Durability Testing Protocols And Accelerated Stressors For AEM Cells

AEM Cell Technology Background and Testing Objectives

Anion Exchange Membrane (AEM) electrolysis represents a significant advancement in hydrogen production technology, emerging as a promising alternative to traditional alkaline and proton exchange membrane (PEM) electrolyzers. The development of AEM cells began in the early 2000s, with substantial progress occurring over the past decade as researchers sought to combine the advantages of both alkaline and PEM technologies while mitigating their respective limitations.

The evolution of AEM technology has been driven by the need for cost-effective, efficient, and sustainable hydrogen production methods. Unlike PEM systems that require expensive platinum group metal catalysts and titanium components, AEM cells can utilize non-precious metal catalysts and less costly materials, potentially reducing capital expenditure by 30-40%. Concurrently, AEM cells offer higher current densities and efficiencies than traditional alkaline systems, positioning them as an economically viable middle-ground solution.

A critical aspect of AEM technology development has been the membrane itself, with significant improvements in ionic conductivity, mechanical stability, and chemical resistance. Early membranes suffered from rapid degradation in alkaline environments, but recent innovations have extended potential lifetimes from hundreds to thousands of hours. This progress trajectory suggests continued enhancement in durability metrics, though substantial challenges remain.

The primary technical objective for durability testing protocols is to establish standardized methodologies that accurately predict AEM cell lifetime under real-world operating conditions. Current testing approaches vary significantly across research institutions and manufacturers, making performance comparisons and lifetime predictions problematic. Standardization would enable meaningful benchmarking and accelerate technology maturation.

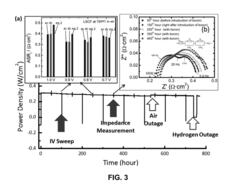

Accelerated stress testing (AST) represents another crucial objective, as it allows for rapid evaluation of long-term degradation mechanisms without waiting for natural aging processes. Developing correlations between accelerated stressors and real-world degradation patterns is essential for validating these protocols and ensuring their predictive accuracy.

Additionally, testing objectives include identifying specific failure modes and degradation mechanisms unique to AEM systems, particularly those related to membrane stability in alkaline environments, catalyst degradation pathways, and interface deterioration between components. Understanding these mechanisms at a fundamental level will inform targeted improvements in materials and system design.

The ultimate goal of these testing protocols is to support the commercialization of AEM technology by providing manufacturers and end-users with reliable performance metrics and lifetime predictions. Current targets in the industry aim for operational lifetimes exceeding 50,000 hours for stationary applications, with degradation rates below 2% per 1,000 hours—benchmarks that require robust testing methodologies to verify and achieve.

Market Demand Analysis for Durable AEM Cells

The global market for Anion Exchange Membrane (AEM) electrolyzers is experiencing significant growth, driven primarily by the increasing demand for green hydrogen as a clean energy carrier. Current market projections indicate that the hydrogen economy could reach $2.5 trillion by 2050, with electrolyzer technologies playing a crucial role in this expansion. Within this landscape, AEM technology represents a promising middle ground between alkaline and PEM electrolyzers, potentially offering cost advantages without sacrificing performance.

Market research reveals that industrial hydrogen users, renewable energy developers, and government entities are the primary stakeholders expressing interest in durable AEM cells. These stakeholders consistently emphasize that durability remains one of the most critical factors influencing purchasing decisions, with many requiring operational lifetimes of 40,000-60,000 hours to achieve competitive levelized cost of hydrogen (LCOH) metrics.

The demand for standardized durability testing protocols has intensified as investment in hydrogen technologies has increased. Investors and end-users require reliable performance data to make informed decisions, yet the industry currently lacks universally accepted testing methodologies specifically for AEM systems. This gap creates market uncertainty and potentially slows adoption rates despite the technology's promise.

Regional analysis shows varying market priorities regarding AEM durability. European markets, influenced by stringent regulatory frameworks, prioritize long-term reliability and comprehensive lifecycle assessment. North American markets focus on cost-performance ratios and integration with existing infrastructure. Asian markets, particularly in China, Japan, and South Korea, emphasize manufacturing scalability alongside durability metrics.

Industry surveys indicate that end-users are willing to pay a premium of 15-20% for AEM systems with verified durability credentials compared to unverified alternatives. This premium reflects the significant downstream costs associated with system failures and unplanned maintenance in hydrogen production facilities.

The market for durability testing equipment and services for AEM cells is also emerging as a distinct segment, estimated to reach $300 million by 2030. This includes specialized testing apparatus, analytical services, and certification programs that can validate manufacturer claims regarding cell longevity under various operating conditions.

Competitive analysis reveals that early movers who can demonstrate superior durability through standardized testing protocols will likely capture disproportionate market share. Several leading electrolyzer manufacturers have already begun investing in proprietary accelerated stress test methodologies, though these remain largely unharmonized across the industry.

Current Durability Testing Challenges and Limitations

The durability testing of Anion Exchange Membrane (AEM) cells currently faces significant methodological and technical challenges that impede accurate lifetime predictions and performance evaluations. Traditional testing protocols often require thousands of hours of operation to assess degradation patterns, making them impractical for rapid technology development cycles. This time-intensive approach creates bottlenecks in research and development pipelines, delaying critical innovations and market entry for promising AEM technologies.

A fundamental limitation in current testing frameworks is the lack of standardization across the industry. Different research groups and manufacturers employ varied testing conditions, metrics, and failure criteria, making cross-study comparisons nearly impossible. This fragmentation hinders collective knowledge advancement and prevents the establishment of reliable benchmarks for AEM cell performance and durability.

The correlation between accelerated stress tests (ASTs) and real-world operational degradation remains poorly established for AEM cells. Unlike proton exchange membrane (PEM) technologies, which have well-validated acceleration factors, AEM cells exhibit complex degradation mechanisms that are not consistently reproduced in accelerated testing environments. This disconnect creates significant uncertainty when translating laboratory results to practical lifetime expectations.

Current protocols also inadequately address the multifaceted nature of AEM degradation. Chemical, mechanical, and thermal degradation pathways often interact synergistically, yet most testing approaches isolate these factors rather than examining their combined effects. This reductionist approach fails to capture the complex interplay of stressors that occurs during actual operation, leading to incomplete understanding of failure modes.

The sensitivity of AEM materials to testing conditions presents another major challenge. Parameters such as humidity levels, temperature fluctuations, and contaminant exposure dramatically affect degradation rates, yet controlling these variables precisely across extended testing periods remains difficult. This variability introduces significant noise into durability data, complicating interpretation and reducing confidence in lifetime projections.

Additionally, there is a critical shortage of in-situ and operando diagnostic techniques capable of monitoring degradation processes in real-time without disrupting cell operation. Current approaches often rely on post-mortem analysis, which provides limited insight into degradation progression and fails to capture transient phenomena that may significantly impact cell longevity.

The field also struggles with inadequate computational models for predicting long-term durability based on short-term testing data. Existing models typically employ simplistic linear extrapolations that fail to account for the non-linear degradation patterns commonly observed in AEM systems, particularly during early and late-stage operation.

Existing Accelerated Stress Test Protocols

01 Membrane electrode assembly (MEA) durability enhancement

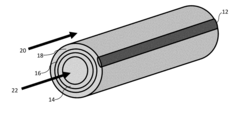

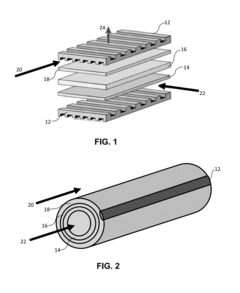

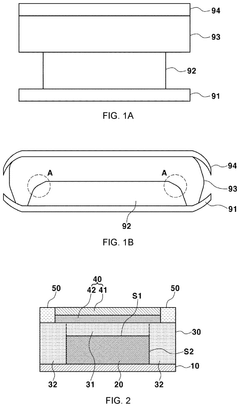

Various techniques are employed to enhance the durability of anion exchange membrane (AEM) cells by improving the membrane electrode assembly. These include optimized catalyst layer compositions, reinforced membrane structures, and novel interface treatments that reduce degradation during operation. These enhancements help maintain performance over extended operational periods by minimizing chemical and mechanical stresses at the electrode-membrane interface.- Membrane electrode assembly (MEA) design improvements: Various design improvements in membrane electrode assemblies (MEAs) can significantly enhance the durability of AEM cells. These improvements include optimized catalyst layer structures, reinforced membrane materials, and novel electrode configurations that reduce mechanical stress during operation. By implementing these design enhancements, the operational lifetime of AEM cells can be extended while maintaining high performance under various operating conditions.

- Advanced catalyst materials for enhanced stability: The development of advanced catalyst materials plays a crucial role in improving AEM cell durability. Novel catalyst compositions, including non-precious metal catalysts and hybrid materials, demonstrate superior resistance to degradation in alkaline environments. These materials maintain high catalytic activity while reducing the degradation mechanisms that typically limit cell lifetime, such as catalyst dissolution, agglomeration, and poisoning effects.

- Protective coatings and interface engineering: Applying protective coatings and engineering interfaces between cell components significantly improves the durability of AEM cells. These approaches include ion-conductive protective layers, hydrophobic treatments, and gradient structures that mitigate degradation at critical interfaces. Such modifications help maintain ionic conductivity while protecting sensitive components from chemical attack and mechanical stress during cycling operations.

- Thermal and water management strategies: Effective thermal and water management strategies are essential for extending AEM cell durability. Advanced systems for controlling temperature distribution, humidity levels, and water transport within the cell prevent membrane dehydration and flooding issues. These management approaches include innovative flow field designs, integrated cooling systems, and dynamic control mechanisms that adapt to changing operating conditions.

- Accelerated testing and lifetime prediction methods: Development of accelerated testing protocols and lifetime prediction methods enables more effective evaluation of AEM cell durability. These approaches include stress tests under extreme conditions, in-situ monitoring techniques, and computational models that correlate short-term performance indicators with long-term durability. By implementing these methods, researchers can rapidly assess and improve the durability of new AEM cell designs and materials without waiting for extended real-time testing.

02 Catalyst stability and loading optimization

Improving AEM cell durability through advanced catalyst formulations that resist degradation in alkaline environments. This includes developing non-precious metal catalysts with enhanced stability, optimizing catalyst loading to balance performance and longevity, and creating protective coatings that shield catalysts from chemical attack while maintaining electrochemical activity. These approaches significantly extend cell lifetime while maintaining high efficiency.Expand Specific Solutions03 Thermal and humidity management systems

Systems designed to control operating temperature and humidity levels within AEM cells to prevent membrane dehydration and thermal degradation. These include advanced water management architectures, integrated cooling systems, and humidity regulation mechanisms that maintain optimal operating conditions. By preventing extreme conditions that accelerate degradation, these systems significantly extend the operational lifetime of AEM cells.Expand Specific Solutions04 Structural reinforcement and mechanical stability

Enhancing the mechanical durability of AEM cells through structural reinforcements and novel cell designs that resist physical stresses. This includes developing composite membranes with reinforcing materials, improved cell compression systems, and stress-distributing components that prevent mechanical failures. These innovations help maintain cell integrity during thermal cycling, pressure fluctuations, and long-term operation.Expand Specific Solutions05 Degradation monitoring and prevention systems

Advanced diagnostic and preventive systems that monitor AEM cell health and implement protective measures to extend durability. These include real-time monitoring of key performance indicators, predictive maintenance algorithms, and automated response systems that adjust operating parameters to prevent accelerated degradation. By identifying and mitigating degradation mechanisms early, these systems significantly extend the useful life of AEM cells.Expand Specific Solutions

Key Industry Players in AEM Cell Development

The AEM cell durability testing market is in a growth phase, with increasing demand driven by the expanding hydrogen economy. The market size is projected to grow significantly as companies invest in developing more reliable and cost-effective AEM technologies. Currently, the technical maturity is moderate, with key players advancing testing protocols at different rates. Leading companies like Contemporary Amperex Technology Co., Ltd. and Svolt Energy Technology are focusing on battery durability innovations, while automotive giants Toyota and Nissan are integrating these technologies into their hydrogen vehicle programs. Research institutions including Dalian Institute of Chemical Physics and international corporations like IBM and Bosch are developing standardized accelerated stress tests to improve cell longevity and performance under various operating conditions.

Contemporary Amperex Technology Co., Ltd.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Critical Degradation Mechanisms and Failure Analysis

- Developed accelerated testing protocols for SOFC cathode materials involve cycling the cells between open circuit voltage and operating potential at high current densities and frequencies, simulating long-term operation in a shorter timeframe to assess durability and reliability.

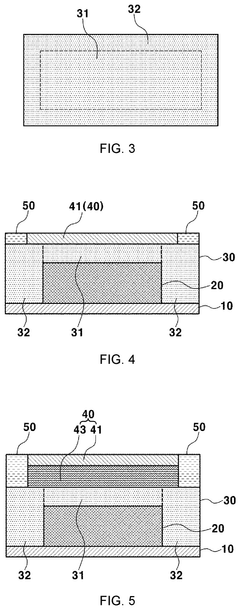

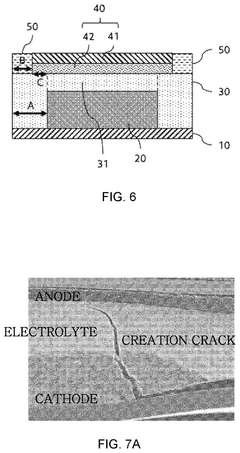

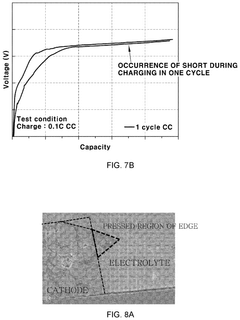

- A novel battery structure with a solid electrolyte layer surrounding the cathode active material layer, an anode layer with a larger area than the cathode, and a spacer to stabilize the structure, along with a manufacturing method applying 400-800 MPa pressure.

Standardization Efforts in AEM Cell Testing

The standardization of testing protocols for Anion Exchange Membrane (AEM) cells represents a critical frontier in advancing this promising technology toward commercial viability. Currently, several international organizations are spearheading efforts to establish uniform testing methodologies that would enable meaningful comparison of research results across different laboratories and accelerate technology development.

The International Electrotechnical Commission (IEC) Technical Committee 105 has been working on developing standards specifically for AEM cells, building upon their established frameworks for other electrochemical technologies. Their working group on hydrogen technologies has recently initiated a dedicated task force focused on AEM testing protocols, with particular emphasis on durability assessment methods.

Similarly, the International Organization for Standardization (ISO) has formed a committee addressing renewable energy technologies, with a subcommittee specifically examining standardization needs for emerging electrochemical systems including AEM cells. Their draft guidelines propose standardized accelerated stress tests that simulate real-world degradation mechanisms.

In the United States, the Department of Energy's Hydrogen and Fuel Cell Technologies Office has funded a consortium of national laboratories to develop a unified testing protocol for AEM cells. This initiative, known as the AEM Electrolysis Benchmarking Project, aims to establish reference procedures for evaluating membrane degradation under various stressors including thermal cycling, mechanical stress, and chemical contamination.

The European Commission, through its Fuel Cells and Hydrogen Joint Undertaking (FCH JU), has launched parallel standardization efforts focusing on harmonizing testing methodologies across European research institutions. Their framework emphasizes reproducibility of accelerated stress tests and correlation with real-world operational conditions.

Industry consortia are also contributing significantly to standardization efforts. The AEM Electrolysis Industry Group, comprising major manufacturers and technology developers, has published recommended practices for durability assessment that are gaining traction as de facto industry standards. Their approach incorporates both short-term accelerated stress tests and longer-term operational stability evaluations.

Academic networks, including the International Society for Alkaline Membranes (ISAM), have established working groups dedicated to testing protocol harmonization. Their recent position paper outlines consensus recommendations for characterizing membrane degradation mechanisms and quantifying performance losses under standardized conditions.

Despite these advances, challenges remain in correlating accelerated stress test results with actual field performance, particularly given the diverse operating conditions and applications for AEM technologies. Ongoing collaborative efforts between standards organizations, industry, and academia are essential to refine these protocols and establish universally accepted benchmarks for AEM cell durability assessment.

Environmental Impact of AEM Cell Lifecycle

The environmental footprint of Anion Exchange Membrane (AEM) cells extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. When developing durability testing protocols and accelerated stressors for AEM cells, it is crucial to consider these environmental implications. The manufacturing process of AEM cells involves energy-intensive production of specialized polymers and catalysts, often requiring rare earth metals and precious metals like platinum and iridium, whose extraction causes significant environmental disruption including habitat destruction and water pollution.

During the operational phase, AEM cells demonstrate considerable environmental advantages compared to traditional energy technologies. They produce zero direct emissions when powered by renewable energy sources, potentially reducing greenhouse gas emissions by 95% compared to fossil fuel alternatives. However, the durability testing protocols themselves can generate environmental impacts through water consumption, chemical waste from electrolytes, and energy usage during accelerated aging tests.

The degradation mechanisms targeted by accelerated stressors—such as membrane chemical degradation, catalyst poisoning, and mechanical stress—directly influence the service life of AEM cells. Extended durability translates to reduced replacement frequency and consequently lower lifecycle environmental impact. Research indicates that doubling AEM cell lifespan can reduce lifecycle carbon emissions by approximately 40% per kilowatt-hour of energy produced.

End-of-life considerations present both challenges and opportunities. Current recycling technologies can recover up to 95% of precious metal catalysts from spent AEM cells, but membrane materials remain difficult to recycle effectively. The chemical compounds used in accelerated stress tests may complicate disposal procedures, requiring specialized waste management protocols to prevent environmental contamination.

Standardizing environmentally conscious durability testing protocols represents an emerging priority in the field. Researchers are developing water-recycling systems for testing facilities that can reduce freshwater consumption by up to 80%. Additionally, biodegradable electrolyte alternatives are being explored to minimize the environmental impact of testing procedures.

The carbon payback period—the time required for an AEM cell to offset the emissions generated during its production through clean operation—is directly influenced by durability. Current generation AEM cells typically achieve carbon payback within 1-3 years depending on usage patterns and energy sources, but improved durability could reduce this timeframe significantly, enhancing their overall environmental value proposition.