Design Rules For Stack Sealing And Materials Compatibility In AEM Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AEM Cell Stack Sealing Background and Objectives

Anion Exchange Membrane (AEM) electrolysis has emerged as a promising alternative to traditional alkaline and proton exchange membrane (PEM) water electrolysis technologies for hydrogen production. The development of effective stack sealing systems represents one of the critical challenges in advancing AEM cell technology toward commercial viability. Stack sealing directly impacts cell performance, durability, and safety by preventing gas crossover, maintaining proper reactant distribution, and ensuring electrical isolation between components.

The evolution of AEM cell stack sealing technology has followed a trajectory from simple compression-based designs to more sophisticated engineered solutions. Early AEM systems borrowed heavily from fuel cell technologies, utilizing basic gasket materials that often proved inadequate for the unique chemical environment of AEM cells. The highly alkaline operating conditions (pH 13-14) combined with elevated temperatures (50-70°C) create a particularly demanding environment for sealing materials.

Recent technological advances have focused on developing specialized elastomers and composite sealing materials capable of withstanding these harsh conditions while maintaining dimensional stability and chemical resistance. The transition from laboratory-scale single cells to commercial-scale stacks has further highlighted the importance of robust sealing solutions that can accommodate thermal cycling, pressure differentials, and long-term operation.

The primary objective of AEM cell stack sealing development is to create a system that maintains gas separation efficiency exceeding 99.5% throughout the operational lifetime of the stack (typically targeted at >40,000 hours) while withstanding the aggressive alkaline environment. Secondary objectives include minimizing material costs, simplifying manufacturing processes, and ensuring compatibility with automated assembly techniques for large-scale production.

Material compatibility represents a particular challenge, as the sealing system must interface with multiple components including bipolar plates (typically stainless steel or titanium), membrane electrode assemblies (MEAs), and various flow field materials. Each interface presents unique chemical and mechanical challenges that must be addressed through careful material selection and design optimization.

Current research directions include the development of multi-layer sealing systems that combine the chemical resistance of fluoroelastomers with the mechanical properties of reinforcing materials, as well as exploring novel manufacturing techniques such as in-situ curing and overmolding to create integrated sealing solutions. Additionally, computational modeling approaches are increasingly being employed to predict stress distributions, potential failure modes, and optimize sealing geometries before physical prototyping.

The advancement of AEM cell stack sealing technology is closely linked to broader industry efforts to reduce the cost of green hydrogen production, with targets of achieving less than $2/kg by 2030, making effective sealing solutions a critical enabler for this emerging clean energy technology.

The evolution of AEM cell stack sealing technology has followed a trajectory from simple compression-based designs to more sophisticated engineered solutions. Early AEM systems borrowed heavily from fuel cell technologies, utilizing basic gasket materials that often proved inadequate for the unique chemical environment of AEM cells. The highly alkaline operating conditions (pH 13-14) combined with elevated temperatures (50-70°C) create a particularly demanding environment for sealing materials.

Recent technological advances have focused on developing specialized elastomers and composite sealing materials capable of withstanding these harsh conditions while maintaining dimensional stability and chemical resistance. The transition from laboratory-scale single cells to commercial-scale stacks has further highlighted the importance of robust sealing solutions that can accommodate thermal cycling, pressure differentials, and long-term operation.

The primary objective of AEM cell stack sealing development is to create a system that maintains gas separation efficiency exceeding 99.5% throughout the operational lifetime of the stack (typically targeted at >40,000 hours) while withstanding the aggressive alkaline environment. Secondary objectives include minimizing material costs, simplifying manufacturing processes, and ensuring compatibility with automated assembly techniques for large-scale production.

Material compatibility represents a particular challenge, as the sealing system must interface with multiple components including bipolar plates (typically stainless steel or titanium), membrane electrode assemblies (MEAs), and various flow field materials. Each interface presents unique chemical and mechanical challenges that must be addressed through careful material selection and design optimization.

Current research directions include the development of multi-layer sealing systems that combine the chemical resistance of fluoroelastomers with the mechanical properties of reinforcing materials, as well as exploring novel manufacturing techniques such as in-situ curing and overmolding to create integrated sealing solutions. Additionally, computational modeling approaches are increasingly being employed to predict stress distributions, potential failure modes, and optimize sealing geometries before physical prototyping.

The advancement of AEM cell stack sealing technology is closely linked to broader industry efforts to reduce the cost of green hydrogen production, with targets of achieving less than $2/kg by 2030, making effective sealing solutions a critical enabler for this emerging clean energy technology.

Market Analysis for AEM Cell Technologies

The global market for Anion Exchange Membrane (AEM) cell technologies is experiencing significant growth, driven by increasing demand for clean energy solutions and the advantages AEM cells offer over traditional alkaline and proton exchange membrane (PEM) technologies. Current market valuations place the AEM electrolyzer sector at approximately $320 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 28.5% through 2030, potentially reaching $1.8 billion by the end of the decade.

Key market drivers include the declining costs of renewable electricity, which makes green hydrogen production increasingly economical, and substantial government investments in hydrogen infrastructure worldwide. The European Union's Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, while the U.S. Hydrogen Shot initiative targets reducing clean hydrogen costs to $1 per kilogram within the decade.

AEM cell technologies occupy a strategic middle ground in the electrolyzer market, combining advantages of both alkaline and PEM systems. This positioning has created a distinct market segment with growing commercial interest. Unlike PEM cells that require expensive platinum group metal catalysts, AEM cells can utilize non-precious metal catalysts, potentially reducing capital costs by 15-20% compared to PEM systems.

Regional analysis reveals Europe leading AEM cell technology adoption, accounting for approximately 42% of the global market share, followed by North America (28%) and Asia-Pacific (24%). China is rapidly expanding its presence in this sector, with significant investments in manufacturing capacity and R&D.

Customer segmentation shows three primary market segments: industrial hydrogen production (55% of current demand), energy storage applications (30%), and transportation fuel production (15%). The industrial segment currently dominates due to established hydrogen needs in sectors like ammonia production and petroleum refining.

Competitive landscape analysis identifies several key players advancing AEM technology, including Enapter, Alchemr, Hydrogenics (Cummins), and Ionomr Innovations. These companies are focusing on scaling production and improving stack sealing and materials compatibility to enhance system durability and performance.

Market barriers include technical challenges related to membrane stability, stack sealing integrity, and materials compatibility in alkaline environments. These issues directly impact system lifetime and operational reliability, which remain critical concerns for commercial adoption. Additionally, the market faces competition from more established electrolyzer technologies and requires further standardization of components and testing protocols.

Key market drivers include the declining costs of renewable electricity, which makes green hydrogen production increasingly economical, and substantial government investments in hydrogen infrastructure worldwide. The European Union's Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, while the U.S. Hydrogen Shot initiative targets reducing clean hydrogen costs to $1 per kilogram within the decade.

AEM cell technologies occupy a strategic middle ground in the electrolyzer market, combining advantages of both alkaline and PEM systems. This positioning has created a distinct market segment with growing commercial interest. Unlike PEM cells that require expensive platinum group metal catalysts, AEM cells can utilize non-precious metal catalysts, potentially reducing capital costs by 15-20% compared to PEM systems.

Regional analysis reveals Europe leading AEM cell technology adoption, accounting for approximately 42% of the global market share, followed by North America (28%) and Asia-Pacific (24%). China is rapidly expanding its presence in this sector, with significant investments in manufacturing capacity and R&D.

Customer segmentation shows three primary market segments: industrial hydrogen production (55% of current demand), energy storage applications (30%), and transportation fuel production (15%). The industrial segment currently dominates due to established hydrogen needs in sectors like ammonia production and petroleum refining.

Competitive landscape analysis identifies several key players advancing AEM technology, including Enapter, Alchemr, Hydrogenics (Cummins), and Ionomr Innovations. These companies are focusing on scaling production and improving stack sealing and materials compatibility to enhance system durability and performance.

Market barriers include technical challenges related to membrane stability, stack sealing integrity, and materials compatibility in alkaline environments. These issues directly impact system lifetime and operational reliability, which remain critical concerns for commercial adoption. Additionally, the market faces competition from more established electrolyzer technologies and requires further standardization of components and testing protocols.

Current Challenges in AEM Cell Stack Sealing

Anion Exchange Membrane (AEM) cells represent a promising alternative to traditional proton exchange membrane technologies, yet they face significant challenges in stack sealing that impede their widespread commercial adoption. The highly alkaline operating environment (pH 14+) creates extreme conditions that conventional sealing materials struggle to withstand over extended operational periods. Current elastomeric seals such as EPDM, silicones, and fluoroelastomers exhibit accelerated degradation when exposed to concentrated hydroxide solutions, leading to mechanical failure and compromised cell performance.

Material compatibility issues represent a primary challenge in AEM stack sealing. The combination of high pH, elevated temperatures (60-80°C), and electrical potentials creates a particularly aggressive environment that attacks polymer chains and accelerates aging processes. Studies have documented significant decreases in tensile strength and elongation properties of sealing materials after just 1000 hours of operation, with some materials losing up to 40% of their initial mechanical properties.

Dimensional stability presents another critical challenge. Sealing materials in AEM cells experience substantial swelling when exposed to alkaline solutions, with some elastomers showing volume increases of 15-25%. This swelling alters the compressive force distribution across the stack, creating uneven contact pressure that leads to localized performance variations and potential leakage pathways. The dynamic nature of this swelling during operational cycles (wet/dry, temperature fluctuations) further complicates the maintenance of consistent sealing performance.

Interface compatibility between sealing materials and other cell components introduces additional complexity. The diverse materials present in an AEM stack—including metallic bipolar plates, composite end plates, and the membrane electrode assembly itself—each interact differently with sealing materials. Galvanic corrosion at metal-seal interfaces has been observed in long-term testing, while adhesion failures between seals and various surfaces lead to progressive leakage paths development.

Manufacturing and assembly challenges further complicate sealing solutions. Current gasket designs often require precise compression forces that are difficult to maintain uniformly across large-area stacks. Tolerance stack-up issues become increasingly problematic as cell count increases, with studies showing compression variations of up to 30% across different regions of the same stack. This non-uniform compression leads to localized over-compression or under-compression, both detrimental to seal integrity and cell performance.

Cost considerations remain a significant barrier, with high-performance sealing materials like perfluorinated elastomers being prohibitively expensive for large-scale applications. The trade-off between material performance and economic viability continues to limit the implementation of optimal sealing solutions in commercial AEM systems, forcing compromises that impact long-term reliability.

Material compatibility issues represent a primary challenge in AEM stack sealing. The combination of high pH, elevated temperatures (60-80°C), and electrical potentials creates a particularly aggressive environment that attacks polymer chains and accelerates aging processes. Studies have documented significant decreases in tensile strength and elongation properties of sealing materials after just 1000 hours of operation, with some materials losing up to 40% of their initial mechanical properties.

Dimensional stability presents another critical challenge. Sealing materials in AEM cells experience substantial swelling when exposed to alkaline solutions, with some elastomers showing volume increases of 15-25%. This swelling alters the compressive force distribution across the stack, creating uneven contact pressure that leads to localized performance variations and potential leakage pathways. The dynamic nature of this swelling during operational cycles (wet/dry, temperature fluctuations) further complicates the maintenance of consistent sealing performance.

Interface compatibility between sealing materials and other cell components introduces additional complexity. The diverse materials present in an AEM stack—including metallic bipolar plates, composite end plates, and the membrane electrode assembly itself—each interact differently with sealing materials. Galvanic corrosion at metal-seal interfaces has been observed in long-term testing, while adhesion failures between seals and various surfaces lead to progressive leakage paths development.

Manufacturing and assembly challenges further complicate sealing solutions. Current gasket designs often require precise compression forces that are difficult to maintain uniformly across large-area stacks. Tolerance stack-up issues become increasingly problematic as cell count increases, with studies showing compression variations of up to 30% across different regions of the same stack. This non-uniform compression leads to localized over-compression or under-compression, both detrimental to seal integrity and cell performance.

Cost considerations remain a significant barrier, with high-performance sealing materials like perfluorinated elastomers being prohibitively expensive for large-scale applications. The trade-off between material performance and economic viability continues to limit the implementation of optimal sealing solutions in commercial AEM systems, forcing compromises that impact long-term reliability.

Current Stack Sealing Design Solutions

01 Sealing materials for AEM cell stacks

Various sealing materials are used in AEM (Anion Exchange Membrane) cell stacks to prevent leakage and ensure proper functioning. These materials include elastomers, gaskets, and specialized polymers that can withstand the alkaline environment of AEM cells. The sealing materials must be chemically resistant, durable, and able to maintain their integrity under operating conditions. Proper selection of sealing materials is crucial for the longevity and efficiency of AEM cell stacks.- Sealing materials for AEM cell stacks: Various sealing materials are used in anion exchange membrane (AEM) cell stacks to prevent leakage and ensure proper functioning. These materials include elastomers, gaskets, and composite seals that can withstand the alkaline environment of AEM cells. The sealing materials must be chemically resistant, provide adequate compression, and maintain integrity over the operational lifetime of the stack. Proper selection of sealing materials is crucial for preventing electrolyte leakage and gas crossover between cells.

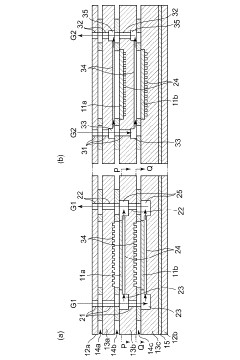

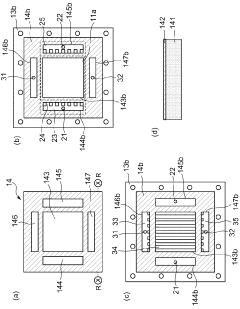

- Stack compression and assembly techniques: Effective sealing of AEM cell stacks requires proper compression and assembly techniques. This includes the use of compression plates, tie rods, and specific torque sequences to ensure uniform pressure distribution across the stack. The assembly process may involve controlled compression of gaskets and seals to achieve optimal contact pressure without damaging membrane electrode assemblies. Some designs incorporate spring elements to maintain compression despite thermal cycling and material relaxation during operation.

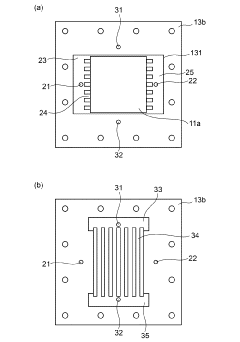

- Edge sealing configurations: Edge sealing is a critical aspect of AEM cell stack design, involving various configurations to prevent leakage at the periphery of the cells. These configurations include frame-integrated seals, edge-molded membranes, and specialized edge sealing compounds. Some designs feature multi-layer sealing approaches with primary and secondary seals to provide redundancy. Edge sealing must accommodate the dimensional changes of components during operation while maintaining an effective barrier against fluid leakage.

- Interface sealing between bipolar plates and MEAs: The interface between bipolar plates and membrane electrode assemblies (MEAs) in AEM cell stacks requires specialized sealing solutions. These include precision-molded gaskets, in-situ cured sealants, and integrated sealing features on bipolar plates. The sealing design must accommodate the flow field geometry while preventing internal and external leakage. Some advanced designs incorporate dual-function seals that provide both electrical insulation and fluid containment at these critical interfaces.

- Dynamic sealing for thermal expansion management: AEM cell stacks require dynamic sealing solutions to manage thermal expansion and contraction during operation. These include floating seal designs, elastomeric seals with specific shore hardness profiles, and composite seals with different expansion coefficients. Some advanced sealing systems incorporate self-adjusting mechanisms that maintain seal integrity despite dimensional changes. The dynamic sealing approach must balance the need for flexibility with the requirement for consistent contact pressure throughout the operational temperature range.

02 Stack compression and assembly techniques

Effective sealing of AEM cell stacks involves specific compression and assembly techniques. These techniques ensure uniform pressure distribution across the stack, preventing leakage while maintaining optimal contact between components. Methods include controlled torque application during assembly, use of compression plates, and specialized clamping systems. Proper stack compression is essential for creating effective seals while avoiding damage to membrane electrode assemblies and other sensitive components.Expand Specific Solutions03 Edge sealing configurations

Edge sealing is a critical aspect of AEM cell stack design that prevents electrolyte leakage and gas crossover. Various configurations include frame sealing, where gaskets are integrated into the frame structure, and direct edge sealing, where the membrane edges are sealed directly. Advanced edge sealing techniques incorporate multi-layer approaches that combine different materials to achieve both flexibility and chemical resistance. These configurations must accommodate thermal expansion while maintaining seal integrity throughout the operational life of the stack.Expand Specific Solutions04 Interface sealing between bipolar plates and MEAs

The interface between bipolar plates and membrane electrode assemblies (MEAs) in AEM cell stacks requires specialized sealing solutions. These interfaces are critical points where electrolyte leakage and gas crossover can occur. Sealing approaches include integrated gaskets molded directly onto bipolar plates, separate compression gaskets, and liquid sealants that cure in place. The sealing solution must accommodate the different materials and surface characteristics of both the bipolar plates and MEAs while ensuring electrical isolation where required.Expand Specific Solutions05 Dynamic sealing for temperature fluctuations

AEM cell stacks experience temperature fluctuations during operation that can compromise sealing integrity. Dynamic sealing solutions address this challenge by accommodating thermal expansion and contraction while maintaining seal effectiveness. These solutions include specially formulated elastomers with appropriate thermal expansion coefficients, floating seal designs that allow for component movement, and multi-material seals with different properties. Advanced dynamic sealing systems may incorporate self-healing properties or progressive compression characteristics to maintain sealing performance across varying operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The AEM cell stack sealing and materials compatibility market is currently in a growth phase, with increasing focus on hydrogen fuel cell technologies for clean energy applications. The market is expected to reach significant scale as automotive and industrial sectors accelerate adoption of hydrogen solutions. Leading players include established fuel cell manufacturers like Ballard Power Systems and Hydrogenics, alongside automotive giants Mercedes-Benz and Ford who are investing heavily in hydrogen technology. Materials specialists such as DuPont and Umicore provide critical components addressing sealing challenges. Technical maturity varies, with companies like Siemens and Toshiba demonstrating advanced solutions, while newer entrants like Hoeller Electrolyzer are bringing innovative approaches to stack design and materials compatibility, creating a competitive landscape balanced between established industrial players and specialized technology providers.

Ballard Power Systems, Inc.

Technical Solution: Ballard has developed proprietary stack sealing technologies for AEM cells that focus on minimizing interfacial resistance while maintaining chemical stability in alkaline environments. Their approach incorporates composite elastomer seals with fluoropolymer-based materials that resist degradation in high pH conditions. The company's design rules emphasize uniform compression distribution across the stack to prevent localized stress points and ensure consistent contact pressure between components. Ballard's materials selection protocol prioritizes compatibility with KOH electrolytes, addressing the unique challenges of hydroxide ion transport while maintaining dimensional stability during thermal cycling. Their stack design incorporates specialized edge sealing techniques that prevent electrolyte leakage while accommodating the differential expansion rates of various stack components during operation.

Strengths: Superior chemical resistance in alkaline environments and excellent long-term durability with minimal performance degradation over thousands of operating hours. Weaknesses: Higher manufacturing costs compared to conventional sealing solutions and limited flexibility for rapid design iterations due to proprietary material formulations.

Hoeller Electrolyzer GmbH

Technical Solution: Hoeller Electrolyzer has developed specialized stack sealing technologies for AEM electrolyzers that focus on the unique challenges of high-pressure operation in alkaline environments. Their approach incorporates advanced composite seals with gradient material properties that provide both chemical resistance at the electrolyte interface and mechanical compliance at compression surfaces. Hoeller's design rules emphasize the importance of material compatibility with both the alkaline electrolyte and the catalyst layers to prevent contamination and poisoning. Their sealing architecture incorporates redundant sealing elements with controlled compression to ensure gas separation while accommodating the differential expansion of stack components during pressurization and thermal cycling. Hoeller has pioneered specialized edge sealing techniques that address the critical interfaces between bipolar plates and membrane electrode assemblies, preventing both liquid and gas crossover while maintaining electrical isolation where required.

Strengths: Exceptional high-pressure operation capability and excellent gas separation performance even under dynamic operating conditions. Weaknesses: More complex assembly procedures compared to conventional designs and higher sensitivity to manufacturing tolerances.

Key Patents and Innovations in Sealing Materials

Electrochemical cell stack

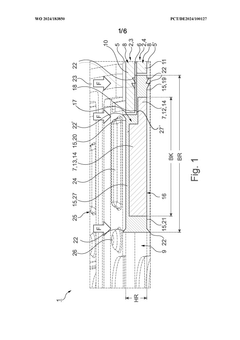

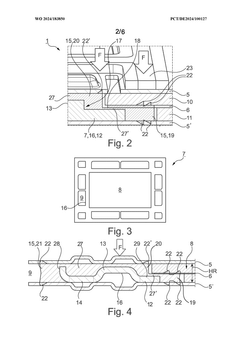

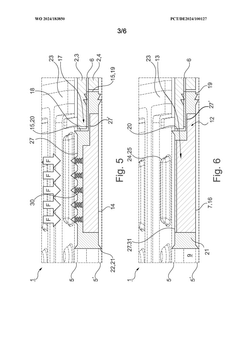

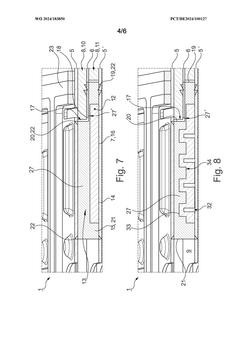

PatentWO2024183850A1

Innovation

- The electrochemical cell stack design features a support frame with a stepped cross-section and integrated sealing arrangement using elastomeric materials with specific Shore A hardness, featuring multiple sealing areas that transmit compressive forces and ensure robust sealing, minimizing leaks and assembly tolerances, and allowing operation under high pressure differences.

Electrochemical cell stack and seal material of the same

PatentActiveJP2020077638A

Innovation

- A sealing material comprising a metal layer coated with an insulating layer to provide mechanical strength, heat resistance, and insulation, preventing short circuits and gas leaks.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of AEM (Anion Exchange Membrane) cell technology represent critical factors in its long-term viability and market adoption. AEM cells offer significant environmental advantages compared to traditional alkaline electrolyzers and PEM cells, primarily due to their reduced dependency on precious metal catalysts. The elimination or substantial reduction of platinum group metals (PGMs) in AEM designs directly addresses resource scarcity concerns and reduces the environmental footprint associated with mining and processing these rare materials.

Material selection for stack sealing components presents both challenges and opportunities from a sustainability perspective. Current sealing materials often utilize fluorinated polymers which, while effective for chemical resistance, pose end-of-life disposal challenges due to their non-biodegradable nature and potential for releasing harmful compounds during incineration. Research into bio-based or recyclable alternatives for gaskets and sealing components could significantly improve the lifecycle assessment of AEM systems.

Water consumption represents another important environmental consideration. AEM cells typically require high-purity water, though at lower purity levels than PEM systems. Implementing closed-loop water recycling systems within AEM installations can minimize freshwater requirements and reduce wastewater discharge, particularly important in water-stressed regions where hydrogen production facilities might be deployed.

Energy efficiency across the full lifecycle must be evaluated when considering materials compatibility. While certain materials may offer superior chemical resistance or longevity, their production might entail energy-intensive processes that offset operational efficiency gains. Comprehensive lifecycle assessment (LCA) methodologies should be applied to sealing materials and stack components to ensure truly sustainable design choices.

Manufacturing processes for AEM stack components also merit environmental scrutiny. Current production methods often involve solvent-based processes for membrane fabrication and adhesive application in sealing systems. Transitioning to aqueous-based or solvent-free manufacturing techniques could reduce volatile organic compound (VOC) emissions and improve worker safety conditions while maintaining material performance requirements.

End-of-life considerations for AEM stacks remain underdeveloped in current design paradigms. Implementing design-for-disassembly principles would facilitate the separation of different materials at end-of-life, enabling more effective recycling of valuable components and proper disposal of non-recyclable elements. This approach aligns with circular economy principles and could significantly reduce the cumulative environmental impact of widespread AEM deployment.

Material selection for stack sealing components presents both challenges and opportunities from a sustainability perspective. Current sealing materials often utilize fluorinated polymers which, while effective for chemical resistance, pose end-of-life disposal challenges due to their non-biodegradable nature and potential for releasing harmful compounds during incineration. Research into bio-based or recyclable alternatives for gaskets and sealing components could significantly improve the lifecycle assessment of AEM systems.

Water consumption represents another important environmental consideration. AEM cells typically require high-purity water, though at lower purity levels than PEM systems. Implementing closed-loop water recycling systems within AEM installations can minimize freshwater requirements and reduce wastewater discharge, particularly important in water-stressed regions where hydrogen production facilities might be deployed.

Energy efficiency across the full lifecycle must be evaluated when considering materials compatibility. While certain materials may offer superior chemical resistance or longevity, their production might entail energy-intensive processes that offset operational efficiency gains. Comprehensive lifecycle assessment (LCA) methodologies should be applied to sealing materials and stack components to ensure truly sustainable design choices.

Manufacturing processes for AEM stack components also merit environmental scrutiny. Current production methods often involve solvent-based processes for membrane fabrication and adhesive application in sealing systems. Transitioning to aqueous-based or solvent-free manufacturing techniques could reduce volatile organic compound (VOC) emissions and improve worker safety conditions while maintaining material performance requirements.

End-of-life considerations for AEM stacks remain underdeveloped in current design paradigms. Implementing design-for-disassembly principles would facilitate the separation of different materials at end-of-life, enabling more effective recycling of valuable components and proper disposal of non-recyclable elements. This approach aligns with circular economy principles and could significantly reduce the cumulative environmental impact of widespread AEM deployment.

Performance Testing and Quality Assurance Protocols

Performance testing and quality assurance protocols for AEM (Anion Exchange Membrane) cells require rigorous methodologies to ensure stack sealing integrity and materials compatibility. These protocols must address both short-term performance validation and long-term durability assessment under various operating conditions. Standardized testing procedures typically begin with leak detection tests using pressure differentials across the stack to identify potential sealing failures before operation commences.

Electrochemical performance testing forms the cornerstone of quality assurance, including polarization curve measurements to characterize cell performance across different current densities. These measurements should be conducted at various temperatures (typically 50-80°C) and humidity levels to simulate real-world operating conditions. Impedance spectroscopy provides critical insights into interfacial resistances and membrane conductivity, helping identify potential materials compatibility issues that may not be apparent during initial assembly.

Accelerated stress testing protocols are essential for predicting long-term reliability. These include thermal cycling (between ambient temperature and 80°C), humidity cycling (between 30% and 100% RH), and load cycling to simulate start-stop operations. During these tests, continuous monitoring of stack resistance and gas crossover rates serves as early indicators of seal degradation or materials incompatibility.

Chemical compatibility testing must evaluate all materials in contact with the aggressive alkaline environment typical in AEM cells. This includes ex-situ exposure tests where sealing materials are immersed in concentrated KOH solutions (1-2M) at elevated temperatures for extended periods (500-1000 hours), followed by mechanical property testing to quantify degradation.

Post-mortem analysis protocols provide valuable insights into failure mechanisms. These include scanning electron microscopy with energy-dispersive X-ray spectroscopy to identify chemical changes at material interfaces, thermogravimetric analysis to assess thermal stability, and mechanical testing of aged components to quantify property changes after exposure to operating conditions.

Statistical quality control methods should be implemented throughout the manufacturing process, with defined acceptance criteria for each critical parameter. These include dimensional tolerances for stack components (±0.05mm typically acceptable), compression force uniformity across the stack (variation <10%), and leak rates below established thresholds (typically <1% of reactant flow rates).

Documentation and traceability systems must be established to track materials batches, assembly procedures, and testing results throughout the product lifecycle, enabling continuous improvement of design rules for stack sealing and materials selection in next-generation AEM cell systems.

Electrochemical performance testing forms the cornerstone of quality assurance, including polarization curve measurements to characterize cell performance across different current densities. These measurements should be conducted at various temperatures (typically 50-80°C) and humidity levels to simulate real-world operating conditions. Impedance spectroscopy provides critical insights into interfacial resistances and membrane conductivity, helping identify potential materials compatibility issues that may not be apparent during initial assembly.

Accelerated stress testing protocols are essential for predicting long-term reliability. These include thermal cycling (between ambient temperature and 80°C), humidity cycling (between 30% and 100% RH), and load cycling to simulate start-stop operations. During these tests, continuous monitoring of stack resistance and gas crossover rates serves as early indicators of seal degradation or materials incompatibility.

Chemical compatibility testing must evaluate all materials in contact with the aggressive alkaline environment typical in AEM cells. This includes ex-situ exposure tests where sealing materials are immersed in concentrated KOH solutions (1-2M) at elevated temperatures for extended periods (500-1000 hours), followed by mechanical property testing to quantify degradation.

Post-mortem analysis protocols provide valuable insights into failure mechanisms. These include scanning electron microscopy with energy-dispersive X-ray spectroscopy to identify chemical changes at material interfaces, thermogravimetric analysis to assess thermal stability, and mechanical testing of aged components to quantify property changes after exposure to operating conditions.

Statistical quality control methods should be implemented throughout the manufacturing process, with defined acceptance criteria for each critical parameter. These include dimensional tolerances for stack components (±0.05mm typically acceptable), compression force uniformity across the stack (variation <10%), and leak rates below established thresholds (typically <1% of reactant flow rates).

Documentation and traceability systems must be established to track materials batches, assembly procedures, and testing results throughout the product lifecycle, enabling continuous improvement of design rules for stack sealing and materials selection in next-generation AEM cell systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!