Dodecane in Chemical Engineering: Challenges and Solutions

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane Background and Objectives

Dodecane, a straight-chain alkane hydrocarbon with the molecular formula C12H26, has been a subject of significant interest in chemical engineering due to its versatile applications and unique properties. The evolution of dodecane research and utilization can be traced back to the early 20th century when petroleum refining processes began to isolate and identify individual hydrocarbon components.

As the petrochemical industry expanded, dodecane emerged as a valuable compound with applications ranging from fuel additives to solvents and chemical intermediates. Its relatively high boiling point and low volatility made it particularly useful in diesel fuel blends and jet fuels, contributing to improved engine performance and fuel efficiency.

The technological advancements in analytical chemistry and separation techniques during the mid-20th century allowed for more precise isolation and characterization of dodecane, leading to a better understanding of its physical and chemical properties. This knowledge paved the way for its expanded use in various industrial processes and products.

In recent decades, the focus on dodecane has shifted towards its potential as a renewable resource. With growing concerns about environmental sustainability and the depletion of fossil fuels, researchers have been exploring bio-based routes for dodecane production. This includes investigating microbial synthesis pathways and developing novel catalytic processes for converting plant-based feedstocks into dodecane and other long-chain hydrocarbons.

The current technological landscape surrounding dodecane is characterized by a dual approach: optimizing its traditional applications while simultaneously exploring innovative and sustainable production methods. Key objectives in this field include enhancing the efficiency of dodecane-based fuel formulations, developing more environmentally friendly synthesis routes, and expanding its use in high-value chemical products.

As we look towards the future, the trajectory of dodecane research and development is likely to be influenced by several factors. These include the global push for cleaner energy sources, advancements in biotechnology and catalysis, and the increasing demand for sustainable chemical feedstocks. The challenge lies in balancing the established industrial uses of dodecane with the need for more sustainable production and consumption patterns.

In conclusion, the background of dodecane in chemical engineering reflects a journey from a simple hydrocarbon component to a multifaceted compound with diverse applications and ongoing research potential. The objectives moving forward are centered on addressing the challenges of sustainability, efficiency, and versatility, positioning dodecane as a critical molecule in the transition towards a more sustainable chemical industry.

As the petrochemical industry expanded, dodecane emerged as a valuable compound with applications ranging from fuel additives to solvents and chemical intermediates. Its relatively high boiling point and low volatility made it particularly useful in diesel fuel blends and jet fuels, contributing to improved engine performance and fuel efficiency.

The technological advancements in analytical chemistry and separation techniques during the mid-20th century allowed for more precise isolation and characterization of dodecane, leading to a better understanding of its physical and chemical properties. This knowledge paved the way for its expanded use in various industrial processes and products.

In recent decades, the focus on dodecane has shifted towards its potential as a renewable resource. With growing concerns about environmental sustainability and the depletion of fossil fuels, researchers have been exploring bio-based routes for dodecane production. This includes investigating microbial synthesis pathways and developing novel catalytic processes for converting plant-based feedstocks into dodecane and other long-chain hydrocarbons.

The current technological landscape surrounding dodecane is characterized by a dual approach: optimizing its traditional applications while simultaneously exploring innovative and sustainable production methods. Key objectives in this field include enhancing the efficiency of dodecane-based fuel formulations, developing more environmentally friendly synthesis routes, and expanding its use in high-value chemical products.

As we look towards the future, the trajectory of dodecane research and development is likely to be influenced by several factors. These include the global push for cleaner energy sources, advancements in biotechnology and catalysis, and the increasing demand for sustainable chemical feedstocks. The challenge lies in balancing the established industrial uses of dodecane with the need for more sustainable production and consumption patterns.

In conclusion, the background of dodecane in chemical engineering reflects a journey from a simple hydrocarbon component to a multifaceted compound with diverse applications and ongoing research potential. The objectives moving forward are centered on addressing the challenges of sustainability, efficiency, and versatility, positioning dodecane as a critical molecule in the transition towards a more sustainable chemical industry.

Market Analysis for Dodecane Applications

The global market for dodecane has been experiencing steady growth, driven by its versatile applications in various industries. As a key component in the production of household and industrial cleaning products, dodecane has seen increased demand due to heightened hygiene awareness, particularly in the wake of global health concerns. The personal care and cosmetics sector has also contributed significantly to market expansion, with dodecane being utilized in formulations for hair care products, moisturizers, and other beauty items.

In the chemical engineering field, dodecane's role as a solvent and reagent in organic synthesis has maintained a consistent demand from research institutions and pharmaceutical companies. Its use as a standard in gas chromatography further cements its position in analytical chemistry applications. The automotive and aerospace industries have shown growing interest in dodecane as a potential component in high-performance fuels and lubricants, owing to its favorable physical properties.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for dodecane applications, particularly in countries like China and India, where rapid industrialization and a burgeoning middle class are driving demand for consumer products. North America and Europe continue to be significant markets, with established chemical and manufacturing sectors maintaining steady consumption levels.

Environmental regulations and sustainability concerns are shaping market dynamics, with increasing emphasis on bio-based alternatives. This trend has spurred research into sustainable production methods for dodecane, potentially opening new market segments for eco-friendly variants. However, the petroleum-derived dodecane still dominates due to cost-effectiveness and established supply chains.

The fragrance industry represents a niche but growing market for dodecane, utilizing it as a fixative and diluent in perfume formulations. This application showcases the compound's versatility and its potential for expansion into specialized, high-value markets.

Challenges in the dodecane market include price volatility linked to fluctuations in crude oil prices, as well as competition from alternative solvents and materials. However, ongoing research into novel applications, such as phase change materials for thermal energy storage, suggests potential for market diversification and growth.

Overall, the market outlook for dodecane remains positive, with projected growth driven by diverse industrial applications and emerging technologies. The compound's unique properties continue to make it an valuable resource in chemical engineering, presenting opportunities for innovation and market expansion in the coming years.

In the chemical engineering field, dodecane's role as a solvent and reagent in organic synthesis has maintained a consistent demand from research institutions and pharmaceutical companies. Its use as a standard in gas chromatography further cements its position in analytical chemistry applications. The automotive and aerospace industries have shown growing interest in dodecane as a potential component in high-performance fuels and lubricants, owing to its favorable physical properties.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for dodecane applications, particularly in countries like China and India, where rapid industrialization and a burgeoning middle class are driving demand for consumer products. North America and Europe continue to be significant markets, with established chemical and manufacturing sectors maintaining steady consumption levels.

Environmental regulations and sustainability concerns are shaping market dynamics, with increasing emphasis on bio-based alternatives. This trend has spurred research into sustainable production methods for dodecane, potentially opening new market segments for eco-friendly variants. However, the petroleum-derived dodecane still dominates due to cost-effectiveness and established supply chains.

The fragrance industry represents a niche but growing market for dodecane, utilizing it as a fixative and diluent in perfume formulations. This application showcases the compound's versatility and its potential for expansion into specialized, high-value markets.

Challenges in the dodecane market include price volatility linked to fluctuations in crude oil prices, as well as competition from alternative solvents and materials. However, ongoing research into novel applications, such as phase change materials for thermal energy storage, suggests potential for market diversification and growth.

Overall, the market outlook for dodecane remains positive, with projected growth driven by diverse industrial applications and emerging technologies. The compound's unique properties continue to make it an valuable resource in chemical engineering, presenting opportunities for innovation and market expansion in the coming years.

Current Challenges in Dodecane Processing

Dodecane processing in chemical engineering faces several significant challenges that hinder its efficient utilization and production. One of the primary issues is the high energy consumption associated with its extraction and purification processes. The separation of dodecane from complex hydrocarbon mixtures often requires extensive distillation columns, which are energy-intensive and contribute to increased operational costs.

Another challenge lies in the thermal stability of dodecane during processing. At elevated temperatures, dodecane can undergo unwanted side reactions, leading to the formation of byproducts and reducing overall yield. This necessitates careful temperature control and the development of more robust catalysts that can operate effectively under milder conditions.

The presence of impurities in dodecane feedstocks poses a significant challenge to downstream applications. Trace amounts of sulfur, nitrogen, and oxygenated compounds can adversely affect catalyst performance and product quality. Developing more efficient and selective purification techniques is crucial to overcome this hurdle and meet stringent product specifications.

Environmental concerns also play a role in dodecane processing challenges. The volatile organic compound (VOC) emissions associated with its production and handling require sophisticated containment and treatment systems to comply with increasingly stringent environmental regulations. This adds complexity and cost to processing facilities.

Scaling up dodecane production while maintaining consistent quality presents another challenge. As demand for dodecane and its derivatives grows, particularly in the aerospace and personal care industries, manufacturers must optimize their processes to ensure uniform product characteristics across larger production volumes.

The transportation and storage of dodecane pose safety and logistical challenges due to its flammability and potential for static accumulation. Developing safer handling protocols and innovative storage solutions is essential to mitigate risks associated with large-scale dodecane processing and distribution.

Lastly, the variability in feedstock composition, particularly when sourcing from different crude oil or biomass sources, complicates process control and product consistency. Adapting processing parameters to accommodate these variations while maintaining product quality requires advanced process monitoring and control systems, as well as flexible plant designs that can handle a range of feedstock qualities.

Another challenge lies in the thermal stability of dodecane during processing. At elevated temperatures, dodecane can undergo unwanted side reactions, leading to the formation of byproducts and reducing overall yield. This necessitates careful temperature control and the development of more robust catalysts that can operate effectively under milder conditions.

The presence of impurities in dodecane feedstocks poses a significant challenge to downstream applications. Trace amounts of sulfur, nitrogen, and oxygenated compounds can adversely affect catalyst performance and product quality. Developing more efficient and selective purification techniques is crucial to overcome this hurdle and meet stringent product specifications.

Environmental concerns also play a role in dodecane processing challenges. The volatile organic compound (VOC) emissions associated with its production and handling require sophisticated containment and treatment systems to comply with increasingly stringent environmental regulations. This adds complexity and cost to processing facilities.

Scaling up dodecane production while maintaining consistent quality presents another challenge. As demand for dodecane and its derivatives grows, particularly in the aerospace and personal care industries, manufacturers must optimize their processes to ensure uniform product characteristics across larger production volumes.

The transportation and storage of dodecane pose safety and logistical challenges due to its flammability and potential for static accumulation. Developing safer handling protocols and innovative storage solutions is essential to mitigate risks associated with large-scale dodecane processing and distribution.

Lastly, the variability in feedstock composition, particularly when sourcing from different crude oil or biomass sources, complicates process control and product consistency. Adapting processing parameters to accommodate these variations while maintaining product quality requires advanced process monitoring and control systems, as well as flexible plant designs that can handle a range of feedstock qualities.

Existing Solutions for Dodecane Challenges

01 Synthesis and purification of dodecane

Dodecane can be synthesized through various chemical processes, including catalytic hydrogenation of long-chain olefins or Fischer-Tropsch synthesis. Purification methods such as distillation or chromatography are often employed to obtain high-purity dodecane for industrial and research applications.- Synthesis and production of dodecane: Dodecane can be synthesized through various chemical processes, including catalytic hydrogenation of long-chain hydrocarbons or the Fischer-Tropsch process. It is also produced as a byproduct in petroleum refining. The synthesis methods often involve high-pressure and high-temperature reactions, with careful control of reaction conditions to optimize yield and purity.

- Applications in cosmetics and personal care products: Dodecane is used in various cosmetic and personal care formulations due to its emollient properties and ability to enhance product texture. It can be found in skincare products, hair care formulations, and makeup items. Dodecane helps improve the spreadability of products and can act as a carrier for other active ingredients.

- Use in industrial lubricants and solvents: Dodecane serves as an important component in industrial lubricants and solvents. Its low volatility and good thermal stability make it suitable for high-temperature applications. It is used in metalworking fluids, cutting oils, and as a solvent in various industrial processes, including extraction and cleaning operations.

- Role in fuel and energy applications: Dodecane is a significant component in diesel and jet fuels, contributing to their combustion properties. It is also used in the development of alternative fuels and energy storage systems. Research is ongoing to explore its potential in improving fuel efficiency and reducing emissions in various transportation and power generation applications.

- Environmental and safety considerations: The use and handling of dodecane require careful consideration of environmental and safety factors. Studies have been conducted to assess its biodegradability and potential environmental impact. Safety measures and proper handling procedures are essential in industrial settings to prevent spills and minimize exposure risks. Research is ongoing to develop more environmentally friendly alternatives and improve the sustainability of dodecane-based products.

02 Use of dodecane in cosmetic and personal care products

Dodecane is utilized in cosmetic and personal care formulations as an emollient, solvent, or carrier oil. It can improve the texture, spreadability, and skin feel of various products such as creams, lotions, and hair care items.Expand Specific Solutions03 Application of dodecane in fuel and lubricant industries

Dodecane is an important component in the fuel and lubricant industries. It is used as a reference compound for diesel fuel testing, as well as a base oil or additive in lubricant formulations to enhance performance and stability.Expand Specific Solutions04 Dodecane as a solvent in chemical processes

Dodecane serves as an effective solvent in various chemical processes, including extraction, separation, and reaction media. Its non-polar nature and low reactivity make it suitable for use in organic synthesis and analytical chemistry applications.Expand Specific Solutions05 Environmental and safety considerations of dodecane

The use and handling of dodecane require consideration of environmental and safety aspects. This includes proper storage, transportation, and disposal methods, as well as assessing its potential impact on aquatic ecosystems and air quality. Research is ongoing to develop more sustainable alternatives and improve its biodegradability.Expand Specific Solutions

Key Industry Players in Dodecane Production

The competitive landscape for dodecane in chemical engineering is characterized by a mature market with established players and ongoing research for new applications. The global market size for dodecane is moderate but growing, driven by its versatile use in various industries. Technologically, dodecane production and application are well-established, with companies like BASF, UBE Corp., and Wanhua Chemical Group leading in production and research. However, there's ongoing innovation in areas such as green chemistry and specialty applications, with research institutions like ETH Zurich and the University of Washington contributing to advancements. The industry is seeing a shift towards more sustainable and efficient processes, with companies like EMS-CHEMIE and Clariant focusing on specialty chemical applications of dodecane.

BASF Corp.

Technical Solution: BASF has developed innovative solutions for dodecane in chemical engineering, focusing on its use as a solvent and in the production of surfactants. They have implemented a novel catalytic process for the selective hydrogenation of dodecene to dodecane, improving yield and reducing energy consumption[1]. BASF has also explored the use of dodecane in phase change materials for thermal energy storage, enhancing its applicability in sustainable energy systems[2]. Their research extends to the development of dodecane-based microemulsions for enhanced oil recovery, demonstrating improved efficiency in extracting residual oil from reservoirs[3].

Strengths: Extensive R&D capabilities, diverse application portfolio, and strong market presence. Weaknesses: High production costs and potential environmental concerns associated with hydrocarbon-based products.

DSM IP Assets BV

Technical Solution: DSM has focused on the application of dodecane in high-performance materials and sustainable solutions. They have developed bio-based dodecane derivatives for use in personal care products, offering environmentally friendly alternatives to traditional petrochemical-based ingredients[12]. The company has also explored the use of dodecane in advanced coating technologies, enhancing durability and performance in various industrial applications[13]. Additionally, DSM has investigated the potential of dodecane-based materials in 3D printing, aiming to expand the range of printable materials for industrial manufacturing[14].

Strengths: Strong expertise in sustainable materials and diverse application portfolio. Weaknesses: Potential challenges in cost-competitiveness with traditional petrochemical-based products and market adoption of novel materials.

Innovative Approaches in Dodecane Engineering

Method for producing oligomers derived from butenes

PatentInactiveUS20050288471A1

Innovation

- A process involving membrane separation to distinguish between linear and branched C4 hydrocarbons, followed by specific chemical reactions such as oligomerization, methanol reaction, hydroformylation, polymerization, or dimerization to produce unbranched octene and dodecene, along with various chemical intermediates, using nickel catalysts and molecular sieves for purification and catalyst poisoning removal.

Host cells and methods for producing diacid compounds

PatentWO2012071439A1

Innovation

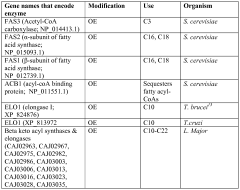

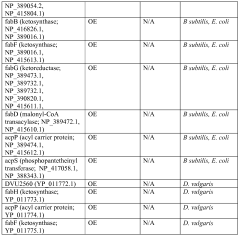

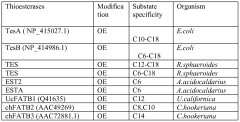

- Genetically engineered host cells using recombinant vectors and pathways such as Type I, II, and III fatty acid synthases, Type I polyketide synthases, and 2-ketoacid biosynthesis to produce specific chain length fatty acids and diacids from fermentable carbon sources, enabling controlled production and secretion of α,ω-dicarboxylic acids and ω-hydroxy fatty acids.

Environmental Impact of Dodecane Use

The use of dodecane in chemical engineering processes has significant environmental implications that warrant careful consideration. As a hydrocarbon compound, dodecane poses potential risks to ecosystems and human health if not properly managed. When released into the environment, dodecane can contaminate soil and water resources, affecting both terrestrial and aquatic ecosystems. Its low solubility in water and tendency to adsorb to soil particles make it persistent in the environment, potentially leading to long-term ecological impacts.

In aquatic environments, dodecane can form a thin film on the water surface, interfering with oxygen transfer and potentially harming aquatic life. This can disrupt the delicate balance of aquatic ecosystems, affecting fish, plants, and microorganisms. Furthermore, the bioaccumulation of dodecane in the food chain may lead to increased concentrations in higher trophic levels, potentially impacting larger predators and even human consumers of aquatic resources.

Air pollution is another concern associated with dodecane use. As a volatile organic compound (VOC), dodecane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. These air quality issues can have detrimental effects on human health, particularly respiratory and cardiovascular systems, as well as damage vegetation and agricultural crops.

The production and transportation of dodecane also carry environmental risks. Accidental spills during handling or transportation can lead to localized contamination of soil and water resources. Such incidents require immediate and often costly remediation efforts to mitigate environmental damage and protect public health.

However, it is important to note that the chemical industry has made significant strides in developing more environmentally friendly practices for handling and using dodecane. Improved containment systems, advanced treatment technologies for waste streams, and stricter regulations have helped reduce the environmental footprint of dodecane use in chemical engineering processes.

Efforts to minimize the environmental impact of dodecane include the development of closed-loop systems that reduce emissions and waste, as well as the implementation of more efficient recovery and recycling processes. Additionally, research into alternative compounds with similar properties but lower environmental risks is ongoing, aiming to find more sustainable solutions for chemical engineering applications.

As the chemical industry continues to evolve, balancing the benefits of dodecane use with its potential environmental impacts remains a critical challenge. Ongoing research, technological advancements, and regulatory frameworks will play crucial roles in mitigating the environmental risks associated with dodecane while maintaining its valuable contributions to chemical engineering processes.

In aquatic environments, dodecane can form a thin film on the water surface, interfering with oxygen transfer and potentially harming aquatic life. This can disrupt the delicate balance of aquatic ecosystems, affecting fish, plants, and microorganisms. Furthermore, the bioaccumulation of dodecane in the food chain may lead to increased concentrations in higher trophic levels, potentially impacting larger predators and even human consumers of aquatic resources.

Air pollution is another concern associated with dodecane use. As a volatile organic compound (VOC), dodecane can contribute to the formation of ground-level ozone and smog when released into the atmosphere. These air quality issues can have detrimental effects on human health, particularly respiratory and cardiovascular systems, as well as damage vegetation and agricultural crops.

The production and transportation of dodecane also carry environmental risks. Accidental spills during handling or transportation can lead to localized contamination of soil and water resources. Such incidents require immediate and often costly remediation efforts to mitigate environmental damage and protect public health.

However, it is important to note that the chemical industry has made significant strides in developing more environmentally friendly practices for handling and using dodecane. Improved containment systems, advanced treatment technologies for waste streams, and stricter regulations have helped reduce the environmental footprint of dodecane use in chemical engineering processes.

Efforts to minimize the environmental impact of dodecane include the development of closed-loop systems that reduce emissions and waste, as well as the implementation of more efficient recovery and recycling processes. Additionally, research into alternative compounds with similar properties but lower environmental risks is ongoing, aiming to find more sustainable solutions for chemical engineering applications.

As the chemical industry continues to evolve, balancing the benefits of dodecane use with its potential environmental impacts remains a critical challenge. Ongoing research, technological advancements, and regulatory frameworks will play crucial roles in mitigating the environmental risks associated with dodecane while maintaining its valuable contributions to chemical engineering processes.

Safety Regulations in Dodecane Handling

Safety regulations in dodecane handling are crucial for ensuring the protection of workers, the environment, and the integrity of industrial processes. These regulations encompass a wide range of measures designed to mitigate risks associated with the storage, transportation, and use of dodecane in chemical engineering applications.

One of the primary safety considerations in dodecane handling is the prevention of fire and explosion hazards. Dodecane is a highly flammable liquid with a relatively low flash point, making it susceptible to ignition under certain conditions. As a result, strict regulations are in place regarding the storage and handling of dodecane in industrial settings. These regulations typically mandate the use of explosion-proof electrical equipment, proper grounding and bonding procedures, and the implementation of adequate ventilation systems to prevent the accumulation of flammable vapors.

Personal protective equipment (PPE) requirements form another critical aspect of safety regulations for dodecane handling. Workers involved in the handling, processing, or transportation of dodecane are required to wear appropriate PPE, including chemical-resistant gloves, safety goggles, and flame-resistant clothing. In some cases, respiratory protection may also be necessary, particularly in areas where dodecane vapors may be present in high concentrations.

Environmental protection is a key focus of safety regulations in dodecane handling. Given the potential for environmental contamination in the event of spills or leaks, regulations often mandate the implementation of robust containment systems and spill response protocols. This includes the use of secondary containment structures for storage tanks, regular inspections of equipment and pipelines, and the development of comprehensive emergency response plans to address potential release scenarios.

Transportation of dodecane is subject to stringent safety regulations, particularly when it comes to road, rail, or maritime transport. These regulations typically cover aspects such as proper labeling and placarding of containers, specific requirements for tank design and construction, and protocols for loading and unloading operations. Additionally, drivers and operators involved in the transportation of dodecane are often required to undergo specialized training to ensure they are equipped to handle potential emergencies.

Workplace safety training and education programs are integral components of safety regulations in dodecane handling. These programs aim to ensure that all personnel involved in dodecane-related operations are fully aware of the associated hazards and are trained in proper handling procedures, emergency response protocols, and the use of safety equipment. Regular refresher courses and safety drills are often mandated to maintain a high level of preparedness among workers.

Compliance with these safety regulations is typically enforced through regular inspections and audits conducted by regulatory agencies or third-party certification bodies. These assessments evaluate various aspects of dodecane handling operations, including equipment maintenance, documentation practices, and adherence to established safety protocols. Non-compliance with safety regulations can result in significant penalties, including fines, operational shutdowns, or revocation of operating licenses.

One of the primary safety considerations in dodecane handling is the prevention of fire and explosion hazards. Dodecane is a highly flammable liquid with a relatively low flash point, making it susceptible to ignition under certain conditions. As a result, strict regulations are in place regarding the storage and handling of dodecane in industrial settings. These regulations typically mandate the use of explosion-proof electrical equipment, proper grounding and bonding procedures, and the implementation of adequate ventilation systems to prevent the accumulation of flammable vapors.

Personal protective equipment (PPE) requirements form another critical aspect of safety regulations for dodecane handling. Workers involved in the handling, processing, or transportation of dodecane are required to wear appropriate PPE, including chemical-resistant gloves, safety goggles, and flame-resistant clothing. In some cases, respiratory protection may also be necessary, particularly in areas where dodecane vapors may be present in high concentrations.

Environmental protection is a key focus of safety regulations in dodecane handling. Given the potential for environmental contamination in the event of spills or leaks, regulations often mandate the implementation of robust containment systems and spill response protocols. This includes the use of secondary containment structures for storage tanks, regular inspections of equipment and pipelines, and the development of comprehensive emergency response plans to address potential release scenarios.

Transportation of dodecane is subject to stringent safety regulations, particularly when it comes to road, rail, or maritime transport. These regulations typically cover aspects such as proper labeling and placarding of containers, specific requirements for tank design and construction, and protocols for loading and unloading operations. Additionally, drivers and operators involved in the transportation of dodecane are often required to undergo specialized training to ensure they are equipped to handle potential emergencies.

Workplace safety training and education programs are integral components of safety regulations in dodecane handling. These programs aim to ensure that all personnel involved in dodecane-related operations are fully aware of the associated hazards and are trained in proper handling procedures, emergency response protocols, and the use of safety equipment. Regular refresher courses and safety drills are often mandated to maintain a high level of preparedness among workers.

Compliance with these safety regulations is typically enforced through regular inspections and audits conducted by regulatory agencies or third-party certification bodies. These assessments evaluate various aspects of dodecane handling operations, including equipment maintenance, documentation practices, and adherence to established safety protocols. Non-compliance with safety regulations can result in significant penalties, including fines, operational shutdowns, or revocation of operating licenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!