EREV noise, vibration, and harshness (NVH) assessment

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV NVH Challenges

Extended Range Electric Vehicles (EREVs) face unique challenges in noise, vibration, and harshness (NVH) assessment due to their complex powertrain systems. The integration of both electric and internal combustion engine (ICE) components creates a multifaceted NVH landscape that requires sophisticated analysis and mitigation strategies.

One of the primary challenges in EREV NVH assessment is the variable noise profile across different operating modes. In pure electric mode, the absence of ICE noise exposes previously masked sounds, such as high-frequency whine from electric motors and inverters. Conversely, during ICE operation, the sudden engagement of the engine can create abrupt changes in the vehicle's sound character, potentially leading to passenger discomfort.

Vibration management presents another significant hurdle. The transition between electric and ICE power sources can introduce complex vibration patterns that are difficult to isolate and mitigate. Additionally, the weight distribution and structural design of EREVs, which must accommodate both electric and conventional powertrain components, can create unique resonance issues that are challenging to predict and address.

The harshness aspect of NVH in EREVs is particularly complex due to the interplay between electric and mechanical systems. The smooth, quiet operation in electric mode sets high expectations for ride quality, making any harshness during ICE operation more noticeable and potentially more objectionable to occupants.

Furthermore, the assessment of NVH in EREVs is complicated by the need for specialized testing methodologies. Traditional NVH evaluation techniques may not fully capture the unique characteristics of these hybrid systems, necessitating the development of new testing protocols and equipment capable of analyzing the full spectrum of EREV operating conditions.

Another challenge lies in the development of appropriate NVH targets for EREVs. The industry lacks standardized benchmarks that account for the dual nature of these vehicles, making it difficult for engineers to establish clear performance goals and evaluate success.

Lastly, the regulatory landscape for EREV NVH is still evolving. As these vehicles become more prevalent, there is a growing need for updated noise regulations that address their unique operational characteristics, particularly in urban environments where low-speed electric operation may pose safety concerns for pedestrians.

One of the primary challenges in EREV NVH assessment is the variable noise profile across different operating modes. In pure electric mode, the absence of ICE noise exposes previously masked sounds, such as high-frequency whine from electric motors and inverters. Conversely, during ICE operation, the sudden engagement of the engine can create abrupt changes in the vehicle's sound character, potentially leading to passenger discomfort.

Vibration management presents another significant hurdle. The transition between electric and ICE power sources can introduce complex vibration patterns that are difficult to isolate and mitigate. Additionally, the weight distribution and structural design of EREVs, which must accommodate both electric and conventional powertrain components, can create unique resonance issues that are challenging to predict and address.

The harshness aspect of NVH in EREVs is particularly complex due to the interplay between electric and mechanical systems. The smooth, quiet operation in electric mode sets high expectations for ride quality, making any harshness during ICE operation more noticeable and potentially more objectionable to occupants.

Furthermore, the assessment of NVH in EREVs is complicated by the need for specialized testing methodologies. Traditional NVH evaluation techniques may not fully capture the unique characteristics of these hybrid systems, necessitating the development of new testing protocols and equipment capable of analyzing the full spectrum of EREV operating conditions.

Another challenge lies in the development of appropriate NVH targets for EREVs. The industry lacks standardized benchmarks that account for the dual nature of these vehicles, making it difficult for engineers to establish clear performance goals and evaluate success.

Lastly, the regulatory landscape for EREV NVH is still evolving. As these vehicles become more prevalent, there is a growing need for updated noise regulations that address their unique operational characteristics, particularly in urban environments where low-speed electric operation may pose safety concerns for pedestrians.

Market Demand Analysis

The market demand for EREV (Extended Range Electric Vehicle) noise, vibration, and harshness (NVH) assessment has been steadily increasing in recent years, driven by the growing adoption of electric and hybrid vehicles worldwide. As consumers become more environmentally conscious and governments implement stricter emissions regulations, the automotive industry is rapidly shifting towards electrification.

EREV technology, which combines the benefits of both electric and conventional powertrains, has gained significant traction in the market. However, the unique characteristics of EREVs present new challenges in terms of NVH performance. Unlike traditional internal combustion engine vehicles, EREVs operate in multiple modes, switching between electric and range-extender operation. This complexity creates a need for specialized NVH assessment tools and methodologies.

The global market for EREV NVH assessment is expected to grow substantially over the next decade. This growth is fueled by several factors, including the increasing production of EREVs, rising consumer expectations for vehicle comfort and refinement, and the need for automotive manufacturers to differentiate their products in a competitive market.

Automotive OEMs are investing heavily in NVH optimization for EREVs to enhance the overall driving experience. The demand for advanced NVH assessment tools, including simulation software, testing equipment, and data analysis platforms, is on the rise. These tools enable manufacturers to identify and address NVH issues early in the development process, reducing time-to-market and associated costs.

The market for EREV NVH assessment services is also expanding, with specialized consulting firms and engineering service providers offering expertise in this niche area. These services cater to both established automotive manufacturers and new entrants in the electric vehicle market, who may lack in-house NVH expertise specific to EREVs.

Geographically, the demand for EREV NVH assessment is particularly strong in regions with a high concentration of automotive manufacturing and stringent noise regulations. North America, Europe, and Asia-Pacific, especially countries like China, Japan, and South Korea, are expected to be the primary markets for these technologies and services.

The increasing focus on autonomous vehicles and their integration with EREV technology is creating new opportunities in the NVH assessment market. As autonomous vehicles require even higher levels of refinement and passenger comfort, the demand for advanced NVH solutions is likely to intensify.

In conclusion, the market demand for EREV NVH assessment is robust and growing, driven by the automotive industry's shift towards electrification, increasing consumer expectations, and regulatory pressures. This trend is expected to continue in the foreseeable future, presenting significant opportunities for technology providers, service companies, and automotive manufacturers in the EREV NVH assessment space.

EREV technology, which combines the benefits of both electric and conventional powertrains, has gained significant traction in the market. However, the unique characteristics of EREVs present new challenges in terms of NVH performance. Unlike traditional internal combustion engine vehicles, EREVs operate in multiple modes, switching between electric and range-extender operation. This complexity creates a need for specialized NVH assessment tools and methodologies.

The global market for EREV NVH assessment is expected to grow substantially over the next decade. This growth is fueled by several factors, including the increasing production of EREVs, rising consumer expectations for vehicle comfort and refinement, and the need for automotive manufacturers to differentiate their products in a competitive market.

Automotive OEMs are investing heavily in NVH optimization for EREVs to enhance the overall driving experience. The demand for advanced NVH assessment tools, including simulation software, testing equipment, and data analysis platforms, is on the rise. These tools enable manufacturers to identify and address NVH issues early in the development process, reducing time-to-market and associated costs.

The market for EREV NVH assessment services is also expanding, with specialized consulting firms and engineering service providers offering expertise in this niche area. These services cater to both established automotive manufacturers and new entrants in the electric vehicle market, who may lack in-house NVH expertise specific to EREVs.

Geographically, the demand for EREV NVH assessment is particularly strong in regions with a high concentration of automotive manufacturing and stringent noise regulations. North America, Europe, and Asia-Pacific, especially countries like China, Japan, and South Korea, are expected to be the primary markets for these technologies and services.

The increasing focus on autonomous vehicles and their integration with EREV technology is creating new opportunities in the NVH assessment market. As autonomous vehicles require even higher levels of refinement and passenger comfort, the demand for advanced NVH solutions is likely to intensify.

In conclusion, the market demand for EREV NVH assessment is robust and growing, driven by the automotive industry's shift towards electrification, increasing consumer expectations, and regulatory pressures. This trend is expected to continue in the foreseeable future, presenting significant opportunities for technology providers, service companies, and automotive manufacturers in the EREV NVH assessment space.

Current NVH State

The current state of NVH (Noise, Vibration, and Harshness) in Extended Range Electric Vehicles (EREVs) presents a complex landscape of challenges and advancements. EREVs, which combine electric motors with range-extending internal combustion engines, face unique NVH issues due to their hybrid nature.

One of the primary concerns in EREV NVH is the transition between electric and combustion engine operation. This shift can create noticeable changes in noise and vibration levels, potentially affecting passenger comfort. Engineers are focusing on developing seamless transition strategies to minimize these effects, employing advanced control algorithms and mechanical damping systems.

Electric motor noise, while generally lower than that of combustion engines, presents its own set of challenges. High-frequency whine from electric motors and power electronics can be more noticeable and potentially more irritating to occupants than the familiar sounds of traditional vehicles. Current efforts are directed towards optimizing motor design and implementing active noise control systems to address these issues.

Tire and road noise have become more prominent in EREVs due to the reduced masking effect of engine noise during electric-only operation. This has led to increased focus on tire technology, road surface engineering, and cabin insulation to mitigate these sources of NVH.

Vibration management in EREVs is particularly critical due to the varying operational modes. The start-stop functionality of the range extender engine can introduce intermittent vibrations, requiring sophisticated engine mounting systems and vibration damping technologies. Additionally, the high torque characteristics of electric motors necessitate robust drivetrain components to prevent unwanted vibrations.

Battery and power electronics cooling systems in EREVs can contribute to NVH issues. The pumps, fans, and fluid movement associated with these systems introduce new noise sources that were not present in traditional vehicles. Current solutions involve optimizing cooling system designs and implementing sound-absorbing materials strategically throughout the vehicle.

The lightweight construction often employed in EREVs to maximize range can exacerbate NVH issues by providing less mass to absorb vibrations and noise. This has led to the development of new lightweight materials with enhanced damping properties and the implementation of active structural control systems.

Overall, the current state of NVH in EREVs reflects a balance between the inherent quietness of electric propulsion and the challenges introduced by the complex powertrain architecture. Manufacturers are investing heavily in research and development to address these issues, recognizing that NVH performance is a key factor in customer satisfaction and brand perception in the evolving electric vehicle market.

One of the primary concerns in EREV NVH is the transition between electric and combustion engine operation. This shift can create noticeable changes in noise and vibration levels, potentially affecting passenger comfort. Engineers are focusing on developing seamless transition strategies to minimize these effects, employing advanced control algorithms and mechanical damping systems.

Electric motor noise, while generally lower than that of combustion engines, presents its own set of challenges. High-frequency whine from electric motors and power electronics can be more noticeable and potentially more irritating to occupants than the familiar sounds of traditional vehicles. Current efforts are directed towards optimizing motor design and implementing active noise control systems to address these issues.

Tire and road noise have become more prominent in EREVs due to the reduced masking effect of engine noise during electric-only operation. This has led to increased focus on tire technology, road surface engineering, and cabin insulation to mitigate these sources of NVH.

Vibration management in EREVs is particularly critical due to the varying operational modes. The start-stop functionality of the range extender engine can introduce intermittent vibrations, requiring sophisticated engine mounting systems and vibration damping technologies. Additionally, the high torque characteristics of electric motors necessitate robust drivetrain components to prevent unwanted vibrations.

Battery and power electronics cooling systems in EREVs can contribute to NVH issues. The pumps, fans, and fluid movement associated with these systems introduce new noise sources that were not present in traditional vehicles. Current solutions involve optimizing cooling system designs and implementing sound-absorbing materials strategically throughout the vehicle.

The lightweight construction often employed in EREVs to maximize range can exacerbate NVH issues by providing less mass to absorb vibrations and noise. This has led to the development of new lightweight materials with enhanced damping properties and the implementation of active structural control systems.

Overall, the current state of NVH in EREVs reflects a balance between the inherent quietness of electric propulsion and the challenges introduced by the complex powertrain architecture. Manufacturers are investing heavily in research and development to address these issues, recognizing that NVH performance is a key factor in customer satisfaction and brand perception in the evolving electric vehicle market.

NVH Assessment Methods

01 Active noise control systems for EREVs

Active noise control systems are implemented in Extended Range Electric Vehicles to reduce unwanted noise and vibrations. These systems use advanced algorithms and sensors to detect and counteract noise, particularly during transitions between electric and combustion engine modes. This technology enhances passenger comfort and overall driving experience in EREVs.- Active noise control systems for EREVs: Active noise control systems are implemented in Extended Range Electric Vehicles to reduce unwanted noise and vibrations. These systems use advanced algorithms and sensors to detect and counteract noise, particularly during transitions between electric and combustion engine modes. This technology enhances passenger comfort and overall driving experience in EREVs.

- Vibration isolation and damping techniques: Various vibration isolation and damping techniques are employed in EREVs to minimize the transmission of vibrations from the powertrain to the vehicle body. These may include advanced mounting systems, tuned mass dampers, and specialized materials to absorb and dissipate vibrational energy, resulting in improved NVH performance.

- Acoustic design and insulation for EREVs: Specific acoustic design considerations and insulation techniques are implemented in EREVs to address NVH issues. This includes the use of sound-absorbing materials, strategic placement of acoustic barriers, and optimized cabin design to minimize noise transmission and enhance overall acoustic comfort for passengers.

- NVH optimization for powertrain components: Powertrain components in EREVs, including the electric motor, generator, and internal combustion engine, are optimized for NVH performance. This involves refining component design, balancing rotating parts, and implementing advanced control strategies to minimize noise and vibration generation at the source.

- Integrated NVH management systems: EREVs incorporate integrated NVH management systems that combine multiple technologies and strategies. These systems may include real-time monitoring, adaptive control algorithms, and coordinated operation of various NVH mitigation technologies to provide comprehensive noise and vibration reduction across different operating conditions.

02 Vibration isolation and damping techniques

Various vibration isolation and damping techniques are employed in EREVs to minimize the transmission of vibrations from the powertrain to the vehicle body. These may include advanced mounting systems, tuned mass dampers, and specialized materials to absorb and dissipate vibrational energy, resulting in improved NVH performance.Expand Specific Solutions03 Acoustic design and insulation

EREVs incorporate specialized acoustic design and insulation strategies to reduce noise transmission into the cabin. This includes the use of sound-absorbing materials, acoustic barriers, and optimized vehicle structures to minimize airborne and structure-borne noise, enhancing the overall quietness of the vehicle interior.Expand Specific Solutions04 NVH optimization for powertrain components

Specific NVH optimization techniques are applied to EREV powertrain components, including the electric motor, generator, and range extender engine. This involves refining component design, balancing, and integration to minimize noise and vibration generation at the source, leading to improved overall NVH performance.Expand Specific Solutions05 Intelligent control strategies for NVH management

Advanced control strategies are developed for EREVs to manage NVH characteristics dynamically. These intelligent systems adjust powertrain operation, active noise control, and other NVH-related parameters based on driving conditions, vehicle speed, and operating mode to maintain optimal comfort levels throughout various driving scenarios.Expand Specific Solutions

Key EREV Manufacturers

The EREV noise, vibration, and harshness (NVH) assessment market is in a growth phase, driven by increasing demand for electric and hybrid vehicles. The global market size is expanding rapidly, with major automotive manufacturers and suppliers investing heavily in this technology. Companies like Robert Bosch GmbH, Ford Motor Co., and ZF Friedrichshafen AG are at the forefront of EREV NVH technology development. The technology is maturing quickly, with advancements in noise reduction, vibration dampening, and overall ride comfort. Chinese companies such as Guangzhou Automobile Group and Chery Automobile Co., Ltd. are also making significant strides in this field, indicating a global push towards improving EREV NVH performance.

Ford Motor Co.

Technical Solution: Ford has developed an advanced EREV NVH assessment system that combines active noise control (ANC) and active vibration control (AVC) technologies. Their system uses strategically placed microphones and accelerometers to detect unwanted noise and vibrations. A sophisticated algorithm then processes this data in real-time to generate counter-signals through the vehicle's audio system and specialized actuators. This approach effectively cancels out a wide range of frequencies, including those specific to electric motors and range extenders[1][3]. Ford has also implemented a multi-layer insulation strategy, using advanced materials like acoustic foams and damping sheets to further reduce NVH transmission[5].

Strengths: Comprehensive approach combining active and passive NVH control; real-time adaptive system. Weaknesses: Potentially high cost due to complex electronics; may increase vehicle weight.

ZF Friedrichshafen AG

Technical Solution: ZF has developed a holistic NVH solution for EREVs focusing on powertrain optimization. Their approach includes advanced electric motor design with reduced electromagnetic noise, innovative mounting systems to isolate vibrations, and specially designed gearboxes with optimized tooth profiles to minimize gear whine[2]. ZF's system also incorporates active mounts that use electromagnetic actuators to counteract vibrations in real-time. Additionally, they have developed a predictive NVH control system that uses vehicle sensor data and machine learning algorithms to anticipate and mitigate NVH issues before they become noticeable to occupants[4].

Strengths: Comprehensive powertrain-focused approach; innovative predictive control system. Weaknesses: May require significant integration efforts with vehicle manufacturers; potentially higher cost for advanced components.

Core NVH Innovations

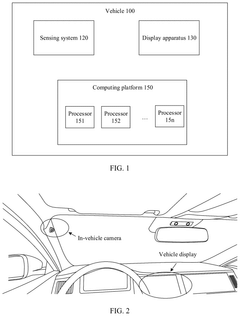

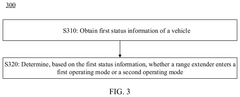

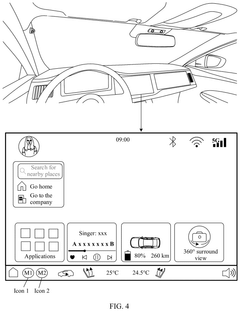

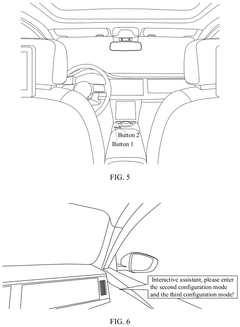

Vehicle control method and control apparatus, and vehicle

PatentPendingUS20250222824A1

Innovation

- A vehicle control method that includes configurable modes (first, second, and third configuration modes) to manage the range extender's operation based on battery state of charge (SOC) and vehicle status, ensuring the battery preferentially supplies power when possible, and the range extender idles or supplies power as needed to maintain dynamics performance.

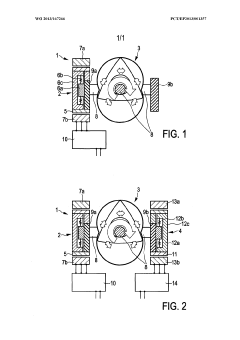

Vibration damping for a range-extender

PatentWO2013167266A2

Innovation

- Integration of a vibration damper into the rotor of the electromechanical energy converter, which acts as a dual-mass oscillator, reducing the need for additional components and eliminating the need for electronic control, thereby effectively damping vibrations and noise.

Regulatory Framework

The regulatory framework surrounding Extended Range Electric Vehicles (EREVs) and their noise, vibration, and harshness (NVH) characteristics is evolving to address the unique challenges posed by these hybrid vehicles. At the international level, the United Nations Economic Commission for Europe (UNECE) has established regulations such as UN Regulation No. 138, which sets standards for the Acoustic Vehicle Alerting System (AVAS) in hybrid and electric vehicles to ensure pedestrian safety.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has implemented Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which mandates minimum sound requirements for hybrid and electric vehicles. This regulation aims to reduce the risk of pedestrian crashes, particularly for individuals with visual impairments. The Environmental Protection Agency (EPA) also plays a role in regulating vehicle noise emissions through the Noise Control Act.

The European Union has adopted similar regulations, including Regulation (EU) No 540/2014, which addresses the sound level of motor vehicles and replacement silencing systems. This regulation includes specific provisions for hybrid and electric vehicles, mandating the use of AVAS for vehicles operating in electric mode.

In Asia, countries like Japan and China have also implemented regulations addressing NVH in electric and hybrid vehicles. Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established guidelines for AVAS, while China has incorporated NVH requirements into its New Energy Vehicle (NEV) policies.

These regulatory frameworks not only focus on external noise emissions but also address interior NVH characteristics. Many countries have adopted or are in the process of adopting ISO standards related to vehicle acoustics and vibration measurement, such as ISO 5128 for measuring interior noise and ISO 2631 for evaluating human exposure to whole-body vibration.

As EREV technology continues to advance, regulatory bodies are likely to refine and expand their frameworks to address emerging NVH challenges. This may include more stringent requirements for low-frequency noise and vibration control, as well as the development of standardized test procedures specifically tailored to EREV powertrains. Manufacturers must stay abreast of these evolving regulations to ensure compliance and optimize their EREV designs for both performance and user comfort.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has implemented Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which mandates minimum sound requirements for hybrid and electric vehicles. This regulation aims to reduce the risk of pedestrian crashes, particularly for individuals with visual impairments. The Environmental Protection Agency (EPA) also plays a role in regulating vehicle noise emissions through the Noise Control Act.

The European Union has adopted similar regulations, including Regulation (EU) No 540/2014, which addresses the sound level of motor vehicles and replacement silencing systems. This regulation includes specific provisions for hybrid and electric vehicles, mandating the use of AVAS for vehicles operating in electric mode.

In Asia, countries like Japan and China have also implemented regulations addressing NVH in electric and hybrid vehicles. Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established guidelines for AVAS, while China has incorporated NVH requirements into its New Energy Vehicle (NEV) policies.

These regulatory frameworks not only focus on external noise emissions but also address interior NVH characteristics. Many countries have adopted or are in the process of adopting ISO standards related to vehicle acoustics and vibration measurement, such as ISO 5128 for measuring interior noise and ISO 2631 for evaluating human exposure to whole-body vibration.

As EREV technology continues to advance, regulatory bodies are likely to refine and expand their frameworks to address emerging NVH challenges. This may include more stringent requirements for low-frequency noise and vibration control, as well as the development of standardized test procedures specifically tailored to EREV powertrains. Manufacturers must stay abreast of these evolving regulations to ensure compliance and optimize their EREV designs for both performance and user comfort.

Environmental Impact

The environmental impact of Extended Range Electric Vehicles (EREVs) in relation to noise, vibration, and harshness (NVH) assessment is a critical consideration in the development and adoption of this technology. EREVs, which combine electric propulsion with a range-extending internal combustion engine, present unique challenges and opportunities in terms of their environmental footprint.

One of the primary environmental benefits of EREVs is their potential to reduce noise pollution in urban areas. When operating in pure electric mode, these vehicles produce significantly less noise compared to conventional internal combustion engine vehicles. This reduction in noise emissions can contribute to improved quality of life in cities and reduce the negative health impacts associated with chronic noise exposure.

However, the NVH characteristics of EREVs become more complex when the range extender is activated. The transition between electric and hybrid modes can introduce new sources of noise and vibration that require careful management. Engineers must optimize the integration of the two power sources to minimize any sudden changes in NVH levels that could negatively impact the driving experience or increase environmental noise.

Vibration control in EREVs also plays a role in environmental impact. Effective vibration dampening not only improves passenger comfort but can also reduce wear and tear on vehicle components. This, in turn, can extend the lifespan of the vehicle and its parts, potentially reducing the environmental impact associated with manufacturing replacement components.

The harshness aspect of NVH in EREVs relates to the overall refinement of the driving experience. A well-tuned EREV system can provide smooth power delivery and seamless transitions between power sources, which can encourage more efficient driving behaviors. This efficiency can translate into reduced energy consumption and, consequently, lower emissions when the range extender is in use.

From a lifecycle perspective, the environmental impact of EREV NVH assessment extends beyond the use phase of the vehicle. The development and implementation of advanced NVH solutions may require additional materials or components, which have their own environmental footprint. Manufacturers must balance the benefits of improved NVH performance against any potential increase in resource consumption or manufacturing complexity.

Moreover, the environmental impact of EREV NVH characteristics can influence consumer acceptance and adoption rates of this technology. Vehicles with superior NVH performance are more likely to be embraced by consumers, potentially accelerating the transition to more environmentally friendly transportation options. This indirect effect on market penetration could have significant long-term environmental benefits by reducing the overall carbon footprint of the transportation sector.

One of the primary environmental benefits of EREVs is their potential to reduce noise pollution in urban areas. When operating in pure electric mode, these vehicles produce significantly less noise compared to conventional internal combustion engine vehicles. This reduction in noise emissions can contribute to improved quality of life in cities and reduce the negative health impacts associated with chronic noise exposure.

However, the NVH characteristics of EREVs become more complex when the range extender is activated. The transition between electric and hybrid modes can introduce new sources of noise and vibration that require careful management. Engineers must optimize the integration of the two power sources to minimize any sudden changes in NVH levels that could negatively impact the driving experience or increase environmental noise.

Vibration control in EREVs also plays a role in environmental impact. Effective vibration dampening not only improves passenger comfort but can also reduce wear and tear on vehicle components. This, in turn, can extend the lifespan of the vehicle and its parts, potentially reducing the environmental impact associated with manufacturing replacement components.

The harshness aspect of NVH in EREVs relates to the overall refinement of the driving experience. A well-tuned EREV system can provide smooth power delivery and seamless transitions between power sources, which can encourage more efficient driving behaviors. This efficiency can translate into reduced energy consumption and, consequently, lower emissions when the range extender is in use.

From a lifecycle perspective, the environmental impact of EREV NVH assessment extends beyond the use phase of the vehicle. The development and implementation of advanced NVH solutions may require additional materials or components, which have their own environmental footprint. Manufacturers must balance the benefits of improved NVH performance against any potential increase in resource consumption or manufacturing complexity.

Moreover, the environmental impact of EREV NVH characteristics can influence consumer acceptance and adoption rates of this technology. Vehicles with superior NVH performance are more likely to be embraced by consumers, potentially accelerating the transition to more environmentally friendly transportation options. This indirect effect on market penetration could have significant long-term environmental benefits by reducing the overall carbon footprint of the transportation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!