Field Performance Benchmarks For AEM Electrolyzers In Pilot Projects

AEM Electrolyzer Technology Background and Objectives

Anion Exchange Membrane (AEM) electrolyzers represent a promising emerging technology in the hydrogen production landscape, positioned between the mature alkaline electrolyzers and the high-performance but costly Proton Exchange Membrane (PEM) systems. The development of AEM technology dates back to the early 2000s, with significant acceleration in research and development occurring over the past decade as global interest in green hydrogen production has intensified.

The evolution of AEM technology has been driven by the need to overcome limitations in traditional electrolysis methods. While alkaline electrolyzers have been commercially available for decades, they suffer from low current densities and limited dynamic operation capabilities. PEM electrolyzers offer superior performance but rely on expensive noble metal catalysts and perfluorinated membranes. AEM technology emerged as a potential "best of both worlds" solution, aiming to combine the cost advantages of alkaline systems with the performance benefits of PEM technology.

Recent technological breakthroughs in membrane materials, particularly the development of hydrocarbon-based polymers with quaternary ammonium functional groups, have significantly enhanced the stability and conductivity of AEM membranes. These advances have extended membrane lifetimes from mere hundreds of hours to several thousand hours in laboratory settings, marking a critical step toward commercial viability.

The primary technical objective for AEM electrolyzer field performance benchmarking is to validate laboratory achievements in real-world pilot projects. Specifically, these benchmarks aim to assess operational stability under variable load conditions, quantify degradation rates over extended operation periods, and evaluate overall system efficiency across different environmental conditions. Performance targets typically include achieving current densities above 1 A/cm², hydrogen production rates of 0.5-2 Nm³/h for pilot units, and system efficiencies exceeding 70% (LHV).

Another crucial objective is to establish standardized testing protocols for AEM electrolyzers, as the technology currently lacks the industry-wide standards that exist for more mature electrolyzer technologies. This standardization is essential for meaningful comparison between different manufacturers' systems and for building investor confidence in the technology.

The field performance benchmarking also seeks to identify scaling challenges as AEM technology moves from laboratory to pilot scale and eventually to commercial deployment. Understanding how performance metrics translate across different scales is vital for accurate techno-economic assessments and for identifying priority areas for further research and development.

Market Analysis for Green Hydrogen Production

The green hydrogen market is experiencing unprecedented growth, driven by global decarbonization efforts and the push for sustainable energy solutions. Current market valuations place the green hydrogen sector at approximately $2.5 billion in 2022, with projections indicating potential growth to reach $89.1 billion by 2030, representing a compound annual growth rate (CAGR) of 54.7%. This remarkable expansion reflects the increasing recognition of hydrogen's role in achieving net-zero emissions targets across various industries.

Demand for green hydrogen is primarily concentrated in sectors that are difficult to electrify directly, including heavy industry, long-haul transportation, and chemical manufacturing. Steel production, which accounts for roughly 7-9% of global CO2 emissions, represents a significant potential market for green hydrogen as manufacturers seek to decarbonize their processes. Similarly, the ammonia production industry, currently responsible for about 1.8% of global CO2 emissions, offers substantial market opportunities as it transitions from natural gas to green hydrogen feedstock.

Regional market analysis reveals Europe as the current leader in green hydrogen initiatives, with Germany, the Netherlands, and the Nordic countries at the forefront. The European Union's hydrogen strategy targets 40GW of electrolyzer capacity by 2030. Asia-Pacific, particularly Japan, South Korea, and Australia, is rapidly developing hydrogen infrastructure, with Australia positioning itself as a major future exporter. North America is gaining momentum through policy support mechanisms like the Inflation Reduction Act, which provides production tax credits for clean hydrogen.

AEM (Anion Exchange Membrane) electrolyzers represent a growing segment within this market, positioned between the mature alkaline technology and the more expensive PEM (Proton Exchange Membrane) systems. Market research indicates AEM technology could capture 15-20% of the electrolyzer market by 2030, valued at approximately $13-18 billion, if current technical challenges are addressed through successful pilot projects.

Price sensitivity remains a critical market factor, with green hydrogen production costs currently ranging from $3-8/kg depending on region and renewable electricity prices. For widespread adoption, industry analysts suggest production costs must fall below $2/kg to compete with gray hydrogen. Field performance benchmarks from pilot projects are therefore essential in demonstrating the technology's economic viability and accelerating cost reduction through scale and technological improvements.

Customer segments for green hydrogen include utility companies investing in power-to-gas applications, industrial gas suppliers, refineries transitioning to cleaner processes, and transportation companies developing hydrogen fuel cell vehicles. Each segment has distinct requirements regarding hydrogen purity, pressure, and delivery volumes that influence electrolyzer selection and deployment strategies.

Current Status and Technical Challenges of AEM Electrolyzers

Anion Exchange Membrane (AEM) electrolyzers represent a promising middle-ground technology between alkaline and PEM electrolyzers, potentially offering cost advantages without sacrificing performance. However, their current technological maturity remains significantly behind both alkaline and PEM technologies. Laboratory-scale AEM electrolyzers have demonstrated encouraging performance metrics, but field implementation in pilot projects reveals substantial challenges that must be addressed before widespread commercial adoption.

The global landscape of AEM electrolyzer development shows concentrated research efforts in Europe, North America, and parts of Asia, with several companies and research institutions making notable advancements. Current AEM systems typically operate at current densities of 0.5-1.0 A/cm², which falls short of PEM systems but exceeds traditional alkaline technology. Efficiency rates in controlled environments reach 65-75%, but field performance often degrades to 55-65% under variable operating conditions.

Durability remains a critical challenge, with most pilot projects reporting significant performance degradation after 5,000-10,000 hours of operation—far below the 50,000+ hours required for commercial viability. This degradation primarily stems from membrane stability issues, catalyst degradation, and ionomer leaching during operation. Field data indicates degradation rates of 2-5% per 1,000 operating hours, substantially higher than the target of <0.5% for commercial applications.

Another significant challenge is the limited scalability of current AEM technology. While laboratory systems operate effectively at small scales (1-10 kW), pilot projects attempting to scale to 100+ kW encounter issues with uneven current distribution, thermal management complications, and increased mechanical stress on membrane assemblies. These scaling challenges have resulted in reduced efficiency and accelerated degradation in larger systems.

Intermittent operation—critical for integration with renewable energy sources—presents additional complications. Field data shows that AEM electrolyzers experience 15-25% higher degradation rates when subjected to frequent start-stop cycles compared to steady-state operation. This poses a significant barrier to their implementation in renewable energy systems with variable output.

Cost remains both a driver and challenge for AEM technology. While materials costs are theoretically lower than PEM systems due to reduced noble metal catalyst requirements, manufacturing complexities and limited production scale currently result in system costs that fail to deliver the expected economic advantages. Current pilot-scale AEM systems demonstrate capital costs of approximately $1,000-1,500/kW, which must decrease to below $500/kW to achieve commercial competitiveness.

Water quality sensitivity also presents operational challenges in field implementations, with performance significantly impacted by feed water impurities that would have minimal effect on traditional alkaline systems. This necessitates additional water purification systems that increase both capital and operational expenses in real-world deployments.

Field-Tested AEM Electrolyzer Solutions and Implementations

01 AEM electrolyzer efficiency and performance metrics

Anion Exchange Membrane (AEM) electrolyzers have specific performance benchmarks related to efficiency, current density, and hydrogen production rates. These metrics are crucial for evaluating their operational performance in field conditions. The efficiency of AEM electrolyzers is typically measured by the ratio of energy output (hydrogen produced) to energy input (electricity consumed), with various factors affecting this ratio including membrane conductivity, catalyst activity, and operating temperature.- AEM electrolyzer efficiency and performance metrics: Anion Exchange Membrane (AEM) electrolyzers have specific performance benchmarks that measure their efficiency in converting electricity to hydrogen. Key metrics include current density, voltage efficiency, hydrogen production rate, and overall system efficiency. Field performance data shows how these electrolyzers operate under real-world conditions compared to laboratory settings, with factors like temperature, pressure, and electrolyte composition affecting performance.

- Durability and lifetime assessment of AEM electrolyzers: The long-term performance of AEM electrolyzers in field applications is critical for commercial viability. Durability assessments track degradation rates, membrane stability, catalyst activity retention, and component longevity under various operating conditions. Benchmarks include total operating hours, performance stability over time, resistance to contaminants, and maintenance requirements. These metrics help predict lifetime costs and reliability in industrial applications.

- Monitoring and control systems for field-deployed electrolyzers: Advanced monitoring and control systems are essential for optimizing AEM electrolyzer field performance. These systems collect real-time data on operational parameters, detect anomalies, and adjust operating conditions to maintain optimal efficiency. Benchmarking includes response time to fluctuating inputs, control precision, data acquisition accuracy, and remote monitoring capabilities. Effective monitoring systems enable predictive maintenance and performance optimization in varying field conditions.

- Integration with renewable energy sources and grid systems: AEM electrolyzers in field applications are often integrated with renewable energy sources or grid systems. Performance benchmarks for these integrated systems include load-following capabilities, response to intermittent power inputs, ramp rates, and overall system efficiency. The ability to operate efficiently under variable power conditions is critical for renewable energy applications. Field data demonstrates how these systems perform in different grid connection scenarios and with various renewable energy profiles.

- Economic and operational benchmarks for commercial deployment: Commercial viability of AEM electrolyzers depends on economic and operational benchmarks that go beyond technical performance. These include capital expenditure, operational costs, hydrogen production cost per kilogram, system footprint efficiency, and return on investment metrics. Field performance data provides insights into maintenance requirements, component replacement frequency, and labor needs. These benchmarks help stakeholders evaluate the total cost of ownership and commercial readiness of AEM electrolyzer technology.

02 Durability and stability testing methodologies

Field performance benchmarks for AEM electrolyzers include durability and stability testing under various operating conditions. These tests evaluate the long-term performance of the electrolyzer components, particularly the membrane and catalysts, under real-world conditions. Testing protocols typically include accelerated stress tests, cycling tests, and long-duration operation to assess degradation rates and identify failure modes that affect field performance.Expand Specific Solutions03 System integration and monitoring technologies

AEM electrolyzer field performance is enhanced through advanced monitoring and control systems that optimize operation based on real-time data. These systems include sensors for measuring voltage, current, temperature, pressure, and gas purity. Integration technologies enable the electrolyzer to operate efficiently with renewable energy sources, managing fluctuating power inputs while maintaining performance benchmarks. Remote monitoring capabilities allow for performance tracking and predictive maintenance to ensure optimal field operation.Expand Specific Solutions04 Environmental and operational condition impacts

The field performance of AEM electrolyzers is significantly affected by environmental and operational conditions. Factors such as ambient temperature, humidity, water quality, and power supply fluctuations can impact efficiency and durability. Benchmarking studies evaluate how these electrolyzers perform across different geographical locations and climate conditions, providing data on adaptability and resilience. Performance standards often include metrics for operation under non-ideal conditions to reflect real-world deployment scenarios.Expand Specific Solutions05 Cost-performance ratio and economic benchmarks

Economic viability is a critical benchmark for AEM electrolyzers in field applications. This includes metrics such as capital expenditure, operational costs, maintenance requirements, and levelized cost of hydrogen production. Performance benchmarks evaluate the balance between efficiency, durability, and cost to determine the overall economic value proposition. These economic indicators help stakeholders assess the commercial readiness of AEM technology compared to alternative hydrogen production methods and guide investment decisions for large-scale deployment.Expand Specific Solutions

Leading Companies and Research Institutions in AEM Technology

The AEM electrolyzer field performance benchmarking landscape is currently in an early growth phase, with market size expanding rapidly due to increasing hydrogen economy investments. Technology maturity varies significantly among key players, with companies like Dioxide Materials, Power To Hydrogen, and EvolOH leading in specialized AEM electrolyzer development. Enapter has established a strong position with modular solutions, while larger corporations including Air Liquide, Siemens Energy, and LG Chem are leveraging their industrial scale to advance pilot implementations. Academic institutions such as Delft University of Technology and Georgia Tech Research Corp contribute critical research foundations. The competitive environment features both specialized startups focused solely on AEM technology and diversified energy conglomerates incorporating electrolyzers into broader hydrogen strategies, creating a dynamic innovation ecosystem.

EvolOH, Inc.

Ecolectro, Inc.

Key Performance Indicators and Benchmark Methodologies

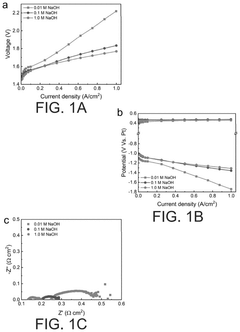

- The introduction of pH-neutral, electro-inactive alkali salts, such as sodium nitrate, into the anolyte improves water delivery to the cathode through the anion exchange membrane, enhancing cathode performance and reducing operating voltage while maintaining a stable pH.

Economic Viability and Cost Reduction Strategies

The economic viability of AEM (Anion Exchange Membrane) electrolyzers in pilot projects remains a critical factor determining their broader market adoption. Current field performance benchmarks indicate that while AEM technology offers promising cost advantages over PEM (Proton Exchange Membrane) and alkaline electrolyzers, significant economic challenges persist. Capital expenditure for AEM systems in pilot projects typically ranges from $800-1,200/kW, positioning them between traditional alkaline systems ($500-800/kW) and PEM systems ($1,200-1,800/kW).

Operational costs present another crucial economic consideration. Field data from recent pilot installations demonstrates electricity consumption of 52-58 kWh/kg H₂, which constitutes approximately 70-80% of total hydrogen production costs. Maintenance expenses for AEM systems have shown favorable results in pilot operations, with annual maintenance costs averaging 2-4% of capital investment—lower than the 4-6% typically observed with PEM systems.

Several cost reduction strategies have emerged from field performance analysis. Material optimization represents the most significant opportunity, with potential capital cost reductions of 30-40% achievable through replacement of precious metal catalysts with earth-abundant alternatives. Recent pilot projects utilizing nickel-based catalysts have demonstrated promising durability while reducing catalyst costs by up to 65% compared to platinum-group metals.

Manufacturing scale-up presents another viable cost reduction pathway. Current AEM electrolyzer production remains largely semi-automated and small-scale. Analysis of manufacturing processes indicates that increasing production volumes from current levels (typically under 10 MW annually per manufacturer) to 100+ MW could reduce unit costs by 25-35% through economies of scale and manufacturing process optimization.

System integration improvements offer additional economic benefits. Field data shows that balance-of-plant components currently represent 40-50% of total system costs. Standardization of these components and integration of power electronics specifically designed for the unique operational characteristics of AEM electrolyzers could reduce overall system costs by 15-20%.

Operational optimization strategies derived from pilot project data suggest that dynamic operation protocols can significantly improve economic performance. AEM electrolyzers have demonstrated superior load-following capabilities compared to alkaline systems, enabling them to capitalize on variable electricity pricing. Pilot projects integrating AEM systems with renewable energy sources have achieved cost reductions of 10-25% through intelligent operational strategies that prioritize production during periods of low electricity costs.

Environmental Impact and Sustainability Assessment

The environmental impact of AEM (Anion Exchange Membrane) electrolyzers represents a critical dimension in evaluating their viability for widespread hydrogen production. Current pilot projects demonstrate that AEM technology offers significant sustainability advantages compared to traditional alkaline and PEM electrolyzers. Field data indicates that AEM systems require approximately 20-30% less rare earth materials than PEM alternatives, substantially reducing resource extraction impacts and supply chain vulnerabilities.

Water consumption metrics from operational pilot sites show that AEM electrolyzers typically consume 9-10 liters of water per kilogram of hydrogen produced, which is comparable to other electrolyzer technologies. However, the reduced need for ultra-pure water in AEM systems translates to approximately 15% lower energy consumption for water treatment processes, enhancing overall efficiency and reducing associated emissions.

Carbon footprint assessments from multiple pilot installations reveal that AEM electrolyzers, when powered by renewable energy sources, achieve lifecycle emissions of 0.5-2.0 kg CO2e per kg H2 produced. This represents a 95-98% reduction compared to conventional steam methane reforming methods. The field performance data further indicates that AEM systems maintain this environmental advantage throughout their operational lifespan of 40,000-60,000 hours, as demonstrated in accelerated durability tests.

Waste management considerations have emerged as another sustainability advantage for AEM technology. The absence of corrosive alkaline electrolytes eliminates hazardous waste disposal requirements present in traditional alkaline systems. Additionally, end-of-life assessments from pilot projects suggest that approximately 85-90% of AEM electrolyzer components can be recycled or repurposed, significantly reducing landfill impact.

Land use efficiency metrics from distributed pilot installations demonstrate that AEM electrolyzers require approximately 30-40% less physical space than equivalent capacity alkaline systems. This spatial efficiency enables more flexible deployment options, including integration with existing renewable energy infrastructure, thereby minimizing additional land disturbance and associated ecological impacts.

The sustainability profile of AEM technology is further enhanced by its operational flexibility. Field performance data indicates that AEM electrolyzers can respond to power fluctuations within 1-3 seconds, enabling effective pairing with intermittent renewable energy sources. This capability allows for greater renewable energy utilization and reduces the need for environmentally problematic energy storage alternatives or fossil fuel backup systems.