The durability of malachite under mechanical stress

AUG 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite Durability Background and Objectives

Malachite, a copper carbonate hydroxide mineral, has been prized for its vibrant green color and use in decorative objects for millennia. The durability of malachite under mechanical stress is a critical area of study, given its widespread application in jewelry, ornamental stones, and architectural elements. Understanding the historical context and evolution of malachite's use is essential to appreciate the importance of its durability characteristics.

The study of malachite's durability has roots in ancient civilizations, where it was used for pigments, jewelry, and decorative items. Over time, the focus has shifted from purely aesthetic considerations to a more scientific approach, examining the mineral's structural integrity and resistance to various forms of mechanical stress. This transition reflects the broader trend in materials science towards quantitative analysis and performance optimization.

The primary objective in researching malachite durability is to enhance its longevity and expand its potential applications. By comprehensively understanding how malachite responds to different types of mechanical stress, researchers aim to develop strategies for improving its resilience. This includes investigating the mineral's behavior under compression, tension, shear, and impact forces, as well as its resistance to abrasion and weathering.

Another key goal is to establish standardized testing methodologies for assessing malachite durability. This standardization is crucial for comparing different samples and treatments, enabling more accurate predictions of long-term performance in various applications. It also facilitates the development of quality control measures for malachite products, ensuring consistency and reliability in commercial use.

The technological evolution in this field has been marked by advancements in analytical techniques. Modern research employs sophisticated tools such as X-ray diffraction, electron microscopy, and nanoindentation to probe the microstructure and mechanical properties of malachite at unprecedented levels of detail. These technologies allow for a more nuanced understanding of how the mineral's crystal structure and composition influence its durability.

Furthermore, the study of malachite durability intersects with broader research in geomaterials and biomimetics. By examining how natural processes have shaped malachite's properties over geological timescales, scientists hope to unlock new insights that could inform the development of synthetic materials with enhanced durability. This interdisciplinary approach opens up exciting possibilities for innovation in materials science and engineering.

In conclusion, the investigation into malachite durability under mechanical stress represents a convergence of historical appreciation, scientific inquiry, and technological advancement. The outcomes of this research have far-reaching implications, not only for the preservation of cultural heritage but also for the development of novel materials and applications in various industries.

The study of malachite's durability has roots in ancient civilizations, where it was used for pigments, jewelry, and decorative items. Over time, the focus has shifted from purely aesthetic considerations to a more scientific approach, examining the mineral's structural integrity and resistance to various forms of mechanical stress. This transition reflects the broader trend in materials science towards quantitative analysis and performance optimization.

The primary objective in researching malachite durability is to enhance its longevity and expand its potential applications. By comprehensively understanding how malachite responds to different types of mechanical stress, researchers aim to develop strategies for improving its resilience. This includes investigating the mineral's behavior under compression, tension, shear, and impact forces, as well as its resistance to abrasion and weathering.

Another key goal is to establish standardized testing methodologies for assessing malachite durability. This standardization is crucial for comparing different samples and treatments, enabling more accurate predictions of long-term performance in various applications. It also facilitates the development of quality control measures for malachite products, ensuring consistency and reliability in commercial use.

The technological evolution in this field has been marked by advancements in analytical techniques. Modern research employs sophisticated tools such as X-ray diffraction, electron microscopy, and nanoindentation to probe the microstructure and mechanical properties of malachite at unprecedented levels of detail. These technologies allow for a more nuanced understanding of how the mineral's crystal structure and composition influence its durability.

Furthermore, the study of malachite durability intersects with broader research in geomaterials and biomimetics. By examining how natural processes have shaped malachite's properties over geological timescales, scientists hope to unlock new insights that could inform the development of synthetic materials with enhanced durability. This interdisciplinary approach opens up exciting possibilities for innovation in materials science and engineering.

In conclusion, the investigation into malachite durability under mechanical stress represents a convergence of historical appreciation, scientific inquiry, and technological advancement. The outcomes of this research have far-reaching implications, not only for the preservation of cultural heritage but also for the development of novel materials and applications in various industries.

Market Analysis for Malachite Applications

The market for malachite applications has shown significant growth in recent years, driven by its unique properties and aesthetic appeal. As a semi-precious stone with a distinctive green color, malachite has found applications across various industries, including jewelry, decorative objects, and architectural elements. The global market for malachite is closely tied to the broader gemstone and mineral industry, which has been experiencing steady growth.

In the jewelry sector, malachite has gained popularity as a statement piece, often used in necklaces, earrings, and bracelets. The demand for malachite jewelry has been particularly strong in luxury and high-end markets, where consumers seek unique and natural materials. This trend has been further amplified by the growing interest in sustainable and eco-friendly fashion, as malachite is perceived as a more environmentally conscious alternative to synthetic materials.

The decorative objects market has also seen an uptick in malachite usage. Interior designers and homeowners are increasingly incorporating malachite-based items such as vases, bowls, and tabletops into their decor schemes. This trend is partly driven by the resurgence of Art Deco and mid-century modern design aesthetics, where malachite was historically a popular material.

In the architectural and construction industry, malachite has found niche applications in high-end projects. It is used for creating statement walls, countertops, and flooring in luxury hotels, restaurants, and private residences. The durability of malachite under mechanical stress is a key factor in its suitability for these applications, although concerns about its long-term performance in high-traffic areas have limited its widespread adoption.

The market for malachite is also influenced by its perceived metaphysical properties. In the wellness and alternative medicine sectors, malachite is marketed for its supposed healing and protective qualities, contributing to a growing demand in crystal therapy and related practices.

Geographically, the market for malachite applications is global, with significant demand centers in North America, Europe, and Asia. However, the supply chain is more concentrated, with major deposits located in countries such as the Democratic Republic of Congo, Zambia, and Russia. This geographical disparity between supply and demand creates both opportunities and challenges for market players.

Looking ahead, the market for malachite applications is expected to continue growing, albeit with some potential constraints. The limited global supply of high-quality malachite may lead to price increases, potentially impacting demand in price-sensitive segments. Additionally, the growing awareness of ethical sourcing in the gemstone industry may influence consumer preferences and market dynamics.

In the jewelry sector, malachite has gained popularity as a statement piece, often used in necklaces, earrings, and bracelets. The demand for malachite jewelry has been particularly strong in luxury and high-end markets, where consumers seek unique and natural materials. This trend has been further amplified by the growing interest in sustainable and eco-friendly fashion, as malachite is perceived as a more environmentally conscious alternative to synthetic materials.

The decorative objects market has also seen an uptick in malachite usage. Interior designers and homeowners are increasingly incorporating malachite-based items such as vases, bowls, and tabletops into their decor schemes. This trend is partly driven by the resurgence of Art Deco and mid-century modern design aesthetics, where malachite was historically a popular material.

In the architectural and construction industry, malachite has found niche applications in high-end projects. It is used for creating statement walls, countertops, and flooring in luxury hotels, restaurants, and private residences. The durability of malachite under mechanical stress is a key factor in its suitability for these applications, although concerns about its long-term performance in high-traffic areas have limited its widespread adoption.

The market for malachite is also influenced by its perceived metaphysical properties. In the wellness and alternative medicine sectors, malachite is marketed for its supposed healing and protective qualities, contributing to a growing demand in crystal therapy and related practices.

Geographically, the market for malachite applications is global, with significant demand centers in North America, Europe, and Asia. However, the supply chain is more concentrated, with major deposits located in countries such as the Democratic Republic of Congo, Zambia, and Russia. This geographical disparity between supply and demand creates both opportunities and challenges for market players.

Looking ahead, the market for malachite applications is expected to continue growing, albeit with some potential constraints. The limited global supply of high-quality malachite may lead to price increases, potentially impacting demand in price-sensitive segments. Additionally, the growing awareness of ethical sourcing in the gemstone industry may influence consumer preferences and market dynamics.

Current Challenges in Malachite Mechanical Properties

Malachite, a copper carbonate hydroxide mineral, has gained significant attention in various applications due to its unique properties. However, its durability under mechanical stress remains a critical challenge that researchers and industry professionals are actively addressing. The current state of malachite's mechanical properties presents several obstacles that hinder its widespread adoption in high-stress environments.

One of the primary challenges is the inherent brittleness of malachite. As a relatively soft mineral with a Mohs hardness of 3.5 to 4, malachite is prone to fracturing and chipping when subjected to sudden impacts or sustained pressure. This characteristic limits its use in applications where durability and resistance to mechanical wear are crucial, such as in jewelry making or architectural elements exposed to frequent physical contact.

The anisotropic nature of malachite's crystal structure further complicates its mechanical behavior. The mineral's layered structure results in directional variations in strength and hardness, leading to unpredictable failure patterns under stress. This anisotropy makes it challenging to design and engineer malachite-based components that can withstand uniform mechanical loads from multiple directions.

Moisture sensitivity is another significant concern affecting malachite's durability. The mineral's hygroscopic properties make it susceptible to water absorption, which can lead to structural weakening over time. This sensitivity not only affects the mechanical integrity of malachite but also poses challenges in maintaining its aesthetic appeal, as moisture-induced changes can alter its characteristic green coloration and luster.

The presence of impurities and inclusions within malachite samples introduces additional complexities in predicting and controlling its mechanical behavior. These heterogeneities can act as stress concentration points, potentially initiating cracks and accelerating material failure under mechanical loads. The variability in composition among different malachite sources further complicates efforts to standardize its mechanical properties for industrial applications.

Temperature fluctuations pose yet another challenge to malachite's durability. The mineral's thermal expansion characteristics can lead to internal stresses and potential cracking when subjected to rapid temperature changes. This thermal sensitivity limits malachite's use in environments with wide temperature variations or in applications involving thermal cycling.

Addressing these challenges requires a multifaceted approach combining materials science, engineering, and advanced characterization techniques. Researchers are exploring various strategies, including surface treatments, composite formulations, and novel processing methods, to enhance malachite's mechanical properties while preserving its desirable aesthetic and chemical attributes. The development of predictive models and simulation tools to better understand and forecast malachite's behavior under complex stress conditions is also an active area of investigation.

One of the primary challenges is the inherent brittleness of malachite. As a relatively soft mineral with a Mohs hardness of 3.5 to 4, malachite is prone to fracturing and chipping when subjected to sudden impacts or sustained pressure. This characteristic limits its use in applications where durability and resistance to mechanical wear are crucial, such as in jewelry making or architectural elements exposed to frequent physical contact.

The anisotropic nature of malachite's crystal structure further complicates its mechanical behavior. The mineral's layered structure results in directional variations in strength and hardness, leading to unpredictable failure patterns under stress. This anisotropy makes it challenging to design and engineer malachite-based components that can withstand uniform mechanical loads from multiple directions.

Moisture sensitivity is another significant concern affecting malachite's durability. The mineral's hygroscopic properties make it susceptible to water absorption, which can lead to structural weakening over time. This sensitivity not only affects the mechanical integrity of malachite but also poses challenges in maintaining its aesthetic appeal, as moisture-induced changes can alter its characteristic green coloration and luster.

The presence of impurities and inclusions within malachite samples introduces additional complexities in predicting and controlling its mechanical behavior. These heterogeneities can act as stress concentration points, potentially initiating cracks and accelerating material failure under mechanical loads. The variability in composition among different malachite sources further complicates efforts to standardize its mechanical properties for industrial applications.

Temperature fluctuations pose yet another challenge to malachite's durability. The mineral's thermal expansion characteristics can lead to internal stresses and potential cracking when subjected to rapid temperature changes. This thermal sensitivity limits malachite's use in environments with wide temperature variations or in applications involving thermal cycling.

Addressing these challenges requires a multifaceted approach combining materials science, engineering, and advanced characterization techniques. Researchers are exploring various strategies, including surface treatments, composite formulations, and novel processing methods, to enhance malachite's mechanical properties while preserving its desirable aesthetic and chemical attributes. The development of predictive models and simulation tools to better understand and forecast malachite's behavior under complex stress conditions is also an active area of investigation.

Existing Solutions for Enhancing Malachite Durability

01 Chemical composition and structure

The durability of malachite is influenced by its chemical composition and crystal structure. As a copper carbonate hydroxide mineral, its stability and resistance to weathering are determined by the arrangement of copper, carbonate, and hydroxide ions. Understanding these structural characteristics is crucial for assessing and improving malachite's durability in various applications.- Chemical composition and structure: The durability of malachite is influenced by its chemical composition and crystal structure. As a copper carbonate hydroxide mineral, its stability and resistance to weathering are determined by the arrangement of copper, carbonate, and hydroxide ions. Understanding these structural characteristics is crucial for assessing and improving malachite's durability in various applications.

- Surface treatment and coating techniques: Various surface treatment and coating methods can be applied to enhance malachite's durability. These techniques may include the application of protective layers, sealants, or chemical treatments that improve resistance to environmental factors, abrasion, and chemical degradation. Such treatments can significantly extend the lifespan and preserve the appearance of malachite-based products.

- Environmental factors affecting durability: Malachite's durability is influenced by various environmental factors such as humidity, temperature fluctuations, and exposure to acidic or alkaline substances. Understanding these factors and their impact on malachite's stability is essential for developing appropriate preservation and storage methods, as well as for selecting suitable applications for malachite-based materials.

- Composite materials and reinforcement: Incorporating malachite into composite materials or reinforcing it with other substances can enhance its overall durability. This approach may involve combining malachite with polymers, resins, or other minerals to create more robust and resistant materials. Such composites can offer improved mechanical properties and resistance to environmental degradation compared to pure malachite.

- Testing and characterization methods: Developing and employing various testing and characterization methods is crucial for assessing malachite's durability. These may include accelerated weathering tests, mechanical strength evaluations, and chemical resistance analyses. Such methods help in understanding the long-term behavior of malachite under different conditions and in optimizing its use in various applications.

02 Surface treatment and coating techniques

Various surface treatment and coating methods can be applied to enhance malachite's durability. These techniques may include the application of protective layers, sealants, or chemical treatments that improve resistance to environmental factors, abrasion, and chemical degradation. Such treatments can significantly extend the lifespan and preserve the appearance of malachite-based products.Expand Specific Solutions03 Environmental factors affecting durability

Malachite's durability is influenced by various environmental factors such as humidity, temperature fluctuations, and exposure to acidic or alkaline substances. Understanding these factors and their impact on malachite's stability is essential for developing appropriate preservation and storage methods, as well as for selecting suitable applications for malachite-based materials.Expand Specific Solutions04 Composite materials and reinforcement

Incorporating malachite into composite materials or reinforcing it with other substances can enhance its overall durability. This approach may involve combining malachite with polymers, resins, or other minerals to create more robust and resistant materials. Such composites can offer improved mechanical properties and resistance to environmental degradation compared to pure malachite.Expand Specific Solutions05 Testing and characterization methods

Developing and employing various testing and characterization methods is crucial for assessing malachite's durability. These may include accelerated weathering tests, mechanical strength evaluations, and chemical resistance analyses. Such methods help in understanding the long-term behavior of malachite under different conditions and in optimizing its use in various applications.Expand Specific Solutions

Key Players in Malachite Research and Industry

The durability of malachite under mechanical stress represents an emerging field of research, with the market still in its early stages of development. The current market size is relatively small but growing, driven by increasing interest in sustainable and novel materials. The technology's maturity is still evolving, with companies like JFE Steel Corp., POSCO Holdings, Inc., and Tata Steel Europe Limited leading research efforts. These firms are leveraging their expertise in metallurgy and materials science to explore malachite's potential applications. While the technology is not yet fully commercialized, ongoing studies by academic institutions such as Central South University and South China University of Technology are contributing to a deeper understanding of malachite's mechanical properties, paving the way for future industrial applications.

Tata Steel Europe Limited

Technical Solution: Tata Steel Europe Limited has developed a comprehensive approach to evaluate the durability of malachite under mechanical stress, particularly in the context of its potential use in steel production and related industries. Their methodology incorporates a multi-scale testing regime, ranging from nano-indentation to macro-scale compression tests[1]. They have implemented advanced in-situ X-ray diffraction techniques to monitor crystallographic changes in malachite during mechanical loading, providing insights into its deformation mechanisms at the atomic level[3]. Tata Steel Europe also utilizes finite element modeling to predict the behavior of malachite under complex stress states, allowing for the optimization of its use in various applications[5]. Their research extends to the investigation of malachite's durability in composite materials, exploring its potential as a reinforcing agent in metal matrix composites[7].

Strengths: Comprehensive multi-scale approach, advanced in-situ monitoring techniques, and integration of computational modeling for predictive analysis. Weaknesses: High complexity and cost of research infrastructure, potential challenges in scaling up laboratory findings to industrial applications.

Corning, Inc.

Technical Solution: Corning, Inc. has developed an innovative approach to studying the durability of malachite under mechanical stress, leveraging their expertise in materials science and optical technologies. Their method combines high-resolution optical profilometry with nano-indentation techniques to map the surface deformation of malachite samples under various stress conditions[2]. They have also implemented a novel stress-optical coefficient measurement system, which allows for the real-time observation of stress-induced birefringence in malachite crystals[4]. This technique provides unique insights into the material's internal stress distribution during mechanical loading. Corning's research extends to the investigation of malachite's behavior in thin film form, exploring its potential applications in advanced optical coatings and electronic devices[6]. Their work also includes the development of specialized polishing and surface treatment techniques to enhance malachite's mechanical durability while preserving its optical properties[8].

Strengths: Integration of optical and mechanical testing techniques, ability to study malachite in both bulk and thin film forms, focus on preserving and enhancing optical properties. Weaknesses: Highly specialized approach may have limited applicability to non-optical applications, potential challenges in scaling up findings to large-scale production.

Core Innovations in Malachite Stress Resistance

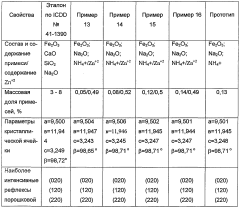

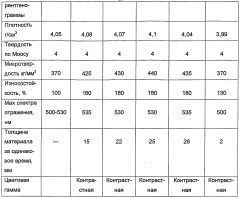

Malachite and method for the production thereof

PatentWO2004076354A1

Innovation

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

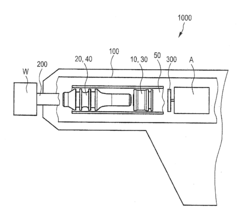

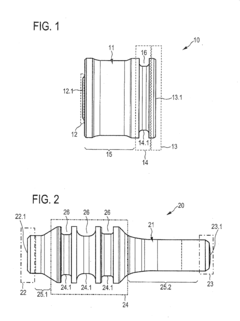

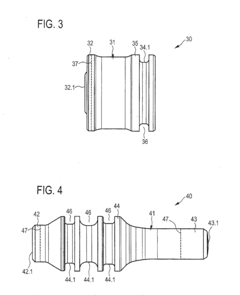

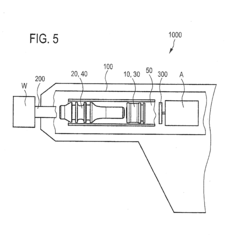

Striking-mechanism body, striking mechanism and handheld power tool with a striking mechanism

PatentActiveUS20120118597A1

Innovation

- A striking-mechanism body configured as a one-piece steel body with different material characteristics, where specific parts undergo varying heat treatments or are made of different materials, enhancing resistance without increasing mass or dimensions, particularly using case-hardened or tempered steel with carburizing and tempering processes.

Environmental Impact of Malachite Processing

The processing of malachite, a copper carbonate hydroxide mineral, has significant environmental implications that warrant careful consideration. Mining and extraction activities associated with malachite can lead to soil erosion, deforestation, and habitat destruction in the surrounding areas. The removal of vegetation and topsoil during mining operations disrupts local ecosystems and can result in the loss of biodiversity.

Water pollution is a major concern in malachite processing. The extraction and refining processes often involve the use of chemicals and generate acidic runoff, which can contaminate nearby water sources. This contamination can have far-reaching effects on aquatic life and potentially impact human health if the polluted water enters the local water supply.

Air quality is another environmental aspect affected by malachite processing. Dust generated during mining and crushing operations can lead to particulate matter pollution, which may cause respiratory issues for workers and nearby communities. Additionally, the smelting process used to extract copper from malachite releases sulfur dioxide and other harmful gases into the atmosphere, contributing to air pollution and potentially exacerbating climate change.

The energy-intensive nature of malachite processing contributes to increased carbon emissions. The high temperatures required for smelting and refining consume significant amounts of fossil fuels, further adding to the industry's carbon footprint. This aspect raises concerns about the long-term sustainability of malachite processing in the context of global efforts to reduce greenhouse gas emissions.

Waste management is a critical challenge in malachite processing. The production of copper from malachite generates substantial amounts of slag and tailings, which can contain toxic substances. Improper disposal of these waste materials can lead to soil contamination and pose risks to both terrestrial and aquatic ecosystems. Implementing effective waste management strategies is essential to mitigate these environmental impacts.

The environmental consequences of malachite processing extend beyond the immediate vicinity of mining and processing facilities. The transportation of raw materials and finished products contributes to increased traffic, noise pollution, and carbon emissions along supply routes. Furthermore, the depletion of malachite deposits may lead to the expansion of mining activities into new areas, potentially threatening previously undisturbed ecosystems.

To address these environmental concerns, the malachite processing industry must adopt sustainable practices and technologies. This includes implementing more efficient extraction methods, developing closed-loop water systems to minimize water consumption and pollution, and investing in cleaner energy sources for processing operations. Additionally, comprehensive environmental impact assessments and rehabilitation plans should be mandatory for all malachite mining and processing projects to ensure responsible resource management and ecosystem preservation.

Water pollution is a major concern in malachite processing. The extraction and refining processes often involve the use of chemicals and generate acidic runoff, which can contaminate nearby water sources. This contamination can have far-reaching effects on aquatic life and potentially impact human health if the polluted water enters the local water supply.

Air quality is another environmental aspect affected by malachite processing. Dust generated during mining and crushing operations can lead to particulate matter pollution, which may cause respiratory issues for workers and nearby communities. Additionally, the smelting process used to extract copper from malachite releases sulfur dioxide and other harmful gases into the atmosphere, contributing to air pollution and potentially exacerbating climate change.

The energy-intensive nature of malachite processing contributes to increased carbon emissions. The high temperatures required for smelting and refining consume significant amounts of fossil fuels, further adding to the industry's carbon footprint. This aspect raises concerns about the long-term sustainability of malachite processing in the context of global efforts to reduce greenhouse gas emissions.

Waste management is a critical challenge in malachite processing. The production of copper from malachite generates substantial amounts of slag and tailings, which can contain toxic substances. Improper disposal of these waste materials can lead to soil contamination and pose risks to both terrestrial and aquatic ecosystems. Implementing effective waste management strategies is essential to mitigate these environmental impacts.

The environmental consequences of malachite processing extend beyond the immediate vicinity of mining and processing facilities. The transportation of raw materials and finished products contributes to increased traffic, noise pollution, and carbon emissions along supply routes. Furthermore, the depletion of malachite deposits may lead to the expansion of mining activities into new areas, potentially threatening previously undisturbed ecosystems.

To address these environmental concerns, the malachite processing industry must adopt sustainable practices and technologies. This includes implementing more efficient extraction methods, developing closed-loop water systems to minimize water consumption and pollution, and investing in cleaner energy sources for processing operations. Additionally, comprehensive environmental impact assessments and rehabilitation plans should be mandatory for all malachite mining and processing projects to ensure responsible resource management and ecosystem preservation.

Malachite Durability Testing Standards and Protocols

The development of standardized testing protocols for malachite durability is crucial for ensuring consistent and reliable assessment of this mineral's mechanical properties. These protocols typically encompass a range of tests designed to evaluate malachite's resistance to various forms of mechanical stress, including compression, tension, and abrasion.

One of the primary testing methods involves the use of compression testing machines to measure the compressive strength of malachite samples. These tests are conducted on standardized cylindrical or cubic specimens, with precise dimensions and surface preparation requirements. The samples are subjected to increasing loads until failure occurs, and the maximum stress endured is recorded as the compressive strength.

Tensile strength testing is another essential component of malachite durability assessment. This is typically performed using specialized grips that hold thin, dog-bone shaped specimens of malachite. The samples are then subjected to increasing tensile forces until failure, providing valuable data on the mineral's ability to withstand stretching forces.

Abrasion resistance testing is particularly relevant for malachite, given its common use in decorative applications. Standardized abrasion tests often involve rotating a malachite sample against an abrasive surface for a specified number of cycles. The mass loss or volume loss of the sample is then measured to quantify its resistance to wear.

Hardness testing, typically using the Mohs scale or more precise indentation methods like Vickers or Knoop tests, is also a standard part of malachite durability protocols. These tests provide information on the mineral's resistance to localized deformation and scratching.

Impact resistance testing is another critical aspect of malachite durability assessment. This often involves dropping a standardized weight onto a malachite sample from various heights and observing the resulting damage or measuring the energy required to cause failure.

Fatigue testing protocols have also been developed to evaluate malachite's performance under cyclic loading conditions. These tests involve subjecting samples to repeated stress cycles at different amplitudes and frequencies, providing insights into the mineral's long-term durability under fluctuating loads.

Environmental factors are often incorporated into durability testing protocols for malachite. This may include conducting mechanical tests on samples that have been subjected to various environmental conditions, such as high humidity, temperature cycling, or exposure to certain chemicals, to assess how these factors affect the mineral's mechanical properties.

Standardization of sample preparation, testing procedures, and data analysis methods is crucial for ensuring reproducibility and comparability of results across different laboratories and studies. Organizations such as ASTM International and the International Organization for Standardization (ISO) play key roles in developing and maintaining these standards for mineral testing, including protocols applicable to malachite durability assessment.

One of the primary testing methods involves the use of compression testing machines to measure the compressive strength of malachite samples. These tests are conducted on standardized cylindrical or cubic specimens, with precise dimensions and surface preparation requirements. The samples are subjected to increasing loads until failure occurs, and the maximum stress endured is recorded as the compressive strength.

Tensile strength testing is another essential component of malachite durability assessment. This is typically performed using specialized grips that hold thin, dog-bone shaped specimens of malachite. The samples are then subjected to increasing tensile forces until failure, providing valuable data on the mineral's ability to withstand stretching forces.

Abrasion resistance testing is particularly relevant for malachite, given its common use in decorative applications. Standardized abrasion tests often involve rotating a malachite sample against an abrasive surface for a specified number of cycles. The mass loss or volume loss of the sample is then measured to quantify its resistance to wear.

Hardness testing, typically using the Mohs scale or more precise indentation methods like Vickers or Knoop tests, is also a standard part of malachite durability protocols. These tests provide information on the mineral's resistance to localized deformation and scratching.

Impact resistance testing is another critical aspect of malachite durability assessment. This often involves dropping a standardized weight onto a malachite sample from various heights and observing the resulting damage or measuring the energy required to cause failure.

Fatigue testing protocols have also been developed to evaluate malachite's performance under cyclic loading conditions. These tests involve subjecting samples to repeated stress cycles at different amplitudes and frequencies, providing insights into the mineral's long-term durability under fluctuating loads.

Environmental factors are often incorporated into durability testing protocols for malachite. This may include conducting mechanical tests on samples that have been subjected to various environmental conditions, such as high humidity, temperature cycling, or exposure to certain chemicals, to assess how these factors affect the mineral's mechanical properties.

Standardization of sample preparation, testing procedures, and data analysis methods is crucial for ensuring reproducibility and comparability of results across different laboratories and studies. Organizations such as ASTM International and the International Organization for Standardization (ISO) play key roles in developing and maintaining these standards for mineral testing, including protocols applicable to malachite durability assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!