How malachite aids in reconstructing historical copper smelting techniques?

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Malachite in Archaeometallurgy

Malachite, a copper carbonate hydroxide mineral, plays a crucial role in archaeometallurgy, particularly in reconstructing historical copper smelting techniques. This green mineral has been extensively used throughout human history, not only as a pigment and ornamental stone but also as a significant copper ore. Its presence in archaeological sites provides valuable insights into ancient metallurgical practices and technological advancements.

The study of malachite in archaeometallurgical contexts involves examining its physical and chemical properties, as well as its occurrence in various archaeological assemblages. Researchers analyze malachite samples found in ancient mining sites, smelting facilities, and artifact production areas to understand the methods used for copper extraction and processing in different historical periods and geographical regions.

One of the key aspects of malachite's role in reconstructing historical copper smelting techniques is its transformation during the smelting process. When heated, malachite decomposes, releasing carbon dioxide and water, leaving behind copper oxide. This process, known as calcination, is an essential step in copper production. By studying the remnants of this process in archaeological sites, researchers can infer the temperatures and conditions used in ancient smelting operations.

Furthermore, the presence of malachite in slag, a byproduct of smelting, provides information about the efficiency of historical smelting techniques. The amount and distribution of residual malachite in slag can indicate the level of technological sophistication and the ability of ancient metalworkers to extract copper from its ores effectively.

Isotopic analysis of malachite samples from different sources also aids in tracing the origin of copper used in ancient artifacts. This information helps archaeologists reconstruct trade routes and understand the economic relationships between different regions in antiquity. Additionally, the study of trace elements in malachite can reveal details about the geological conditions under which the copper deposits formed, further enhancing our understanding of ancient resource exploitation.

The examination of malachite in archaeometallurgical contexts also extends to the study of corrosion products on ancient copper artifacts. As copper objects age, they often form a patina that includes malachite. By analyzing these corrosion layers, researchers can gain insights into the original composition of the artifacts and the environmental conditions they were exposed to over time.

The study of malachite in archaeometallurgical contexts involves examining its physical and chemical properties, as well as its occurrence in various archaeological assemblages. Researchers analyze malachite samples found in ancient mining sites, smelting facilities, and artifact production areas to understand the methods used for copper extraction and processing in different historical periods and geographical regions.

One of the key aspects of malachite's role in reconstructing historical copper smelting techniques is its transformation during the smelting process. When heated, malachite decomposes, releasing carbon dioxide and water, leaving behind copper oxide. This process, known as calcination, is an essential step in copper production. By studying the remnants of this process in archaeological sites, researchers can infer the temperatures and conditions used in ancient smelting operations.

Furthermore, the presence of malachite in slag, a byproduct of smelting, provides information about the efficiency of historical smelting techniques. The amount and distribution of residual malachite in slag can indicate the level of technological sophistication and the ability of ancient metalworkers to extract copper from its ores effectively.

Isotopic analysis of malachite samples from different sources also aids in tracing the origin of copper used in ancient artifacts. This information helps archaeologists reconstruct trade routes and understand the economic relationships between different regions in antiquity. Additionally, the study of trace elements in malachite can reveal details about the geological conditions under which the copper deposits formed, further enhancing our understanding of ancient resource exploitation.

The examination of malachite in archaeometallurgical contexts also extends to the study of corrosion products on ancient copper artifacts. As copper objects age, they often form a patina that includes malachite. By analyzing these corrosion layers, researchers can gain insights into the original composition of the artifacts and the environmental conditions they were exposed to over time.

Market for Historical Metallurgy Research

The market for historical metallurgy research has experienced significant growth in recent years, driven by increasing interest in archaeological studies, cultural heritage preservation, and advancements in analytical techniques. This niche sector intersects with various industries, including archaeology, materials science, museum curation, and educational institutions.

The demand for historical metallurgy research is primarily fueled by academic institutions, museums, and government agencies involved in archaeological projects and heritage conservation efforts. Universities and research centers worldwide are investing in specialized laboratories and equipment to conduct in-depth analyses of ancient metal artifacts, including those related to copper smelting techniques.

Museums and cultural institutions represent a substantial portion of the market, as they seek to enhance their understanding and interpretation of historical artifacts. This knowledge not only improves the accuracy of exhibitions but also contributes to the overall preservation and restoration of metallic artifacts.

The private sector also plays a role in this market, with consulting firms specializing in archaeometallurgy offering their expertise to various projects. These firms often collaborate with academic institutions and government agencies, providing specialized services in artifact analysis and historical reconstruction.

Geographically, the market for historical metallurgy research is global, with significant activities in regions rich in archaeological sites and historical copper production. Europe, the Middle East, and parts of Asia and South America are particularly active in this field, given their extensive history of metalworking.

Technological advancements have greatly expanded the capabilities and precision of historical metallurgy research. The development of non-destructive analytical techniques, such as X-ray fluorescence (XRF) and neutron activation analysis (NAA), has increased the demand for specialized equipment and expertise in this field.

The market is also influenced by broader trends in heritage tourism and public interest in historical narratives. As museums and historical sites strive to offer more engaging and informative experiences, the demand for detailed, scientifically-backed information on ancient technologies, including copper smelting, continues to grow.

While specific market size figures are challenging to determine due to the specialized nature of this field, the overall trend indicates steady growth. This growth is supported by increased funding for archaeological research, heritage preservation initiatives, and the integration of advanced scientific methods in historical studies.

The demand for historical metallurgy research is primarily fueled by academic institutions, museums, and government agencies involved in archaeological projects and heritage conservation efforts. Universities and research centers worldwide are investing in specialized laboratories and equipment to conduct in-depth analyses of ancient metal artifacts, including those related to copper smelting techniques.

Museums and cultural institutions represent a substantial portion of the market, as they seek to enhance their understanding and interpretation of historical artifacts. This knowledge not only improves the accuracy of exhibitions but also contributes to the overall preservation and restoration of metallic artifacts.

The private sector also plays a role in this market, with consulting firms specializing in archaeometallurgy offering their expertise to various projects. These firms often collaborate with academic institutions and government agencies, providing specialized services in artifact analysis and historical reconstruction.

Geographically, the market for historical metallurgy research is global, with significant activities in regions rich in archaeological sites and historical copper production. Europe, the Middle East, and parts of Asia and South America are particularly active in this field, given their extensive history of metalworking.

Technological advancements have greatly expanded the capabilities and precision of historical metallurgy research. The development of non-destructive analytical techniques, such as X-ray fluorescence (XRF) and neutron activation analysis (NAA), has increased the demand for specialized equipment and expertise in this field.

The market is also influenced by broader trends in heritage tourism and public interest in historical narratives. As museums and historical sites strive to offer more engaging and informative experiences, the demand for detailed, scientifically-backed information on ancient technologies, including copper smelting, continues to grow.

While specific market size figures are challenging to determine due to the specialized nature of this field, the overall trend indicates steady growth. This growth is supported by increased funding for archaeological research, heritage preservation initiatives, and the integration of advanced scientific methods in historical studies.

Current Challenges in Ancient Smelting Analysis

The analysis of ancient copper smelting techniques faces several significant challenges that hinder our understanding of historical metallurgical processes. One of the primary obstacles is the scarcity of well-preserved archaeological evidence. Many ancient smelting sites have been destroyed or significantly altered over time, making it difficult to reconstruct the exact methods and technologies used.

The interpretation of malachite's role in these processes is particularly complex. While malachite is a common copper ore and was likely used in ancient smelting, determining its precise contribution to the smelting process requires sophisticated analytical techniques. The chemical and physical changes that occur during smelting often obscure the original composition of the ore, making it challenging to trace the use of specific minerals like malachite in the final product.

Another major challenge lies in replicating ancient smelting conditions in modern experimental settings. Factors such as furnace design, fuel type, and smelting temperatures can significantly impact the process and its outcomes. Researchers must rely on limited archaeological evidence and historical accounts to recreate these conditions, which may not always accurately reflect the original techniques.

The variability in ore composition across different geographical regions and time periods further complicates the analysis. Malachite deposits can vary in purity and associated minerals, affecting the smelting process and the resulting copper. This variability makes it difficult to establish standardized models for ancient smelting techniques based on malachite use.

Additionally, the lack of written records from many ancient civilizations regarding their metallurgical practices poses a significant challenge. Researchers must often rely on indirect evidence, such as slag composition and tool marks, to infer smelting techniques. This absence of direct documentation makes it challenging to validate hypotheses about the specific role of malachite in historical copper production.

The interdisciplinary nature of this research also presents challenges. Effective analysis requires collaboration between archaeologists, chemists, metallurgists, and historians. Integrating diverse methodologies and perspectives can be complex, potentially leading to conflicting interpretations of the available evidence.

Lastly, the ethical considerations surrounding the analysis of ancient artifacts limit the extent of destructive testing that can be performed. Non-invasive analytical techniques are preferred, but they may not always provide the depth of information needed to fully understand the smelting processes and the role of specific minerals like malachite.

The interpretation of malachite's role in these processes is particularly complex. While malachite is a common copper ore and was likely used in ancient smelting, determining its precise contribution to the smelting process requires sophisticated analytical techniques. The chemical and physical changes that occur during smelting often obscure the original composition of the ore, making it challenging to trace the use of specific minerals like malachite in the final product.

Another major challenge lies in replicating ancient smelting conditions in modern experimental settings. Factors such as furnace design, fuel type, and smelting temperatures can significantly impact the process and its outcomes. Researchers must rely on limited archaeological evidence and historical accounts to recreate these conditions, which may not always accurately reflect the original techniques.

The variability in ore composition across different geographical regions and time periods further complicates the analysis. Malachite deposits can vary in purity and associated minerals, affecting the smelting process and the resulting copper. This variability makes it difficult to establish standardized models for ancient smelting techniques based on malachite use.

Additionally, the lack of written records from many ancient civilizations regarding their metallurgical practices poses a significant challenge. Researchers must often rely on indirect evidence, such as slag composition and tool marks, to infer smelting techniques. This absence of direct documentation makes it challenging to validate hypotheses about the specific role of malachite in historical copper production.

The interdisciplinary nature of this research also presents challenges. Effective analysis requires collaboration between archaeologists, chemists, metallurgists, and historians. Integrating diverse methodologies and perspectives can be complex, potentially leading to conflicting interpretations of the available evidence.

Lastly, the ethical considerations surrounding the analysis of ancient artifacts limit the extent of destructive testing that can be performed. Non-invasive analytical techniques are preferred, but they may not always provide the depth of information needed to fully understand the smelting processes and the role of specific minerals like malachite.

Existing Methods for Analyzing Malachite Artifacts

01 Synthesis and preparation of malachite

Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with controlled morphology and properties for different applications.- Synthesis and preparation of malachite: Various methods for synthesizing and preparing malachite, including chemical reactions, hydrothermal processes, and precipitation techniques. These methods aim to produce high-quality malachite with desired properties for different applications.

- Applications of malachite in catalysis: Malachite and its derivatives are used as catalysts in various chemical reactions and industrial processes. The unique structure and properties of malachite make it an effective catalyst for oxidation, reduction, and other transformations.

- Malachite-based pigments and dyes: Utilization of malachite as a pigment or dye in various applications, including paints, inks, and textiles. The distinctive green color of malachite makes it a valuable material in the production of colorants.

- Malachite in environmental remediation: Application of malachite and its derivatives in environmental remediation processes, such as water treatment, heavy metal removal, and pollution control. The adsorption properties of malachite make it effective in removing contaminants from various media.

- Malachite-based nanostructures and composites: Development and characterization of malachite-based nanostructures and composite materials for advanced applications in electronics, sensors, and energy storage devices. These materials combine the properties of malachite with other components to create novel functionalities.

02 Applications of malachite in catalysis

Malachite and its derivatives are used as catalysts or catalyst supports in various chemical reactions. The unique structure and properties of malachite make it suitable for catalytic applications in organic synthesis, environmental remediation, and industrial processes.Expand Specific Solutions03 Malachite-based materials for environmental applications

Development of malachite-based materials for environmental applications, such as water treatment, pollutant removal, and adsorption of heavy metals. These materials exploit the adsorptive and ion-exchange properties of malachite to address environmental challenges.Expand Specific Solutions04 Malachite in pigments and colorants

Utilization of malachite as a pigment or colorant in various applications, including paints, inks, and decorative materials. The unique green color and stability of malachite make it valuable in the production of durable and aesthetically pleasing colorants.Expand Specific Solutions05 Malachite-based nanostructures and composites

Fabrication and characterization of malachite-based nanostructures and composites for advanced applications. These materials combine the properties of malachite with other components to create novel functional materials with enhanced performance in various fields.Expand Specific Solutions

Key Players in Archaeometallurgy Research

The field of historical copper smelting reconstruction using malachite is in its early developmental stage, with a growing market driven by increasing interest in archaeometallurgy and heritage preservation. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Kunming University of Science & Technology and Central South University. Major players such as Freeport-McMoRan and Vale SA, while not directly involved, contribute to the broader copper industry knowledge base. Smaller specialized firms and academic institutions are leading the charge in developing and refining techniques for using malachite to understand ancient smelting processes, indicating a niche but expanding area of study with potential for technological advancements.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed advanced analytical techniques for studying malachite and its role in historical copper smelting. They utilize X-ray diffraction (XRD) and scanning electron microscopy (SEM) to analyze the microstructure and composition of malachite samples from archaeological sites[1]. Their research focuses on identifying trace elements and isotopic signatures in malachite that can provide insights into ancient smelting temperatures and techniques[2]. The university has also created experimental setups to replicate historical smelting conditions, allowing for comparative studies between modern reproductions and archaeological artifacts[3].

Strengths: Access to advanced analytical equipment and interdisciplinary expertise in archaeology and materials science. Weaknesses: Limited access to diverse archaeological samples from different geographical regions.

Central South University

Technical Solution: Central South University has developed a comprehensive approach to reconstructing historical copper smelting techniques using malachite as a key indicator. Their method combines archaeometallurgical analysis with experimental archaeology. They use advanced spectroscopic techniques, including Raman spectroscopy and X-ray fluorescence (XRF), to characterize malachite samples from archaeological sites[1]. The university has also created a database of malachite signatures from different geological sources, allowing for provenance studies of ancient copper artifacts[2]. Their research includes the development of machine learning algorithms to identify patterns in malachite composition that correlate with specific smelting techniques used in different historical periods[3].

Strengths: Strong integration of data science and materials analysis, extensive database of malachite signatures. Weaknesses: Potential overreliance on computational models without sufficient experimental validation.

Core Innovations in Malachite-Based Reconstruction

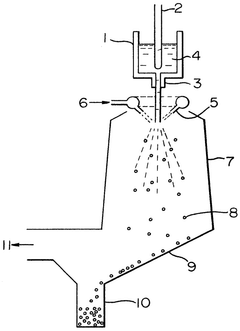

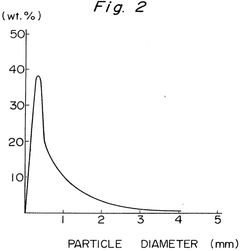

Method of spray smelting copper

PatentInactiveCA1051205A

Innovation

- A method that skips the converter by melting copper ore or roasted copper ore with a flux, separating matte or white metal, and then oxidizing it with oxygen or oxygen-enriched air to produce finely divided blister copper, which is simultaneously cooled and solidified, allowing for continuous smelting and minimizing waste gas formation.

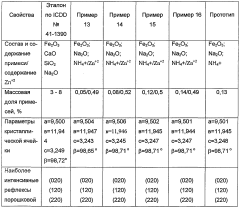

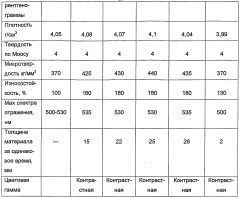

Malachite and method for the production thereof

PatentWO2004076354A1

Innovation

- The process involves evaporating a solution of basic copper carbonate and ammonium carbonate with controlled zinc content, forming polycrystalline malachite with alternating light and dark green layers, and condensing vapor to achieve malachite with enhanced mechanical properties and reduced impurities.

Environmental Impact of Historical Smelting

The historical copper smelting techniques, while revolutionary for their time, had significant environmental impacts that are still being studied and understood today. The use of malachite in these processes provides valuable insights into the environmental consequences of early metallurgy.

Copper smelting, particularly in ancient times, released substantial amounts of pollutants into the atmosphere. The burning of wood or charcoal as fuel, combined with the heating of copper ores like malachite, produced emissions rich in carbon dioxide, sulfur dioxide, and particulate matter. These emissions contributed to local air pollution and, over time, may have had broader impacts on regional air quality and climate patterns.

The smelting process also generated slag, a waste product that often contained heavy metals and other toxic substances. As malachite and other copper ores were processed, elements like arsenic, lead, and mercury could be released into the environment. These contaminants would accumulate in nearby soils and water sources, potentially affecting local ecosystems and human health for generations to come.

Deforestation was another significant environmental consequence of historical copper smelting. The demand for wood to fuel smelting furnaces led to extensive logging in areas surrounding smelting sites. This deforestation not only altered local landscapes but also disrupted habitats and potentially contributed to soil erosion and changes in local hydrology.

The analysis of malachite and other copper minerals found in archaeological sites provides crucial information about the scale and intensity of historical smelting operations. By examining the composition and distribution of these minerals in soil and sediment samples, researchers can estimate the extent of environmental contamination caused by ancient metallurgical activities.

Furthermore, the study of malachite in historical contexts helps in understanding the long-term persistence of pollutants in the environment. Copper and associated heavy metals from ancient smelting sites can remain in soils and sediments for thousands of years, continuing to impact local ecosystems long after the cessation of smelting activities.

The environmental legacy of historical copper smelting, as revealed through the study of malachite and other archaeological evidence, serves as a valuable lesson in the long-term consequences of industrial processes. This knowledge informs modern environmental policies and remediation efforts, highlighting the importance of sustainable practices in current metallurgical and industrial operations.

Copper smelting, particularly in ancient times, released substantial amounts of pollutants into the atmosphere. The burning of wood or charcoal as fuel, combined with the heating of copper ores like malachite, produced emissions rich in carbon dioxide, sulfur dioxide, and particulate matter. These emissions contributed to local air pollution and, over time, may have had broader impacts on regional air quality and climate patterns.

The smelting process also generated slag, a waste product that often contained heavy metals and other toxic substances. As malachite and other copper ores were processed, elements like arsenic, lead, and mercury could be released into the environment. These contaminants would accumulate in nearby soils and water sources, potentially affecting local ecosystems and human health for generations to come.

Deforestation was another significant environmental consequence of historical copper smelting. The demand for wood to fuel smelting furnaces led to extensive logging in areas surrounding smelting sites. This deforestation not only altered local landscapes but also disrupted habitats and potentially contributed to soil erosion and changes in local hydrology.

The analysis of malachite and other copper minerals found in archaeological sites provides crucial information about the scale and intensity of historical smelting operations. By examining the composition and distribution of these minerals in soil and sediment samples, researchers can estimate the extent of environmental contamination caused by ancient metallurgical activities.

Furthermore, the study of malachite in historical contexts helps in understanding the long-term persistence of pollutants in the environment. Copper and associated heavy metals from ancient smelting sites can remain in soils and sediments for thousands of years, continuing to impact local ecosystems long after the cessation of smelting activities.

The environmental legacy of historical copper smelting, as revealed through the study of malachite and other archaeological evidence, serves as a valuable lesson in the long-term consequences of industrial processes. This knowledge informs modern environmental policies and remediation efforts, highlighting the importance of sustainable practices in current metallurgical and industrial operations.

Preservation of Malachite Artifacts

The preservation of malachite artifacts is crucial for understanding historical copper smelting techniques. Malachite, a copper carbonate hydroxide mineral, often forms as a weathering product of copper ores and ancient copper objects. Its presence in archaeological sites provides valuable insights into past metallurgical practices.

Malachite artifacts require careful handling and storage to prevent degradation. Environmental factors such as humidity, temperature, and light exposure can significantly impact their preservation. Controlling these factors is essential to maintain the integrity of malachite objects and the information they hold about ancient copper production methods.

Conservation techniques for malachite artifacts have evolved over time. Traditional methods often involved cleaning and applying protective coatings, which sometimes altered the artifact's surface. Modern approaches prioritize minimal intervention and reversible treatments. Advanced imaging techniques, such as X-ray fluorescence (XRF) and Raman spectroscopy, allow for non-invasive analysis of malachite artifacts, providing information about their composition and potential smelting processes without compromising their integrity.

Proper documentation is vital in preserving malachite artifacts and their historical context. Detailed records of an artifact's provenance, condition, and any conservation treatments applied are essential for future research. This information helps researchers trace the object's history and understand its relationship to copper smelting techniques in different periods and regions.

The study of malachite's formation on copper artifacts can reveal information about the original smelting conditions. By examining the crystal structure and chemical composition of malachite layers, researchers can infer details about the temperature, atmosphere, and duration of ancient smelting processes. This knowledge contributes to the reconstruction of historical metallurgical techniques.

Collaboration between archaeologists, conservators, and materials scientists is crucial for the effective preservation and study of malachite artifacts. Interdisciplinary approaches combine expertise in archaeological context, conservation methods, and materials analysis to extract maximum information from these valuable objects while ensuring their long-term preservation.

As technology advances, new preservation techniques continue to emerge. 3D scanning and printing technologies now allow for the creation of precise replicas of malachite artifacts, reducing the need for handling original objects and providing opportunities for wider access to these historical resources. These digital preservation methods complement traditional conservation practices, enhancing our ability to study and protect malachite artifacts as windows into past copper smelting techniques.

Malachite artifacts require careful handling and storage to prevent degradation. Environmental factors such as humidity, temperature, and light exposure can significantly impact their preservation. Controlling these factors is essential to maintain the integrity of malachite objects and the information they hold about ancient copper production methods.

Conservation techniques for malachite artifacts have evolved over time. Traditional methods often involved cleaning and applying protective coatings, which sometimes altered the artifact's surface. Modern approaches prioritize minimal intervention and reversible treatments. Advanced imaging techniques, such as X-ray fluorescence (XRF) and Raman spectroscopy, allow for non-invasive analysis of malachite artifacts, providing information about their composition and potential smelting processes without compromising their integrity.

Proper documentation is vital in preserving malachite artifacts and their historical context. Detailed records of an artifact's provenance, condition, and any conservation treatments applied are essential for future research. This information helps researchers trace the object's history and understand its relationship to copper smelting techniques in different periods and regions.

The study of malachite's formation on copper artifacts can reveal information about the original smelting conditions. By examining the crystal structure and chemical composition of malachite layers, researchers can infer details about the temperature, atmosphere, and duration of ancient smelting processes. This knowledge contributes to the reconstruction of historical metallurgical techniques.

Collaboration between archaeologists, conservators, and materials scientists is crucial for the effective preservation and study of malachite artifacts. Interdisciplinary approaches combine expertise in archaeological context, conservation methods, and materials analysis to extract maximum information from these valuable objects while ensuring their long-term preservation.

As technology advances, new preservation techniques continue to emerge. 3D scanning and printing technologies now allow for the creation of precise replicas of malachite artifacts, reducing the need for handling original objects and providing opportunities for wider access to these historical resources. These digital preservation methods complement traditional conservation practices, enhancing our ability to study and protect malachite artifacts as windows into past copper smelting techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!