Water Purity Requirements And Deionization Strategies For AEM Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AEM Water Purity Background and Objectives

Anion Exchange Membrane (AEM) technology has emerged as a promising alternative to traditional water purification methods, with its development trajectory spanning over three decades. Initially conceived in the 1990s as a theoretical concept, AEM systems have evolved significantly through continuous research and innovation in electrochemical separation technologies. The fundamental principle behind AEM technology leverages ion-selective membranes to facilitate the removal of contaminants from water through electrochemical processes, offering advantages in energy efficiency and operational flexibility compared to conventional methods.

The evolution of AEM technology has been marked by several significant milestones, including the development of more stable membrane materials, enhanced ion selectivity, and improved durability under various operating conditions. Recent advancements have focused on addressing the challenges of membrane fouling, chlorine resistance, and operational longevity, which have historically limited widespread adoption of this technology in industrial applications.

Water purity requirements for AEM systems represent a critical consideration that directly impacts system performance, efficiency, and lifespan. The presence of certain ionic species, particularly multivalent cations such as calcium and magnesium, can significantly impair membrane functionality through scaling and fouling mechanisms. Additionally, organic contaminants and particulate matter can accelerate membrane degradation and reduce system efficiency over time.

The primary technical objectives in advancing AEM water purification technology include developing comprehensive water quality parameters specifically tailored for AEM operations, establishing standardized pretreatment protocols to ensure optimal feed water quality, and creating robust monitoring systems to maintain water purity throughout the operational cycle. These objectives aim to maximize system performance while minimizing maintenance requirements and extending operational lifespan.

Current research trends indicate a growing focus on understanding the complex interactions between water impurities and AEM materials at the molecular level. This fundamental research is expected to inform the development of next-generation membranes with enhanced selectivity and resistance to fouling. Parallel efforts are being directed toward optimizing deionization strategies that can effectively address varying water quality challenges across different industrial applications.

The technological trajectory suggests that future developments will likely center on creating integrated water treatment solutions that combine multiple purification technologies to achieve optimal water quality for AEM systems. This holistic approach recognizes that water purity requirements vary significantly based on specific applications, from industrial process water to specialized laboratory environments, necessitating tailored solutions rather than one-size-fits-all approaches.

The evolution of AEM technology has been marked by several significant milestones, including the development of more stable membrane materials, enhanced ion selectivity, and improved durability under various operating conditions. Recent advancements have focused on addressing the challenges of membrane fouling, chlorine resistance, and operational longevity, which have historically limited widespread adoption of this technology in industrial applications.

Water purity requirements for AEM systems represent a critical consideration that directly impacts system performance, efficiency, and lifespan. The presence of certain ionic species, particularly multivalent cations such as calcium and magnesium, can significantly impair membrane functionality through scaling and fouling mechanisms. Additionally, organic contaminants and particulate matter can accelerate membrane degradation and reduce system efficiency over time.

The primary technical objectives in advancing AEM water purification technology include developing comprehensive water quality parameters specifically tailored for AEM operations, establishing standardized pretreatment protocols to ensure optimal feed water quality, and creating robust monitoring systems to maintain water purity throughout the operational cycle. These objectives aim to maximize system performance while minimizing maintenance requirements and extending operational lifespan.

Current research trends indicate a growing focus on understanding the complex interactions between water impurities and AEM materials at the molecular level. This fundamental research is expected to inform the development of next-generation membranes with enhanced selectivity and resistance to fouling. Parallel efforts are being directed toward optimizing deionization strategies that can effectively address varying water quality challenges across different industrial applications.

The technological trajectory suggests that future developments will likely center on creating integrated water treatment solutions that combine multiple purification technologies to achieve optimal water quality for AEM systems. This holistic approach recognizes that water purity requirements vary significantly based on specific applications, from industrial process water to specialized laboratory environments, necessitating tailored solutions rather than one-size-fits-all approaches.

Market Analysis for High-Purity Water in AEM Systems

The global market for high-purity water systems in Anion Exchange Membrane (AEM) applications is experiencing robust growth, driven by increasing adoption of AEM technology across multiple sectors. Current market valuations indicate the high-purity water treatment sector specifically for electrochemical systems reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030.

The demand for high-purity water in AEM systems stems primarily from five key sectors: hydrogen production via water electrolysis, fuel cell applications, industrial electrochemical processes, pharmaceutical manufacturing, and advanced electronics production. Among these, the hydrogen economy represents the fastest-growing segment, with green hydrogen initiatives worldwide creating substantial demand for water purification technologies compatible with AEM electrolyzers.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for nearly 42% of global demand, followed by North America and Europe at 28% and 24% respectively. China's aggressive investment in hydrogen infrastructure has positioned it as the single largest national market, while Germany leads European demand due to its ambitious decarbonization targets.

Market research indicates that end-users are increasingly prioritizing water purification systems that offer specific performance attributes for AEM applications. These include removal of multivalent cations (particularly Ca2+, Mg2+, and Fe3+) that cause membrane fouling, elimination of silica that can degrade membrane performance, and reduction of organic contaminants that interfere with electrode reactions.

Consumer preference analysis shows growing demand for integrated water purification solutions specifically designed for AEM systems rather than generic deionization technologies. This trend has created a specialized market segment with premium pricing potential, as customers demonstrate willingness to pay 15-20% more for purification systems with proven compatibility with AEM technology.

The competitive landscape features both established water treatment companies expanding into AEM-specific solutions and specialized startups focusing exclusively on this niche. Recent market entrants have gained traction by offering modular, scalable systems that can be tailored to different AEM applications and deployment scales.

Supply chain analysis reveals potential constraints in specialized ion exchange resins and advanced membrane materials needed for high-performance water purification systems. These constraints may impact market growth if manufacturing capacity does not expand in parallel with increasing demand from the AEM sector.

The demand for high-purity water in AEM systems stems primarily from five key sectors: hydrogen production via water electrolysis, fuel cell applications, industrial electrochemical processes, pharmaceutical manufacturing, and advanced electronics production. Among these, the hydrogen economy represents the fastest-growing segment, with green hydrogen initiatives worldwide creating substantial demand for water purification technologies compatible with AEM electrolyzers.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for nearly 42% of global demand, followed by North America and Europe at 28% and 24% respectively. China's aggressive investment in hydrogen infrastructure has positioned it as the single largest national market, while Germany leads European demand due to its ambitious decarbonization targets.

Market research indicates that end-users are increasingly prioritizing water purification systems that offer specific performance attributes for AEM applications. These include removal of multivalent cations (particularly Ca2+, Mg2+, and Fe3+) that cause membrane fouling, elimination of silica that can degrade membrane performance, and reduction of organic contaminants that interfere with electrode reactions.

Consumer preference analysis shows growing demand for integrated water purification solutions specifically designed for AEM systems rather than generic deionization technologies. This trend has created a specialized market segment with premium pricing potential, as customers demonstrate willingness to pay 15-20% more for purification systems with proven compatibility with AEM technology.

The competitive landscape features both established water treatment companies expanding into AEM-specific solutions and specialized startups focusing exclusively on this niche. Recent market entrants have gained traction by offering modular, scalable systems that can be tailored to different AEM applications and deployment scales.

Supply chain analysis reveals potential constraints in specialized ion exchange resins and advanced membrane materials needed for high-performance water purification systems. These constraints may impact market growth if manufacturing capacity does not expand in parallel with increasing demand from the AEM sector.

Current Deionization Technologies and Challenges

Deionization technologies for Anion Exchange Membrane (AEM) systems have evolved significantly over recent decades, with several established methods currently dominating the market. Reverse Osmosis (RO) remains the most widely implemented technology, utilizing semi-permeable membranes to remove ions, molecules, and larger particles from water. While RO systems achieve up to 99% ion removal efficiency, they face limitations including high energy consumption, membrane fouling issues, and significant water wastage—typically 25-50% of input water becomes concentrate waste.

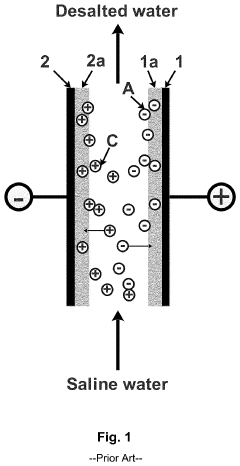

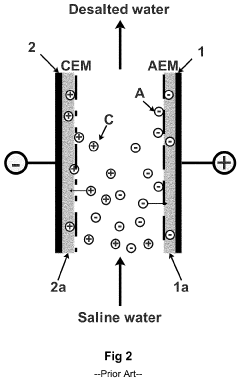

Electrodeionization (EDI) represents another prominent technology, combining ion exchange resins with ion-selective membranes in an electric field to remove ionized species. EDI systems offer continuous operation without chemical regeneration requirements and produce high-purity water suitable for AEM applications. However, these systems demand pre-treatment processes, exhibit sensitivity to feed water quality variations, and involve relatively high capital costs.

Ion Exchange (IX) technologies utilize specialized resins to exchange hydrogen and hydroxide ions for cations and anions in water. While effective at producing ultrapure water with resistivity approaching 18.2 MΩ·cm, traditional IX systems require periodic chemical regeneration, creating secondary waste streams containing concentrated regenerant chemicals that present disposal challenges.

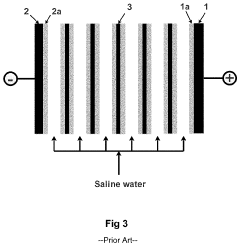

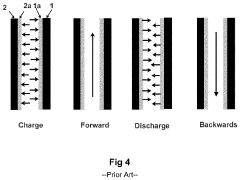

Capacitive Deionization (CDI) has emerged as a promising alternative, employing electrically charged electrodes to adsorb ions from water flowing between them. CDI offers advantages in energy efficiency for brackish water treatment and operational flexibility, but currently faces limitations in treating high-salinity waters and suffers from electrode degradation over extended operational periods.

The primary challenges confronting current deionization technologies for AEM systems include membrane fouling and scaling, which significantly reduce system efficiency and increase maintenance requirements. Biofouling particularly affects membrane-based systems, as microorganisms form biofilms that obstruct water flow and decrease ion removal efficiency. Energy consumption remains a critical concern, with most technologies requiring substantial electrical input, limiting their application in resource-constrained environments.

Selective ion removal presents another significant challenge, as most current technologies remove ions indiscriminately, whereas AEM systems may require specific ion profiles. Additionally, the trade-off between water recovery rates and energy consumption continues to challenge system designers, with higher recovery rates typically demanding increased energy input. The environmental impact of concentrate and waste disposal from deionization processes also presents regulatory and sustainability challenges that must be addressed for widespread implementation.

Electrodeionization (EDI) represents another prominent technology, combining ion exchange resins with ion-selective membranes in an electric field to remove ionized species. EDI systems offer continuous operation without chemical regeneration requirements and produce high-purity water suitable for AEM applications. However, these systems demand pre-treatment processes, exhibit sensitivity to feed water quality variations, and involve relatively high capital costs.

Ion Exchange (IX) technologies utilize specialized resins to exchange hydrogen and hydroxide ions for cations and anions in water. While effective at producing ultrapure water with resistivity approaching 18.2 MΩ·cm, traditional IX systems require periodic chemical regeneration, creating secondary waste streams containing concentrated regenerant chemicals that present disposal challenges.

Capacitive Deionization (CDI) has emerged as a promising alternative, employing electrically charged electrodes to adsorb ions from water flowing between them. CDI offers advantages in energy efficiency for brackish water treatment and operational flexibility, but currently faces limitations in treating high-salinity waters and suffers from electrode degradation over extended operational periods.

The primary challenges confronting current deionization technologies for AEM systems include membrane fouling and scaling, which significantly reduce system efficiency and increase maintenance requirements. Biofouling particularly affects membrane-based systems, as microorganisms form biofilms that obstruct water flow and decrease ion removal efficiency. Energy consumption remains a critical concern, with most technologies requiring substantial electrical input, limiting their application in resource-constrained environments.

Selective ion removal presents another significant challenge, as most current technologies remove ions indiscriminately, whereas AEM systems may require specific ion profiles. Additionally, the trade-off between water recovery rates and energy consumption continues to challenge system designers, with higher recovery rates typically demanding increased energy input. The environmental impact of concentrate and waste disposal from deionization processes also presents regulatory and sustainability challenges that must be addressed for widespread implementation.

Established Deionization Strategies for AEM Applications

01 Water purification methods for AEM systems

Various water purification methods are employed in anion exchange membrane systems to ensure optimal performance. These methods include filtration, ion exchange, and electrochemical processes that remove impurities and contaminants from water. Purification techniques are essential for maintaining the efficiency and longevity of AEM systems by preventing fouling and scaling of the membranes.- Water purification methods for AEM systems: Various water purification methods are employed in anion exchange membrane systems to ensure optimal performance. These methods include filtration, ion exchange, and electrochemical processes that remove impurities and contaminants from water. Proper water purification is essential for maintaining the efficiency and longevity of AEM systems, as impurities can interfere with ion transport and membrane functionality.

- Impact of water purity on AEM performance: The purity of water significantly affects the performance of anion exchange membrane systems. High levels of impurities can lead to membrane fouling, reduced ion conductivity, and decreased system efficiency. Maintaining appropriate water purity standards helps prevent degradation of the membrane, extends operational lifetime, and ensures consistent performance in applications such as fuel cells, electrolyzers, and water treatment systems.

- Monitoring and control systems for water quality in AEM applications: Advanced monitoring and control systems are implemented to maintain water purity in anion exchange membrane applications. These systems include sensors, analyzers, and automated control mechanisms that continuously measure parameters such as conductivity, pH, and ion concentration. Real-time monitoring allows for immediate adjustments to water treatment processes, ensuring that water quality remains within specifications for optimal AEM system operation.

- Specialized membrane materials for improved water purity tolerance: Innovative membrane materials are being developed to enhance tolerance to varying water purity levels in AEM systems. These advanced materials incorporate modified polymers, composite structures, and functional groups that resist fouling and degradation when exposed to impurities. By improving the membrane's resilience to water quality fluctuations, these materials extend system lifetime and maintain performance even under challenging water conditions.

- Pretreatment technologies for water in AEM systems: Pretreatment technologies are essential for preparing water before it enters anion exchange membrane systems. These technologies include filtration systems, softening processes, and chemical treatments that remove specific contaminants that could damage the membrane or reduce system efficiency. Effective pretreatment extends membrane life, reduces maintenance requirements, and ensures consistent performance across various applications including water purification, energy generation, and industrial processes.

02 Impact of water quality on AEM performance

Water quality significantly affects the performance and durability of anion exchange membrane systems. High levels of impurities can lead to membrane fouling, reduced ion conductivity, and decreased system efficiency. Maintaining proper water purity levels is crucial for ensuring optimal ion exchange capacity, preventing premature degradation of membranes, and extending the operational lifespan of AEM systems.Expand Specific Solutions03 Monitoring and control systems for water purity in AEM applications

Advanced monitoring and control systems are implemented to maintain water purity in anion exchange membrane applications. These systems include sensors that continuously measure parameters such as conductivity, pH, and ion concentration. Real-time monitoring allows for immediate detection of water quality issues, enabling automated adjustments to purification processes and ensuring consistent performance of AEM systems.Expand Specific Solutions04 Pretreatment technologies for AEM feed water

Pretreatment technologies are essential for preparing feed water before it enters anion exchange membrane systems. These technologies include sediment filtration, carbon adsorption, and chemical treatments that remove particulates, organic compounds, and other contaminants. Effective pretreatment prevents membrane fouling, reduces maintenance requirements, and ensures consistent water quality for optimal AEM system operation.Expand Specific Solutions05 Novel membrane materials for improved water purity handling

Research and development efforts focus on creating novel anion exchange membrane materials with enhanced resistance to impurities in water. These advanced materials incorporate modified polymers, composite structures, and functional coatings that improve selectivity, stability, and fouling resistance. The innovative membrane designs enable AEM systems to maintain high performance even when processing water with varying levels of purity, extending application possibilities in challenging environments.Expand Specific Solutions

Leading Companies in AEM Water Treatment Industry

The AEM (Anion Exchange Membrane) water purification market is currently in a growth phase, with increasing demand driven by stringent water quality requirements across industries. The global market is expanding at approximately 8-10% annually, reaching an estimated $2.5 billion. Technologically, deionization strategies for AEM systems are advancing rapidly, with varying maturity levels among key players. Kurita Water Industries and Evoqua Water Technologies lead with comprehensive commercial solutions, while MIT and Organo Corp. focus on breakthrough research in membrane technology. Merck Patent GmbH and Ecolab USA are developing specialized chemical treatments, while companies like NxStage Medical and Nomura Micro Science are adapting AEM technologies for specific applications in healthcare and semiconductor manufacturing respectively. The competitive landscape shows a mix of established water treatment corporations and specialized technology innovators.

Organo Corp.

Technical Solution: Organo Corporation has developed the PURELITE™ AEM water purification system specifically designed to address the unique water purity challenges in anion exchange membrane applications. Their technology employs a multi-barrier approach beginning with their patented ORGANOGUARD™ pre-filtration system that removes particulates down to 0.1 microns and reduces organic contaminants. The core of their system utilizes specialized mixed-bed ion exchange technology with their proprietary AEM-SAFE™ resins that selectively remove cations and anions harmful to AEM performance, particularly focusing on multivalent ions like calcium, magnesium, and iron that can cause membrane fouling. Organo's system incorporates continuous electrodeionization (CEDI) as a final polishing step, achieving resistivity values consistently above 17 MΩ·cm. Their technology maintains silica levels below 0.5 ppb and TOC below 3 ppb, meeting the stringent requirements for AEM systems. The PURELITE™ system also features an integrated degasification module that reduces dissolved carbon dioxide and oxygen to prevent carbonate formation and oxidative degradation of the AEM components.

Strengths: Exceptional removal of silica and multivalent ions that are particularly problematic for AEM systems. Compact design with smaller footprint compared to competing technologies. Weaknesses: Higher replacement frequency required for specialized resins compared to conventional systems. Limited scalability for very large industrial applications.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed an innovative approach to water purification for AEM systems that addresses the specific ionic contaminants affecting AEM performance and durability. Their technology, known as Selective Electrodialysis for AEM Applications (SEDAA), combines conventional electrodialysis with novel ion-selective membranes that preferentially remove carbonate, chloride, and transition metal ions that poison AEM catalysts. The MIT approach utilizes computational modeling to predict ion transport behavior and optimize membrane selectivity, resulting in a system that achieves water purity with conductivity below 0.07 μS/cm while consuming 30% less energy than conventional deionization methods. Their research has demonstrated that controlling specific ionic ratios, rather than simply achieving overall low conductivity, significantly improves AEM performance and longevity. The MIT system incorporates real-time monitoring using advanced spectroscopic techniques that can detect sub-ppb levels of critical contaminants. Recent publications from the MIT team have shown that their selective deionization approach increases AEM fuel cell power density by up to 22% compared to systems using conventionally purified water, primarily by preventing carbonate poisoning of the membrane.

Strengths: Energy-efficient approach with significantly lower power consumption than conventional deionization technologies. Advanced monitoring capabilities provide unprecedented insight into specific contaminant levels. Weaknesses: Technology remains primarily in research phase with limited commercial implementation. Current designs have limited throughput capacity compared to established industrial systems.

Critical Patents in AEM Water Purification Technology

Anion exchange polymers and anion exchange membranes

PatentWO2023283006A9

Innovation

- A mechanically reinforced anion exchange membrane is developed using a poly(phenylene) backbone with quaternary ammonium functional groups and an inert porous scaffold material, synthesized through super-acid catalyzed polymerization, which includes functionalized fluorene and piperidine-containing structures, and optionally cross-linked to enhance mechanical stability and conductivity.

Single module, flow-electrode apparatus and method for continous water desalination and ion separation by capacitive deionization

PatentActiveUS11261109B2

Innovation

- A single module, flow-electrode apparatus utilizing suspended conductive particles in a fluid within a single cell with ion exchange membranes allows for continuous water desalination and ion separation by recirculating the fluid between compartments with opposite charges, eliminating the need for separate adsorption and regeneration modes and reducing energy consumption.

Environmental Impact Assessment of Deionization Processes

The environmental impact of deionization processes for Anion Exchange Membrane (AEM) systems requires comprehensive assessment due to their growing implementation in water treatment facilities. Traditional deionization methods often involve significant chemical usage, energy consumption, and waste generation that can adversely affect ecosystems and contribute to carbon footprints.

Ion exchange resins, commonly used in AEM deionization systems, present environmental concerns throughout their lifecycle. The production of these synthetic polymers involves petroleum-based raw materials, contributing to resource depletion and manufacturing emissions. Additionally, the regeneration of exhausted resins typically requires strong acids and bases, resulting in highly concentrated waste streams that may contain heavy metals and other contaminants requiring specialized disposal.

Energy consumption represents another significant environmental consideration. Electrodeionization (EDI) and capacitive deionization (CDI) technologies, while offering chemical-free alternatives, demand substantial electrical power. The environmental impact varies considerably depending on regional energy sources, with renewable-powered systems demonstrating significantly lower carbon emissions compared to those reliant on fossil fuels.

Water usage efficiency also factors prominently in environmental assessments. Reverse osmosis systems, often used in conjunction with AEM technologies, typically reject 20-50% of feed water as concentrate, creating disposal challenges and potentially stressing water-scarce regions. More efficient designs incorporating brine recirculation and recovery systems can substantially reduce this environmental burden.

Waste management presents ongoing challenges across deionization technologies. Membrane replacement generates solid waste, while regeneration processes produce liquid waste streams requiring neutralization and treatment. Advanced systems incorporating zero liquid discharge (ZLD) technologies can minimize environmental impact but often at higher energy and capital costs.

Life cycle assessment (LCA) studies indicate that modern AEM deionization systems generally demonstrate improved environmental performance compared to conventional ion exchange technologies. Hybrid approaches combining membrane processes with selective ion exchange show particular promise in reducing chemical consumption, waste generation, and energy requirements simultaneously.

Regulatory frameworks increasingly emphasize environmental performance metrics beyond simple effluent quality. Carbon footprint calculations, water usage efficiency, and chemical reduction targets are becoming standard requirements in many jurisdictions, driving innovation toward more sustainable deionization processes for AEM systems.

Ion exchange resins, commonly used in AEM deionization systems, present environmental concerns throughout their lifecycle. The production of these synthetic polymers involves petroleum-based raw materials, contributing to resource depletion and manufacturing emissions. Additionally, the regeneration of exhausted resins typically requires strong acids and bases, resulting in highly concentrated waste streams that may contain heavy metals and other contaminants requiring specialized disposal.

Energy consumption represents another significant environmental consideration. Electrodeionization (EDI) and capacitive deionization (CDI) technologies, while offering chemical-free alternatives, demand substantial electrical power. The environmental impact varies considerably depending on regional energy sources, with renewable-powered systems demonstrating significantly lower carbon emissions compared to those reliant on fossil fuels.

Water usage efficiency also factors prominently in environmental assessments. Reverse osmosis systems, often used in conjunction with AEM technologies, typically reject 20-50% of feed water as concentrate, creating disposal challenges and potentially stressing water-scarce regions. More efficient designs incorporating brine recirculation and recovery systems can substantially reduce this environmental burden.

Waste management presents ongoing challenges across deionization technologies. Membrane replacement generates solid waste, while regeneration processes produce liquid waste streams requiring neutralization and treatment. Advanced systems incorporating zero liquid discharge (ZLD) technologies can minimize environmental impact but often at higher energy and capital costs.

Life cycle assessment (LCA) studies indicate that modern AEM deionization systems generally demonstrate improved environmental performance compared to conventional ion exchange technologies. Hybrid approaches combining membrane processes with selective ion exchange show particular promise in reducing chemical consumption, waste generation, and energy requirements simultaneously.

Regulatory frameworks increasingly emphasize environmental performance metrics beyond simple effluent quality. Carbon footprint calculations, water usage efficiency, and chemical reduction targets are becoming standard requirements in many jurisdictions, driving innovation toward more sustainable deionization processes for AEM systems.

Cost-Benefit Analysis of Advanced Purification Methods

The implementation of advanced water purification methods for Anion Exchange Membrane (AEM) systems requires careful cost-benefit analysis to determine the most economically viable solutions. Initial capital investments for high-grade deionization systems typically range from $50,000 to $250,000 depending on capacity and technology sophistication, with reverse osmosis (RO) systems generally representing the lower end and electrodeionization (EDI) systems the higher end of this spectrum.

Operational costs must be evaluated against performance benefits. RO systems, while having lower upfront costs, incur higher operational expenses due to membrane replacement (approximately $2,000-5,000 annually) and energy consumption (0.5-2.5 kWh per cubic meter of water). EDI systems demonstrate higher energy efficiency (0.1-0.8 kWh per cubic meter) and reduced maintenance costs over their operational lifetime, which typically extends to 7-10 years compared to 3-5 years for RO membranes.

Water recovery rates significantly impact economic viability. Traditional deionization methods achieve 70-80% recovery rates, while advanced systems incorporating recirculation and concentration management can reach 90-95%, substantially reducing wastewater treatment costs and raw water consumption. For facilities processing 10,000 gallons daily, this improvement translates to annual savings of $15,000-25,000 in water costs alone.

Quality assurance benefits must be monetized when evaluating purification investments. Inadequate water purity in AEM systems leads to membrane fouling and degradation, reducing system efficiency by 15-30% and shortening membrane lifespan by up to 50%. Advanced purification methods that maintain consistent water quality below 5 μS/cm conductivity and remove specific contaminants (silica, organics, multivalent ions) effectively prevent these issues, extending operational lifespans and maintaining performance metrics.

Return on investment (ROI) calculations indicate that higher-grade purification systems typically achieve breakeven within 2-4 years when accounting for all operational benefits. Facilities operating at larger scales (>50,000 gallons daily) see faster ROI, often within 18-24 months. Smaller operations may benefit from modular or scalable solutions that balance initial investment against gradual capacity expansion.

Environmental compliance considerations add another dimension to cost-benefit analysis. Increasingly stringent discharge regulations impose costs for non-compliance (potential fines of $10,000-100,000 depending on jurisdiction), making advanced purification systems with higher recovery rates and reduced chemical usage increasingly attractive from both environmental and economic perspectives.

Operational costs must be evaluated against performance benefits. RO systems, while having lower upfront costs, incur higher operational expenses due to membrane replacement (approximately $2,000-5,000 annually) and energy consumption (0.5-2.5 kWh per cubic meter of water). EDI systems demonstrate higher energy efficiency (0.1-0.8 kWh per cubic meter) and reduced maintenance costs over their operational lifetime, which typically extends to 7-10 years compared to 3-5 years for RO membranes.

Water recovery rates significantly impact economic viability. Traditional deionization methods achieve 70-80% recovery rates, while advanced systems incorporating recirculation and concentration management can reach 90-95%, substantially reducing wastewater treatment costs and raw water consumption. For facilities processing 10,000 gallons daily, this improvement translates to annual savings of $15,000-25,000 in water costs alone.

Quality assurance benefits must be monetized when evaluating purification investments. Inadequate water purity in AEM systems leads to membrane fouling and degradation, reducing system efficiency by 15-30% and shortening membrane lifespan by up to 50%. Advanced purification methods that maintain consistent water quality below 5 μS/cm conductivity and remove specific contaminants (silica, organics, multivalent ions) effectively prevent these issues, extending operational lifespans and maintaining performance metrics.

Return on investment (ROI) calculations indicate that higher-grade purification systems typically achieve breakeven within 2-4 years when accounting for all operational benefits. Facilities operating at larger scales (>50,000 gallons daily) see faster ROI, often within 18-24 months. Smaller operations may benefit from modular or scalable solutions that balance initial investment against gradual capacity expansion.

Environmental compliance considerations add another dimension to cost-benefit analysis. Increasingly stringent discharge regulations impose costs for non-compliance (potential fines of $10,000-100,000 depending on jurisdiction), making advanced purification systems with higher recovery rates and reduced chemical usage increasingly attractive from both environmental and economic perspectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!