Low-Temperature Operation Of AEM Electrolyzers In Cold Climates

AEM Electrolyzer Technology Background and Objectives

Anion Exchange Membrane (AEM) electrolyzers represent a promising technology in the hydrogen production landscape, emerging as a potential alternative to traditional alkaline and Proton Exchange Membrane (PEM) electrolyzers. The development of AEM technology dates back to the early 2000s, with significant advancements occurring in the past decade as researchers sought to combine the advantages of both alkaline and PEM systems while minimizing their respective drawbacks.

The evolution of AEM technology has been driven by the global push for green hydrogen production as a key component of decarbonization strategies. Unlike PEM electrolyzers that require precious metal catalysts, AEM systems can utilize non-noble metal catalysts, potentially reducing capital costs. Simultaneously, they offer higher current densities and efficiencies than traditional alkaline systems, positioning them as a middle-ground solution in the electrolyzer technology spectrum.

Operating AEM electrolyzers in cold climates presents unique challenges that have not been fully addressed in the technology's development trajectory. Conventional AEM systems typically operate optimally at temperatures between 50-60°C, with performance degradation observed at lower temperatures due to decreased ionic conductivity, slower reaction kinetics, and increased membrane resistance. This temperature sensitivity becomes particularly problematic in cold climate regions where ambient temperatures can fall well below freezing.

The primary technical objective for low-temperature operation of AEM electrolyzers is to maintain efficient hydrogen production performance at temperatures approaching or below 0°C without significant energy penalties or system modifications. This includes developing membrane materials that retain high ionic conductivity at low temperatures, catalyst formulations that maintain activity despite reduced thermal energy, and system designs that effectively manage water states to prevent freezing within critical components.

Secondary objectives include ensuring system durability during temperature cycling, minimizing warm-up periods and associated energy requirements, and maintaining competitive system economics despite the additional engineering required for cold climate operation. The ultimate goal is to expand the geographical deployment potential of AEM electrolyzers to regions previously considered unsuitable due to their cold climate conditions.

Recent research trends indicate growing interest in polymer chemistry modifications, electrolyte formulations with antifreeze properties, and innovative system architectures that incorporate waste heat recovery or thermal management strategies. These developments align with the broader industry goal of making green hydrogen production viable across diverse geographical and climatic conditions, supporting the global transition to renewable energy systems.

Market Analysis for Cold Climate Hydrogen Production

The hydrogen market in cold climate regions presents significant growth opportunities driven by increasing demand for clean energy solutions and the strategic importance of energy security in these areas. Northern regions of North America, Europe, and Asia collectively represent a substantial potential market for hydrogen production technologies capable of operating in sub-zero temperatures.

Current market assessments indicate that cold climate regions account for approximately 25% of global hydrogen demand potential, with projections showing accelerated growth as these regions intensify decarbonization efforts. Countries like Canada, Norway, Finland, and Russia are particularly active in developing hydrogen infrastructure adapted to harsh winter conditions, recognizing hydrogen as a critical component of their energy transition strategies.

The market demand is primarily driven by three key sectors in cold climate regions: industrial applications, transportation, and building heating. Industrial users in these regions, particularly in mining, metallurgy, and chemical processing, require reliable hydrogen supplies regardless of seasonal temperature fluctuations. The transportation sector shows growing interest in hydrogen fuel cells that can perform consistently in sub-zero conditions, especially for heavy-duty vehicles and public transportation fleets operating in northern cities.

Market analysis reveals that cold climate hydrogen production faces a premium cost structure compared to temperate region production, with operational costs typically 15-30% higher due to additional insulation requirements, heating systems, and specialized materials needed for low-temperature operation. However, this cost differential is gradually narrowing as specialized technologies for cold climate operation mature and achieve economies of scale.

Government policies are significantly shaping market development, with several cold climate nations implementing specific incentives for winterized hydrogen production facilities. These include enhanced capital subsidies, operational support mechanisms, and research grants specifically targeting cold-weather hydrogen technologies. The European Union's hydrogen strategy explicitly acknowledges the need for cold-resistant hydrogen infrastructure in its northern member states.

Customer willingness to pay premiums for locally-produced hydrogen in cold regions is emerging as a notable market trend, driven by energy security concerns and the desire to avoid transportation challenges associated with importing hydrogen from distant production facilities. This localization preference creates market opportunities for distributed AEM electrolyzer systems specifically designed for cold climate operation.

The competitive landscape remains relatively open, with few hydrogen production technologies specifically optimized for sub-zero environments, suggesting significant first-mover advantages for companies that can effectively address the technical challenges of low-temperature AEM electrolysis. Market forecasts indicate that cold climate hydrogen production could represent a specialized market segment worth several billion dollars annually by 2030.

Low-Temperature Challenges in AEM Electrolysis

AEM (Anion Exchange Membrane) electrolyzers face significant operational challenges when deployed in cold climate regions, where ambient temperatures can drop well below freezing. These low-temperature conditions introduce multiple technical hurdles that affect system performance, durability, and economic viability.

The primary challenge stems from the fundamental electrochemical properties of AEM materials at reduced temperatures. As temperatures decrease, ion conductivity in the membrane diminishes substantially, leading to increased ohmic resistance and reduced overall system efficiency. Studies indicate that AEM conductivity can decrease by 30-50% when operating at 0°C compared to standard operating temperatures (50-60°C).

Water management becomes particularly problematic in sub-zero environments. The risk of freezing within the system components can cause mechanical damage to the membrane, catalyst layers, and flow channels. Even at temperatures slightly above freezing, water transport mechanisms through the membrane are significantly hindered, affecting reaction kinetics at the electrode-membrane interface.

Catalyst activity presents another critical challenge. Low-temperature operation reduces reaction kinetics for both hydrogen evolution and oxygen evolution reactions. This necessitates higher overpotentials to maintain production rates, further decreasing system efficiency. Platinum-group metal catalysts show less severe activity drops compared to non-precious alternatives, creating a cost-performance trade-off that becomes more pronounced in cold conditions.

The mechanical properties of AEM materials also change unfavorably at low temperatures. Membranes typically become less flexible and more brittle, increasing the risk of cracking during thermal cycling. This mechanical stress accelerates degradation and shortens the operational lifetime of the electrolyzer stack.

Start-up procedures become considerably more complex and energy-intensive in cold climates. Systems require preheating mechanisms to reach minimum operational temperatures, consuming additional energy and extending start-up times. This reduces the responsiveness of AEM electrolyzers to fluctuating renewable energy inputs, limiting their effectiveness in grid-balancing applications.

Balance-of-plant components face their own set of challenges. Pumps, valves, sensors, and control systems must be rated for low-temperature operation, often requiring specialized materials and designs. Heat exchangers must be properly sized to maintain thermal stability, while insulation requirements increase system complexity and footprint.

The combined effect of these challenges results in significantly higher operational costs in cold climates. Energy consumption increases due to both reduced efficiency and additional heating requirements, while maintenance intervals typically shorten due to accelerated degradation mechanisms. These factors currently limit the geographical deployment potential of AEM electrolyzers in regions with extended cold seasons.

Current Solutions for Low-Temperature AEM Operation

01 Electrode materials for low-temperature AEM electrolyzers

Specialized electrode materials can enhance the performance of anion exchange membrane (AEM) electrolyzers at low temperatures. These materials include advanced catalysts and electrode structures that maintain high efficiency despite reduced kinetics at lower temperatures. The electrodes are designed to minimize activation energy requirements and improve ion conductivity, allowing for effective hydrogen production even when operating below standard temperatures.- Membrane materials for low-temperature AEM electrolyzers: Advanced membrane materials are crucial for efficient low-temperature operation of anion exchange membrane (AEM) electrolyzers. These materials are designed to maintain high ionic conductivity and mechanical stability at lower temperatures, reducing energy requirements while enhancing durability. Specialized polymer compositions with improved alkaline stability allow for effective hydroxide ion transport even at reduced operating temperatures, which is essential for maintaining electrolyzer efficiency.

- Catalyst optimization for cold-start and low-temperature operation: Novel catalyst formulations enable AEM electrolyzers to operate efficiently at lower temperatures. These catalysts feature enhanced kinetics that reduce activation energy requirements, allowing for faster reaction rates even in cold conditions. Nanostructured materials with high surface area and specialized dopants improve hydrogen evolution and oxygen evolution reactions at reduced temperatures, addressing one of the key challenges in low-temperature electrolyzer operation.

- System design modifications for thermal management: Specialized system architectures for AEM electrolyzers incorporate thermal management features that enable efficient low-temperature operation. These designs include integrated heating elements, insulation systems, and thermal circulation pathways that maintain optimal operating conditions despite lower ambient temperatures. Advanced control systems continuously monitor and adjust operating parameters to ensure stable performance during cold starts and low-temperature operation cycles.

- Electrolyte composition for improved low-temperature conductivity: Tailored electrolyte formulations enhance ionic conductivity at lower temperatures in AEM electrolyzers. These specialized solutions contain additives that lower the freezing point and maintain optimal viscosity characteristics in cold conditions. Some formulations incorporate anti-freezing compounds and ionic conductivity enhancers that specifically address the challenges of low-temperature operation, ensuring efficient ion transport across the membrane even when thermal energy is reduced.

- Electrode structure optimization for cold environments: Advanced electrode designs feature specialized structures that maintain high performance in low-temperature conditions. These electrodes incorporate porous architectures with optimized hydrophobicity/hydrophilicity balance to manage water transport at reduced temperatures. Multi-layered configurations with gradient structures help maintain reaction kinetics and mass transport efficiency despite the challenges posed by colder operating environments, ensuring consistent hydrogen production even at lower temperatures.

02 Membrane modifications for cold-weather operation

Modifications to anion exchange membranes can improve their conductivity and stability at low temperatures. These modifications include incorporating specific functional groups, adjusting membrane thickness, and using composite structures that maintain ion transport capabilities in cold conditions. Enhanced membranes prevent performance degradation that typically occurs when temperature decreases, ensuring consistent electrolysis efficiency year-round.Expand Specific Solutions03 Electrolyte composition for sub-zero operation

Specialized electrolyte formulations can prevent freezing and maintain ionic conductivity at very low temperatures. These electrolytes often contain antifreeze compounds, specific salt concentrations, or additives that lower the freezing point while preserving electrochemical performance. The optimized compositions ensure that AEM electrolyzers can continue functioning efficiently even in cold environments where standard systems would fail.Expand Specific Solutions04 Thermal management systems for AEM electrolyzers

Integrated thermal management systems help maintain optimal operating conditions for AEM electrolyzers in cold environments. These systems may include insulation, controlled heating elements, heat exchangers, or waste heat recovery mechanisms. By regulating temperature within the electrolyzer stack, these systems prevent performance losses and component damage that could occur during low-temperature operation, while minimizing additional energy consumption.Expand Specific Solutions05 System control strategies for temperature fluctuations

Advanced control algorithms and operational strategies can optimize AEM electrolyzer performance during temperature variations. These approaches include adaptive power management, predictive temperature compensation, and dynamic operating parameter adjustments. The control systems monitor conditions in real-time and modify electrolyzer settings to maintain efficiency and protect components when operating in cold environments, ensuring reliable hydrogen production regardless of ambient temperature changes.Expand Specific Solutions

Leading Companies in Cold-Resistant Electrolyzer Development

The AEM electrolyzer market for low-temperature operation in cold climates is in its early growth stage, with significant research momentum but limited commercial deployment. Market size is expanding as hydrogen economy initiatives gain traction globally, though still representing a niche segment within the broader electrolyzer market. Technical maturity varies across players, with companies like Dioxide Materials and Asahi Kasei leading commercial development of specialized membranes and catalysts for cold-climate operation. Research institutions including California Institute of Technology, Technical University of Denmark, and University of Maryland are advancing fundamental solutions to ion conductivity challenges at low temperatures. Industrial giants such as Air Liquide, Linde, and Siemens Gamesa are strategically positioning themselves in this space, recognizing the potential for widespread adoption in regions with seasonal temperature variations.

Dioxide Materials, Inc.

Uchicago Argonne LLC

Key Innovations in Cold-Resistant Membrane Technologies

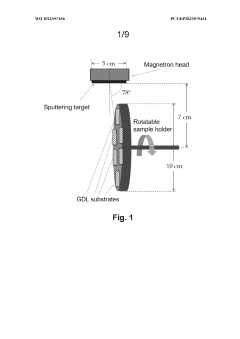

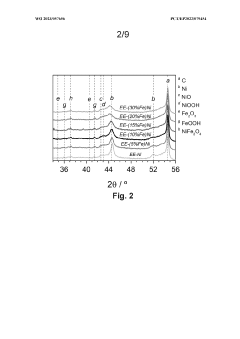

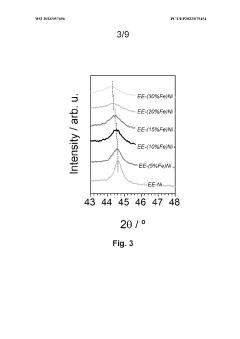

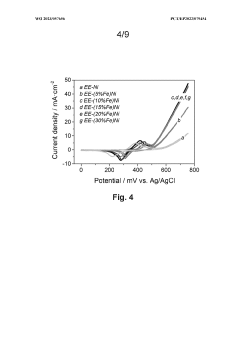

- A porous, layered metal alloy electrocatalyst electrode is developed using magnetron sputtering in oblique angle deposition geometry, eliminating the need for ionomers and incorporating a NiFe alloy with controlled composition and porosity, deposited onto a macroporous gas diffusion layer, enhancing electrochemical activity and stability.

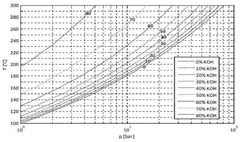

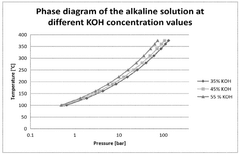

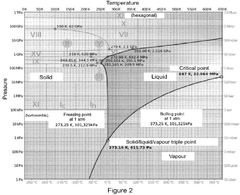

- A high temperature and pressure alkaline electrolysis method using a reversible cell with multilayer electrodes and a hydrophobic layer, where the aqueous alkaline solution of potassium hydroxide is heated and pressurized to maintain the liquid state, allowing efficient hydrogen and oxygen production.

Energy Efficiency Considerations in Cold Climate Operation

Operating AEM electrolyzers in cold climates presents significant energy efficiency challenges that must be addressed through careful system design and operational strategies. The energy consumption of these systems increases substantially at lower temperatures due to decreased ionic conductivity in the membrane and slower reaction kinetics. Studies indicate that operating an AEM electrolyzer at 0°C can require up to 30% more energy input compared to operation at standard temperatures (20-25°C).

Heat management becomes a critical factor in cold climate operation. The initial heating of the system from sub-zero temperatures requires considerable energy input, creating an unfavorable startup energy profile. This challenge is particularly pronounced in remote or off-grid applications where energy resources may already be constrained. Implementing effective insulation systems can reduce heat loss by 40-60%, significantly improving overall system efficiency.

Thermal integration strategies offer promising solutions for enhancing energy efficiency. Waste heat recovery systems can capture and recirculate thermal energy from the electrolyzer operation itself, which typically generates heat during the electrolysis process. Advanced thermal integration with other processes or facilities nearby can create symbiotic energy relationships, where waste heat from industrial processes provides the necessary thermal energy for electrolyzer operation.

The balance between electrical and thermal energy inputs requires careful optimization in cold climates. Research indicates that preheating the water supply and maintaining optimal operating temperatures through controlled heating elements can improve overall system efficiency by 15-25%. However, these heating systems themselves consume energy, necessitating sophisticated control algorithms that balance temperature maintenance against additional energy consumption.

Renewable energy integration presents both challenges and opportunities for cold climate operation. Wind and solar resources often exhibit seasonal variations that may coincide with the coldest periods, potentially limiting available power when heating demands are highest. Energy storage solutions become particularly valuable in this context, allowing excess renewable energy to be stored during favorable periods and utilized during extreme cold conditions.

Advanced materials development focuses on creating membrane and catalyst systems with improved low-temperature performance characteristics. Recent innovations in membrane technology have demonstrated the potential to reduce the temperature-dependent efficiency losses by up to 20%, representing a significant advancement for cold climate applications. These materials innovations, combined with system-level thermal management strategies, will be essential for achieving economically viable AEM electrolyzer operation in cold climate regions.

Integration with Renewable Energy in Arctic Environments

The integration of AEM electrolyzers with renewable energy sources presents unique challenges and opportunities in Arctic environments. Wind and solar power generation in these regions follows distinct seasonal patterns, with solar energy virtually nonexistent during polar winters while wind resources often peak during colder months. This complementary relationship creates a foundation for hybrid renewable systems specifically designed for cold climate operation.

Arctic renewable energy infrastructure must contend with extreme conditions including ice accumulation, permafrost, and structural challenges from thermal expansion and contraction. These factors necessitate specialized engineering approaches for both the energy generation systems and their integration with electrolyzers. Thermal management becomes a critical consideration, as waste heat from electrolyzers can potentially be redirected to prevent freezing in renewable energy components.

Recent pilot projects in northern Canada, Alaska, and Scandinavia have demonstrated promising results for integrated systems. The Raglan Mine project in Quebec successfully paired wind turbines with hydrogen production facilities, utilizing excess renewable energy for hydrogen generation while maintaining operations at temperatures as low as -40°C. Similar initiatives in Norway have incorporated hydropower alongside wind resources to ensure consistent energy supply despite seasonal fluctuations.

Energy storage represents a fundamental challenge in Arctic renewable integration. Hydrogen produced during peak renewable generation periods can serve as both an energy carrier and seasonal storage medium, addressing the intermittency issues inherent to Arctic renewable resources. This approach enables communities to maintain energy independence during extended periods of limited renewable availability.

Grid stability considerations are particularly relevant in remote Arctic communities that typically operate on isolated microgrids. AEM electrolyzers with enhanced cold-start capabilities can provide valuable grid services, including frequency regulation and load balancing. When properly integrated with renewable sources, these systems can improve overall grid resilience while reducing dependence on diesel generators commonly used in remote northern settlements.

Economic viability remains a significant hurdle, with initial capital costs approximately 30-40% higher than comparable installations in temperate regions due to specialized equipment requirements and logistical challenges. However, operational cost savings from reduced diesel imports can potentially offset these expenses over system lifetimes, particularly as renewable technology costs continue to decline and carbon pricing mechanisms expand globally.