EREV potential in heavy-duty commercial vehicles

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Technology Evolution

The evolution of Extended Range Electric Vehicle (EREV) technology in heavy-duty commercial vehicles has been marked by significant advancements and milestones over the past decade. Initially, EREV technology was primarily focused on passenger vehicles, but its potential for application in the commercial sector has gained traction due to the increasing demand for sustainable transportation solutions.

In the early stages of EREV development for heavy-duty vehicles, the primary challenge was adapting the technology to meet the power and range requirements of commercial operations. The first generation of EREV systems for trucks featured relatively small battery packs and relied heavily on the range extender, typically a diesel generator, to provide the necessary power for long-haul operations.

As battery technology improved, the second generation of EREV systems saw an increase in battery capacity and a reduction in the reliance on the range extender. This shift allowed for longer electric-only operation, reducing emissions and fuel consumption. Manufacturers began to experiment with different range extender configurations, including more efficient diesel engines and alternative fuel options such as natural gas.

The third generation of EREV technology for heavy-duty vehicles has been characterized by the integration of advanced power management systems and the use of regenerative braking to maximize energy efficiency. This phase has also seen the introduction of modular battery designs, allowing for customization based on specific route requirements and payload needs.

Recent developments in EREV technology have focused on improving the overall system efficiency and reducing the total cost of ownership. This has led to the exploration of novel range extender technologies, such as fuel cells, which offer the potential for zero-emission operation when combined with renewable hydrogen production.

The latest advancements in EREV systems for heavy-duty commercial vehicles include the integration of artificial intelligence and machine learning algorithms to optimize power distribution and predict energy needs based on route characteristics and driving conditions. This predictive capability allows for more efficient use of the battery and range extender, further improving overall vehicle performance and reducing operational costs.

Looking ahead, the future of EREV technology in heavy-duty commercial vehicles is likely to be shaped by continued improvements in battery energy density, the development of more efficient and compact range extenders, and the integration of smart charging infrastructure. These advancements are expected to further extend the electric-only range of vehicles while reducing the size and weight of the overall powertrain system.

In the early stages of EREV development for heavy-duty vehicles, the primary challenge was adapting the technology to meet the power and range requirements of commercial operations. The first generation of EREV systems for trucks featured relatively small battery packs and relied heavily on the range extender, typically a diesel generator, to provide the necessary power for long-haul operations.

As battery technology improved, the second generation of EREV systems saw an increase in battery capacity and a reduction in the reliance on the range extender. This shift allowed for longer electric-only operation, reducing emissions and fuel consumption. Manufacturers began to experiment with different range extender configurations, including more efficient diesel engines and alternative fuel options such as natural gas.

The third generation of EREV technology for heavy-duty vehicles has been characterized by the integration of advanced power management systems and the use of regenerative braking to maximize energy efficiency. This phase has also seen the introduction of modular battery designs, allowing for customization based on specific route requirements and payload needs.

Recent developments in EREV technology have focused on improving the overall system efficiency and reducing the total cost of ownership. This has led to the exploration of novel range extender technologies, such as fuel cells, which offer the potential for zero-emission operation when combined with renewable hydrogen production.

The latest advancements in EREV systems for heavy-duty commercial vehicles include the integration of artificial intelligence and machine learning algorithms to optimize power distribution and predict energy needs based on route characteristics and driving conditions. This predictive capability allows for more efficient use of the battery and range extender, further improving overall vehicle performance and reducing operational costs.

Looking ahead, the future of EREV technology in heavy-duty commercial vehicles is likely to be shaped by continued improvements in battery energy density, the development of more efficient and compact range extenders, and the integration of smart charging infrastructure. These advancements are expected to further extend the electric-only range of vehicles while reducing the size and weight of the overall powertrain system.

Market Demand Analysis

The market demand for Extended Range Electric Vehicles (EREVs) in the heavy-duty commercial vehicle sector is experiencing significant growth, driven by increasing environmental regulations and the need for more sustainable transportation solutions. As governments worldwide implement stricter emissions standards, fleet operators are seeking alternatives to traditional diesel-powered trucks that can meet these requirements while maintaining operational efficiency.

The heavy-duty commercial vehicle market, which includes long-haul trucks, buses, and specialized vehicles, represents a substantial portion of the global transportation industry. This sector has been traditionally dominated by diesel engines due to their power and range capabilities. However, the shift towards electrification has created a new opportunity for EREV technology to address the unique challenges faced by heavy-duty vehicles.

EREVs offer a compelling solution for heavy-duty commercial vehicles by combining the benefits of electric propulsion with the extended range provided by an onboard generator. This technology addresses the range anxiety often associated with pure battery electric vehicles while still significantly reducing emissions compared to conventional diesel engines. The ability to operate in zero-emission mode for shorter distances, particularly in urban areas, makes EREVs an attractive option for fleet operators looking to comply with local air quality regulations.

Market research indicates that the demand for EREVs in the heavy-duty commercial vehicle segment is expected to grow substantially over the next decade. This growth is fueled by several factors, including the decreasing cost of battery technology, improvements in electric drivetrain efficiency, and the development of more robust charging infrastructure. Additionally, government incentives and subsidies for clean energy vehicles are further stimulating market demand for EREV technology in this sector.

Fleet operators are particularly interested in EREVs due to their potential for lower total cost of ownership. While the initial purchase price of EREV heavy-duty vehicles may be higher than traditional diesel counterparts, the reduced fuel and maintenance costs over the vehicle's lifetime can result in significant savings. This economic advantage, coupled with the environmental benefits, is driving increased adoption among forward-thinking transportation companies.

The market demand for EREVs in heavy-duty commercial vehicles is not uniform across all regions. Developed markets with stringent emissions regulations, such as Europe and North America, are currently leading the adoption of this technology. However, emerging markets are also showing growing interest as they seek to leapfrog older technologies and implement more sustainable transportation solutions.

As the technology matures and becomes more widely available, industry analysts predict a rapid acceleration in market demand for EREV heavy-duty commercial vehicles. This trend is expected to continue as more manufacturers enter the market, driving competition and innovation, which in turn will lead to improved performance and reduced costs for end-users.

The heavy-duty commercial vehicle market, which includes long-haul trucks, buses, and specialized vehicles, represents a substantial portion of the global transportation industry. This sector has been traditionally dominated by diesel engines due to their power and range capabilities. However, the shift towards electrification has created a new opportunity for EREV technology to address the unique challenges faced by heavy-duty vehicles.

EREVs offer a compelling solution for heavy-duty commercial vehicles by combining the benefits of electric propulsion with the extended range provided by an onboard generator. This technology addresses the range anxiety often associated with pure battery electric vehicles while still significantly reducing emissions compared to conventional diesel engines. The ability to operate in zero-emission mode for shorter distances, particularly in urban areas, makes EREVs an attractive option for fleet operators looking to comply with local air quality regulations.

Market research indicates that the demand for EREVs in the heavy-duty commercial vehicle segment is expected to grow substantially over the next decade. This growth is fueled by several factors, including the decreasing cost of battery technology, improvements in electric drivetrain efficiency, and the development of more robust charging infrastructure. Additionally, government incentives and subsidies for clean energy vehicles are further stimulating market demand for EREV technology in this sector.

Fleet operators are particularly interested in EREVs due to their potential for lower total cost of ownership. While the initial purchase price of EREV heavy-duty vehicles may be higher than traditional diesel counterparts, the reduced fuel and maintenance costs over the vehicle's lifetime can result in significant savings. This economic advantage, coupled with the environmental benefits, is driving increased adoption among forward-thinking transportation companies.

The market demand for EREVs in heavy-duty commercial vehicles is not uniform across all regions. Developed markets with stringent emissions regulations, such as Europe and North America, are currently leading the adoption of this technology. However, emerging markets are also showing growing interest as they seek to leapfrog older technologies and implement more sustainable transportation solutions.

As the technology matures and becomes more widely available, industry analysts predict a rapid acceleration in market demand for EREV heavy-duty commercial vehicles. This trend is expected to continue as more manufacturers enter the market, driving competition and innovation, which in turn will lead to improved performance and reduced costs for end-users.

Technical Challenges

The development of Extended Range Electric Vehicles (EREVs) for heavy-duty commercial applications faces several significant technical challenges. These obstacles must be overcome to realize the full potential of this technology in the trucking industry.

One of the primary challenges is the development of high-capacity, long-lasting battery systems. Heavy-duty vehicles require substantial energy storage to maintain their range and performance. Current battery technologies struggle to meet the demanding requirements of commercial trucking, particularly in terms of energy density and cycle life. Researchers are exploring advanced lithium-ion chemistries and solid-state batteries to address these limitations.

The integration of efficient range extenders presents another hurdle. These onboard generators must be compact, lightweight, and highly efficient to maximize the vehicle's electric range while minimizing fuel consumption. Developing range extenders that can operate at peak efficiency across various driving conditions is crucial for optimizing overall system performance.

Thermal management is a critical challenge in EREV heavy-duty vehicles. The high-power demands of commercial operations generate significant heat, which can impact battery life and overall system efficiency. Advanced cooling systems and thermal management strategies are necessary to maintain optimal operating temperatures and ensure long-term reliability.

Power electronics and drivetrain components face unique challenges in heavy-duty applications. These systems must be robust enough to handle the high torque and power requirements of commercial vehicles while maintaining efficiency across a wide range of operating conditions. Developing durable, high-performance electric motors and power inverters is essential for EREV success in this sector.

The charging infrastructure for heavy-duty EREVs presents both technical and logistical challenges. Fast-charging systems capable of rapidly replenishing large battery packs are crucial for maintaining operational efficiency. However, the development of such high-power charging stations requires significant advancements in power delivery and grid integration technologies.

Weight management is another critical factor in EREV design for heavy-duty vehicles. The addition of battery packs and range extenders can significantly increase vehicle weight, potentially reducing payload capacity. Engineers must find innovative ways to optimize vehicle design and materials to offset this added weight without compromising structural integrity or safety.

Lastly, the development of sophisticated energy management systems poses a significant challenge. These systems must efficiently balance power distribution between the battery, range extender, and drivetrain to maximize performance and minimize emissions. Advanced algorithms and predictive technologies are needed to optimize energy use across various driving scenarios and terrains.

One of the primary challenges is the development of high-capacity, long-lasting battery systems. Heavy-duty vehicles require substantial energy storage to maintain their range and performance. Current battery technologies struggle to meet the demanding requirements of commercial trucking, particularly in terms of energy density and cycle life. Researchers are exploring advanced lithium-ion chemistries and solid-state batteries to address these limitations.

The integration of efficient range extenders presents another hurdle. These onboard generators must be compact, lightweight, and highly efficient to maximize the vehicle's electric range while minimizing fuel consumption. Developing range extenders that can operate at peak efficiency across various driving conditions is crucial for optimizing overall system performance.

Thermal management is a critical challenge in EREV heavy-duty vehicles. The high-power demands of commercial operations generate significant heat, which can impact battery life and overall system efficiency. Advanced cooling systems and thermal management strategies are necessary to maintain optimal operating temperatures and ensure long-term reliability.

Power electronics and drivetrain components face unique challenges in heavy-duty applications. These systems must be robust enough to handle the high torque and power requirements of commercial vehicles while maintaining efficiency across a wide range of operating conditions. Developing durable, high-performance electric motors and power inverters is essential for EREV success in this sector.

The charging infrastructure for heavy-duty EREVs presents both technical and logistical challenges. Fast-charging systems capable of rapidly replenishing large battery packs are crucial for maintaining operational efficiency. However, the development of such high-power charging stations requires significant advancements in power delivery and grid integration technologies.

Weight management is another critical factor in EREV design for heavy-duty vehicles. The addition of battery packs and range extenders can significantly increase vehicle weight, potentially reducing payload capacity. Engineers must find innovative ways to optimize vehicle design and materials to offset this added weight without compromising structural integrity or safety.

Lastly, the development of sophisticated energy management systems poses a significant challenge. These systems must efficiently balance power distribution between the battery, range extender, and drivetrain to maximize performance and minimize emissions. Advanced algorithms and predictive technologies are needed to optimize energy use across various driving scenarios and terrains.

Current EREV Solutions

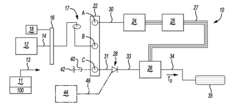

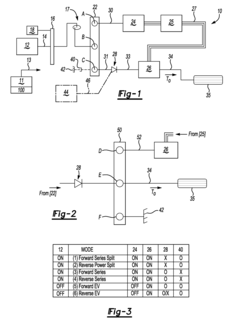

01 Powertrain configuration for EREV

Extended Range Electric Vehicles (EREVs) utilize a unique powertrain configuration that combines an electric motor with an internal combustion engine. The electric motor serves as the primary power source, while the internal combustion engine acts as a range extender, generating electricity to charge the battery when needed. This configuration allows for longer driving ranges compared to pure electric vehicles while maintaining low emissions.- Powertrain configuration for EREV: Extended Range Electric Vehicles (EREVs) utilize a unique powertrain configuration that combines an electric motor with an internal combustion engine. The electric motor serves as the primary power source, while the internal combustion engine acts as a range extender, generating electricity to charge the battery when needed. This configuration allows for longer driving ranges compared to pure electric vehicles while maintaining the benefits of electric propulsion.

- Battery management systems for EREV: Advanced battery management systems are crucial for optimizing the performance and efficiency of EREVs. These systems monitor and control battery charging, discharging, and overall health. They also manage the interaction between the battery, electric motor, and range extender to ensure optimal energy usage and extend battery life.

- Range extender technologies: Range extenders in EREVs can employ various technologies to generate electricity efficiently. These may include advanced internal combustion engines, fuel cells, or other alternative power sources. The focus is on developing compact, lightweight, and efficient range extenders that can provide reliable power generation while minimizing emissions and fuel consumption.

- Energy management strategies for EREV: Sophisticated energy management strategies are employed in EREVs to optimize the use of electric power and the range extender. These strategies determine when to activate the range extender, how to distribute power between the electric motor and range extender, and how to manage regenerative braking. The goal is to maximize overall efficiency and minimize fuel consumption while meeting the vehicle's power demands.

- Charging infrastructure for EREV: Developing and integrating charging infrastructure is essential for the widespread adoption of EREVs. This includes the design and implementation of charging stations, fast-charging technologies, and smart grid integration. The focus is on creating a convenient and efficient charging network that supports the unique needs of EREVs, considering their extended range capabilities and potential for both electric and hybrid operation.

02 Battery management and charging systems

EREVs employ advanced battery management and charging systems to optimize energy usage and extend driving range. These systems include intelligent charging algorithms, regenerative braking, and power distribution control. They also incorporate fast-charging capabilities and battery thermal management to enhance overall performance and longevity of the vehicle's power source.Expand Specific Solutions03 Control strategies for mode switching

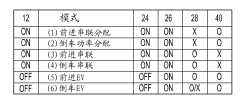

EREVs implement sophisticated control strategies to manage the transition between electric-only mode and range-extended mode. These strategies optimize energy efficiency, performance, and emissions by determining the most appropriate operating mode based on factors such as battery state of charge, driving conditions, and user preferences. Advanced algorithms and sensors are used to ensure seamless mode switching and optimal power delivery.Expand Specific Solutions04 Lightweight materials and aerodynamic design

To maximize efficiency and range, EREVs incorporate lightweight materials such as advanced composites and high-strength alloys in their construction. Additionally, aerodynamic design principles are applied to reduce drag and improve overall vehicle efficiency. These features contribute to increased electric-only range and reduced energy consumption in both electric and range-extended modes.Expand Specific Solutions05 Integration of renewable energy sources

Some EREV designs incorporate the integration of renewable energy sources, such as solar panels, to supplement the vehicle's power supply. These systems can provide additional charging capabilities, further extending the electric-only range and reducing reliance on grid charging or the range extender. Advanced energy management systems are employed to optimize the utilization of renewable energy inputs in conjunction with the vehicle's primary power sources.Expand Specific Solutions

Key Industry Players

The EREV (Extended Range Electric Vehicle) market for heavy-duty commercial vehicles is in an early growth stage, with increasing interest due to environmental regulations and the push for cleaner transportation. The market size is expanding, driven by the need for long-range, zero-emission solutions in the trucking industry. Technologically, EREVs are advancing rapidly, with companies like GM, Cummins, and Nikola leading development. These firms are focusing on improving battery technology, fuel cell integration, and overall powertrain efficiency. While not yet fully mature, EREV technology is progressing quickly, with major players investing heavily in research and development to overcome range and charging infrastructure challenges.

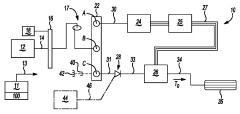

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced EREV system for heavy-duty commercial vehicles, leveraging their experience from the Chevrolet Volt. Their solution integrates a high-capacity battery pack with a range-extending engine, optimized for commercial vehicle duty cycles. The system utilizes a series hybrid configuration, where the engine acts solely as a generator, providing maximum flexibility in power management. GM's EREV technology for heavy-duty vehicles incorporates advanced thermal management systems to maintain optimal battery performance under various load conditions[1]. The company has also implemented smart power distribution algorithms that dynamically adjust the power split between battery and engine, maximizing efficiency based on route, payload, and driving conditions[3].

Strengths: Extensive experience in EREV technology, optimized for commercial vehicle applications, advanced thermal management. Weaknesses: Potentially higher initial cost compared to conventional powertrains, complexity of system integration in heavy-duty vehicles.

Cummins, Inc.

Technical Solution: Cummins has developed a range-extended electric powertrain specifically for heavy-duty commercial vehicles. Their EREV solution combines a compact, high-efficiency diesel engine with an advanced electric drive system. The powertrain utilizes a series hybrid architecture, where the diesel engine serves as a generator to charge the battery pack and provide extended range. Cummins' system incorporates their expertise in diesel engine technology, resulting in a highly efficient range extender that meets stringent emissions standards[2]. The electric drive system features high-power density motors and advanced power electronics, enabling improved vehicle performance and energy recovery through regenerative braking. Cummins has also implemented an intelligent energy management system that optimizes the use of stored electrical energy and engine-generated power based on real-time vehicle data and route information[4].

Strengths: Strong expertise in diesel engine technology, highly efficient range extender, advanced energy management system. Weaknesses: Reliance on diesel fuel for range extension may face challenges in markets pushing for zero-emission solutions.

Core EREV Innovations

Low Fuel Consumption Extended Range Electric Vehicle Powertrain

PatentInactiveCN102275518A

Innovation

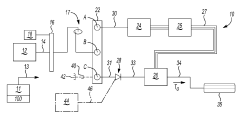

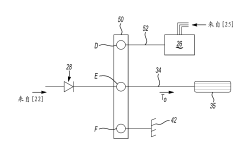

- An extended-range electric vehicle is designed, which uses an engine with direct mechanical lines to connect to the driving wheels. It realizes forward and reverse pure electric modes and series modes through two motors and one-way clutches, and uses a passive rectifier bypass device and an auxiliary starting motor. Optimize power delivery, reduce motor size and improve fuel efficiency.

Low content extended-range electric vehicle powertrain

PatentInactiveUS8196687B2

Innovation

- The extended-range electric vehicle design incorporates a direct mechanical path between the engine and drive wheels through a series mode, utilizing two electric machines, a one-way clutch, and an auxiliary starter motor, enabling efficient power transmission and operation in various modes, including electric-only and power-split modes.

Regulatory Framework

The regulatory framework surrounding Extended Range Electric Vehicles (EREVs) in heavy-duty commercial vehicles is evolving rapidly as governments worldwide seek to reduce emissions and promote sustainable transportation solutions. At the federal level in the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) have established greenhouse gas emissions and fuel efficiency standards for medium- and heavy-duty vehicles. These regulations incentivize the adoption of advanced technologies, including EREVs, by offering credits for vehicles that exceed the standards.

In the European Union, the European Commission has set ambitious targets for reducing CO2 emissions from heavy-duty vehicles. The regulation (EU) 2019/1242 establishes CO2 emission performance standards for new heavy-duty vehicles, with specific targets for 2025 and 2030. This regulatory framework encourages manufacturers to invest in low-emission technologies, including EREVs, to meet these stringent requirements.

China, as the world's largest automotive market, has also implemented policies to promote the adoption of new energy vehicles in the commercial sector. The New Energy Vehicle (NEV) mandate and associated subsidy programs have been extended to include heavy-duty vehicles, providing financial incentives for the development and deployment of EREVs in commercial applications.

At the state and local levels, various jurisdictions have implemented additional regulations and incentives to accelerate the transition to low-emission commercial vehicles. For example, California's Advanced Clean Trucks regulation requires manufacturers to sell an increasing percentage of zero-emission trucks, which may include EREVs depending on their electric range and emissions profile.

The regulatory landscape also includes emissions standards for urban areas, such as Low Emission Zones (LEZs) and Ultra Low Emission Zones (ULEZs), which restrict access for high-polluting vehicles. These zones create a strong incentive for fleet operators to adopt cleaner technologies like EREVs, particularly for last-mile delivery and urban logistics applications.

Furthermore, many countries have established tax incentives and grant programs to support the adoption of low-emission commercial vehicles. These financial mechanisms help offset the higher upfront costs associated with EREV technology, making it more attractive for fleet operators to invest in these vehicles.

As the technology matures and its benefits become more apparent, it is likely that regulatory frameworks will continue to evolve to further support the adoption of EREVs in heavy-duty commercial vehicles. This may include more stringent emissions standards, expanded incentive programs, and potentially mandates for certain vehicle classes or applications to transition to low-emission technologies.

In the European Union, the European Commission has set ambitious targets for reducing CO2 emissions from heavy-duty vehicles. The regulation (EU) 2019/1242 establishes CO2 emission performance standards for new heavy-duty vehicles, with specific targets for 2025 and 2030. This regulatory framework encourages manufacturers to invest in low-emission technologies, including EREVs, to meet these stringent requirements.

China, as the world's largest automotive market, has also implemented policies to promote the adoption of new energy vehicles in the commercial sector. The New Energy Vehicle (NEV) mandate and associated subsidy programs have been extended to include heavy-duty vehicles, providing financial incentives for the development and deployment of EREVs in commercial applications.

At the state and local levels, various jurisdictions have implemented additional regulations and incentives to accelerate the transition to low-emission commercial vehicles. For example, California's Advanced Clean Trucks regulation requires manufacturers to sell an increasing percentage of zero-emission trucks, which may include EREVs depending on their electric range and emissions profile.

The regulatory landscape also includes emissions standards for urban areas, such as Low Emission Zones (LEZs) and Ultra Low Emission Zones (ULEZs), which restrict access for high-polluting vehicles. These zones create a strong incentive for fleet operators to adopt cleaner technologies like EREVs, particularly for last-mile delivery and urban logistics applications.

Furthermore, many countries have established tax incentives and grant programs to support the adoption of low-emission commercial vehicles. These financial mechanisms help offset the higher upfront costs associated with EREV technology, making it more attractive for fleet operators to invest in these vehicles.

As the technology matures and its benefits become more apparent, it is likely that regulatory frameworks will continue to evolve to further support the adoption of EREVs in heavy-duty commercial vehicles. This may include more stringent emissions standards, expanded incentive programs, and potentially mandates for certain vehicle classes or applications to transition to low-emission technologies.

Environmental Impact

The environmental impact of Extended Range Electric Vehicles (EREVs) in heavy-duty commercial vehicles is a critical consideration in the transition towards sustainable transportation. EREVs offer significant potential for reducing greenhouse gas emissions and improving air quality in urban areas, particularly when compared to conventional diesel-powered trucks.

One of the primary environmental benefits of EREVs in heavy-duty commercial vehicles is the reduction in tailpipe emissions. When operating in electric mode, these vehicles produce zero direct emissions, which can substantially improve local air quality, especially in densely populated urban areas where commercial vehicles frequently operate. This reduction in pollutants such as nitrogen oxides (NOx) and particulate matter (PM) can have a positive impact on public health and reduce the environmental burden on cities.

Furthermore, the overall carbon footprint of EREVs can be significantly lower than that of traditional diesel trucks, depending on the source of electricity used for charging. As power grids increasingly incorporate renewable energy sources, the environmental benefits of EREVs are expected to grow. This aligns with global efforts to decarbonize the transportation sector and meet climate change mitigation targets.

The use of regenerative braking in EREVs also contributes to their environmental advantages. This technology allows for the recovery of energy typically lost during braking, improving overall energy efficiency and reducing the vehicle's energy consumption. As a result, EREVs can achieve better fuel economy and lower emissions per mile traveled compared to conventional vehicles.

However, it is important to consider the full lifecycle environmental impact of EREVs, including the production and disposal of batteries. The manufacturing process for large battery packs used in heavy-duty EREVs can be energy-intensive and may involve the extraction of rare earth metals. Addressing these concerns through sustainable manufacturing practices and the development of recycling infrastructure for batteries is crucial to maximizing the environmental benefits of EREV technology.

Additionally, the extended range capability of EREVs, provided by their onboard generators, offers a balance between pure electric operation and the flexibility needed for long-haul transportation. This feature can help overcome range anxiety and charging infrastructure limitations, potentially accelerating the adoption of electrified commercial vehicles and their associated environmental benefits.

In conclusion, while EREVs present significant environmental advantages for heavy-duty commercial vehicles, realizing their full potential requires a holistic approach. This includes continued improvements in battery technology, the expansion of clean energy sources for charging, and the development of sustainable practices throughout the vehicle lifecycle. As these factors align, EREVs have the potential to play a crucial role in reducing the environmental impact of the commercial transportation sector.

One of the primary environmental benefits of EREVs in heavy-duty commercial vehicles is the reduction in tailpipe emissions. When operating in electric mode, these vehicles produce zero direct emissions, which can substantially improve local air quality, especially in densely populated urban areas where commercial vehicles frequently operate. This reduction in pollutants such as nitrogen oxides (NOx) and particulate matter (PM) can have a positive impact on public health and reduce the environmental burden on cities.

Furthermore, the overall carbon footprint of EREVs can be significantly lower than that of traditional diesel trucks, depending on the source of electricity used for charging. As power grids increasingly incorporate renewable energy sources, the environmental benefits of EREVs are expected to grow. This aligns with global efforts to decarbonize the transportation sector and meet climate change mitigation targets.

The use of regenerative braking in EREVs also contributes to their environmental advantages. This technology allows for the recovery of energy typically lost during braking, improving overall energy efficiency and reducing the vehicle's energy consumption. As a result, EREVs can achieve better fuel economy and lower emissions per mile traveled compared to conventional vehicles.

However, it is important to consider the full lifecycle environmental impact of EREVs, including the production and disposal of batteries. The manufacturing process for large battery packs used in heavy-duty EREVs can be energy-intensive and may involve the extraction of rare earth metals. Addressing these concerns through sustainable manufacturing practices and the development of recycling infrastructure for batteries is crucial to maximizing the environmental benefits of EREV technology.

Additionally, the extended range capability of EREVs, provided by their onboard generators, offers a balance between pure electric operation and the flexibility needed for long-haul transportation. This feature can help overcome range anxiety and charging infrastructure limitations, potentially accelerating the adoption of electrified commercial vehicles and their associated environmental benefits.

In conclusion, while EREVs present significant environmental advantages for heavy-duty commercial vehicles, realizing their full potential requires a holistic approach. This includes continued improvements in battery technology, the expansion of clean energy sources for charging, and the development of sustainable practices throughout the vehicle lifecycle. As these factors align, EREVs have the potential to play a crucial role in reducing the environmental impact of the commercial transportation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!