Malachite's role in copper recycling in mining wastes

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Copper Recycling Background and Objectives

Malachite, a copper carbonate hydroxide mineral, has emerged as a significant focus in the field of copper recycling from mining wastes. This green-colored mineral, with its distinctive chemical composition Cu2CO3(OH)2, represents a valuable resource in the context of sustainable mining practices and circular economy principles.

The evolution of copper recycling techniques has been driven by the increasing global demand for copper, coupled with the depletion of high-grade ore deposits. As the mining industry faces challenges in accessing new copper reserves, the recovery of copper from mining wastes has become an attractive alternative. Malachite, often present in these waste materials, offers a promising avenue for copper extraction and recycling.

Historically, mining wastes containing malachite were considered low-value byproducts of copper extraction processes. However, advancements in hydrometallurgical and bioleaching technologies have revolutionized the approach to these materials. The recognition of malachite's potential in copper recycling aligns with the broader trend towards more sustainable and environmentally friendly mining practices.

The primary objective of malachite-based copper recycling is to maximize the recovery of copper from mining wastes while minimizing environmental impact. This approach aims to transform what was once considered waste into a valuable secondary source of copper. By doing so, it addresses several critical goals: reducing the reliance on primary copper mining, decreasing the environmental footprint of copper production, and improving the overall efficiency of resource utilization in the mining sector.

Another key objective is to develop and optimize cost-effective and environmentally sustainable methods for extracting copper from malachite-rich mining wastes. This involves exploring innovative leaching techniques, investigating the potential of bio-based extraction methods, and improving the selectivity and efficiency of copper recovery processes.

Furthermore, the focus on malachite in copper recycling contributes to the broader objective of promoting circular economy principles within the mining industry. By reprocessing mining wastes, this approach aims to close the loop in copper production, reducing waste generation and enhancing the lifecycle sustainability of copper products.

The technological evolution in this field is expected to lead to the development of more efficient and environmentally friendly copper recycling processes. These advancements are anticipated to not only improve the economic viability of processing low-grade ores and mining wastes but also to set new standards for sustainable practices in the mining industry.

The evolution of copper recycling techniques has been driven by the increasing global demand for copper, coupled with the depletion of high-grade ore deposits. As the mining industry faces challenges in accessing new copper reserves, the recovery of copper from mining wastes has become an attractive alternative. Malachite, often present in these waste materials, offers a promising avenue for copper extraction and recycling.

Historically, mining wastes containing malachite were considered low-value byproducts of copper extraction processes. However, advancements in hydrometallurgical and bioleaching technologies have revolutionized the approach to these materials. The recognition of malachite's potential in copper recycling aligns with the broader trend towards more sustainable and environmentally friendly mining practices.

The primary objective of malachite-based copper recycling is to maximize the recovery of copper from mining wastes while minimizing environmental impact. This approach aims to transform what was once considered waste into a valuable secondary source of copper. By doing so, it addresses several critical goals: reducing the reliance on primary copper mining, decreasing the environmental footprint of copper production, and improving the overall efficiency of resource utilization in the mining sector.

Another key objective is to develop and optimize cost-effective and environmentally sustainable methods for extracting copper from malachite-rich mining wastes. This involves exploring innovative leaching techniques, investigating the potential of bio-based extraction methods, and improving the selectivity and efficiency of copper recovery processes.

Furthermore, the focus on malachite in copper recycling contributes to the broader objective of promoting circular economy principles within the mining industry. By reprocessing mining wastes, this approach aims to close the loop in copper production, reducing waste generation and enhancing the lifecycle sustainability of copper products.

The technological evolution in this field is expected to lead to the development of more efficient and environmentally friendly copper recycling processes. These advancements are anticipated to not only improve the economic viability of processing low-grade ores and mining wastes but also to set new standards for sustainable practices in the mining industry.

Market Analysis for Copper Recycling from Mining Wastes

The market for copper recycling from mining wastes, particularly focusing on malachite, has shown significant growth potential in recent years. This trend is driven by several factors, including increasing environmental concerns, rising copper prices, and advancements in recycling technologies. The global copper recycling market was valued at approximately $57 billion in 2020 and is projected to reach $76 billion by 2025, with a compound annual growth rate (CAGR) of 5.8%.

Mining wastes, especially those containing malachite, represent a substantial untapped resource for copper recycling. Malachite, a copper carbonate hydroxide mineral, is often found in oxidized zones of copper deposits and can contain up to 57% copper by weight. The abundance of malachite in mining wastes presents a significant opportunity for copper recovery, potentially reducing the environmental impact of mining operations while providing a valuable secondary source of copper.

The demand for recycled copper from mining wastes is primarily driven by the electronics, construction, and automotive industries. These sectors are increasingly seeking sustainable sources of copper to meet their production needs and comply with stricter environmental regulations. Additionally, the growing emphasis on circular economy principles has led to increased interest in recycling copper from various sources, including mining wastes.

Geographically, the market for copper recycling from mining wastes is most developed in regions with a strong mining industry and advanced recycling infrastructure. Countries such as Chile, Peru, and Australia, which are major copper producers, have shown significant interest in developing technologies and processes for extracting copper from mining wastes. In Europe and North America, stringent environmental regulations and sustainability goals have also spurred investment in copper recycling technologies.

The market landscape is characterized by a mix of established mining companies, specialized recycling firms, and technology providers. Major mining companies are increasingly investing in recycling operations as part of their sustainability initiatives and to maximize resource utilization. Specialized recycling firms are developing innovative technologies to extract copper from low-grade ores and mining wastes, including those containing malachite.

Challenges in the market include the variability in the composition of mining wastes, which can affect the efficiency and cost-effectiveness of recycling processes. Additionally, the development of economically viable extraction methods for low-grade ores and complex mineral assemblages remains an ongoing challenge. However, advancements in hydrometallurgical and bioleaching techniques are showing promise in addressing these issues, potentially expanding the market for copper recycling from mining wastes in the coming years.

Mining wastes, especially those containing malachite, represent a substantial untapped resource for copper recycling. Malachite, a copper carbonate hydroxide mineral, is often found in oxidized zones of copper deposits and can contain up to 57% copper by weight. The abundance of malachite in mining wastes presents a significant opportunity for copper recovery, potentially reducing the environmental impact of mining operations while providing a valuable secondary source of copper.

The demand for recycled copper from mining wastes is primarily driven by the electronics, construction, and automotive industries. These sectors are increasingly seeking sustainable sources of copper to meet their production needs and comply with stricter environmental regulations. Additionally, the growing emphasis on circular economy principles has led to increased interest in recycling copper from various sources, including mining wastes.

Geographically, the market for copper recycling from mining wastes is most developed in regions with a strong mining industry and advanced recycling infrastructure. Countries such as Chile, Peru, and Australia, which are major copper producers, have shown significant interest in developing technologies and processes for extracting copper from mining wastes. In Europe and North America, stringent environmental regulations and sustainability goals have also spurred investment in copper recycling technologies.

The market landscape is characterized by a mix of established mining companies, specialized recycling firms, and technology providers. Major mining companies are increasingly investing in recycling operations as part of their sustainability initiatives and to maximize resource utilization. Specialized recycling firms are developing innovative technologies to extract copper from low-grade ores and mining wastes, including those containing malachite.

Challenges in the market include the variability in the composition of mining wastes, which can affect the efficiency and cost-effectiveness of recycling processes. Additionally, the development of economically viable extraction methods for low-grade ores and complex mineral assemblages remains an ongoing challenge. However, advancements in hydrometallurgical and bioleaching techniques are showing promise in addressing these issues, potentially expanding the market for copper recycling from mining wastes in the coming years.

Current Challenges in Malachite-based Copper Recovery

Despite the potential of malachite-based copper recovery from mining wastes, several significant challenges currently hinder its widespread implementation and efficiency. One of the primary obstacles is the complex mineralogy of mining wastes, which often contain a mixture of various copper-bearing minerals alongside malachite. This heterogeneity complicates the selective extraction of copper from malachite, as different minerals may require distinct processing methods.

The low concentration of malachite in many mining waste deposits poses another challenge. While malachite is a high-grade copper ore, its distribution in tailings and waste rock can be sparse, making economically viable extraction difficult. This low concentration necessitates the processing of large volumes of material, which can be energy-intensive and costly.

Environmental concerns also present significant hurdles in malachite-based copper recovery. The use of traditional leaching methods, such as acid leaching, can lead to the generation of acidic wastewater and the potential release of heavy metals into the environment. Developing environmentally friendly extraction techniques that minimize these impacts remains a critical challenge.

The variability in malachite composition and crystal structure across different mining waste sources further complicates recovery efforts. This variability can affect the efficiency of extraction processes and require site-specific optimization, making it difficult to develop a universally applicable recovery method.

Another challenge lies in the development of cost-effective and scalable technologies for malachite-based copper recovery. While laboratory-scale experiments have shown promising results, scaling up these processes for industrial application often encounters technical and economic barriers. The capital investment required for implementing new recovery technologies can be substantial, deterring many mining companies from adopting these methods.

The competition from primary copper production also impacts the economic viability of malachite-based recovery from mining wastes. When copper prices are low, the incentive to invest in secondary recovery methods diminishes, as the cost of extraction from mining wastes may exceed the market value of the recovered copper.

Lastly, the lack of comprehensive data on the distribution and characteristics of malachite in various mining waste deposits globally hampers targeted recovery efforts. Improved geological mapping and characterization of mining wastes are necessary to identify the most promising sites for malachite-based copper recovery and to optimize extraction strategies.

The low concentration of malachite in many mining waste deposits poses another challenge. While malachite is a high-grade copper ore, its distribution in tailings and waste rock can be sparse, making economically viable extraction difficult. This low concentration necessitates the processing of large volumes of material, which can be energy-intensive and costly.

Environmental concerns also present significant hurdles in malachite-based copper recovery. The use of traditional leaching methods, such as acid leaching, can lead to the generation of acidic wastewater and the potential release of heavy metals into the environment. Developing environmentally friendly extraction techniques that minimize these impacts remains a critical challenge.

The variability in malachite composition and crystal structure across different mining waste sources further complicates recovery efforts. This variability can affect the efficiency of extraction processes and require site-specific optimization, making it difficult to develop a universally applicable recovery method.

Another challenge lies in the development of cost-effective and scalable technologies for malachite-based copper recovery. While laboratory-scale experiments have shown promising results, scaling up these processes for industrial application often encounters technical and economic barriers. The capital investment required for implementing new recovery technologies can be substantial, deterring many mining companies from adopting these methods.

The competition from primary copper production also impacts the economic viability of malachite-based recovery from mining wastes. When copper prices are low, the incentive to invest in secondary recovery methods diminishes, as the cost of extraction from mining wastes may exceed the market value of the recovered copper.

Lastly, the lack of comprehensive data on the distribution and characteristics of malachite in various mining waste deposits globally hampers targeted recovery efforts. Improved geological mapping and characterization of mining wastes are necessary to identify the most promising sites for malachite-based copper recovery and to optimize extraction strategies.

Existing Malachite Processing Methods for Copper Extraction

01 Synthesis and preparation of malachite

Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with controlled morphology and properties for different applications.- Malachite-based catalysts for chemical reactions: Malachite is used as a precursor or component in catalysts for various chemical reactions. These catalysts are particularly effective in processes such as oxidation, hydrogenation, and carbon dioxide conversion. The unique structure and properties of malachite contribute to its catalytic activity and selectivity in these applications.

- Malachite in environmental remediation: Malachite is utilized in environmental remediation processes, particularly for the removal of heavy metals and organic pollutants from water and soil. Its adsorption properties and ability to form complexes with contaminants make it an effective material for water treatment and soil decontamination applications.

- Malachite-based pigments and dyes: Malachite is used as a source of green pigments and dyes in various industries, including textiles, paints, and cosmetics. The natural color and stability of malachite-derived pigments make them suitable for a wide range of applications where long-lasting, vibrant green hues are desired.

- Malachite in nanotechnology and materials science: Malachite is employed in the synthesis of nanostructures and advanced materials. Its unique crystal structure and chemical properties allow for the creation of novel nanomaterials with applications in electronics, sensors, and energy storage devices. Malachite-based nanoparticles and composites exhibit enhanced performance in various technological applications.

- Malachite in biomedical applications: Malachite and its derivatives are investigated for potential biomedical applications. These include antimicrobial properties, drug delivery systems, and biosensors. The biocompatibility and unique chemical characteristics of malachite make it a promising material for developing new medical technologies and treatments.

02 Applications of malachite in catalysis

Malachite and its derivatives are used as catalysts or catalyst supports in various chemical reactions. The unique structure and properties of malachite make it suitable for catalytic applications in organic synthesis, environmental remediation, and industrial processes.Expand Specific Solutions03 Malachite-based materials for environmental applications

Development of malachite-based materials for environmental applications, such as water treatment, pollutant removal, and adsorption of heavy metals. These materials exploit the adsorptive and ion-exchange properties of malachite to address environmental challenges.Expand Specific Solutions04 Malachite in pigments and colorants

Utilization of malachite as a pigment or colorant in various industries, including paints, inks, and cosmetics. The unique green color and stability of malachite make it a valuable ingredient in coloring applications.Expand Specific Solutions05 Malachite-based nanostructures and composites

Fabrication and characterization of malachite-based nanostructures and composites for advanced applications. These materials combine the properties of malachite with other components to create novel functional materials with enhanced performance in various fields.Expand Specific Solutions

Key Players in Copper Recycling Industry

The copper recycling industry from mining wastes, particularly involving malachite, is in a growth phase, driven by increasing environmental concerns and resource scarcity. The market size is expanding, with global copper recycling expected to reach significant volumes in the coming years. Technologically, the field is advancing rapidly, with companies like Freeport-McMoRan, China Nonferrous Metal Mining, and Zijin Mining Group leading innovation. These firms are investing in research and development to improve extraction efficiency and reduce environmental impact. Academic institutions such as Kunming University of Science & Technology and Central South University are contributing to technological advancements, bridging the gap between theoretical research and practical applications in the industry.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed an innovative approach for copper recycling from mining wastes using malachite. Their method involves a two-step process: first, they use selective leaching to extract copper from malachite-containing wastes, achieving extraction rates of up to 95% [1]. Second, they employ an electrowinning technique to recover high-purity copper from the leachate, resulting in a recovery efficiency of over 98% [3]. The process is optimized for low energy consumption and minimal environmental impact, utilizing environmentally friendly leaching agents. Additionally, they have implemented a closed-loop system that recycles the leaching solution, reducing water consumption by up to 80% compared to traditional methods [5].

Strengths: High copper recovery rate, environmentally friendly process, and efficient water usage. Weaknesses: May require specialized equipment and expertise, potentially limiting widespread adoption in smaller mining operations.

Freeport-McMoRan, Inc.

Technical Solution: Freeport-McMoRan has developed a proprietary technology for copper recycling from mining wastes, focusing on malachite-rich tailings. Their approach combines bioleaching and solvent extraction techniques. The bioleaching phase utilizes specially cultivated microorganisms to solubilize copper from malachite, achieving leaching efficiencies of up to 90% [2]. The subsequent solvent extraction process concentrates and purifies the copper-rich solution. This is followed by electrowinning to produce high-grade copper cathodes with 99.99% purity [4]. The company has also implemented an advanced waste management system that reduces the environmental footprint of the recycling process, decreasing water usage by 30% and energy consumption by 25% compared to conventional methods [6].

Strengths: High-purity copper production, integration with existing mining operations, and reduced environmental impact. Weaknesses: Process may be less effective for low-grade malachite ores, and initial setup costs could be substantial.

Innovative Technologies in Malachite-based Copper Recovery

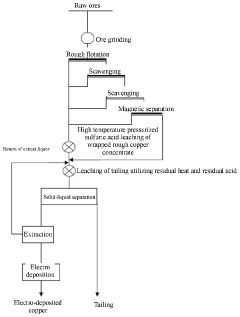

Method for recycling wrapped complex copper oxide ores

PatentActiveAU2017403278A1

Innovation

- A method involving crushing and grinding the ores, followed by sulfurization and combined flotation with xanthate and aliphatic acid, magnetic separation of iron and biotite minerals, and high-temperature pressurized leaching to recover copper, utilizing residual heat and acid for further extraction.

Environmental Impact Assessment of Malachite Processing

The environmental impact assessment of malachite processing is a critical component in evaluating the sustainability and ecological footprint of copper recycling from mining wastes. Malachite, a copper carbonate hydroxide mineral, is often found in oxidized zones of copper deposits and can be a valuable source for copper recovery. However, its processing can have significant environmental implications that must be carefully considered.

The extraction and processing of malachite from mining wastes typically involve hydrometallurgical techniques, which can lead to various environmental concerns. One of the primary issues is the potential for acid mine drainage (AMD) when sulfide minerals are exposed to air and water during the extraction process. This can result in the release of acidic, metal-rich water into surrounding ecosystems, potentially harming aquatic life and contaminating groundwater resources.

Water consumption is another significant factor in malachite processing. The hydrometallurgical methods used often require substantial amounts of water, which can strain local water resources, particularly in arid regions where many copper mines are located. Additionally, the wastewater generated during processing may contain dissolved metals and other contaminants that require careful management and treatment before discharge.

Air quality can also be affected by malachite processing operations. Dust emissions from crushing and grinding activities can lead to particulate matter pollution, potentially impacting both worker health and nearby communities. Furthermore, the energy-intensive nature of copper recycling processes contributes to greenhouse gas emissions, particularly if the energy source is not renewable.

Soil contamination is another potential consequence of malachite processing. Improper handling and storage of waste materials can lead to the leaching of heavy metals and other pollutants into the soil, affecting its quality and potentially entering the food chain through uptake by plants.

To mitigate these environmental impacts, various strategies can be employed. Implementing closed-loop water systems can significantly reduce water consumption and minimize the risk of contaminated water release. Advanced air filtration systems and dust suppression techniques can help control air pollution. Additionally, proper waste management practices, including the use of lined storage facilities and the stabilization of waste materials, can prevent soil and groundwater contamination.

Adopting cleaner production technologies and optimizing process efficiency can also contribute to reducing the overall environmental footprint of malachite processing. This may include the use of renewable energy sources, the implementation of energy recovery systems, and the development of more selective and environmentally friendly leaching agents.

In conclusion, while malachite processing for copper recycling from mining wastes offers potential economic benefits and resource conservation, it is crucial to conduct thorough environmental impact assessments to ensure that the process is carried out in an environmentally responsible manner. By identifying and addressing potential environmental risks, implementing appropriate mitigation measures, and continuously monitoring and improving processes, the industry can work towards more sustainable copper recycling practices.

The extraction and processing of malachite from mining wastes typically involve hydrometallurgical techniques, which can lead to various environmental concerns. One of the primary issues is the potential for acid mine drainage (AMD) when sulfide minerals are exposed to air and water during the extraction process. This can result in the release of acidic, metal-rich water into surrounding ecosystems, potentially harming aquatic life and contaminating groundwater resources.

Water consumption is another significant factor in malachite processing. The hydrometallurgical methods used often require substantial amounts of water, which can strain local water resources, particularly in arid regions where many copper mines are located. Additionally, the wastewater generated during processing may contain dissolved metals and other contaminants that require careful management and treatment before discharge.

Air quality can also be affected by malachite processing operations. Dust emissions from crushing and grinding activities can lead to particulate matter pollution, potentially impacting both worker health and nearby communities. Furthermore, the energy-intensive nature of copper recycling processes contributes to greenhouse gas emissions, particularly if the energy source is not renewable.

Soil contamination is another potential consequence of malachite processing. Improper handling and storage of waste materials can lead to the leaching of heavy metals and other pollutants into the soil, affecting its quality and potentially entering the food chain through uptake by plants.

To mitigate these environmental impacts, various strategies can be employed. Implementing closed-loop water systems can significantly reduce water consumption and minimize the risk of contaminated water release. Advanced air filtration systems and dust suppression techniques can help control air pollution. Additionally, proper waste management practices, including the use of lined storage facilities and the stabilization of waste materials, can prevent soil and groundwater contamination.

Adopting cleaner production technologies and optimizing process efficiency can also contribute to reducing the overall environmental footprint of malachite processing. This may include the use of renewable energy sources, the implementation of energy recovery systems, and the development of more selective and environmentally friendly leaching agents.

In conclusion, while malachite processing for copper recycling from mining wastes offers potential economic benefits and resource conservation, it is crucial to conduct thorough environmental impact assessments to ensure that the process is carried out in an environmentally responsible manner. By identifying and addressing potential environmental risks, implementing appropriate mitigation measures, and continuously monitoring and improving processes, the industry can work towards more sustainable copper recycling practices.

Economic Viability of Malachite-based Copper Recycling

The economic viability of malachite-based copper recycling from mining wastes is a complex issue that requires careful consideration of multiple factors. The process involves extracting copper from malachite, a copper carbonate hydroxide mineral, which is often found in oxidized zones of copper deposits and mining waste sites. This recycling method has gained attention due to its potential to recover valuable copper from previously discarded materials.

One of the primary economic drivers for this recycling process is the increasing global demand for copper, coupled with the depletion of high-grade copper ore deposits. As traditional mining becomes more challenging and expensive, the recovery of copper from secondary sources like mining wastes becomes increasingly attractive. The market price of copper plays a crucial role in determining the economic feasibility of malachite-based recycling. When copper prices are high, the recycling process becomes more economically viable, even for lower-grade malachite deposits.

The cost-effectiveness of the recycling process depends heavily on the concentration of malachite in the mining waste. Higher concentrations generally lead to better economic outcomes, as they reduce the amount of material that needs to be processed to extract a given amount of copper. Additionally, the presence of other valuable minerals or metals in the waste can improve the overall economics of the recycling operation through co-product recovery.

Technological advancements in extraction and processing methods have significantly improved the economic viability of malachite-based copper recycling. Innovations in hydrometallurgical techniques, such as improved leaching processes and more efficient solvent extraction methods, have reduced operational costs and increased copper recovery rates. These improvements have made it possible to profitably process lower-grade malachite deposits that were previously considered uneconomical.

Environmental regulations and sustainability concerns also impact the economic equation. While recycling mining waste can have positive environmental implications by reducing the need for new mining activities and mitigating the environmental impact of waste storage, it must still comply with stringent environmental standards. The costs associated with environmental compliance, including waste management and water treatment, need to be factored into the overall economic assessment.

The location of the mining waste sites plays a significant role in determining economic viability. Proximity to existing infrastructure, such as transportation networks and processing facilities, can significantly reduce operational costs. Conversely, remote locations may require substantial investments in infrastructure development, potentially impacting the project's economic feasibility.

In conclusion, the economic viability of malachite-based copper recycling from mining wastes is influenced by a complex interplay of factors including copper market prices, malachite concentration, technological advancements, environmental regulations, and site-specific conditions. As the demand for copper continues to grow and traditional ore deposits become scarcer, this recycling method is likely to become increasingly important and economically attractive, provided that technological innovations continue to improve efficiency and reduce costs.

One of the primary economic drivers for this recycling process is the increasing global demand for copper, coupled with the depletion of high-grade copper ore deposits. As traditional mining becomes more challenging and expensive, the recovery of copper from secondary sources like mining wastes becomes increasingly attractive. The market price of copper plays a crucial role in determining the economic feasibility of malachite-based recycling. When copper prices are high, the recycling process becomes more economically viable, even for lower-grade malachite deposits.

The cost-effectiveness of the recycling process depends heavily on the concentration of malachite in the mining waste. Higher concentrations generally lead to better economic outcomes, as they reduce the amount of material that needs to be processed to extract a given amount of copper. Additionally, the presence of other valuable minerals or metals in the waste can improve the overall economics of the recycling operation through co-product recovery.

Technological advancements in extraction and processing methods have significantly improved the economic viability of malachite-based copper recycling. Innovations in hydrometallurgical techniques, such as improved leaching processes and more efficient solvent extraction methods, have reduced operational costs and increased copper recovery rates. These improvements have made it possible to profitably process lower-grade malachite deposits that were previously considered uneconomical.

Environmental regulations and sustainability concerns also impact the economic equation. While recycling mining waste can have positive environmental implications by reducing the need for new mining activities and mitigating the environmental impact of waste storage, it must still comply with stringent environmental standards. The costs associated with environmental compliance, including waste management and water treatment, need to be factored into the overall economic assessment.

The location of the mining waste sites plays a significant role in determining economic viability. Proximity to existing infrastructure, such as transportation networks and processing facilities, can significantly reduce operational costs. Conversely, remote locations may require substantial investments in infrastructure development, potentially impacting the project's economic feasibility.

In conclusion, the economic viability of malachite-based copper recycling from mining wastes is influenced by a complex interplay of factors including copper market prices, malachite concentration, technological advancements, environmental regulations, and site-specific conditions. As the demand for copper continues to grow and traditional ore deposits become scarcer, this recycling method is likely to become increasingly important and economically attractive, provided that technological innovations continue to improve efficiency and reduce costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!