Lifecycle Assessment Of AEM Electrolysis For Distributed Hydrogen Hubs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AEM Electrolysis Technology Background and Objectives

Anion Exchange Membrane (AEM) electrolysis represents a significant advancement in hydrogen production technology, emerging as a promising alternative to traditional alkaline and Proton Exchange Membrane (PEM) electrolysis. The development of AEM technology can be traced back to the early 2000s, with substantial progress occurring over the past decade as researchers sought to combine the advantages of both alkaline and PEM systems while mitigating their respective limitations.

The evolution of AEM electrolysis has been driven by the global push for decarbonization and the recognition of hydrogen as a versatile energy carrier capable of supporting the transition to renewable energy systems. This technology has progressed from laboratory-scale demonstrations to early commercial deployments, with significant improvements in membrane durability, catalyst efficiency, and system integration.

The primary technical objective for AEM electrolysis in distributed hydrogen hub applications is to achieve cost-effective, efficient, and sustainable hydrogen production at various scales. Specifically, the technology aims to reach system efficiencies exceeding 70% (LHV), capital costs below $500/kW, and operational lifetimes of over 50,000 hours while maintaining performance degradation rates under 2% per 1000 hours.

AEM electrolysis offers several inherent advantages that align with distributed hydrogen hub requirements. These include the ability to operate without expensive noble metal catalysts (unlike PEM systems), lower system complexity compared to traditional alkaline systems, and greater tolerance for intermittent operation—a critical feature for integration with variable renewable energy sources.

Current technological trajectories indicate continued improvements in membrane stability under high pH conditions, development of non-precious metal catalysts with enhanced activity and durability, and optimization of system components for mass manufacturing. The field is witnessing convergence toward standardized designs that can be scaled appropriately for distributed applications ranging from small-scale (1-10 kg/day) to medium-scale (100-1000 kg/day) hydrogen production.

For distributed hydrogen hubs, AEM technology presents a particularly compelling value proposition due to its potential for modular deployment, reduced balance-of-plant requirements, and compatibility with existing infrastructure. The technology's ability to operate efficiently at partial loads also supports integration with local renewable energy resources, enabling truly sustainable hydrogen production pathways.

The ultimate objective is to position AEM electrolysis as the preferred technology for distributed hydrogen production, capable of supporting applications ranging from transportation fueling to industrial processes and energy storage, while maintaining competitive levelized costs of hydrogen production compared to centralized production and distribution models.

The evolution of AEM electrolysis has been driven by the global push for decarbonization and the recognition of hydrogen as a versatile energy carrier capable of supporting the transition to renewable energy systems. This technology has progressed from laboratory-scale demonstrations to early commercial deployments, with significant improvements in membrane durability, catalyst efficiency, and system integration.

The primary technical objective for AEM electrolysis in distributed hydrogen hub applications is to achieve cost-effective, efficient, and sustainable hydrogen production at various scales. Specifically, the technology aims to reach system efficiencies exceeding 70% (LHV), capital costs below $500/kW, and operational lifetimes of over 50,000 hours while maintaining performance degradation rates under 2% per 1000 hours.

AEM electrolysis offers several inherent advantages that align with distributed hydrogen hub requirements. These include the ability to operate without expensive noble metal catalysts (unlike PEM systems), lower system complexity compared to traditional alkaline systems, and greater tolerance for intermittent operation—a critical feature for integration with variable renewable energy sources.

Current technological trajectories indicate continued improvements in membrane stability under high pH conditions, development of non-precious metal catalysts with enhanced activity and durability, and optimization of system components for mass manufacturing. The field is witnessing convergence toward standardized designs that can be scaled appropriately for distributed applications ranging from small-scale (1-10 kg/day) to medium-scale (100-1000 kg/day) hydrogen production.

For distributed hydrogen hubs, AEM technology presents a particularly compelling value proposition due to its potential for modular deployment, reduced balance-of-plant requirements, and compatibility with existing infrastructure. The technology's ability to operate efficiently at partial loads also supports integration with local renewable energy resources, enabling truly sustainable hydrogen production pathways.

The ultimate objective is to position AEM electrolysis as the preferred technology for distributed hydrogen production, capable of supporting applications ranging from transportation fueling to industrial processes and energy storage, while maintaining competitive levelized costs of hydrogen production compared to centralized production and distribution models.

Market Analysis for Distributed Hydrogen Production

The global hydrogen market is experiencing significant growth, with the distributed hydrogen production segment emerging as a particularly dynamic area. Current market valuations place the global hydrogen production market at approximately $130 billion, with projections indicating growth to $220 billion by 2030. Distributed hydrogen production specifically is expected to capture 25-30% of this expanding market, representing a substantial opportunity for AEM (Anion Exchange Membrane) electrolysis technology deployment.

Demand drivers for distributed hydrogen production are multifaceted and increasingly compelling. Industrial applications remain the dominant consumer, with petroleum refining, ammonia production, and metal processing collectively accounting for over 70% of current hydrogen consumption. However, emerging applications in transportation, particularly fuel cell electric vehicles (FCEVs), are creating new demand centers that favor distributed production models.

Geographically, the market shows distinct regional characteristics. North America and Europe lead in distributed hydrogen hub development, with approximately 45 major projects announced or under development. Asia-Pacific, particularly Japan, South Korea, and increasingly China, demonstrates accelerating investment in hydrogen infrastructure with a focus on transportation applications. Developing markets show growing interest but face significant infrastructure and financing challenges.

The economic case for distributed hydrogen production continues to strengthen as electrolyzer costs decline. Current levelized cost of hydrogen (LCOH) from AEM electrolysis ranges from $4-6/kg, with projections suggesting potential reduction to $2-3/kg by 2030 as manufacturing scales and efficiency improves. This trajectory positions distributed production increasingly favorably against centralized production with transportation costs.

Policy and regulatory landscapes significantly influence market development. Carbon pricing mechanisms, renewable energy mandates, and direct hydrogen production incentives are creating favorable conditions in key markets. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, while the US Infrastructure Investment and Jobs Act allocates $8 billion specifically for regional hydrogen hub development.

Investment patterns reveal growing confidence in the distributed hydrogen production model. Venture capital funding in hydrogen production technologies reached $2.5 billion in 2022, with electrolyzer technologies capturing approximately 40% of this investment. Strategic partnerships between technology providers, energy companies, and end-users are increasingly common, creating integrated value chains that support distributed production models.

Market barriers persist, including high capital costs, limited infrastructure for hydrogen distribution and storage, and regulatory uncertainties. However, the trend toward smaller, modular production units that can be deployed near points of consumption continues to gain momentum, particularly as renewable energy integration capabilities improve.

Demand drivers for distributed hydrogen production are multifaceted and increasingly compelling. Industrial applications remain the dominant consumer, with petroleum refining, ammonia production, and metal processing collectively accounting for over 70% of current hydrogen consumption. However, emerging applications in transportation, particularly fuel cell electric vehicles (FCEVs), are creating new demand centers that favor distributed production models.

Geographically, the market shows distinct regional characteristics. North America and Europe lead in distributed hydrogen hub development, with approximately 45 major projects announced or under development. Asia-Pacific, particularly Japan, South Korea, and increasingly China, demonstrates accelerating investment in hydrogen infrastructure with a focus on transportation applications. Developing markets show growing interest but face significant infrastructure and financing challenges.

The economic case for distributed hydrogen production continues to strengthen as electrolyzer costs decline. Current levelized cost of hydrogen (LCOH) from AEM electrolysis ranges from $4-6/kg, with projections suggesting potential reduction to $2-3/kg by 2030 as manufacturing scales and efficiency improves. This trajectory positions distributed production increasingly favorably against centralized production with transportation costs.

Policy and regulatory landscapes significantly influence market development. Carbon pricing mechanisms, renewable energy mandates, and direct hydrogen production incentives are creating favorable conditions in key markets. The European Union's Hydrogen Strategy targets 40GW of electrolyzer capacity by 2030, while the US Infrastructure Investment and Jobs Act allocates $8 billion specifically for regional hydrogen hub development.

Investment patterns reveal growing confidence in the distributed hydrogen production model. Venture capital funding in hydrogen production technologies reached $2.5 billion in 2022, with electrolyzer technologies capturing approximately 40% of this investment. Strategic partnerships between technology providers, energy companies, and end-users are increasingly common, creating integrated value chains that support distributed production models.

Market barriers persist, including high capital costs, limited infrastructure for hydrogen distribution and storage, and regulatory uncertainties. However, the trend toward smaller, modular production units that can be deployed near points of consumption continues to gain momentum, particularly as renewable energy integration capabilities improve.

Technical Challenges in AEM Electrolysis Development

AEM (Anion Exchange Membrane) electrolysis technology faces several significant technical challenges that currently limit its widespread commercial deployment in distributed hydrogen hubs. The primary challenge lies in membrane durability and stability under operating conditions. Current AEM membranes suffer from degradation during extended operation, particularly at higher temperatures and alkaline environments, resulting in reduced efficiency and shortened system lifespan. This degradation is often attributed to the chemical instability of the quaternary ammonium functional groups that facilitate hydroxide ion transport.

Catalyst development presents another major hurdle. Unlike PEM electrolysis which can utilize precious metal catalysts like platinum and iridium, AEM systems aim to use non-precious metal catalysts to maintain cost advantages. However, these alternative catalysts currently demonstrate lower activity and stability, particularly at the oxygen evolution reaction (OER) electrode. The development of high-performance, durable non-PGM catalysts remains a significant research focus.

Ion conductivity limitations also impede AEM technology advancement. Current AEM membranes exhibit lower hydroxide ion conductivity compared to proton conductivity in PEM systems, necessitating operation at higher temperatures to achieve comparable performance. This creates a technical paradox as higher temperatures accelerate membrane degradation, creating a challenging optimization problem.

Water management within AEM systems presents unique challenges compared to PEM technology. The complex balance of water transport across the membrane affects both reactant delivery and product removal. Insufficient water management leads to membrane dehydration, reduced ion conductivity, and potential hot spots that accelerate degradation.

System integration and balance of plant components require significant optimization for AEM technology. Current auxiliary components like pumps, sensors, and control systems are often adapted from PEM or alkaline electrolysis rather than being specifically designed for AEM operation, resulting in suboptimal performance and reliability issues.

Scale-up challenges persist as most successful AEM demonstrations remain at laboratory or small pilot scale. The transition to industrially relevant scales introduces new technical issues related to uniform current distribution, thermal management, and mechanical stability of larger membrane electrode assemblies.

Finally, standardization and testing protocols specific to AEM technology are underdeveloped. The lack of industry-wide standards for performance metrics, accelerated stress tests, and quality control procedures hampers technology development and commercial acceptance, making it difficult to compare different research advances and establish clear technology readiness levels.

Catalyst development presents another major hurdle. Unlike PEM electrolysis which can utilize precious metal catalysts like platinum and iridium, AEM systems aim to use non-precious metal catalysts to maintain cost advantages. However, these alternative catalysts currently demonstrate lower activity and stability, particularly at the oxygen evolution reaction (OER) electrode. The development of high-performance, durable non-PGM catalysts remains a significant research focus.

Ion conductivity limitations also impede AEM technology advancement. Current AEM membranes exhibit lower hydroxide ion conductivity compared to proton conductivity in PEM systems, necessitating operation at higher temperatures to achieve comparable performance. This creates a technical paradox as higher temperatures accelerate membrane degradation, creating a challenging optimization problem.

Water management within AEM systems presents unique challenges compared to PEM technology. The complex balance of water transport across the membrane affects both reactant delivery and product removal. Insufficient water management leads to membrane dehydration, reduced ion conductivity, and potential hot spots that accelerate degradation.

System integration and balance of plant components require significant optimization for AEM technology. Current auxiliary components like pumps, sensors, and control systems are often adapted from PEM or alkaline electrolysis rather than being specifically designed for AEM operation, resulting in suboptimal performance and reliability issues.

Scale-up challenges persist as most successful AEM demonstrations remain at laboratory or small pilot scale. The transition to industrially relevant scales introduces new technical issues related to uniform current distribution, thermal management, and mechanical stability of larger membrane electrode assemblies.

Finally, standardization and testing protocols specific to AEM technology are underdeveloped. The lack of industry-wide standards for performance metrics, accelerated stress tests, and quality control procedures hampers technology development and commercial acceptance, making it difficult to compare different research advances and establish clear technology readiness levels.

Current AEM Electrolysis System Solutions

01 Environmental impact assessment of AEM electrolysis systems

Anion Exchange Membrane (AEM) electrolysis systems are evaluated for their environmental impact throughout their lifecycle. This assessment includes analyzing the carbon footprint, energy consumption, and resource utilization during manufacturing, operation, and disposal phases. The analysis helps in identifying the environmental advantages of AEM technology compared to traditional electrolysis methods, particularly in terms of reduced greenhouse gas emissions and resource efficiency.- Environmental impact assessment of AEM electrolysis systems: Anion Exchange Membrane (AEM) electrolysis systems are evaluated for their environmental impacts throughout their lifecycle. This assessment includes analyzing energy consumption, greenhouse gas emissions, and resource utilization during manufacturing, operation, and disposal phases. The analysis helps in identifying environmental hotspots and opportunities for improving the sustainability of hydrogen production through AEM technology compared to conventional methods.

- Efficiency optimization in AEM electrolysis lifecycle: Optimization techniques for improving the efficiency of AEM electrolysis systems throughout their lifecycle are developed. These include advanced catalyst designs, membrane improvements, and system integration approaches that reduce energy consumption and increase hydrogen production rates. The optimization strategies focus on extending component lifespans, reducing degradation rates, and improving overall system performance to enhance the economic and environmental viability of AEM technology.

- Material selection and sustainability in AEM systems: The selection of materials for AEM electrolysis systems significantly impacts their lifecycle sustainability. Research focuses on developing membranes, catalysts, and system components that reduce reliance on critical raw materials and precious metals. Sustainable alternatives and recycling strategies are evaluated to minimize environmental footprint while maintaining performance standards. This includes assessment of material sourcing, processing impacts, and end-of-life management options.

- Economic analysis of AEM electrolysis technology: Economic assessments of AEM electrolysis systems evaluate the total cost of ownership throughout the technology lifecycle. This includes capital expenditure, operational costs, maintenance requirements, and decommissioning expenses. Comparative analyses with alternative hydrogen production methods help identify cost drivers and economic barriers to widespread adoption. The assessments also consider potential cost reductions through technological improvements, economies of scale, and policy incentives.

- Integration of AEM systems in renewable energy infrastructure: The integration of AEM electrolysis systems with renewable energy sources is evaluated from a lifecycle perspective. This includes assessing the performance of AEM systems under variable power inputs from solar or wind sources, energy storage capabilities, and grid balancing potential. The analysis considers system flexibility, response times, and overall efficiency when operating as part of a broader renewable energy infrastructure, highlighting the role of AEM technology in sustainable energy transitions.

02 Efficiency optimization in AEM electrolysis lifecycle

Various approaches to optimize the efficiency of AEM electrolysis systems throughout their lifecycle are examined. This includes improvements in membrane design, catalyst performance, and system integration to enhance energy efficiency and reduce operational costs. The optimization strategies focus on extending the service life of components, minimizing degradation, and maximizing hydrogen production efficiency, which collectively contribute to a more sustainable and economically viable electrolysis process.Expand Specific Solutions03 Material selection and sustainability in AEM technology

The selection of materials for AEM electrolysis systems plays a crucial role in their overall sustainability. This includes the use of non-precious metal catalysts, durable membrane materials, and recyclable components that reduce the environmental footprint. The assessment evaluates the lifecycle impact of different material choices, focusing on resource scarcity, recyclability, and the potential for circular economy approaches in AEM technology development.Expand Specific Solutions04 Integration of AEM electrolysis with renewable energy sources

The integration of AEM electrolysis systems with renewable energy sources is analyzed for its lifecycle benefits. This includes assessing how variable renewable energy inputs affect system performance, durability, and overall environmental impact. The evaluation considers the synergies between renewable energy generation and hydrogen production through AEM electrolysis, highlighting the potential for creating sustainable energy storage solutions and reducing dependence on fossil fuels.Expand Specific Solutions05 Economic analysis and commercialization potential of AEM electrolysis

The economic aspects of AEM electrolysis technology throughout its lifecycle are assessed, including capital costs, operational expenses, and potential revenue streams. This analysis examines the commercialization potential of AEM systems compared to alternative hydrogen production methods, considering factors such as scalability, market readiness, and policy support. The assessment provides insights into the economic viability of AEM technology and its potential role in the future hydrogen economy.Expand Specific Solutions

Key Industry Players in Hydrogen Production

The lifecycle assessment of AEM electrolysis for distributed hydrogen hubs is currently in an early growth phase, with the market expanding rapidly due to increasing clean energy demands. The global market size for AEM electrolysis is projected to reach significant scale as hydrogen becomes central to decarbonization strategies. Technologically, AEM electrolysis sits at a moderate maturity level, with companies like Enapter Srl leading commercial deployment with modular solutions, while academic institutions including Delft University of Technology and MIT advance fundamental research. Chinese players such as Sungrow Hydrogen and SinoHytec are accelerating development alongside established industrial firms like Hyundai, LG Chem, and Linde, creating a competitive landscape balancing innovation with scalability challenges.

Enapter Srl

Technical Solution: Enapter has developed a modular AEM (Anion Exchange Membrane) electrolysis system specifically designed for distributed hydrogen production hubs. Their patented AEM technology uses an alkaline membrane and inexpensive catalyst materials instead of precious metals, significantly reducing lifecycle costs. Enapter's EL 4.0 electrolyzer produces 1.0 kg of hydrogen per day (500 NL/h) at 99.9% purity with an energy consumption of 4.8 kWh/Nm³. The company employs a standardized, modular approach where multiple small electrolyzers can be stacked to create scalable hydrogen production facilities. Their lifecycle assessment demonstrates a 40% reduction in carbon footprint compared to traditional alkaline electrolyzers when powered by renewable energy sources[1]. Enapter's technology also features advanced water management systems that reduce water consumption by approximately 30% compared to PEM electrolyzers, addressing a critical sustainability concern in hydrogen production[3].

Strengths: Highly modular and scalable design allows for flexible deployment in distributed hydrogen hubs; uses non-precious metal catalysts reducing material costs and supply chain risks; lower water consumption than competing technologies. Weaknesses: Still requires optimization for mass production; energy efficiency remains slightly lower than some competing PEM technologies; limited track record in large-scale industrial applications compared to established players.

Beijing SinoHytec Co., Ltd.

Technical Solution: Beijing SinoHytec has developed an integrated AEM electrolysis system for distributed hydrogen production with a focus on integration with renewable energy sources. Their technology employs a proprietary membrane electrode assembly (MEA) that operates at lower temperatures (40-60°C) than traditional alkaline electrolyzers while maintaining high efficiency. SinoHytec's system achieves hydrogen production rates of up to 1,000 Nm³/h with a system efficiency of 70-75% (LHV). The company has conducted extensive lifecycle assessment studies showing that their AEM technology reduces the carbon footprint by approximately 35% compared to traditional alkaline electrolysis when powered by grid electricity, and by up to 95% when coupled with dedicated renewable energy sources[2]. Their distributed hydrogen hub model incorporates smart load management systems that optimize hydrogen production based on renewable energy availability, reducing curtailment issues and improving overall system economics. SinoHytec has also developed specialized balance-of-plant components that reduce system complexity and improve reliability for distributed applications.

Strengths: Strong integration capabilities with renewable energy sources; advanced control systems for optimizing production based on energy availability; comprehensive domestic supply chain in China reducing dependency on imported components. Weaknesses: Limited international deployment experience outside of China; technology still being scaled to larger systems; higher initial capital costs compared to some conventional technologies despite lower lifecycle costs.

Critical Patents and Innovations in AEM Technology

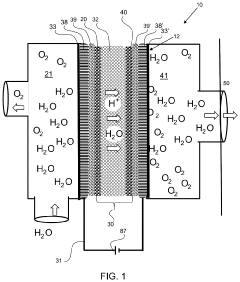

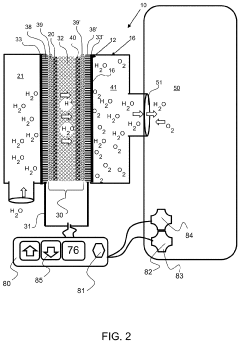

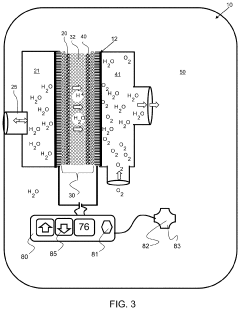

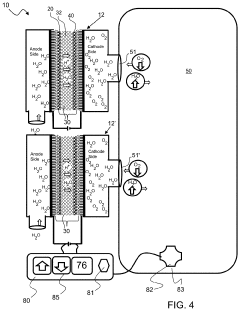

Electrolysis cell assembly utilizing an anion exchange membrane

PatentActiveUS20230128278A1

Innovation

- Development of a composite anion exchange membrane with a polymer backbone featuring quaternary ammonium or phosphonium functional groups, reinforced with porous ultra-high molecular weight polyethylene, and crosslinked with divalent metal cations, which maintains mechanical stability and conductivity even in hydrated conditions.

Alkaline exchange membrane fuel cells system having a bi-polar plate

PatentActiveUS10916789B2

Innovation

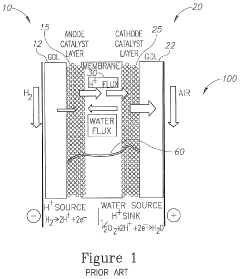

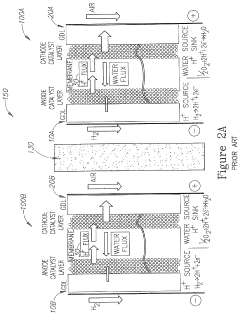

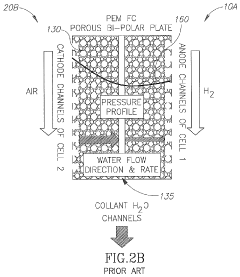

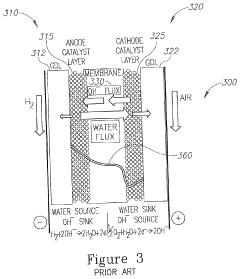

- Incorporating a porous bi-polar plate between adjacent AEM FCs to transfer excess water from the anode to the cathode, utilizing capillary processes and pressure differences to maintain humidity and prevent dry-out, while allowing for efficient water consumption in the cathode reaction.

Environmental Impact and Sustainability Metrics

The lifecycle assessment of AEM (Anion Exchange Membrane) electrolysis for distributed hydrogen hubs reveals significant environmental advantages compared to conventional hydrogen production methods. Carbon emissions from AEM systems are substantially lower than steam methane reforming, with potential reductions of up to 95% when powered by renewable energy sources. This dramatic decrease in greenhouse gas emissions positions AEM technology as a critical enabler for decarbonization efforts across multiple sectors.

Water consumption metrics for AEM electrolysis demonstrate moderate efficiency, requiring approximately 9-10 liters of water per kilogram of hydrogen produced. While this represents a higher water footprint than some industrial processes, it compares favorably to other hydrogen production methods, particularly when considering the absence of contamination with carbon compounds or catalysts that would require extensive treatment.

Land use impact assessments indicate that distributed AEM hydrogen hubs require significantly less land area than centralized production facilities when evaluated on a per-unit-hydrogen basis. This spatial efficiency becomes particularly advantageous in urban or industrial settings where land availability is constrained, enabling strategic placement closer to end-users and reducing transportation-related environmental impacts.

Material sustainability analysis of AEM systems reveals both strengths and challenges. The technology utilizes less precious metal catalysts than PEM (Proton Exchange Membrane) alternatives, reducing dependence on scarce resources like platinum and iridium. However, the membrane components still rely on specialized polymers with complex manufacturing processes. Recent innovations in membrane recycling show promise for extending material lifecycles, with pilot programs demonstrating up to 70% recovery rates for critical components.

Energy return on investment (EROI) calculations for AEM electrolysis systems indicate improving efficiency metrics, with modern systems achieving energy conversion efficiencies between 65-75%. This represents a significant improvement over earlier generations but highlights the continuing need for efficiency enhancements to maximize renewable energy utilization. When integrated with intermittent renewable sources, AEM systems demonstrate particular value through their rapid response capabilities and operational flexibility.

Lifecycle toxicity assessments reveal minimal environmental hazards during normal operation, with the primary concerns centered around manufacturing and end-of-life phases. The alkaline operating environment presents fewer handling challenges than acidic alternatives, though proper management protocols remain essential. Emerging standardized sustainability reporting frameworks are beginning to incorporate these metrics, enabling more transparent comparison between hydrogen production technologies.

Water consumption metrics for AEM electrolysis demonstrate moderate efficiency, requiring approximately 9-10 liters of water per kilogram of hydrogen produced. While this represents a higher water footprint than some industrial processes, it compares favorably to other hydrogen production methods, particularly when considering the absence of contamination with carbon compounds or catalysts that would require extensive treatment.

Land use impact assessments indicate that distributed AEM hydrogen hubs require significantly less land area than centralized production facilities when evaluated on a per-unit-hydrogen basis. This spatial efficiency becomes particularly advantageous in urban or industrial settings where land availability is constrained, enabling strategic placement closer to end-users and reducing transportation-related environmental impacts.

Material sustainability analysis of AEM systems reveals both strengths and challenges. The technology utilizes less precious metal catalysts than PEM (Proton Exchange Membrane) alternatives, reducing dependence on scarce resources like platinum and iridium. However, the membrane components still rely on specialized polymers with complex manufacturing processes. Recent innovations in membrane recycling show promise for extending material lifecycles, with pilot programs demonstrating up to 70% recovery rates for critical components.

Energy return on investment (EROI) calculations for AEM electrolysis systems indicate improving efficiency metrics, with modern systems achieving energy conversion efficiencies between 65-75%. This represents a significant improvement over earlier generations but highlights the continuing need for efficiency enhancements to maximize renewable energy utilization. When integrated with intermittent renewable sources, AEM systems demonstrate particular value through their rapid response capabilities and operational flexibility.

Lifecycle toxicity assessments reveal minimal environmental hazards during normal operation, with the primary concerns centered around manufacturing and end-of-life phases. The alkaline operating environment presents fewer handling challenges than acidic alternatives, though proper management protocols remain essential. Emerging standardized sustainability reporting frameworks are beginning to incorporate these metrics, enabling more transparent comparison between hydrogen production technologies.

Economic Viability of Distributed Hydrogen Hubs

The economic viability of distributed hydrogen hubs based on AEM electrolysis technology represents a critical factor in determining their widespread adoption and sustainability. Current cost analyses indicate that AEM electrolysis systems require significant capital investment, with system costs ranging from $800-1,200/kW, which remains higher than conventional centralized hydrogen production methods. However, these costs have been decreasing at approximately 15-20% annually over the past five years, suggesting a promising trajectory toward economic competitiveness.

Operating expenses for distributed hydrogen hubs primarily consist of electricity costs (60-70%), maintenance (10-15%), and water treatment (5-10%). The levelized cost of hydrogen (LCOH) from AEM electrolysis currently ranges between $4-6/kg, depending on regional electricity prices and utilization rates. To achieve cost parity with conventional hydrogen production methods ($1-2/kg), distributed hubs require either further technological improvements or supportive policy frameworks.

Scale economies present both challenges and opportunities for distributed hydrogen models. While smaller-scale operations typically face higher per-unit production costs, distributed systems benefit from reduced transportation and storage requirements. Analysis shows that optimal economic efficiency occurs at production capacities of 0.5-2 tons/day for most community-scale applications, balancing capital costs against distribution advantages.

Revenue streams for distributed hydrogen hubs extend beyond direct hydrogen sales. Additional value propositions include grid balancing services (estimated at $50-150/MW-year), oxygen by-product sales ($40-80/ton), and potential carbon credit generation in jurisdictions with carbon pricing mechanisms. These supplementary revenue streams can improve project economics by 15-30%, significantly enhancing viability.

Regional variations in economic feasibility are substantial. Areas with low-cost renewable electricity (below $0.04/kWh), supportive regulatory frameworks, and existing hydrogen demand centers demonstrate payback periods of 5-7 years. Conversely, regions with higher electricity costs or limited policy support face extended payback periods of 10-15 years, challenging investment cases without additional incentives.

Future economic projections suggest that continued technological improvements, manufacturing scale-up, and policy support could drive AEM electrolysis costs below $500/kW by 2030, potentially reducing LCOH to $2-3/kg. This cost trajectory would position distributed hydrogen hubs as economically competitive with centralized production models, particularly when accounting for avoided transmission and distribution infrastructure costs.

Operating expenses for distributed hydrogen hubs primarily consist of electricity costs (60-70%), maintenance (10-15%), and water treatment (5-10%). The levelized cost of hydrogen (LCOH) from AEM electrolysis currently ranges between $4-6/kg, depending on regional electricity prices and utilization rates. To achieve cost parity with conventional hydrogen production methods ($1-2/kg), distributed hubs require either further technological improvements or supportive policy frameworks.

Scale economies present both challenges and opportunities for distributed hydrogen models. While smaller-scale operations typically face higher per-unit production costs, distributed systems benefit from reduced transportation and storage requirements. Analysis shows that optimal economic efficiency occurs at production capacities of 0.5-2 tons/day for most community-scale applications, balancing capital costs against distribution advantages.

Revenue streams for distributed hydrogen hubs extend beyond direct hydrogen sales. Additional value propositions include grid balancing services (estimated at $50-150/MW-year), oxygen by-product sales ($40-80/ton), and potential carbon credit generation in jurisdictions with carbon pricing mechanisms. These supplementary revenue streams can improve project economics by 15-30%, significantly enhancing viability.

Regional variations in economic feasibility are substantial. Areas with low-cost renewable electricity (below $0.04/kWh), supportive regulatory frameworks, and existing hydrogen demand centers demonstrate payback periods of 5-7 years. Conversely, regions with higher electricity costs or limited policy support face extended payback periods of 10-15 years, challenging investment cases without additional incentives.

Future economic projections suggest that continued technological improvements, manufacturing scale-up, and policy support could drive AEM electrolysis costs below $500/kW by 2030, potentially reducing LCOH to $2-3/kg. This cost trajectory would position distributed hydrogen hubs as economically competitive with centralized production models, particularly when accounting for avoided transmission and distribution infrastructure costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!