studies.

Regulatory frameworks are increasingly favorable toward industrial microgrid development. Carbon reduction mandates, renewable portfolio standards, and financial incentives for distributed energy resources are creating market pull across major industrial economies. The Inflation Reduction Act in the United States, for example, provides investment tax credits that can offset up to 30% of battery storage installation costs when paired with renewable generation.

Market segmentation reveals that manufacturing facilities represent the largest customer segment (42%), followed by data centers (23%), mining operations (18%), and other industrial facilities (17%). Geographically, Asia-Pacific leads market adoption with 38% market share, followed by North America (32%) and Europe (24%).

Customer requirements analysis indicates that industrial users prioritize reliability (99.999% uptime requirements), scalability, integration capabilities with existing industrial control systems, and total cost of ownership. Second-life battery solutions must address these requirements while overcoming concerns about performance consistency and operational lifespan.

The competitive landscape features traditional energy storage providers expanding into second-life applications, specialized second-life battery firms, and industrial automation companies developing integrated microgrid solutions. Strategic partnerships between battery manufacturers, recycling companies, and industrial energy management firms are becoming increasingly common as the value chain matures.

Second-life battery deployment represents a rapidly expanding segment within this market. With electric vehicle battery production increasing exponentially, the volume of batteries reaching their end-of-first-life stage is creating a substantial supply pipeline for industrial applications. Industry analysts estimate that by 2025, over 200 GWh of EV batteries will become available for second-life applications, with industrial microgrids positioned as a primary deployment channel.

Demand drivers for industrial microgrid battery storage include energy cost management, with facilities reporting 15-30% reductions in energy expenses through peak shaving and time-of-use optimization. Additionally, manufacturing facilities implementing battery storage solutions have demonstrated improved power quality metrics, with voltage sag incidents reduced by up to 95% in documented case studies.

Regulatory frameworks are increasingly favorable toward industrial microgrid development. Carbon reduction mandates, renewable portfolio standards, and financial incentives for distributed energy resources are creating market pull across major industrial economies. The Inflation Reduction Act in the United States, for example, provides investment tax credits that can offset up to 30% of battery storage installation costs when paired with renewable generation.

Market segmentation reveals that manufacturing facilities represent the largest customer segment (42%), followed by data centers (23%), mining operations (18%), and other industrial facilities (17%). Geographically, Asia-Pacific leads market adoption with 38% market share, followed by North America (32%) and Europe (24%).

Customer requirements analysis indicates that industrial users prioritize reliability (99.999% uptime requirements), scalability, integration capabilities with existing industrial control systems, and total cost of ownership. Second-life battery solutions must address these requirements while overcoming concerns about performance consistency and operational lifespan.

The competitive landscape features traditional energy storage providers expanding into second-life applications, specialized second-life battery firms, and industrial automation companies developing integrated microgrid solutions. Strategic partnerships between battery manufacturers, recycling companies, and industrial energy management firms are becoming increasingly common as the value chain matures.

Technical Challenges in Large-Scale Battery Repurposing

The repurposing of electric vehicle (EV) batteries for second-life applications in industrial microgrids presents numerous technical challenges that must be addressed to ensure safe, efficient, and economically viable deployment. These challenges span multiple domains including battery assessment, system integration, and operational management.

Battery heterogeneity represents a primary obstacle in large-scale repurposing efforts. Second-life batteries typically arrive with varying chemistries, form factors, capacities, and degradation levels. This heterogeneity complicates the development of standardized testing protocols and integration frameworks necessary for industrial microgrid applications, where reliability and predictability are paramount.

Accurate state-of-health (SOH) assessment constitutes another significant challenge. Current methodologies for determining remaining useful life often rely on simplified models that fail to account for the complex degradation mechanisms present in aged batteries. The development of advanced diagnostic tools capable of precisely evaluating SOH without extensive laboratory testing remains an active area of research with substantial technical barriers.

System integration challenges emerge when incorporating second-life batteries into existing microgrid infrastructure. The design of power electronics interfaces must accommodate batteries with disparate voltage ranges, current capabilities, and response characteristics. Additionally, thermal management systems must be reconfigured to address the altered heat generation profiles of aged cells, which often exhibit increased internal resistance.

Battery management systems (BMS) require significant adaptation for second-life applications. Original BMS configurations are typically optimized for automotive use cases and may not provide the functionality required for stationary storage applications. Developing BMS solutions that can effectively monitor and balance heterogeneous battery arrays while maintaining safety parameters presents considerable technical complexity.

Safety concerns are heightened with repurposed batteries due to their uncertain history and condition. Thermal runaway risks may be elevated in aged cells, necessitating more robust detection and mitigation systems than would be required for new batteries. The development of fail-safe mechanisms appropriate for industrial environments where maintenance expertise may be limited presents additional challenges.

Scalability issues become apparent when transitioning from pilot projects to large-scale deployments. The manual processes often employed in smaller implementations prove impractical at scale, requiring automation of testing, sorting, and integration procedures. Creating scalable workflows while maintaining quality control standards demands innovative technical solutions.

Regulatory compliance adds another layer of complexity, as standards for second-life battery applications continue to evolve. Engineering solutions must anticipate emerging requirements related to safety, performance, and end-of-life management, often necessitating adaptive design approaches that can accommodate regulatory changes without major system overhauls.

Battery heterogeneity represents a primary obstacle in large-scale repurposing efforts. Second-life batteries typically arrive with varying chemistries, form factors, capacities, and degradation levels. This heterogeneity complicates the development of standardized testing protocols and integration frameworks necessary for industrial microgrid applications, where reliability and predictability are paramount.

Accurate state-of-health (SOH) assessment constitutes another significant challenge. Current methodologies for determining remaining useful life often rely on simplified models that fail to account for the complex degradation mechanisms present in aged batteries. The development of advanced diagnostic tools capable of precisely evaluating SOH without extensive laboratory testing remains an active area of research with substantial technical barriers.

System integration challenges emerge when incorporating second-life batteries into existing microgrid infrastructure. The design of power electronics interfaces must accommodate batteries with disparate voltage ranges, current capabilities, and response characteristics. Additionally, thermal management systems must be reconfigured to address the altered heat generation profiles of aged cells, which often exhibit increased internal resistance.

Battery management systems (BMS) require significant adaptation for second-life applications. Original BMS configurations are typically optimized for automotive use cases and may not provide the functionality required for stationary storage applications. Developing BMS solutions that can effectively monitor and balance heterogeneous battery arrays while maintaining safety parameters presents considerable technical complexity.

Safety concerns are heightened with repurposed batteries due to their uncertain history and condition. Thermal runaway risks may be elevated in aged cells, necessitating more robust detection and mitigation systems than would be required for new batteries. The development of fail-safe mechanisms appropriate for industrial environments where maintenance expertise may be limited presents additional challenges.

Scalability issues become apparent when transitioning from pilot projects to large-scale deployments. The manual processes often employed in smaller implementations prove impractical at scale, requiring automation of testing, sorting, and integration procedures. Creating scalable workflows while maintaining quality control standards demands innovative technical solutions.

Regulatory compliance adds another layer of complexity, as standards for second-life battery applications continue to evolve. Engineering solutions must anticipate emerging requirements related to safety, performance, and end-of-life management, often necessitating adaptive design approaches that can accommodate regulatory changes without major system overhauls.

Current Integration Solutions for Second-Life Batteries

01 Battery assessment and classification for second-life applications

Methods and systems for evaluating used batteries to determine their suitability for second-life applications. This involves testing battery performance parameters such as capacity, internal resistance, and state of health to classify batteries according to their remaining useful life. Advanced diagnostic techniques help identify which batteries can be repurposed for less demanding applications after their primary use in electric vehicles or other high-performance settings.- Battery management systems for second-life applications: Advanced battery management systems are essential for repurposing used batteries in second-life applications. These systems monitor battery health, state of charge, and performance parameters to ensure safe and efficient operation. They incorporate algorithms that can adapt to the degraded characteristics of used batteries and optimize their remaining capacity. Such management systems enable reliable integration of second-life batteries into various applications while extending their useful lifespan.

- Electric vehicle battery repurposing technologies: Technologies specifically designed for repurposing electric vehicle batteries for second-life applications focus on assessment, reconfiguration, and integration. These technologies include methods for evaluating battery degradation patterns unique to automotive use, techniques for reconfiguring battery modules to match new application requirements, and systems for integrating these batteries into stationary energy storage applications. The repurposing process often involves disassembly of battery packs, testing of individual modules, and reassembly into new configurations.

- Energy storage systems using second-life batteries: Energy storage systems utilizing second-life batteries provide cost-effective solutions for grid support, renewable energy integration, and backup power applications. These systems are designed to accommodate batteries with varying levels of degradation while maintaining system reliability. They often incorporate power electronics specifically designed to handle the characteristics of used batteries and include thermal management systems to extend battery life in their second application. Such systems enable more sustainable use of battery resources while providing valuable grid services.

- Battery testing and grading methodologies: Specialized testing and grading methodologies have been developed to assess second-life batteries and determine their suitability for various applications. These methods include accelerated aging tests, capacity measurement techniques, internal resistance analysis, and predictive modeling of remaining useful life. The testing protocols help classify used batteries according to their performance capabilities, allowing for appropriate matching with second-life applications based on their power and energy requirements. This enables more efficient utilization of battery resources after their primary use.

- Circular economy models for battery lifecycle management: Comprehensive approaches to battery lifecycle management incorporate circular economy principles to maximize the value of battery resources. These models include strategies for collection, assessment, repurposing, and eventual recycling of battery materials. They often involve collaborative frameworks between battery manufacturers, vehicle producers, energy companies, and recycling facilities. By establishing standardized processes for battery second-life applications and end-of-life management, these approaches reduce waste, lower environmental impact, and improve the overall sustainability of battery technologies.

02 Energy storage systems using repurposed batteries

Implementation of second-life batteries in stationary energy storage systems, particularly for renewable energy integration and grid support. These systems combine multiple used batteries with varying performance characteristics to create cost-effective storage solutions. The approach includes power management systems that optimize battery performance based on individual cell characteristics, extending the useful life of repurposed batteries while maintaining system reliability.Expand Specific Solutions03 Battery management systems for second-life applications

Specialized battery management systems designed specifically for second-life batteries that account for their degraded and variable performance characteristics. These systems include adaptive algorithms that continuously monitor and adjust operating parameters to optimize performance and safety. Features include cell balancing, thermal management, and predictive maintenance capabilities tailored to the unique challenges of repurposed batteries.Expand Specific Solutions04 Refurbishment and reconditioning techniques

Methods for refurbishing and reconditioning used batteries to improve their performance in second-life applications. These techniques include cell replacement, electrode restoration, and electrolyte refreshment to extend battery life. The processes involve disassembly, testing, repair, and reassembly of battery packs to create standardized modules suitable for various second-life applications while ensuring safety and reliability.Expand Specific Solutions05 Business models and sustainability aspects

Economic and environmental frameworks for implementing second-life battery solutions at scale. These models address the entire lifecycle of batteries, from initial use through repurposing to eventual recycling. Key aspects include valuation methodologies for used batteries, standardization efforts to facilitate repurposing, and analysis of environmental benefits through reduced resource extraction and waste. The approaches also consider regulatory compliance and safety standards specific to second-life battery applications.Expand Specific Solutions

Key Industry Players in Battery Recycling and Microgrids

The second-life battery deployment in industrial microgrids market is currently in its growth phase, with an expanding market size driven by sustainability initiatives and energy storage demands. Major players like LG Energy Solution, Samsung SDI, CATL, and SK On are leading technological innovation in this space. These companies are leveraging their expertise in battery manufacturing to develop advanced battery management systems that extend the useful life of EV batteries in stationary applications. The technology maturity varies, with established players demonstrating commercial-scale deployments while newer entrants like Hygge Energy focus on niche integration solutions. The competitive landscape is characterized by strategic partnerships between battery manufacturers and energy management companies, with increasing focus on standardization and scalability to address the growing industrial microgrid market.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive second-life battery management system specifically designed for industrial microgrids. Their technology focuses on battery module reconfiguration and adaptive state-of-health monitoring to optimize performance of retired EV batteries. The system employs advanced battery management algorithms that continuously assess individual cell conditions and dynamically adjust power distribution across the repurposed battery array. LG Chem's solution includes proprietary diagnostic tools that can accurately predict remaining useful life of second-life batteries with up to 95% accuracy, enabling more reliable microgrid operation. Their industrial implementation includes containerized battery storage units with integrated thermal management systems specifically calibrated for the unique characteristics of aged cells.

Strengths: Leverages extensive experience in original battery manufacturing to better understand degradation patterns; integrated supply chain from EV battery recovery to microgrid deployment. Weaknesses: System requires significant processing power for continuous battery health monitoring, potentially increasing operational costs in remote locations.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered a modular second-life battery platform called "Battery Rebirth" specifically for industrial microgrid applications. The system incorporates advanced cell sorting technology that uses machine learning algorithms to group cells with similar degradation patterns, maximizing overall system efficiency. Their technology includes a proprietary Battery Management System (BMS) that adapts to the unique characteristics of aged cells, implementing specialized charging protocols that extend usable life by an estimated 30-40% compared to conventional approaches. CATL's industrial microgrid solution features standardized battery modules that can be hot-swapped without disrupting system operation, allowing for gradual capacity expansion and maintenance without downtime. The company has implemented this technology in several industrial parks across China, demonstrating reliable performance even with batteries that have lost up to 30% of their original capacity.

Strengths: Massive production scale allows access to large quantities of end-of-life EV batteries; sophisticated cell matching technology maximizes performance consistency. Weaknesses: Current implementations primarily limited to domestic Chinese market; standardization challenges when integrating batteries from multiple vehicle manufacturers.

Critical Patents and Research in Battery Repurposing

Separable connecting member for secondary battery module and method of improving the performance of battery module by leveling voltage

PatentActiveUS7538516B2

Innovation

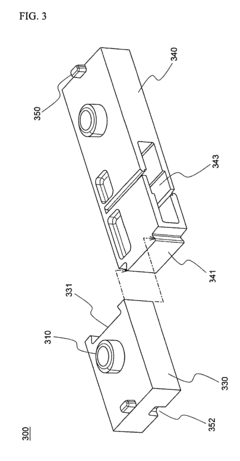

- A separation-type connecting member is used to connect electrode terminals of unit cells in a battery module, featuring separate terminal connecting bodies that are coupled with conductive members, including safety elements like fuses or PTCs, to reduce short circuits and allow for voltage leveling by connecting the cells in parallel before series connection.

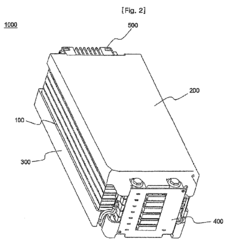

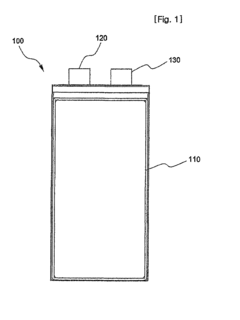

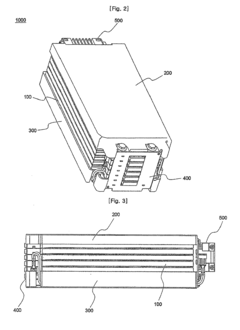

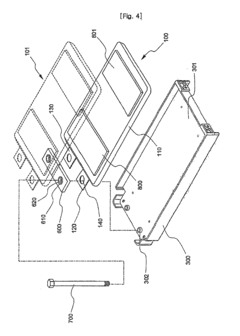

Secondary battery module

PatentActiveEP2450981A1

Innovation

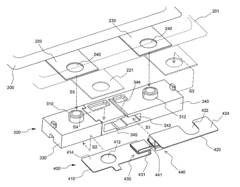

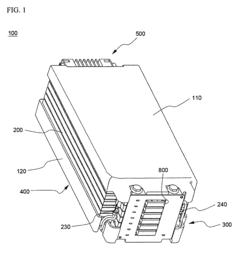

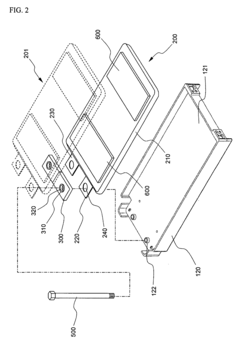

- A battery module design featuring a stackable structure with separated upper and lower cases, high-strength safety members, double-sided adhesive members for stabilization, and integrated circuit units for sensing and controlling, allowing for flexible capacity and output adjustments while maintaining a compact size and enhancing mechanical safety.

Safety and Reliability Standards for Repurposed Batteries

The development of safety and reliability standards for repurposed batteries represents a critical foundation for the large-scale deployment of second-life batteries in industrial microgrids. Currently, several international organizations including IEEE, IEC, and UL are actively developing specialized standards addressing the unique challenges of repurposed batteries. These standards focus on establishing consistent testing protocols, performance metrics, and safety requirements that account for the degraded nature of used batteries.

Key safety standards under development include thermal runaway prevention measures, battery management system requirements, and enclosure specifications designed specifically for second-life applications. These standards recognize that repurposed batteries have undergone varying degrees of degradation and usage patterns in their first life, necessitating more comprehensive testing than new batteries.

Reliability standards are evolving to address the performance variability inherent in second-life batteries. These include standardized methods for capacity estimation, state-of-health assessment, and remaining useful life prediction. The IEC 63330 working group is specifically focused on developing testing procedures for second-life batteries, while UL 1974 provides guidelines for evaluation and classification of battery packs and modules for repurposing.

Certification pathways are being established to verify compliance with these emerging standards. This includes third-party testing requirements and documentation processes that trace the battery's history from first to second life. The European Union's Battery Directive revision specifically addresses second-life batteries, mandating minimum performance and durability requirements.

Grid integration standards are also evolving to accommodate the unique characteristics of repurposed batteries in microgrid applications. These include IEEE 2030.2.1 for interoperability requirements and IEC 62933 for electrical energy storage systems. These standards ensure that second-life battery systems can safely interact with existing grid infrastructure and other distributed energy resources.

Insurance requirements are increasingly tied to compliance with these standards, with insurers developing specialized policies for facilities utilizing second-life batteries. This creates additional market pressure for standardization and certification. The convergence of these standards is expected to accelerate in the next 3-5 years, providing a more cohesive regulatory framework that will enable wider adoption of second-life batteries in industrial microgrids while maintaining appropriate safety margins.

Key safety standards under development include thermal runaway prevention measures, battery management system requirements, and enclosure specifications designed specifically for second-life applications. These standards recognize that repurposed batteries have undergone varying degrees of degradation and usage patterns in their first life, necessitating more comprehensive testing than new batteries.

Reliability standards are evolving to address the performance variability inherent in second-life batteries. These include standardized methods for capacity estimation, state-of-health assessment, and remaining useful life prediction. The IEC 63330 working group is specifically focused on developing testing procedures for second-life batteries, while UL 1974 provides guidelines for evaluation and classification of battery packs and modules for repurposing.

Certification pathways are being established to verify compliance with these emerging standards. This includes third-party testing requirements and documentation processes that trace the battery's history from first to second life. The European Union's Battery Directive revision specifically addresses second-life batteries, mandating minimum performance and durability requirements.

Grid integration standards are also evolving to accommodate the unique characteristics of repurposed batteries in microgrid applications. These include IEEE 2030.2.1 for interoperability requirements and IEC 62933 for electrical energy storage systems. These standards ensure that second-life battery systems can safely interact with existing grid infrastructure and other distributed energy resources.

Insurance requirements are increasingly tied to compliance with these standards, with insurers developing specialized policies for facilities utilizing second-life batteries. This creates additional market pressure for standardization and certification. The convergence of these standards is expected to accelerate in the next 3-5 years, providing a more cohesive regulatory framework that will enable wider adoption of second-life batteries in industrial microgrids while maintaining appropriate safety margins.

Environmental Impact and Sustainability Benefits

The deployment of second-life batteries in industrial microgrids represents a significant advancement in sustainable energy management practices. These repurposed batteries, primarily from electric vehicles (EVs), offer substantial environmental benefits by extending their useful life beyond their original application. This approach directly addresses the growing concern of battery waste management, which has become increasingly critical as global EV adoption accelerates.

The environmental impact of second-life battery deployment manifests primarily through resource conservation. By reusing batteries that retain 70-80% of their original capacity, industries can significantly reduce the demand for new battery production. This translates to decreased mining activities for critical materials such as lithium, cobalt, and nickel—resources associated with considerable environmental degradation, habitat destruction, and water pollution during extraction processes.

Carbon footprint reduction constitutes another major sustainability benefit. Life cycle assessments indicate that repurposing EV batteries for stationary storage applications can reduce greenhouse gas emissions by 15-25% compared to manufacturing new storage systems. This reduction stems from avoiding the energy-intensive processes required for new battery production, which typically accounts for 30-50% of a battery's lifetime carbon footprint.

The circular economy principles embodied in second-life battery applications create cascading environmental benefits throughout the value chain. By establishing a structured pathway for battery reuse, this approach helps minimize the environmental burden associated with premature disposal while creating economic incentives for proper end-of-life management. Studies suggest that industrial microgrids utilizing second-life batteries can achieve a 40-60% reduction in overall environmental impact compared to conventional energy storage solutions.

Water conservation represents an often-overlooked sustainability advantage. Battery manufacturing is water-intensive, requiring approximately 7,000-9,000 gallons of water per ton of lithium extracted. Second-life applications effectively distribute this water footprint across multiple use phases, improving the sustainability metrics of both the original and secondary applications.

From a waste management perspective, large-scale deployment of second-life batteries delays and potentially reduces the volume of battery materials entering waste streams. This provides additional time for recycling technologies to mature and become more economically viable, creating a more sustainable long-term solution for battery materials. Current estimates suggest that effective second-life utilization can extend the total useful life of battery materials by 5-10 years before recycling becomes necessary.

The environmental impact of second-life battery deployment manifests primarily through resource conservation. By reusing batteries that retain 70-80% of their original capacity, industries can significantly reduce the demand for new battery production. This translates to decreased mining activities for critical materials such as lithium, cobalt, and nickel—resources associated with considerable environmental degradation, habitat destruction, and water pollution during extraction processes.

Carbon footprint reduction constitutes another major sustainability benefit. Life cycle assessments indicate that repurposing EV batteries for stationary storage applications can reduce greenhouse gas emissions by 15-25% compared to manufacturing new storage systems. This reduction stems from avoiding the energy-intensive processes required for new battery production, which typically accounts for 30-50% of a battery's lifetime carbon footprint.

The circular economy principles embodied in second-life battery applications create cascading environmental benefits throughout the value chain. By establishing a structured pathway for battery reuse, this approach helps minimize the environmental burden associated with premature disposal while creating economic incentives for proper end-of-life management. Studies suggest that industrial microgrids utilizing second-life batteries can achieve a 40-60% reduction in overall environmental impact compared to conventional energy storage solutions.

Water conservation represents an often-overlooked sustainability advantage. Battery manufacturing is water-intensive, requiring approximately 7,000-9,000 gallons of water per ton of lithium extracted. Second-life applications effectively distribute this water footprint across multiple use phases, improving the sustainability metrics of both the original and secondary applications.

From a waste management perspective, large-scale deployment of second-life batteries delays and potentially reduces the volume of battery materials entering waste streams. This provides additional time for recycling technologies to mature and become more economically viable, creating a more sustainable long-term solution for battery materials. Current estimates suggest that effective second-life utilization can extend the total useful life of battery materials by 5-10 years before recycling becomes necessary.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!