System Efficiency Mapping Across Load Profiles In AEM Electrolyzers

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AEM Electrolyzer Technology Background and Objectives

Anion Exchange Membrane (AEM) electrolyzers represent a promising technology in the hydrogen production landscape, emerging as a potential bridge between the established alkaline and PEM (Proton Exchange Membrane) technologies. The development of AEM electrolyzers can be traced back to the early 2000s, with significant acceleration in research and development efforts over the past decade. This technology aims to combine the cost advantages of alkaline systems with the operational benefits of PEM systems, creating a more economically viable solution for green hydrogen production.

The evolution of AEM technology has been driven by the global push for decarbonization and the recognition of hydrogen as a critical energy carrier in a sustainable energy ecosystem. Initial iterations faced challenges with membrane stability and performance, but recent advancements in materials science have significantly improved durability and efficiency metrics. The technology has progressed from laboratory-scale demonstrations to pilot projects, with commercial deployment beginning to emerge in specialized applications.

The primary technical objective for AEM electrolyzer development is to optimize system efficiency across varying load profiles, which is crucial for integration with intermittent renewable energy sources. Current research focuses on understanding and improving the electrochemical performance under dynamic operating conditions, as fluctuating power inputs from wind or solar sources create unique challenges for electrolysis systems.

Specifically, researchers aim to map efficiency patterns across different load scenarios to identify optimal operating parameters and potential areas for improvement. This includes investigating catalyst behavior, membrane response, and overall system dynamics under varying current densities and power inputs. The goal is to develop AEM systems capable of maintaining high efficiency (>70%) even during rapid load changes, while ensuring membrane and catalyst longevity.

Additional objectives include reducing system costs to below $500/kW, extending operational lifetimes to >50,000 hours, and achieving hydrogen production rates comparable to established technologies (>1 Nm³/h per cell stack area). These targets are considered essential for commercial viability and market adoption.

The broader context of this research encompasses the growing hydrogen economy, where efficient electrolysis technologies are fundamental to establishing hydrogen as a mainstream energy vector. AEM technology, if successfully optimized for variable load operation, could play a pivotal role in enabling cost-effective green hydrogen production at scale, supporting applications ranging from industrial processes to energy storage and transportation.

The evolution of AEM technology has been driven by the global push for decarbonization and the recognition of hydrogen as a critical energy carrier in a sustainable energy ecosystem. Initial iterations faced challenges with membrane stability and performance, but recent advancements in materials science have significantly improved durability and efficiency metrics. The technology has progressed from laboratory-scale demonstrations to pilot projects, with commercial deployment beginning to emerge in specialized applications.

The primary technical objective for AEM electrolyzer development is to optimize system efficiency across varying load profiles, which is crucial for integration with intermittent renewable energy sources. Current research focuses on understanding and improving the electrochemical performance under dynamic operating conditions, as fluctuating power inputs from wind or solar sources create unique challenges for electrolysis systems.

Specifically, researchers aim to map efficiency patterns across different load scenarios to identify optimal operating parameters and potential areas for improvement. This includes investigating catalyst behavior, membrane response, and overall system dynamics under varying current densities and power inputs. The goal is to develop AEM systems capable of maintaining high efficiency (>70%) even during rapid load changes, while ensuring membrane and catalyst longevity.

Additional objectives include reducing system costs to below $500/kW, extending operational lifetimes to >50,000 hours, and achieving hydrogen production rates comparable to established technologies (>1 Nm³/h per cell stack area). These targets are considered essential for commercial viability and market adoption.

The broader context of this research encompasses the growing hydrogen economy, where efficient electrolysis technologies are fundamental to establishing hydrogen as a mainstream energy vector. AEM technology, if successfully optimized for variable load operation, could play a pivotal role in enabling cost-effective green hydrogen production at scale, supporting applications ranging from industrial processes to energy storage and transportation.

Market Analysis for AEM Electrolyzer Applications

The global market for AEM (Anion Exchange Membrane) electrolyzers is experiencing significant growth, driven by the increasing demand for green hydrogen as a clean energy carrier. Current market valuations indicate that the hydrogen production equipment market is projected to reach $13.5 billion by 2025, with AEM technology capturing an expanding share due to its cost advantages over PEM (Proton Exchange Membrane) and operational benefits over alkaline systems.

The industrial sector represents the largest application segment for AEM electrolyzers, with refineries and ammonia production facilities seeking to decarbonize their hydrogen feedstock. This market is expected to grow at a CAGR of 14.8% through 2030, as industrial players face increasing regulatory pressure to reduce carbon emissions. The European Union's hydrogen strategy, which aims for 40GW of electrolyzer capacity by 2030, is a significant market driver.

Transportation applications form the fastest-growing segment, with a projected CAGR of 21.3% from 2023-2028. Hydrogen refueling infrastructure development, particularly in Japan, South Korea, Germany, and California, is creating substantial demand for efficient electrolyzer systems that can operate under variable load conditions – a key strength of AEM technology when properly optimized.

Energy storage applications represent another promising market, with grid-scale projects increasingly incorporating hydrogen production to manage renewable energy intermittency. This segment is expected to grow as renewable penetration increases, with particular interest in AEM systems that can efficiently ramp production in response to excess renewable generation.

Regional analysis shows Europe leading AEM electrolyzer adoption with approximately 45% market share, driven by aggressive decarbonization policies and substantial funding initiatives like the European Clean Hydrogen Alliance. Asia-Pacific follows with 30% market share, with China, Japan, and South Korea making significant investments in hydrogen infrastructure.

Market barriers include competition from established alkaline and PEM technologies, which currently dominate industrial installations. However, AEM's potential for lower capital costs (20-30% less than PEM) and better efficiency across variable loads is creating competitive differentiation, particularly for distributed and intermittent renewable energy applications.

Customer requirements increasingly emphasize system efficiency across diverse operational profiles, with specifications commonly demanding >70% system efficiency at rated capacity and >60% efficiency at 20% load. This highlights the critical importance of efficiency mapping across load profiles as a key market differentiator for AEM electrolyzer manufacturers seeking competitive advantage.

The industrial sector represents the largest application segment for AEM electrolyzers, with refineries and ammonia production facilities seeking to decarbonize their hydrogen feedstock. This market is expected to grow at a CAGR of 14.8% through 2030, as industrial players face increasing regulatory pressure to reduce carbon emissions. The European Union's hydrogen strategy, which aims for 40GW of electrolyzer capacity by 2030, is a significant market driver.

Transportation applications form the fastest-growing segment, with a projected CAGR of 21.3% from 2023-2028. Hydrogen refueling infrastructure development, particularly in Japan, South Korea, Germany, and California, is creating substantial demand for efficient electrolyzer systems that can operate under variable load conditions – a key strength of AEM technology when properly optimized.

Energy storage applications represent another promising market, with grid-scale projects increasingly incorporating hydrogen production to manage renewable energy intermittency. This segment is expected to grow as renewable penetration increases, with particular interest in AEM systems that can efficiently ramp production in response to excess renewable generation.

Regional analysis shows Europe leading AEM electrolyzer adoption with approximately 45% market share, driven by aggressive decarbonization policies and substantial funding initiatives like the European Clean Hydrogen Alliance. Asia-Pacific follows with 30% market share, with China, Japan, and South Korea making significant investments in hydrogen infrastructure.

Market barriers include competition from established alkaline and PEM technologies, which currently dominate industrial installations. However, AEM's potential for lower capital costs (20-30% less than PEM) and better efficiency across variable loads is creating competitive differentiation, particularly for distributed and intermittent renewable energy applications.

Customer requirements increasingly emphasize system efficiency across diverse operational profiles, with specifications commonly demanding >70% system efficiency at rated capacity and >60% efficiency at 20% load. This highlights the critical importance of efficiency mapping across load profiles as a key market differentiator for AEM electrolyzer manufacturers seeking competitive advantage.

Technical Challenges in AEM Electrolyzer Efficiency

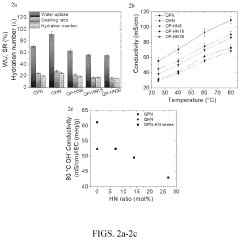

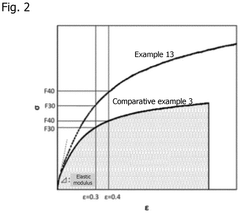

AEM (Anion Exchange Membrane) electrolyzers face significant efficiency challenges across varying load profiles, presenting complex technical hurdles for widespread implementation. The primary challenge stems from the membrane's inherent ionic conductivity limitations, which directly impact system efficiency, particularly during dynamic operation. Unlike PEM (Proton Exchange Membrane) systems, AEM technology exhibits pronounced efficiency degradation when operating outside optimal load ranges, typically between 40-80% of rated capacity.

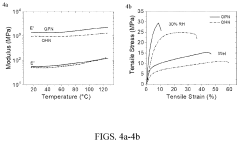

Material stability presents another critical challenge, as hydroxide-conducting polymers in AEM systems demonstrate accelerated degradation under fluctuating load conditions. This degradation manifests as reduced membrane conductivity and increased ohmic resistance, resulting in efficiency losses of 5-15% after just 1,000 hours of operation under variable loads. The chemical stability of AEM materials in highly alkaline environments remains problematic, especially during rapid load transitions that create localized pH and temperature gradients.

Catalyst utilization efficiency across different load profiles represents a significant technical barrier. At low loads (below 30% capacity), catalyst activity decreases disproportionately, while high loads (above 90%) accelerate catalyst degradation through mechanisms including agglomeration and detachment. Current non-precious metal catalysts used in AEM systems show particularly poor performance stability under fluctuating conditions compared to their precious metal counterparts in PEM systems.

Water management across varying load profiles introduces additional complexity. During low-load operation, insufficient water transport leads to membrane dehydration and increased resistance, while high-load operation can cause flooding in gas diffusion layers, blocking active sites. This bidirectional challenge requires sophisticated control systems that can adapt to changing conditions, adding complexity and cost to AEM electrolyzer systems.

Heat management presents particular difficulties in AEM systems operating under variable loads. The thermal response lag during load transitions creates temperature gradients that affect local reaction kinetics and membrane conductivity. Current thermal management systems struggle to maintain optimal operating temperatures (typically 50-60°C) during rapid load changes, resulting in temporary efficiency losses of 3-8% during transitions.

System control and balance of plant components face significant challenges in adapting to variable renewable energy inputs. The response time of AEM electrolyzers to load changes (typically 10-30 seconds) creates mismatches with rapid fluctuations in renewable power sources, necessitating complex power electronics and control algorithms to maintain stable operation while preserving efficiency across the operational envelope.

Material stability presents another critical challenge, as hydroxide-conducting polymers in AEM systems demonstrate accelerated degradation under fluctuating load conditions. This degradation manifests as reduced membrane conductivity and increased ohmic resistance, resulting in efficiency losses of 5-15% after just 1,000 hours of operation under variable loads. The chemical stability of AEM materials in highly alkaline environments remains problematic, especially during rapid load transitions that create localized pH and temperature gradients.

Catalyst utilization efficiency across different load profiles represents a significant technical barrier. At low loads (below 30% capacity), catalyst activity decreases disproportionately, while high loads (above 90%) accelerate catalyst degradation through mechanisms including agglomeration and detachment. Current non-precious metal catalysts used in AEM systems show particularly poor performance stability under fluctuating conditions compared to their precious metal counterparts in PEM systems.

Water management across varying load profiles introduces additional complexity. During low-load operation, insufficient water transport leads to membrane dehydration and increased resistance, while high-load operation can cause flooding in gas diffusion layers, blocking active sites. This bidirectional challenge requires sophisticated control systems that can adapt to changing conditions, adding complexity and cost to AEM electrolyzer systems.

Heat management presents particular difficulties in AEM systems operating under variable loads. The thermal response lag during load transitions creates temperature gradients that affect local reaction kinetics and membrane conductivity. Current thermal management systems struggle to maintain optimal operating temperatures (typically 50-60°C) during rapid load changes, resulting in temporary efficiency losses of 3-8% during transitions.

System control and balance of plant components face significant challenges in adapting to variable renewable energy inputs. The response time of AEM electrolyzers to load changes (typically 10-30 seconds) creates mismatches with rapid fluctuations in renewable power sources, necessitating complex power electronics and control algorithms to maintain stable operation while preserving efficiency across the operational envelope.

Current Efficiency Mapping Methodologies

01 Electrode materials and configurations for AEM electrolyzers

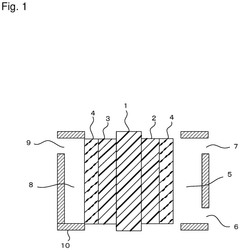

The efficiency of anion exchange membrane (AEM) electrolyzers can be significantly improved through optimized electrode materials and configurations. Advanced catalysts such as nickel-based alloys and noble metal nanoparticles enhance the electrochemical reactions at lower overpotentials. Electrode structures with high surface area and optimized porosity facilitate better ion transport and gas evolution, while reducing electrical resistance across the cell. These improvements in electrode design directly contribute to higher system efficiency and reduced energy consumption during hydrogen production.- AEM electrolyzer design and materials: Anion Exchange Membrane (AEM) electrolyzers utilize specialized membrane materials and electrode designs to enhance efficiency. These systems incorporate advanced catalysts and membrane materials that facilitate ion transport while minimizing resistance. The design focuses on optimizing the interface between electrodes and membranes to improve overall system performance and energy conversion efficiency.

- Thermal management and heat recovery systems: Efficient thermal management is crucial for AEM electrolyzer performance. Systems incorporate heat exchangers and thermal integration strategies to maintain optimal operating temperatures and recover waste heat. Advanced cooling mechanisms prevent efficiency losses due to overheating while heat recovery systems repurpose thermal energy for preheating feedwater or other processes, significantly improving overall system efficiency.

- Power supply and electrical optimization: Power conditioning and electrical optimization play vital roles in AEM electrolyzer efficiency. Systems employ advanced power electronics, including DC-DC converters and rectifiers, to provide stable and appropriate power input. Dynamic response capabilities allow for operation with variable renewable energy sources, while control systems optimize voltage and current parameters to maintain peak efficiency across varying load conditions.

- System integration and balance of plant: Comprehensive system integration approaches enhance AEM electrolyzer efficiency through optimized balance of plant components. These systems incorporate water purification, gas separation, compression, and storage subsystems designed to work harmoniously. Advanced control algorithms coordinate operations between components, reducing parasitic loads and energy losses while ensuring stable operation across varying production demands.

- Catalyst and electrode innovations: Novel catalyst formulations and electrode structures significantly impact AEM electrolyzer efficiency. Advanced non-precious metal catalysts reduce activation energy requirements while specialized electrode architectures enhance reactant transport and bubble management. Three-dimensional electrode designs increase active surface area and facilitate efficient mass transport, while nanostructured materials improve catalytic activity and durability under operating conditions.

02 Membrane technology advancements for AEM systems

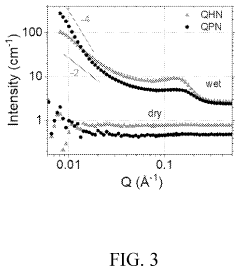

Innovations in anion exchange membrane technology are crucial for improving electrolyzer efficiency. Advanced membrane materials with enhanced ionic conductivity and chemical stability allow for more efficient hydroxide ion transport while maintaining structural integrity under alkaline conditions. Thinner membranes with reinforced structures reduce ohmic resistance while preventing gas crossover. Modified membrane surfaces with functional groups improve water management and ion exchange capacity, leading to higher current densities and overall system efficiency in hydrogen production applications.Expand Specific Solutions03 Thermal management and system integration techniques

Effective thermal management is essential for maintaining optimal operating conditions in AEM electrolyzers. Advanced cooling systems that regulate temperature uniformity across cell stacks prevent hotspots and membrane degradation. Heat recovery systems capture and utilize waste heat, improving overall system efficiency. Integrated balance-of-plant components, including water purification systems, gas separation units, and power conditioning equipment, are designed to work synergistically with the electrolyzer stack. This comprehensive system integration approach minimizes energy losses and maximizes hydrogen production efficiency.Expand Specific Solutions04 Control systems and operational strategies

Sophisticated control systems and operational strategies significantly enhance AEM electrolyzer efficiency. Advanced monitoring systems with real-time feedback loops adjust operating parameters such as current density, temperature, and feed water flow rates to maintain optimal performance. Dynamic response capabilities allow systems to operate efficiently under variable loads, making them suitable for integration with renewable energy sources. Predictive maintenance algorithms identify potential issues before they affect performance, while automated startup and shutdown sequences minimize stress on components and extend system lifetime while maintaining high efficiency.Expand Specific Solutions05 Electrolyte composition and water management

Optimized electrolyte compositions play a critical role in AEM electrolyzer efficiency. Carefully formulated alkaline solutions with specific ion concentrations enhance ionic conductivity while minimizing side reactions and membrane degradation. Additives that improve wettability and reduce surface tension facilitate better gas bubble release from electrode surfaces. Advanced water management systems ensure proper hydration of the membrane while preventing flooding or drying, maintaining consistent performance across varying operating conditions. Purification systems that remove contaminants from feed water prevent catalyst poisoning and membrane fouling, preserving long-term efficiency.Expand Specific Solutions

Key Industry Players in AEM Electrolyzer Development

The AEM electrolyzer market is currently in a growth phase, characterized by increasing adoption as green hydrogen gains prominence in the energy transition landscape. The market size is expanding rapidly, projected to reach significant scale by 2030 as hydrogen becomes central to decarbonization strategies. Technologically, AEM electrolyzers are advancing toward commercial maturity, with companies at varying development stages. Enapter Srl leads with modular AEM solutions, while Shanghai Zhizhen and Sungrow Hydrogen focus on core components development. Academic institutions like Delft University and National University of Singapore contribute fundamental research, while established industrial players including ABB Group, Schneider Electric, and Panasonic are entering the space with system integration capabilities. The competitive landscape reflects a mix of specialized startups and diversifying energy conglomerates pursuing efficiency improvements across different load profiles.

Enapter Srl

Technical Solution: Enapter has developed a proprietary Anion Exchange Membrane (AEM) electrolyzer technology that focuses on modular, scalable hydrogen production. Their AEM electrolyzers employ a unique approach to system efficiency mapping across varying load profiles, utilizing patented electrocatalysts and membrane electrode assemblies that maintain high efficiency even during partial load operation. Enapter's system incorporates real-time monitoring and adaptive control algorithms that continuously adjust operational parameters based on the current load profile, enabling optimal performance across the entire operational range. Their EL 4.0 electrolyzer modules feature dynamic response capabilities that allow for rapid adaptation to fluctuating renewable energy inputs while maintaining efficiency. The company has implemented a sophisticated thermal management system that regulates operating temperatures according to load conditions, significantly improving overall system efficiency by reducing energy losses during load transitions.

Strengths: Highly modular design allows for flexible scaling and distributed hydrogen production; superior partial-load efficiency compared to traditional electrolyzers; rapid response to load changes makes it ideal for integration with intermittent renewable energy sources. Weaknesses: Higher upfront capital costs compared to traditional alkaline systems; relatively newer technology with less long-term operational data available in industrial settings.

Shanghai Zhizhen New Energy Co., Ltd.

Technical Solution: Shanghai Zhizhen New Energy has developed advanced AEM electrolyzer systems with sophisticated load profile management capabilities. Their technology incorporates a multi-stage power conditioning system that optimizes electrical input across various load conditions, maintaining efficiency even during significant power fluctuations. The company's proprietary membrane technology features enhanced ionic conductivity that performs consistently across different current densities, addressing one of the key challenges in electrolyzer efficiency mapping. Their systems employ dynamic pressure regulation that automatically adjusts based on the operational load, optimizing gas production rates while minimizing energy consumption. Shanghai Zhizhen has also implemented an intelligent control system that uses machine learning algorithms to predict optimal operating parameters based on historical performance data across different load profiles, continuously improving system efficiency through operational learning.

Strengths: Excellent performance stability across wide load ranges (10-100%); integrated power electronics specifically designed for renewable energy integration; comprehensive data analytics platform for performance optimization. Weaknesses: Limited deployment in large-scale industrial applications; higher maintenance requirements compared to conventional technologies; system complexity requires specialized technical expertise for operation and maintenance.

Critical Patents and Research in Load-Responsive AEM Systems

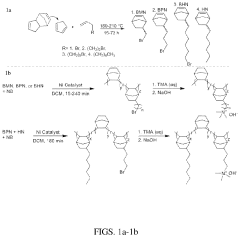

Vinyl-addition polynorbornene cationic compositions and uses thereof in anion exchange membrane fuel cells and electrolyzers

PatentPendingUS20240132647A1

Innovation

- The development of anion exchange polymeric compositions based on a polynorbornene copolymer structure with quaternary ammonium groups and optional hydrocarbon or fluorine-substituted alkyl groups, which are uncrosslinked, enhancing hydroxide conductivity and mechanical strength while maintaining low water uptake.

Ion exchange membrane, polyolefin-based porous membrane, membrane electrode assembly, water electrolysis device, and method for producing polyolefin-based porous membrane

PatentPendingEP4506397A1

Innovation

- The development of an ion-exchange membrane with a polyolefin-based porous support, specifically designed to have tear resistance and toughness within certain ranges, reduces membrane resistance and enhances the membrane's tenacity, thereby improving the lifespan of water electrolyzers.

Cost-Benefit Analysis of Variable Load Operation

Operating AEM electrolyzers under variable load conditions presents a complex economic equation that must be carefully evaluated. The cost-benefit analysis reveals that while variable load operation offers significant advantages in grid integration scenarios, it also introduces operational challenges that impact overall system economics. Primary benefits include the ability to utilize low-cost electricity during off-peak periods, which can reduce hydrogen production costs by 15-30% compared to constant load operation. Additionally, electrolyzers operating in grid-balancing services can generate supplementary revenue streams through demand response programs and ancillary services, potentially offsetting 5-12% of operational costs annually.

However, these benefits must be weighed against several cost factors. Variable load operation typically reduces system lifetime by 10-15% due to accelerated degradation of membranes and catalysts from frequent power cycling. Maintenance costs increase by approximately 8-20% compared to steady-state operation, primarily due to more frequent component replacements and increased monitoring requirements. The efficiency losses during transient operations further impact economics, with efficiency decreases of 3-7% observed during rapid load changes.

Capital expenditure considerations also play a crucial role in this analysis. AEM electrolyzers designed specifically for variable load operation require more robust power electronics, advanced control systems, and sometimes larger balance-of-plant components, increasing initial investment by 10-25%. However, these systems typically demonstrate better long-term performance under variable conditions, potentially justifying the higher upfront costs through extended operational lifespans.

The economic breakeven point for variable load operation depends heavily on electricity market dynamics. In markets with high price volatility (where peak/off-peak price differentials exceed 40%), variable operation becomes economically advantageous despite higher maintenance costs. Conversely, in markets with stable electricity pricing, constant load operation often remains more cost-effective. Modeling suggests that with current technology, variable load operation becomes financially advantageous when electricity price variations exceed €30-40/MWh on a regular basis.

Future technological improvements are expected to shift this equation further in favor of variable operation. Advances in membrane materials and catalyst formulations specifically designed for cycling conditions could reduce degradation rates by 40-60%, while next-generation power electronics may decrease efficiency losses during transitions by up to 50%. These developments would significantly improve the cost-benefit ratio for variable load operation, potentially making it the preferred operational strategy across most market conditions by 2030.

However, these benefits must be weighed against several cost factors. Variable load operation typically reduces system lifetime by 10-15% due to accelerated degradation of membranes and catalysts from frequent power cycling. Maintenance costs increase by approximately 8-20% compared to steady-state operation, primarily due to more frequent component replacements and increased monitoring requirements. The efficiency losses during transient operations further impact economics, with efficiency decreases of 3-7% observed during rapid load changes.

Capital expenditure considerations also play a crucial role in this analysis. AEM electrolyzers designed specifically for variable load operation require more robust power electronics, advanced control systems, and sometimes larger balance-of-plant components, increasing initial investment by 10-25%. However, these systems typically demonstrate better long-term performance under variable conditions, potentially justifying the higher upfront costs through extended operational lifespans.

The economic breakeven point for variable load operation depends heavily on electricity market dynamics. In markets with high price volatility (where peak/off-peak price differentials exceed 40%), variable operation becomes economically advantageous despite higher maintenance costs. Conversely, in markets with stable electricity pricing, constant load operation often remains more cost-effective. Modeling suggests that with current technology, variable load operation becomes financially advantageous when electricity price variations exceed €30-40/MWh on a regular basis.

Future technological improvements are expected to shift this equation further in favor of variable operation. Advances in membrane materials and catalyst formulations specifically designed for cycling conditions could reduce degradation rates by 40-60%, while next-generation power electronics may decrease efficiency losses during transitions by up to 50%. These developments would significantly improve the cost-benefit ratio for variable load operation, potentially making it the preferred operational strategy across most market conditions by 2030.

Integration Strategies with Renewable Energy Sources

The integration of AEM (Anion Exchange Membrane) electrolyzers with renewable energy sources represents a critical pathway toward sustainable hydrogen production systems. Renewable energy sources such as solar photovoltaic (PV) and wind power offer complementary generation profiles that can be strategically paired with electrolyzer operations to maximize system efficiency. Solar energy provides predictable daytime generation peaks, while wind power often exhibits higher output during evening and overnight periods, creating opportunities for extended operational hours.

Variable renewable energy (VRE) output presents unique challenges for AEM electrolyzer integration, as these systems demonstrate different efficiency characteristics across varying load profiles. Implementing advanced forecasting algorithms for renewable generation can enable proactive adjustment of electrolyzer operational parameters, allowing systems to prepare for upcoming changes in power availability. This predictive approach minimizes efficiency losses during transient operations and extends stack lifetime by reducing thermal and mechanical stress.

Buffer technologies play an essential role in smoothing the intermittency of renewable sources. Short-duration battery storage systems can provide power quality improvements and rapid response capabilities, while hydrogen storage itself serves as a longer-duration energy buffer. Hybrid approaches combining multiple renewable sources with appropriate storage technologies create more consistent power availability for electrolyzer operation, enabling higher capacity factors and improved economic performance.

Grid-connected configurations offer additional flexibility through bidirectional power flow capabilities. During periods of excess renewable generation, electrolyzers can increase hydrogen production, while during shortfalls, systems can modulate production or potentially provide grid services through responsive load management. Advanced power electronics with high-speed response capabilities are crucial for managing the interface between renewable generators and electrolyzer stacks, ensuring optimal power conditioning and protection against harmful transients.

Microgrid architectures present particularly promising integration frameworks, especially for remote or island applications. These systems can incorporate local renewable resources, electrolyzer units, and storage technologies within a coordinated control structure that optimizes for both hydrogen production and local energy needs. The development of standardized integration protocols and modular system designs will accelerate deployment across diverse geographical and operational contexts.

Cost optimization remains a fundamental consideration, with levelized cost of hydrogen (LCOH) calculations increasingly favoring renewable-powered electrolysis as renewable generation costs continue to decline. Strategic siting decisions that co-locate electrolyzers with high-quality renewable resources can significantly improve project economics through reduced transmission requirements and higher capacity utilization rates.

Variable renewable energy (VRE) output presents unique challenges for AEM electrolyzer integration, as these systems demonstrate different efficiency characteristics across varying load profiles. Implementing advanced forecasting algorithms for renewable generation can enable proactive adjustment of electrolyzer operational parameters, allowing systems to prepare for upcoming changes in power availability. This predictive approach minimizes efficiency losses during transient operations and extends stack lifetime by reducing thermal and mechanical stress.

Buffer technologies play an essential role in smoothing the intermittency of renewable sources. Short-duration battery storage systems can provide power quality improvements and rapid response capabilities, while hydrogen storage itself serves as a longer-duration energy buffer. Hybrid approaches combining multiple renewable sources with appropriate storage technologies create more consistent power availability for electrolyzer operation, enabling higher capacity factors and improved economic performance.

Grid-connected configurations offer additional flexibility through bidirectional power flow capabilities. During periods of excess renewable generation, electrolyzers can increase hydrogen production, while during shortfalls, systems can modulate production or potentially provide grid services through responsive load management. Advanced power electronics with high-speed response capabilities are crucial for managing the interface between renewable generators and electrolyzer stacks, ensuring optimal power conditioning and protection against harmful transients.

Microgrid architectures present particularly promising integration frameworks, especially for remote or island applications. These systems can incorporate local renewable resources, electrolyzer units, and storage technologies within a coordinated control structure that optimizes for both hydrogen production and local energy needs. The development of standardized integration protocols and modular system designs will accelerate deployment across diverse geographical and operational contexts.

Cost optimization remains a fundamental consideration, with levelized cost of hydrogen (LCOH) calculations increasingly favoring renewable-powered electrolysis as renewable generation costs continue to decline. Strategic siting decisions that co-locate electrolyzers with high-quality renewable resources can significantly improve project economics through reduced transmission requirements and higher capacity utilization rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!