Gas Crossover And Safety Considerations In AEM Electrolyzer Operation

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AEM Electrolysis Background and Safety Objectives

Anion Exchange Membrane (AEM) electrolysis represents a promising green hydrogen production technology that has gained significant attention in recent years as the world transitions toward renewable energy systems. Unlike traditional alkaline electrolysis and proton exchange membrane (PEM) electrolysis, AEM technology offers a unique combination of advantages including the use of non-noble metal catalysts, operation in alkaline conditions, and potentially lower system costs. The evolution of this technology has accelerated since the early 2010s, with substantial improvements in membrane stability, catalyst performance, and system integration.

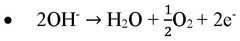

The fundamental principle of AEM electrolysis involves water splitting at the anode to produce oxygen, electrons, and protons, while hydrogen is generated at the cathode. The distinguishing feature is the solid polymer electrolyte that conducts hydroxide ions (OH-) from cathode to anode, enabling efficient ionic transport while maintaining physical separation between the hydrogen and oxygen production chambers. This separation is critical but not absolute, which introduces the central safety challenge of gas crossover.

Gas crossover in AEM electrolyzers occurs when hydrogen molecules migrate through the membrane to the oxygen side or vice versa, creating potentially explosive gas mixtures. This phenomenon becomes particularly concerning at high current densities, elevated pressures, and during dynamic operation conditions that are increasingly common in renewable energy-coupled systems. The safety implications are substantial, as hydrogen-oxygen mixtures can form explosive atmospheres when hydrogen concentration reaches 4-75% in oxygen.

The primary safety objectives in AEM electrolyzer development focus on minimizing gas crossover while maintaining operational efficiency. This includes engineering membranes with optimal thickness and ion conductivity that simultaneously limit gas permeation, developing advanced gas detection systems capable of early warning, and implementing robust system architectures with appropriate pressure differentials to mitigate crossover effects. Additionally, safety protocols must address transient operation conditions, such as start-up, shutdown, and load-following scenarios where gas crossover risks may be heightened.

Current research trajectories aim to establish comprehensive safety standards specifically tailored to AEM technology, as existing hydrogen safety frameworks may not fully address the unique characteristics of these systems. The development of in-situ monitoring techniques for real-time gas composition analysis represents another critical objective, potentially enabling predictive safety management rather than reactive measures.

As AEM electrolysis moves toward commercial deployment and scaling, resolving these safety considerations becomes increasingly urgent. The technology's promise for cost-effective green hydrogen production can only be realized through parallel advancement in operational safety measures that ensure reliable performance across diverse application environments, from distributed energy systems to industrial-scale hydrogen production facilities.

The fundamental principle of AEM electrolysis involves water splitting at the anode to produce oxygen, electrons, and protons, while hydrogen is generated at the cathode. The distinguishing feature is the solid polymer electrolyte that conducts hydroxide ions (OH-) from cathode to anode, enabling efficient ionic transport while maintaining physical separation between the hydrogen and oxygen production chambers. This separation is critical but not absolute, which introduces the central safety challenge of gas crossover.

Gas crossover in AEM electrolyzers occurs when hydrogen molecules migrate through the membrane to the oxygen side or vice versa, creating potentially explosive gas mixtures. This phenomenon becomes particularly concerning at high current densities, elevated pressures, and during dynamic operation conditions that are increasingly common in renewable energy-coupled systems. The safety implications are substantial, as hydrogen-oxygen mixtures can form explosive atmospheres when hydrogen concentration reaches 4-75% in oxygen.

The primary safety objectives in AEM electrolyzer development focus on minimizing gas crossover while maintaining operational efficiency. This includes engineering membranes with optimal thickness and ion conductivity that simultaneously limit gas permeation, developing advanced gas detection systems capable of early warning, and implementing robust system architectures with appropriate pressure differentials to mitigate crossover effects. Additionally, safety protocols must address transient operation conditions, such as start-up, shutdown, and load-following scenarios where gas crossover risks may be heightened.

Current research trajectories aim to establish comprehensive safety standards specifically tailored to AEM technology, as existing hydrogen safety frameworks may not fully address the unique characteristics of these systems. The development of in-situ monitoring techniques for real-time gas composition analysis represents another critical objective, potentially enabling predictive safety management rather than reactive measures.

As AEM electrolysis moves toward commercial deployment and scaling, resolving these safety considerations becomes increasingly urgent. The technology's promise for cost-effective green hydrogen production can only be realized through parallel advancement in operational safety measures that ensure reliable performance across diverse application environments, from distributed energy systems to industrial-scale hydrogen production facilities.

Market Analysis for AEM Electrolyzers

The global market for Anion Exchange Membrane (AEM) electrolyzers is experiencing significant growth as hydrogen gains prominence in the clean energy transition. Current market valuations indicate that AEM technology occupies approximately 5-10% of the overall electrolyzer market, which was valued at around $290 million in 2022 and is projected to reach $2.2 billion by 2030, representing a compound annual growth rate of 28.4%.

The demand for AEM electrolyzers is primarily driven by their positioning as a middle-ground solution between alkaline and Proton Exchange Membrane (PEM) technologies. AEM systems offer several market advantages, including the use of non-precious metal catalysts (unlike PEM), operation without highly corrosive electrolytes (unlike alkaline), and higher current densities than traditional alkaline systems. These benefits translate to potentially lower capital expenditure and operating costs, making AEM technology increasingly attractive to industrial hydrogen producers.

Regional market analysis reveals that Europe currently leads AEM electrolyzer adoption, supported by aggressive decarbonization policies and substantial government funding for hydrogen infrastructure. The European Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating significant market opportunities for AEM technology. North America follows as the second-largest market, with the U.S. Hydrogen Shot initiative targeting $1/kg hydrogen production costs, which aligns well with AEM's cost-reduction potential.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to witness the fastest growth rate in AEM electrolyzer adoption. China's 14th Five-Year Plan emphasizes hydrogen as a strategic industry, while Japan and South Korea have established ambitious hydrogen roadmaps focusing on domestic production capabilities.

Market segmentation by application shows that industrial uses currently dominate AEM electrolyzer deployments, particularly in ammonia production, refining, and chemical manufacturing. However, the energy storage sector is projected to be the fastest-growing application segment, with grid-scale hydrogen storage solutions gaining traction as renewable energy penetration increases.

A critical market driver specific to AEM technology is the growing concern over gas crossover safety issues in hydrogen production. End-users are increasingly prioritizing operational safety, creating market demand for advanced AEM designs with improved gas separation capabilities and enhanced safety features. This trend is reflected in recent procurement specifications from major industrial gas companies and energy utilities, which now commonly include stringent safety requirements related to gas crossover prevention.

The demand for AEM electrolyzers is primarily driven by their positioning as a middle-ground solution between alkaline and Proton Exchange Membrane (PEM) technologies. AEM systems offer several market advantages, including the use of non-precious metal catalysts (unlike PEM), operation without highly corrosive electrolytes (unlike alkaline), and higher current densities than traditional alkaline systems. These benefits translate to potentially lower capital expenditure and operating costs, making AEM technology increasingly attractive to industrial hydrogen producers.

Regional market analysis reveals that Europe currently leads AEM electrolyzer adoption, supported by aggressive decarbonization policies and substantial government funding for hydrogen infrastructure. The European Hydrogen Strategy aims to install at least 40 GW of electrolyzer capacity by 2030, creating significant market opportunities for AEM technology. North America follows as the second-largest market, with the U.S. Hydrogen Shot initiative targeting $1/kg hydrogen production costs, which aligns well with AEM's cost-reduction potential.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to witness the fastest growth rate in AEM electrolyzer adoption. China's 14th Five-Year Plan emphasizes hydrogen as a strategic industry, while Japan and South Korea have established ambitious hydrogen roadmaps focusing on domestic production capabilities.

Market segmentation by application shows that industrial uses currently dominate AEM electrolyzer deployments, particularly in ammonia production, refining, and chemical manufacturing. However, the energy storage sector is projected to be the fastest-growing application segment, with grid-scale hydrogen storage solutions gaining traction as renewable energy penetration increases.

A critical market driver specific to AEM technology is the growing concern over gas crossover safety issues in hydrogen production. End-users are increasingly prioritizing operational safety, creating market demand for advanced AEM designs with improved gas separation capabilities and enhanced safety features. This trend is reflected in recent procurement specifications from major industrial gas companies and energy utilities, which now commonly include stringent safety requirements related to gas crossover prevention.

Gas Crossover Challenges in AEM Technology

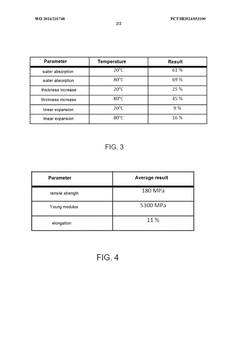

Gas crossover represents one of the most significant challenges in Anion Exchange Membrane (AEM) electrolyzer technology, posing both efficiency and safety concerns. This phenomenon occurs when hydrogen and oxygen gases permeate through the membrane and contaminate the opposite electrode chamber. In AEM electrolyzers, the crossover rates are typically higher than in traditional alkaline electrolyzers due to the thinner membranes employed to reduce ohmic losses and enhance overall efficiency.

The primary mechanism driving gas crossover in AEM systems involves both diffusion and convection processes. Diffusion occurs due to concentration gradients across the membrane, while convection results from pressure differentials and electro-osmotic drag. These mechanisms are exacerbated by several factors unique to AEM technology, including membrane hydration levels, operating temperature, pressure differentials, and current density variations.

Experimental measurements have shown that crossover rates in AEM electrolyzers can reach 1-5% of produced gases under standard operating conditions, significantly higher than the 0.1-0.5% typically observed in proton exchange membrane (PEM) systems. This increased permeability stems from the larger ionic channels required for hydroxide ion transport compared to proton transport channels in PEM systems.

The consequences of gas crossover extend beyond efficiency losses. When hydrogen crosses to the oxygen side, or vice versa, it creates potentially explosive mixtures. The lower explosive limit (LEL) for hydrogen in oxygen is approximately 4% by volume, while the upper explosive limit (UEL) is around 94%. Operating within these boundaries presents a significant safety hazard, particularly during system startup, shutdown, or under partial load conditions when gas production rates are lower but crossover continues.

Material degradation represents another critical concern resulting from gas crossover. When hydrogen permeates to the oxygen evolution side, it can be catalytically recombined at the anode, generating localized heat that accelerates membrane degradation. Similarly, oxygen crossing to the hydrogen side can lead to peroxide formation, which attacks the polymer backbone of the membrane and catalyst layers, reducing system longevity.

Recent research has demonstrated that crossover rates increase exponentially with temperature, with a 10°C increase typically resulting in a 15-25% higher crossover rate. This temperature sensitivity creates additional challenges for thermal management systems in AEM electrolyzers, requiring careful balance between performance optimization and safety considerations.

The economic impact of gas crossover manifests in reduced faradaic efficiency, increased balance-of-plant requirements for gas purification, and more stringent safety systems. These factors collectively contribute to higher capital and operational costs, presenting significant barriers to widespread commercial adoption of AEM electrolyzer technology.

The primary mechanism driving gas crossover in AEM systems involves both diffusion and convection processes. Diffusion occurs due to concentration gradients across the membrane, while convection results from pressure differentials and electro-osmotic drag. These mechanisms are exacerbated by several factors unique to AEM technology, including membrane hydration levels, operating temperature, pressure differentials, and current density variations.

Experimental measurements have shown that crossover rates in AEM electrolyzers can reach 1-5% of produced gases under standard operating conditions, significantly higher than the 0.1-0.5% typically observed in proton exchange membrane (PEM) systems. This increased permeability stems from the larger ionic channels required for hydroxide ion transport compared to proton transport channels in PEM systems.

The consequences of gas crossover extend beyond efficiency losses. When hydrogen crosses to the oxygen side, or vice versa, it creates potentially explosive mixtures. The lower explosive limit (LEL) for hydrogen in oxygen is approximately 4% by volume, while the upper explosive limit (UEL) is around 94%. Operating within these boundaries presents a significant safety hazard, particularly during system startup, shutdown, or under partial load conditions when gas production rates are lower but crossover continues.

Material degradation represents another critical concern resulting from gas crossover. When hydrogen permeates to the oxygen evolution side, it can be catalytically recombined at the anode, generating localized heat that accelerates membrane degradation. Similarly, oxygen crossing to the hydrogen side can lead to peroxide formation, which attacks the polymer backbone of the membrane and catalyst layers, reducing system longevity.

Recent research has demonstrated that crossover rates increase exponentially with temperature, with a 10°C increase typically resulting in a 15-25% higher crossover rate. This temperature sensitivity creates additional challenges for thermal management systems in AEM electrolyzers, requiring careful balance between performance optimization and safety considerations.

The economic impact of gas crossover manifests in reduced faradaic efficiency, increased balance-of-plant requirements for gas purification, and more stringent safety systems. These factors collectively contribute to higher capital and operational costs, presenting significant barriers to widespread commercial adoption of AEM electrolyzer technology.

Current Gas Crossover Mitigation Strategies

01 Membrane design to reduce gas crossover in AEM electrolyzers

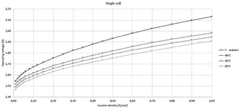

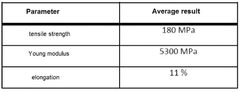

Advanced membrane designs can significantly reduce gas crossover in anion exchange membrane (AEM) electrolyzers. These designs focus on improving the membrane's selectivity and barrier properties while maintaining high ionic conductivity. Techniques include incorporating specialized polymers, cross-linking structures, and composite materials that create more effective barriers against hydrogen and oxygen permeation while allowing efficient hydroxide ion transport. These membrane innovations help maintain electrolyzer efficiency and safety by minimizing unwanted gas mixing.- Membrane design to reduce gas crossover in AEM electrolyzers: Advanced membrane designs can significantly reduce gas crossover in anion exchange membrane (AEM) electrolyzers. These designs focus on optimizing membrane thickness, composition, and structure to create effective barriers against hydrogen and oxygen permeation while maintaining high ionic conductivity. Innovations include composite membranes with specialized layers, reinforced structures, and modified polymer compositions that enhance selectivity and mechanical stability under operating conditions.

- Catalyst layer modifications to minimize gas crossover: Modifications to catalyst layers can help minimize gas crossover in AEM electrolyzers. By optimizing catalyst loading, distribution, and composition, these approaches enhance electrochemical reactions while creating barriers that reduce unwanted gas permeation. Advanced catalyst designs incorporate specific materials that promote selective gas evolution and consumption at the electrodes, effectively reducing the concentration gradient that drives crossover while maintaining high efficiency and performance.

- Operating condition optimization to control gas crossover: Controlling operating conditions such as pressure differentials, temperature, and current density can significantly reduce gas crossover in AEM electrolyzers. Strategic management of these parameters helps minimize the driving forces for gas permeation through the membrane while maintaining efficient operation. Techniques include implementing precise pressure balancing systems, optimized temperature control strategies, and current density modulation to achieve the best balance between performance and gas separation.

- System design and gas management strategies: Innovative system designs and gas management strategies can effectively address gas crossover issues in AEM electrolyzers. These approaches include specialized cell architectures, flow field designs, and gas collection systems that minimize mixing of hydrogen and oxygen. Advanced designs incorporate features such as improved gas separation chambers, optimized flow channels, and strategic placement of components to enhance gas purity and system safety while reducing crossover-related efficiency losses.

- Detection and mitigation systems for gas crossover: Detection and mitigation systems are crucial for managing gas crossover in AEM electrolyzers. These systems include sensors and monitoring equipment that can detect gas mixing at early stages, coupled with automated response mechanisms to address crossover events. Advanced solutions incorporate real-time gas composition analysis, pressure monitoring, and intelligent control systems that can adjust operating parameters or trigger safety protocols when crossover is detected, ensuring safe and efficient electrolyzer operation.

02 Electrode catalysts and structures for minimizing gas crossover

Specialized electrode catalysts and structures can be designed to minimize gas crossover in AEM electrolyzers. These include advanced catalyst layers with optimized porosity and hydrophobicity that promote efficient gas evolution while preventing gas diffusion through the membrane. Some designs incorporate gradient structures or protective layers that direct evolved gases away from the membrane interface. By controlling the electrochemical reaction sites and gas transport pathways, these electrode innovations significantly reduce unwanted gas permeation across the membrane.Expand Specific Solutions03 Operating parameters and control strategies to reduce crossover

Specific operating parameters and control strategies can be implemented to minimize gas crossover in AEM electrolyzers. These include optimized pressure differentials between anode and cathode compartments, controlled temperature profiles, and precise electrolyte flow rates. Advanced control systems can monitor gas composition in real-time and adjust operating conditions accordingly. By maintaining optimal operating windows and implementing dynamic response protocols, these strategies effectively reduce gas permeation through the membrane while maintaining high electrolyzer performance.Expand Specific Solutions04 System design and component integration for crossover prevention

Innovative system designs and component integration approaches can prevent gas crossover in AEM electrolyzers. These include specialized cell architectures with improved gas separation channels, enhanced sealing technologies, and integrated gas recombination systems. Some designs incorporate auxiliary components like gas purification units or recirculation systems that capture and process any crossed-over gases. By addressing crossover at the system level, these approaches provide comprehensive solutions that maintain electrolyzer safety and efficiency even under varying operating conditions.Expand Specific Solutions05 Detection and mitigation strategies for gas crossover

Advanced detection and mitigation strategies can be employed to address gas crossover in AEM electrolyzers. These include in-situ monitoring systems that use sensors to detect hydrogen in oxygen streams or vice versa, coupled with automated safety protocols. Some approaches incorporate catalytic recombination units that convert any crossed-over gases back to water. Early detection systems can trigger preventive measures before dangerous gas mixtures form. These strategies ensure safe operation by providing real-time monitoring and response capabilities to manage crossover events effectively.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The AEM electrolyzer gas crossover and safety market is in an early growth phase, with increasing attention due to hydrogen's role in clean energy transitions. The market size is expanding rapidly, projected to reach significant scale as green hydrogen adoption accelerates. Technologically, the field is advancing from early commercial to mature stages, with varying levels of development across key players. Companies like W.L. Gore & Associates and Ionomr Innovations are pioneering advanced membrane materials to reduce crossover issues, while Enapter has commercialized modular AEM electrolyzers. Established industrial firms including Siemens Energy, AGC, and 3M are leveraging their materials expertise to address safety challenges. Research institutions like École Polytechnique Fédérale de Lausanne and University of Stuttgart are advancing fundamental understanding of crossover mechanisms, collaborating with industry to develop next-generation solutions.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed a comprehensive gas crossover management system for AEM electrolyzers that combines advanced membrane technology with intelligent monitoring systems. Their solution incorporates specialized membrane materials with optimized ion conductivity while minimizing hydrogen permeation. The system features real-time gas detection sensors integrated directly into the electrolyzer stack that continuously monitor hydrogen concentration levels in the oxygen stream and vice versa. When gas crossover approaches critical thresholds, their proprietary control algorithms automatically adjust operating parameters such as pressure differentials, temperature, and current density to minimize crossover effects. Additionally, Siemens has implemented a multi-stage safety protocol that includes automated purging systems, pressure relief valves, and emergency shutdown procedures that activate when gas mixtures approach flammability limits. Their design also incorporates physical separation barriers between cell components to prevent direct mixing in case of membrane failure.

Strengths: Siemens' integrated approach combines hardware and software solutions for comprehensive safety management. Their real-time monitoring system allows for proactive intervention before dangerous conditions develop. Weaknesses: The complex control systems require sophisticated electronics that may increase system cost and create additional potential failure points. The solution may also reduce overall system efficiency when operating in safety-prioritized modes.

W. L. Gore & Associates, Inc.

Technical Solution: W.L. Gore has pioneered advanced membrane technology specifically designed to address gas crossover challenges in AEM electrolyzers. Their proprietary expanded polytetrafluoroethylene (ePTFE) based membranes incorporate specialized ion-exchange materials that maintain high ionic conductivity while significantly reducing gas permeability. The membrane architecture features a reinforced composite structure with nanoscale pore control that physically limits gas molecule transport while allowing efficient hydroxide ion passage. Gore's solution includes membrane treatments that enhance chemical stability in the highly alkaline environment of AEM electrolyzers, extending operational lifetime even under fluctuating load conditions that typically accelerate degradation and increase crossover risks. Their membranes incorporate self-healing properties that can mitigate small defects before they lead to catastrophic failure. Additionally, Gore has developed specialized edge-sealing technology that prevents bypass leakage around membrane edges—a common failure point in electrolyzer stacks that can lead to dangerous gas mixing.

Strengths: Gore's membranes offer exceptional mechanical durability while maintaining high ionic conductivity, allowing for safer operation at higher pressure differentials. Their specialized materials demonstrate superior resistance to chemical degradation, extending safe operational lifetime. Weaknesses: The advanced materials and manufacturing processes result in higher initial costs compared to standard membranes. The specialized nature of their solution may require modifications to existing electrolyzer designs for optimal integration.

Key Patents in AEM Safety Technology

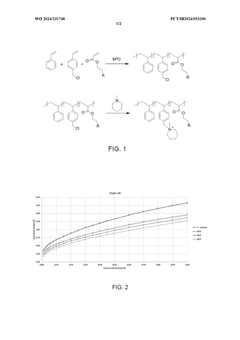

Anionic exchange membrane

PatentWO2024231748A1

Innovation

- An AEM comprising a porous polyolefin material support and a polyfunctional copolymer with monomeric units capable of migrating hydroxide ions and paraffinic groups, which form hydrophobic and hydrophilic phases, enhancing mechanical strength and ion conductivity through hydrophobic interactions and the formation of ion channels.

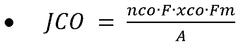

Co 2 and h 2o co-electrolyser system

PatentWO2024235958A1

Innovation

- A CO2 and H2O co-electrolyser system utilizing an anion-exchange membrane (AEM) electrolyser with a mineralization system that converts bicarbonate and carbonate ions into stable metal carbonates, preventing ion crossover and enhancing CO2 storage and conversion, while producing syngas for further conversion to methane.

Regulatory Framework for Hydrogen Production

The regulatory landscape for hydrogen production, particularly from AEM electrolyzers, is evolving rapidly as governments worldwide recognize hydrogen's potential in decarbonization strategies. Current regulatory frameworks primarily address safety concerns related to gas crossover in electrolyzers, which presents explosion risks when hydrogen and oxygen mix beyond certain thresholds.

In the United States, the Department of Energy (DOE) has established comprehensive guidelines for hydrogen production facilities, with specific provisions for electrolyzer operations under Code of Federal Regulations Title 29, Part 1910.103. These regulations mandate continuous gas monitoring systems, automatic shutdown mechanisms, and specific ventilation requirements to mitigate crossover risks in AEM systems.

The European Union has implemented more stringent standards through the ATEX Directive 2014/34/EU and Pressure Equipment Directive 2014/68/EU, which specifically address equipment used in potentially explosive atmospheres. For AEM electrolyzers, these directives require manufacturers to incorporate multiple redundant safety systems and undergo rigorous certification processes that verify containment of crossover events.

ISO standards, particularly ISO 22734:2019 "Hydrogen generators using water electrolysis," provide internationally recognized specifications for safe electrolyzer design and operation. This standard explicitly addresses gas purity requirements and crossover prevention measures, serving as a technical baseline for many national regulatory frameworks.

Japan and South Korea have pioneered hydrogen-specific regulatory frameworks through their respective High-Pressure Gas Safety Acts, which include special provisions for electrolysis systems. These frameworks emphasize regular inspection protocols and operator certification requirements that specifically address crossover detection and emergency response procedures.

Emerging economies are rapidly adopting modified versions of established regulatory frameworks, with China's Hydrogen Energy and Fuel Cell Industry Development Plan (2021-2035) introducing standardized safety protocols for electrolyzer manufacturing and operation that specifically target gas separation integrity.

Insurance requirements increasingly reflect regulatory compliance, with providers requiring documented adherence to safety standards before underwriting electrolyzer installations. This market-driven enforcement mechanism has accelerated industry adoption of crossover prevention technologies and monitoring systems beyond minimum regulatory requirements.

The regulatory landscape continues to evolve, with international harmonization efforts underway through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to standardize safety requirements for hydrogen production technologies, with particular attention to crossover management in next-generation electrolyzers like AEM systems.

In the United States, the Department of Energy (DOE) has established comprehensive guidelines for hydrogen production facilities, with specific provisions for electrolyzer operations under Code of Federal Regulations Title 29, Part 1910.103. These regulations mandate continuous gas monitoring systems, automatic shutdown mechanisms, and specific ventilation requirements to mitigate crossover risks in AEM systems.

The European Union has implemented more stringent standards through the ATEX Directive 2014/34/EU and Pressure Equipment Directive 2014/68/EU, which specifically address equipment used in potentially explosive atmospheres. For AEM electrolyzers, these directives require manufacturers to incorporate multiple redundant safety systems and undergo rigorous certification processes that verify containment of crossover events.

ISO standards, particularly ISO 22734:2019 "Hydrogen generators using water electrolysis," provide internationally recognized specifications for safe electrolyzer design and operation. This standard explicitly addresses gas purity requirements and crossover prevention measures, serving as a technical baseline for many national regulatory frameworks.

Japan and South Korea have pioneered hydrogen-specific regulatory frameworks through their respective High-Pressure Gas Safety Acts, which include special provisions for electrolysis systems. These frameworks emphasize regular inspection protocols and operator certification requirements that specifically address crossover detection and emergency response procedures.

Emerging economies are rapidly adopting modified versions of established regulatory frameworks, with China's Hydrogen Energy and Fuel Cell Industry Development Plan (2021-2035) introducing standardized safety protocols for electrolyzer manufacturing and operation that specifically target gas separation integrity.

Insurance requirements increasingly reflect regulatory compliance, with providers requiring documented adherence to safety standards before underwriting electrolyzer installations. This market-driven enforcement mechanism has accelerated industry adoption of crossover prevention technologies and monitoring systems beyond minimum regulatory requirements.

The regulatory landscape continues to evolve, with international harmonization efforts underway through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to standardize safety requirements for hydrogen production technologies, with particular attention to crossover management in next-generation electrolyzers like AEM systems.

Risk Assessment Methodologies for AEM Systems

Risk assessment in AEM (Anion Exchange Membrane) electrolyzer systems requires structured methodologies to identify, evaluate, and mitigate potential hazards associated with gas crossover phenomena. The HAZOP (Hazard and Operability Study) methodology stands as a cornerstone approach, systematically examining process parameters like pressure differentials, membrane integrity, and gas detection systems to identify deviation-related risks. This methodology enables comprehensive identification of potential failure modes that could lead to dangerous hydrogen-oxygen mixing.

Fault Tree Analysis (FTA) complements HAZOP by establishing causal relationships between system failures and gas crossover events. By mapping potential failure pathways—from membrane degradation to control system malfunctions—FTA quantifies risk probabilities and identifies critical components requiring enhanced safety measures. This approach is particularly valuable for understanding complex interdependencies within AEM systems.

Quantitative Risk Assessment (QRA) techniques provide numerical evaluation of gas crossover risks through mathematical modeling of gas permeation rates, concentration buildups, and explosion probabilities. These models incorporate membrane properties, operating conditions, and system geometries to establish safety thresholds and operational boundaries for AEM electrolyzers.

The Layer of Protection Analysis (LOPA) methodology evaluates the effectiveness of multiple safeguards implemented to prevent gas crossover incidents. This approach assesses independent protection layers—from physical barriers to automated shutdown systems—calculating their combined risk reduction capabilities and identifying potential common-mode failures that could compromise multiple safety systems simultaneously.

Real-time monitoring methodologies represent an evolving approach, utilizing continuous gas composition analysis, pressure differential monitoring, and electrochemical impedance spectroscopy to detect early signs of membrane degradation or crossover events. These methodologies incorporate machine learning algorithms to recognize patterns indicative of developing safety issues before they reach critical levels.

Industry-specific standards like IEC 62282 (Fuel Cell Technologies) and ISO 22734 (Hydrogen Generators) provide standardized risk assessment frameworks tailored to hydrogen production systems. These frameworks establish minimum safety requirements and testing protocols specifically addressing gas crossover concerns in electrochemical systems, ensuring consistent safety evaluation across different AEM electrolyzer designs and applications.

Fault Tree Analysis (FTA) complements HAZOP by establishing causal relationships between system failures and gas crossover events. By mapping potential failure pathways—from membrane degradation to control system malfunctions—FTA quantifies risk probabilities and identifies critical components requiring enhanced safety measures. This approach is particularly valuable for understanding complex interdependencies within AEM systems.

Quantitative Risk Assessment (QRA) techniques provide numerical evaluation of gas crossover risks through mathematical modeling of gas permeation rates, concentration buildups, and explosion probabilities. These models incorporate membrane properties, operating conditions, and system geometries to establish safety thresholds and operational boundaries for AEM electrolyzers.

The Layer of Protection Analysis (LOPA) methodology evaluates the effectiveness of multiple safeguards implemented to prevent gas crossover incidents. This approach assesses independent protection layers—from physical barriers to automated shutdown systems—calculating their combined risk reduction capabilities and identifying potential common-mode failures that could compromise multiple safety systems simultaneously.

Real-time monitoring methodologies represent an evolving approach, utilizing continuous gas composition analysis, pressure differential monitoring, and electrochemical impedance spectroscopy to detect early signs of membrane degradation or crossover events. These methodologies incorporate machine learning algorithms to recognize patterns indicative of developing safety issues before they reach critical levels.

Industry-specific standards like IEC 62282 (Fuel Cell Technologies) and ISO 22734 (Hydrogen Generators) provide standardized risk assessment frameworks tailored to hydrogen production systems. These frameworks establish minimum safety requirements and testing protocols specifically addressing gas crossover concerns in electrochemical systems, ensuring consistent safety evaluation across different AEM electrolyzer designs and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!