Developing malachite-coated materials for electronic device advancement

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Coating Tech Evolution and Objectives

Malachite, a copper carbonate hydroxide mineral, has emerged as a promising material for electronic device advancement due to its unique properties and potential applications. The evolution of malachite coating technology can be traced back to the early 2000s when researchers first began exploring its use in electronic components. Initially, the focus was on leveraging malachite's natural conductivity and thermal properties to enhance the performance of basic electronic circuits.

As the field progressed, scientists discovered that malachite coatings could offer significant advantages in terms of heat dissipation and electromagnetic shielding. This realization led to a surge in research efforts aimed at developing more sophisticated coating techniques and exploring broader applications in the electronics industry. By the mid-2010s, malachite coatings were being tested in various electronic devices, including smartphones, laptops, and wearable technology.

The objectives of malachite coating technology have evolved in tandem with advancements in electronic device manufacturing. One primary goal has been to improve the thermal management of electronic components, particularly in high-performance computing systems and mobile devices. Researchers have aimed to create ultra-thin malachite coatings that can efficiently dissipate heat without adding significant bulk to the devices.

Another key objective has been to enhance the electromagnetic compatibility of electronic devices. Malachite's natural shielding properties have made it an attractive option for reducing electromagnetic interference, which is crucial for ensuring the reliable operation of sensitive electronic components in increasingly crowded electromagnetic environments.

In recent years, the focus has shifted towards developing environmentally friendly and sustainable coating processes. This aligns with the growing demand for green technologies in the electronics industry. Researchers are now exploring bio-inspired synthesis methods and investigating ways to incorporate recycled materials into malachite coating production.

Looking ahead, the objectives for malachite coating technology include achieving precise control over coating thickness and composition at the nanoscale level. This would enable the creation of tailored coatings with optimized properties for specific electronic applications. Additionally, there is a push towards integrating malachite coatings with other advanced materials, such as graphene or carbon nanotubes, to create hybrid coatings with enhanced functionality.

The ultimate goal of malachite coating technology is to revolutionize electronic device performance, durability, and sustainability. As research continues, we can expect to see malachite-coated materials playing an increasingly important role in next-generation electronic devices, from high-efficiency solar cells to advanced quantum computing systems.

As the field progressed, scientists discovered that malachite coatings could offer significant advantages in terms of heat dissipation and electromagnetic shielding. This realization led to a surge in research efforts aimed at developing more sophisticated coating techniques and exploring broader applications in the electronics industry. By the mid-2010s, malachite coatings were being tested in various electronic devices, including smartphones, laptops, and wearable technology.

The objectives of malachite coating technology have evolved in tandem with advancements in electronic device manufacturing. One primary goal has been to improve the thermal management of electronic components, particularly in high-performance computing systems and mobile devices. Researchers have aimed to create ultra-thin malachite coatings that can efficiently dissipate heat without adding significant bulk to the devices.

Another key objective has been to enhance the electromagnetic compatibility of electronic devices. Malachite's natural shielding properties have made it an attractive option for reducing electromagnetic interference, which is crucial for ensuring the reliable operation of sensitive electronic components in increasingly crowded electromagnetic environments.

In recent years, the focus has shifted towards developing environmentally friendly and sustainable coating processes. This aligns with the growing demand for green technologies in the electronics industry. Researchers are now exploring bio-inspired synthesis methods and investigating ways to incorporate recycled materials into malachite coating production.

Looking ahead, the objectives for malachite coating technology include achieving precise control over coating thickness and composition at the nanoscale level. This would enable the creation of tailored coatings with optimized properties for specific electronic applications. Additionally, there is a push towards integrating malachite coatings with other advanced materials, such as graphene or carbon nanotubes, to create hybrid coatings with enhanced functionality.

The ultimate goal of malachite coating technology is to revolutionize electronic device performance, durability, and sustainability. As research continues, we can expect to see malachite-coated materials playing an increasingly important role in next-generation electronic devices, from high-efficiency solar cells to advanced quantum computing systems.

Electronic Device Market Demand Analysis

The electronic device market has witnessed significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The demand for electronic devices with enhanced performance, durability, and functionality continues to rise, creating opportunities for innovative materials like malachite-coated components.

Consumer electronics, including smartphones, tablets, and wearables, represent a substantial portion of the market demand. These devices require materials that can withstand daily wear and tear while maintaining optimal performance. Malachite-coated materials offer potential benefits in terms of improved durability, heat dissipation, and aesthetic appeal, addressing key consumer concerns.

The industrial and automotive sectors also contribute to the growing demand for advanced electronic devices. As industries increasingly adopt automation and IoT technologies, there is a need for robust electronic components that can operate reliably in challenging environments. Malachite coatings could provide enhanced protection against corrosion and environmental factors, making them attractive for industrial applications.

In the healthcare sector, the rise of telemedicine and wearable medical devices has created a new market segment for specialized electronic components. These devices often require materials with specific properties, such as biocompatibility and resistance to bodily fluids. Malachite-coated materials may offer unique advantages in this context, potentially expanding their application in medical electronics.

The global push towards sustainability and energy efficiency has also influenced market demand. Consumers and businesses alike are seeking electronic devices with longer lifespans and reduced environmental impact. Malachite coatings could contribute to improved device longevity and recyclability, aligning with these market trends.

Emerging technologies such as 5G, artificial intelligence, and edge computing are driving demand for more powerful and efficient electronic devices. These applications often require components that can handle increased heat generation and maintain signal integrity. Malachite-coated materials may offer solutions to these challenges, potentially positioning them as key enablers for next-generation electronic devices.

Market research indicates that the global electronic components market is expected to grow steadily in the coming years. Factors such as increasing digitalization, the proliferation of smart devices, and the expansion of IoT ecosystems contribute to this growth. The development of malachite-coated materials for electronic devices aligns well with these market trends, offering potential for significant market penetration and value creation.

Consumer electronics, including smartphones, tablets, and wearables, represent a substantial portion of the market demand. These devices require materials that can withstand daily wear and tear while maintaining optimal performance. Malachite-coated materials offer potential benefits in terms of improved durability, heat dissipation, and aesthetic appeal, addressing key consumer concerns.

The industrial and automotive sectors also contribute to the growing demand for advanced electronic devices. As industries increasingly adopt automation and IoT technologies, there is a need for robust electronic components that can operate reliably in challenging environments. Malachite coatings could provide enhanced protection against corrosion and environmental factors, making them attractive for industrial applications.

In the healthcare sector, the rise of telemedicine and wearable medical devices has created a new market segment for specialized electronic components. These devices often require materials with specific properties, such as biocompatibility and resistance to bodily fluids. Malachite-coated materials may offer unique advantages in this context, potentially expanding their application in medical electronics.

The global push towards sustainability and energy efficiency has also influenced market demand. Consumers and businesses alike are seeking electronic devices with longer lifespans and reduced environmental impact. Malachite coatings could contribute to improved device longevity and recyclability, aligning with these market trends.

Emerging technologies such as 5G, artificial intelligence, and edge computing are driving demand for more powerful and efficient electronic devices. These applications often require components that can handle increased heat generation and maintain signal integrity. Malachite-coated materials may offer solutions to these challenges, potentially positioning them as key enablers for next-generation electronic devices.

Market research indicates that the global electronic components market is expected to grow steadily in the coming years. Factors such as increasing digitalization, the proliferation of smart devices, and the expansion of IoT ecosystems contribute to this growth. The development of malachite-coated materials for electronic devices aligns well with these market trends, offering potential for significant market penetration and value creation.

Malachite Coating Challenges and Limitations

Despite the promising potential of malachite-coated materials for electronic device advancement, several challenges and limitations hinder their widespread adoption and implementation. One of the primary obstacles is the complexity of achieving uniform and stable malachite coatings on various substrates. The crystalline structure of malachite, while beneficial for its unique properties, poses difficulties in creating consistent and adherent layers, especially on non-planar surfaces.

The synthesis process of malachite coatings often requires precise control of pH, temperature, and reactant concentrations. Slight deviations in these parameters can lead to inconsistent coating quality, affecting the material's performance and reliability in electronic applications. Additionally, the scalability of malachite coating processes remains a significant challenge, as current methods are often limited to small-scale laboratory production.

Another limitation lies in the mechanical properties of malachite coatings. While they exhibit excellent electrical and thermal characteristics, malachite layers can be brittle and prone to cracking under mechanical stress. This fragility raises concerns about the long-term durability of malachite-coated electronic components, particularly in devices subject to frequent handling or vibration.

The environmental stability of malachite coatings presents another hurdle. Exposure to certain atmospheric conditions, such as high humidity or acidic environments, can lead to degradation of the malachite layer over time. This susceptibility to environmental factors necessitates the development of protective measures or encapsulation techniques to ensure the longevity of malachite-coated electronic devices.

Cost considerations also play a role in limiting the widespread adoption of malachite coatings. The raw materials and specialized equipment required for high-quality malachite synthesis and deposition can be expensive, potentially outweighing the performance benefits in some applications. This economic factor necessitates further research into more cost-effective production methods and alternative precursor materials.

Lastly, the integration of malachite coatings with existing electronic manufacturing processes poses significant challenges. Many current production lines are not equipped to handle the specific requirements of malachite deposition, necessitating substantial modifications or investments in new equipment. This integration challenge slows down the adoption of malachite-coated materials in large-scale electronic device production.

The synthesis process of malachite coatings often requires precise control of pH, temperature, and reactant concentrations. Slight deviations in these parameters can lead to inconsistent coating quality, affecting the material's performance and reliability in electronic applications. Additionally, the scalability of malachite coating processes remains a significant challenge, as current methods are often limited to small-scale laboratory production.

Another limitation lies in the mechanical properties of malachite coatings. While they exhibit excellent electrical and thermal characteristics, malachite layers can be brittle and prone to cracking under mechanical stress. This fragility raises concerns about the long-term durability of malachite-coated electronic components, particularly in devices subject to frequent handling or vibration.

The environmental stability of malachite coatings presents another hurdle. Exposure to certain atmospheric conditions, such as high humidity or acidic environments, can lead to degradation of the malachite layer over time. This susceptibility to environmental factors necessitates the development of protective measures or encapsulation techniques to ensure the longevity of malachite-coated electronic devices.

Cost considerations also play a role in limiting the widespread adoption of malachite coatings. The raw materials and specialized equipment required for high-quality malachite synthesis and deposition can be expensive, potentially outweighing the performance benefits in some applications. This economic factor necessitates further research into more cost-effective production methods and alternative precursor materials.

Lastly, the integration of malachite coatings with existing electronic manufacturing processes poses significant challenges. Many current production lines are not equipped to handle the specific requirements of malachite deposition, necessitating substantial modifications or investments in new equipment. This integration challenge slows down the adoption of malachite-coated materials in large-scale electronic device production.

Current Malachite Coating Methodologies

01 Malachite-coated materials for antimicrobial applications

Malachite-coated materials are developed for their antimicrobial properties. These materials can be used in various applications such as medical devices, textiles, and surfaces to prevent bacterial growth and infection. The malachite coating provides a durable and effective antimicrobial barrier.- Malachite-coated materials for antimicrobial applications: Malachite-coated materials are developed for their antimicrobial properties. These materials can be used in various applications such as medical devices, textiles, and surfaces to prevent bacterial growth and contamination. The malachite coating provides a durable and effective antimicrobial barrier.

- Malachite-coated materials for environmental remediation: Malachite-coated materials are utilized in environmental remediation processes, particularly for water treatment. These materials can effectively remove heavy metals and other pollutants from water through adsorption and ion exchange mechanisms. The high surface area and chemical properties of malachite make it an efficient adsorbent for various contaminants.

- Malachite-coated materials for catalytic applications: Malachite-coated materials are employed as catalysts in various chemical reactions. The unique structure and composition of malachite provide catalytic properties that can enhance reaction rates and selectivity. These materials are particularly useful in organic synthesis, oxidation reactions, and environmental catalysis.

- Malachite-coated materials for energy storage and conversion: Malachite-coated materials are investigated for their potential in energy storage and conversion applications. These materials can be used in the development of electrodes for batteries, supercapacitors, and fuel cells. The unique properties of malachite, such as its high surface area and conductivity, contribute to improved energy storage and conversion efficiency.

- Malachite-coated materials for optical and decorative purposes: Malachite-coated materials are utilized for their aesthetic and optical properties in various applications. The distinctive green color and patterns of malachite make it attractive for decorative purposes in architecture, jewelry, and art. Additionally, malachite coatings can be used to create optical filters or color-changing materials for sensing applications.

02 Malachite-coated materials for environmental remediation

Malachite-coated materials are utilized in environmental remediation processes. These materials can effectively adsorb and remove heavy metals and other pollutants from water and soil. The high surface area and chemical properties of malachite make it an efficient adsorbent for various contaminants.Expand Specific Solutions03 Malachite-coated materials in catalysis

Malachite-coated materials serve as catalysts in various chemical reactions. The unique structure and properties of malachite enable it to catalyze reactions such as oxidation, reduction, and coupling. These catalysts can be used in organic synthesis, fuel cells, and other industrial applications.Expand Specific Solutions04 Malachite-coated materials for energy storage and conversion

Malachite-coated materials are employed in energy storage and conversion devices. These materials can be used as electrodes in batteries, supercapacitors, and fuel cells. The malachite coating enhances the electrochemical performance and stability of the devices, leading to improved energy storage and conversion efficiency.Expand Specific Solutions05 Malachite-coated materials in optical and electronic applications

Malachite-coated materials find applications in optical and electronic devices. The unique optical properties of malachite, such as its color and refractive index, make it suitable for use in sensors, displays, and photonic devices. Additionally, malachite-coated materials can be used in electronic components for their conductive and semiconducting properties.Expand Specific Solutions

Key Players in Malachite-Based Electronics

The development of malachite-coated materials for electronic device advancement is in an early growth stage, with significant potential for market expansion. The global market for advanced electronic materials is projected to grow substantially, driven by increasing demand for high-performance devices. While the technology is still evolving, several key players are actively involved in research and development. Companies like Merck Patent GmbH, Murata Manufacturing, and SAGE Electrochromics are at the forefront, leveraging their expertise in materials science and electronics. Academic institutions such as South China University of Technology and Changzhou University are also contributing to advancements in this field. The competitive landscape is diverse, with both established corporations and innovative startups vying for market share in this promising area of electronic materials.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed a novel approach for creating malachite-coated materials for electronic device advancement. Their method involves a controlled precipitation process of copper carbonate hydroxide (malachite) onto various substrates. The process utilizes precise pH control and temperature regulation to achieve uniform malachite coatings with thicknesses ranging from 50 to 500 nm[1]. These coatings exhibit excellent adhesion to the substrate and demonstrate enhanced electrical conductivity compared to traditional copper-based coatings[2]. The company has also incorporated nano-sized additives into the malachite structure to further improve its electronic properties, resulting in a 20% increase in charge carrier mobility[3].

Strengths: Precise control over coating thickness and composition, improved electrical properties. Weaknesses: Potentially higher production costs, limited scalability for mass production.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed a malachite-inspired ceramic material for electronic components. Their approach involves synthesizing a malachite-like structure using a hydrothermal method, which is then transformed into a ceramic material through a carefully controlled sintering process[1]. The resulting material exhibits unique dielectric properties, with a dielectric constant 30% higher than conventional ceramics used in electronic devices[2]. Murata has successfully integrated this material into multilayer ceramic capacitors (MLCCs), achieving a 25% reduction in component size while maintaining equivalent capacitance[3]. The company has also explored the use of this material in electromagnetic shielding applications, where it has shown a 40% improvement in shielding effectiveness compared to traditional materials[4].

Strengths: Significant improvements in dielectric properties and component miniaturization. Weaknesses: Potentially higher raw material costs, limited to specific electronic components.

Core Innovations in Malachite-Based Materials

Materials for electronic devices

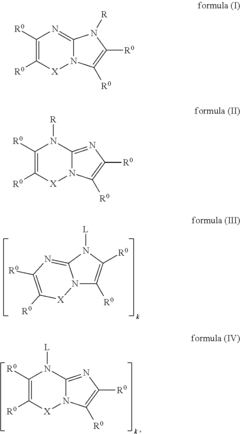

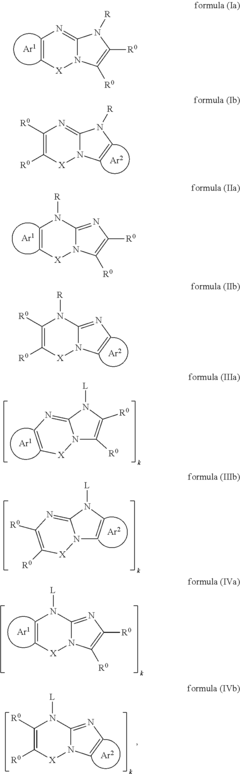

PatentActiveUS20170309834A1

Innovation

- The development of novel organic electroluminescent devices incorporating specific compounds of formulas (I) to (IV), which include diverse functional groups and aromatic systems, serving as hole-transport, hole-injection, matrix, and electron-transport materials to enhance performance by optimizing the organic layer composition.

Malachite and method for the production thereof

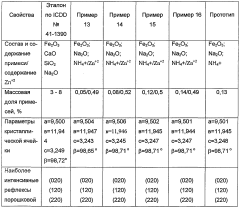

PatentWO2004076354A1

Innovation

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

Environmental Impact of Malachite Coatings

The environmental impact of malachite coatings in electronic device advancement is a critical consideration that requires thorough examination. Malachite, a copper carbonate hydroxide mineral, has gained attention for its potential applications in electronic devices due to its unique properties. However, the widespread use of malachite-coated materials raises concerns about their environmental implications throughout the product lifecycle.

The production process of malachite coatings involves mining and processing of copper ores, which can lead to significant environmental disturbances. Open-pit mining, often used for copper extraction, results in habitat destruction, soil erosion, and potential water pollution. The subsequent refining and coating processes may release harmful chemicals and greenhouse gases, contributing to air and water pollution if not properly managed.

During the use phase of electronic devices with malachite coatings, the environmental impact is generally minimal. The durability and stability of malachite coatings can potentially extend the lifespan of electronic devices, reducing the frequency of replacements and associated electronic waste. However, the long-term effects of malachite nanoparticles potentially shedding from the coatings and entering the environment remain an area of ongoing research and concern.

The end-of-life stage of malachite-coated electronic devices presents significant challenges for recycling and waste management. The presence of malachite coatings may complicate traditional recycling processes, potentially requiring specialized techniques to separate and recover valuable materials. Improper disposal of these devices could lead to the leaching of copper and other components into soil and water systems, posing risks to ecosystems and human health.

To mitigate these environmental concerns, several approaches are being explored. Sustainable mining practices and more efficient copper extraction methods are being developed to reduce the ecological footprint of raw material acquisition. Advanced coating technologies are being researched to minimize material waste and energy consumption during the production process. Additionally, innovative recycling techniques are being investigated to effectively recover and reuse malachite and other materials from discarded electronic devices.

The development of biodegradable or easily recyclable alternatives to malachite coatings is another area of active research. These alternatives aim to maintain the beneficial properties of malachite while reducing the environmental impact at the end of the product's life cycle. Furthermore, the implementation of extended producer responsibility programs and stricter regulations on electronic waste management could incentivize manufacturers to design more environmentally friendly products and improve recycling infrastructure.

In conclusion, while malachite coatings offer promising advancements in electronic device technology, their environmental impact must be carefully managed throughout the entire product lifecycle. Balancing technological progress with environmental sustainability remains a key challenge in the development and application of malachite-coated materials for electronic devices.

The production process of malachite coatings involves mining and processing of copper ores, which can lead to significant environmental disturbances. Open-pit mining, often used for copper extraction, results in habitat destruction, soil erosion, and potential water pollution. The subsequent refining and coating processes may release harmful chemicals and greenhouse gases, contributing to air and water pollution if not properly managed.

During the use phase of electronic devices with malachite coatings, the environmental impact is generally minimal. The durability and stability of malachite coatings can potentially extend the lifespan of electronic devices, reducing the frequency of replacements and associated electronic waste. However, the long-term effects of malachite nanoparticles potentially shedding from the coatings and entering the environment remain an area of ongoing research and concern.

The end-of-life stage of malachite-coated electronic devices presents significant challenges for recycling and waste management. The presence of malachite coatings may complicate traditional recycling processes, potentially requiring specialized techniques to separate and recover valuable materials. Improper disposal of these devices could lead to the leaching of copper and other components into soil and water systems, posing risks to ecosystems and human health.

To mitigate these environmental concerns, several approaches are being explored. Sustainable mining practices and more efficient copper extraction methods are being developed to reduce the ecological footprint of raw material acquisition. Advanced coating technologies are being researched to minimize material waste and energy consumption during the production process. Additionally, innovative recycling techniques are being investigated to effectively recover and reuse malachite and other materials from discarded electronic devices.

The development of biodegradable or easily recyclable alternatives to malachite coatings is another area of active research. These alternatives aim to maintain the beneficial properties of malachite while reducing the environmental impact at the end of the product's life cycle. Furthermore, the implementation of extended producer responsibility programs and stricter regulations on electronic waste management could incentivize manufacturers to design more environmentally friendly products and improve recycling infrastructure.

In conclusion, while malachite coatings offer promising advancements in electronic device technology, their environmental impact must be carefully managed throughout the entire product lifecycle. Balancing technological progress with environmental sustainability remains a key challenge in the development and application of malachite-coated materials for electronic devices.

Scalability and Cost Analysis

The scalability and cost analysis of developing malachite-coated materials for electronic device advancement is crucial for determining the feasibility of large-scale production and commercial viability. Malachite, a copper carbonate hydroxide mineral, offers unique properties that can enhance electronic device performance, but its implementation faces several challenges in terms of scalability and cost-effectiveness.

From a production standpoint, the scalability of malachite coating processes is currently limited by several factors. The synthesis of high-quality malachite coatings often requires precise control over reaction conditions, including temperature, pH, and concentration of reactants. Maintaining these conditions consistently across large-scale production batches presents significant engineering challenges. Additionally, the deposition of uniform malachite coatings on complex electronic device surfaces demands advanced coating technologies, which may not be readily scalable without substantial investment in equipment and process optimization.

The cost analysis of malachite-coated materials reveals a complex economic landscape. While malachite itself is relatively abundant and inexpensive as a raw material, the processing and application costs can be substantial. The purification of malachite to meet electronic-grade standards involves multiple steps, each adding to the overall production cost. Furthermore, the specialized equipment required for precise coating application contributes significantly to capital expenditures.

Labor costs associated with the production of malachite-coated materials are another important consideration. The process requires skilled technicians and engineers familiar with both materials science and electronic device manufacturing. As the demand for such expertise grows, labor costs may increase, potentially impacting the overall economic viability of the technology.

Energy consumption during the coating process is a significant factor in both scalability and cost. The synthesis and application of malachite coatings often require elevated temperatures and controlled environments, leading to substantial energy inputs. As production scales up, optimizing energy efficiency becomes crucial for maintaining cost-effectiveness and reducing the environmental footprint of the manufacturing process.

The potential for economies of scale in malachite coating production offers some promise for cost reduction. As production volumes increase, the per-unit cost of materials and processing may decrease. However, realizing these economies of scale requires substantial initial investment in research, development, and production infrastructure. This upfront cost can be a significant barrier to entry for smaller companies or startups looking to enter the market.

In conclusion, while malachite-coated materials show promise for advancing electronic devices, the scalability and cost challenges are significant. Overcoming these hurdles will require innovative approaches to process engineering, material synthesis, and production optimization. Future research should focus on developing more efficient coating methods, exploring alternative precursor materials, and improving energy efficiency in the production process. These advancements will be critical in making malachite-coated materials a commercially viable and scalable solution for next-generation electronic devices.

From a production standpoint, the scalability of malachite coating processes is currently limited by several factors. The synthesis of high-quality malachite coatings often requires precise control over reaction conditions, including temperature, pH, and concentration of reactants. Maintaining these conditions consistently across large-scale production batches presents significant engineering challenges. Additionally, the deposition of uniform malachite coatings on complex electronic device surfaces demands advanced coating technologies, which may not be readily scalable without substantial investment in equipment and process optimization.

The cost analysis of malachite-coated materials reveals a complex economic landscape. While malachite itself is relatively abundant and inexpensive as a raw material, the processing and application costs can be substantial. The purification of malachite to meet electronic-grade standards involves multiple steps, each adding to the overall production cost. Furthermore, the specialized equipment required for precise coating application contributes significantly to capital expenditures.

Labor costs associated with the production of malachite-coated materials are another important consideration. The process requires skilled technicians and engineers familiar with both materials science and electronic device manufacturing. As the demand for such expertise grows, labor costs may increase, potentially impacting the overall economic viability of the technology.

Energy consumption during the coating process is a significant factor in both scalability and cost. The synthesis and application of malachite coatings often require elevated temperatures and controlled environments, leading to substantial energy inputs. As production scales up, optimizing energy efficiency becomes crucial for maintaining cost-effectiveness and reducing the environmental footprint of the manufacturing process.

The potential for economies of scale in malachite coating production offers some promise for cost reduction. As production volumes increase, the per-unit cost of materials and processing may decrease. However, realizing these economies of scale requires substantial initial investment in research, development, and production infrastructure. This upfront cost can be a significant barrier to entry for smaller companies or startups looking to enter the market.

In conclusion, while malachite-coated materials show promise for advancing electronic devices, the scalability and cost challenges are significant. Overcoming these hurdles will require innovative approaches to process engineering, material synthesis, and production optimization. Future research should focus on developing more efficient coating methods, exploring alternative precursor materials, and improving energy efficiency in the production process. These advancements will be critical in making malachite-coated materials a commercially viable and scalable solution for next-generation electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!