Evaluating Triton X-100 in Biofilm Disruption Efficiency

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 Background and Objectives

Triton X-100, a nonionic surfactant, has been a subject of interest in the field of biofilm disruption for several decades. This versatile compound, first synthesized in the 1950s, has found widespread applications in various industries, including biotechnology, pharmaceuticals, and environmental remediation. The evolution of Triton X-100's use in biofilm disruption can be traced back to the early 1980s when researchers began exploring its potential to penetrate and dismantle microbial communities adhering to surfaces.

The primary objective of evaluating Triton X-100 in biofilm disruption efficiency is to address the growing concern of biofilm-associated infections and contaminations in medical, industrial, and environmental settings. Biofilms, complex aggregations of microorganisms embedded in a self-produced extracellular matrix, pose significant challenges due to their increased resistance to antimicrobial agents and conventional cleaning methods. The ability of Triton X-100 to disrupt these stubborn structures has garnered attention as a potential solution to mitigate biofilm-related problems.

Recent technological advancements in microscopy, molecular biology, and analytical chemistry have enabled researchers to gain deeper insights into the mechanisms by which Triton X-100 interacts with biofilms. These developments have paved the way for more targeted and efficient applications of the surfactant in various scenarios. The current research landscape focuses on optimizing Triton X-100 concentrations, understanding its synergistic effects with other compounds, and exploring its potential in combination with physical or mechanical disruption methods.

As we look towards the future, the evaluation of Triton X-100 in biofilm disruption efficiency aims to achieve several key objectives. These include developing more effective and eco-friendly biofilm removal strategies, reducing the reliance on harsh chemicals or antibiotics, and creating novel formulations that can penetrate even the most recalcitrant biofilms. Additionally, there is a growing interest in understanding the long-term effects of Triton X-100 on microbial communities and the surrounding environment, ensuring its sustainable use in various applications.

The ongoing research in this field is driven by the need to address the economic and health implications of biofilm formation across diverse sectors. From medical device-associated infections to biofouling in industrial pipelines, the potential applications of Triton X-100 as an efficient biofilm disruptor are vast and promising. As such, the evaluation of its efficacy continues to be a critical area of study, with implications for public health, industrial processes, and environmental management.

The primary objective of evaluating Triton X-100 in biofilm disruption efficiency is to address the growing concern of biofilm-associated infections and contaminations in medical, industrial, and environmental settings. Biofilms, complex aggregations of microorganisms embedded in a self-produced extracellular matrix, pose significant challenges due to their increased resistance to antimicrobial agents and conventional cleaning methods. The ability of Triton X-100 to disrupt these stubborn structures has garnered attention as a potential solution to mitigate biofilm-related problems.

Recent technological advancements in microscopy, molecular biology, and analytical chemistry have enabled researchers to gain deeper insights into the mechanisms by which Triton X-100 interacts with biofilms. These developments have paved the way for more targeted and efficient applications of the surfactant in various scenarios. The current research landscape focuses on optimizing Triton X-100 concentrations, understanding its synergistic effects with other compounds, and exploring its potential in combination with physical or mechanical disruption methods.

As we look towards the future, the evaluation of Triton X-100 in biofilm disruption efficiency aims to achieve several key objectives. These include developing more effective and eco-friendly biofilm removal strategies, reducing the reliance on harsh chemicals or antibiotics, and creating novel formulations that can penetrate even the most recalcitrant biofilms. Additionally, there is a growing interest in understanding the long-term effects of Triton X-100 on microbial communities and the surrounding environment, ensuring its sustainable use in various applications.

The ongoing research in this field is driven by the need to address the economic and health implications of biofilm formation across diverse sectors. From medical device-associated infections to biofouling in industrial pipelines, the potential applications of Triton X-100 as an efficient biofilm disruptor are vast and promising. As such, the evaluation of its efficacy continues to be a critical area of study, with implications for public health, industrial processes, and environmental management.

Biofilm Disruption Market Analysis

The biofilm disruption market has been experiencing significant growth in recent years, driven by increasing awareness of biofilm-related issues across various industries. The global market for biofilm disruption technologies is projected to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding 10% during the forecast period.

Key factors contributing to market growth include the rising prevalence of biofilm-associated infections in healthcare settings, growing concerns about biofouling in industrial processes, and the need for effective biofilm control in water treatment systems. The healthcare sector remains the largest end-user segment, accounting for a substantial portion of the market share due to the critical importance of biofilm management in medical devices and hospital environments.

In the industrial sector, biofilm disruption technologies are gaining traction in food and beverage processing, oil and gas production, and manufacturing facilities. These industries are increasingly adopting biofilm control strategies to improve operational efficiency, reduce maintenance costs, and ensure product quality and safety.

The water treatment industry represents another significant market segment, with municipalities and industrial water treatment facilities seeking innovative solutions to combat biofilm formation in distribution systems and treatment plants. This demand is further fueled by stringent regulations regarding water quality and the need for sustainable water management practices.

Geographically, North America and Europe currently dominate the biofilm disruption market, owing to advanced healthcare infrastructure, stringent regulatory frameworks, and high adoption rates of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of biofilm-related issues.

The competitive landscape of the biofilm disruption market is characterized by the presence of both established players and innovative start-ups. Major companies are investing heavily in research and development to introduce novel biofilm disruption technologies, including advanced chemical formulations, enzymatic solutions, and physical disruption methods.

Triton X-100, as a non-ionic surfactant, has garnered attention in the biofilm disruption market due to its potential effectiveness in breaking down biofilm structures. Its evaluation in biofilm disruption efficiency aligns with the market's demand for cost-effective and efficient solutions. The growing interest in surfactant-based approaches for biofilm control is expected to create new opportunities for products like Triton X-100, particularly in industrial and research applications.

Key factors contributing to market growth include the rising prevalence of biofilm-associated infections in healthcare settings, growing concerns about biofouling in industrial processes, and the need for effective biofilm control in water treatment systems. The healthcare sector remains the largest end-user segment, accounting for a substantial portion of the market share due to the critical importance of biofilm management in medical devices and hospital environments.

In the industrial sector, biofilm disruption technologies are gaining traction in food and beverage processing, oil and gas production, and manufacturing facilities. These industries are increasingly adopting biofilm control strategies to improve operational efficiency, reduce maintenance costs, and ensure product quality and safety.

The water treatment industry represents another significant market segment, with municipalities and industrial water treatment facilities seeking innovative solutions to combat biofilm formation in distribution systems and treatment plants. This demand is further fueled by stringent regulations regarding water quality and the need for sustainable water management practices.

Geographically, North America and Europe currently dominate the biofilm disruption market, owing to advanced healthcare infrastructure, stringent regulatory frameworks, and high adoption rates of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of biofilm-related issues.

The competitive landscape of the biofilm disruption market is characterized by the presence of both established players and innovative start-ups. Major companies are investing heavily in research and development to introduce novel biofilm disruption technologies, including advanced chemical formulations, enzymatic solutions, and physical disruption methods.

Triton X-100, as a non-ionic surfactant, has garnered attention in the biofilm disruption market due to its potential effectiveness in breaking down biofilm structures. Its evaluation in biofilm disruption efficiency aligns with the market's demand for cost-effective and efficient solutions. The growing interest in surfactant-based approaches for biofilm control is expected to create new opportunities for products like Triton X-100, particularly in industrial and research applications.

Triton X-100 Challenges in Biofilm Removal

Triton X-100, a widely used non-ionic surfactant, faces several challenges in its application for biofilm removal. One of the primary issues is its limited penetration ability into mature biofilms. Biofilms are complex structures composed of microorganisms embedded in a self-produced extracellular polymeric substance (EPS) matrix. This matrix acts as a protective barrier, hindering the diffusion of antimicrobial agents and surfactants like Triton X-100.

The effectiveness of Triton X-100 in biofilm disruption is highly dependent on the biofilm's composition and age. Mature biofilms with dense EPS matrices are particularly resistant to Triton X-100 treatment. The surfactant may only affect the outer layers of the biofilm, leaving the inner core intact. This partial removal can lead to rapid regrowth of the biofilm, rendering the treatment ineffective in the long term.

Another challenge is the potential for microbial adaptation to Triton X-100. Repeated exposure to sub-lethal concentrations of the surfactant may induce changes in the microbial community, leading to increased resistance. Some microorganisms may alter their membrane composition or upregulate efflux pumps to counteract the effects of Triton X-100, further reducing its efficacy in biofilm removal.

The cytotoxicity of Triton X-100 at higher concentrations poses a significant challenge, especially in biomedical applications. While increased concentrations may improve biofilm disruption, they also raise concerns about potential damage to host tissues or cells. This limits the usable concentration range, particularly in sensitive environments such as medical devices or wound treatments.

Environmental concerns also present challenges for Triton X-100 usage. The surfactant's persistence in the environment and potential for bioaccumulation in aquatic organisms have raised ecological concerns. This has led to restrictions on its use in certain applications and geographical regions, necessitating the development of more environmentally friendly alternatives.

The interaction of Triton X-100 with other components in complex biological systems can also reduce its effectiveness. Proteins, lipids, and other biomolecules present in the environment may bind to Triton X-100, reducing its available concentration for biofilm disruption. This sequestration effect can significantly diminish the surfactant's performance, especially in protein-rich environments.

Lastly, the variability in biofilm composition across different microbial species and environmental conditions presents a challenge in developing standardized Triton X-100 treatment protocols. The optimal concentration and exposure time may vary significantly depending on the specific biofilm characteristics, making it difficult to establish universal guidelines for its application in biofilm removal.

The effectiveness of Triton X-100 in biofilm disruption is highly dependent on the biofilm's composition and age. Mature biofilms with dense EPS matrices are particularly resistant to Triton X-100 treatment. The surfactant may only affect the outer layers of the biofilm, leaving the inner core intact. This partial removal can lead to rapid regrowth of the biofilm, rendering the treatment ineffective in the long term.

Another challenge is the potential for microbial adaptation to Triton X-100. Repeated exposure to sub-lethal concentrations of the surfactant may induce changes in the microbial community, leading to increased resistance. Some microorganisms may alter their membrane composition or upregulate efflux pumps to counteract the effects of Triton X-100, further reducing its efficacy in biofilm removal.

The cytotoxicity of Triton X-100 at higher concentrations poses a significant challenge, especially in biomedical applications. While increased concentrations may improve biofilm disruption, they also raise concerns about potential damage to host tissues or cells. This limits the usable concentration range, particularly in sensitive environments such as medical devices or wound treatments.

Environmental concerns also present challenges for Triton X-100 usage. The surfactant's persistence in the environment and potential for bioaccumulation in aquatic organisms have raised ecological concerns. This has led to restrictions on its use in certain applications and geographical regions, necessitating the development of more environmentally friendly alternatives.

The interaction of Triton X-100 with other components in complex biological systems can also reduce its effectiveness. Proteins, lipids, and other biomolecules present in the environment may bind to Triton X-100, reducing its available concentration for biofilm disruption. This sequestration effect can significantly diminish the surfactant's performance, especially in protein-rich environments.

Lastly, the variability in biofilm composition across different microbial species and environmental conditions presents a challenge in developing standardized Triton X-100 treatment protocols. The optimal concentration and exposure time may vary significantly depending on the specific biofilm characteristics, making it difficult to establish universal guidelines for its application in biofilm removal.

Current Triton X-100 Application Methods

01 Triton X-100 in cell lysis and protein extraction

Triton X-100 is widely used as a detergent for cell lysis and protein extraction due to its high disruption efficiency. It effectively solubilizes cell membranes and releases intracellular components, making it valuable in various biological research applications and protein purification processes.- Triton X-100 in cell lysis and protein extraction: Triton X-100 is widely used as a detergent for cell lysis and protein extraction due to its high disruption efficiency. It effectively solubilizes cell membranes and releases intracellular components, making it valuable in various biological research applications and industrial processes.

- Optimization of Triton X-100 concentration: The disruption efficiency of Triton X-100 can be optimized by adjusting its concentration. Different cell types and experimental conditions may require varying concentrations of Triton X-100 to achieve optimal lysis and protein extraction while minimizing potential interference with downstream analyses.

- Combination of Triton X-100 with other lysis methods: Combining Triton X-100 with other lysis methods, such as sonication or freeze-thaw cycles, can enhance its disruption efficiency. This synergistic approach can lead to more complete cell lysis and improved protein extraction, particularly for challenging sample types or when working with hard-to-lyse cells.

- Triton X-100 in membrane protein solubilization: Triton X-100 is particularly effective in solubilizing membrane proteins due to its ability to disrupt lipid-protein interactions. This property makes it valuable for studying membrane-associated proteins and for purifying membrane-bound enzymes or receptors in their active forms.

- Environmental and safety considerations of Triton X-100: While Triton X-100 is highly effective for cell disruption, its use may have environmental and safety implications. Researchers are exploring alternative, more environmentally friendly detergents or methods that can achieve similar disruption efficiency while minimizing potential negative impacts on ecosystems and human health.

02 Optimization of Triton X-100 concentration

The disruption efficiency of Triton X-100 can be optimized by adjusting its concentration. Different cell types and experimental conditions may require varying concentrations of Triton X-100 to achieve optimal lysis and protein extraction while minimizing potential interference with downstream applications.Expand Specific Solutions03 Combination of Triton X-100 with other lysis methods

Triton X-100 can be combined with other lysis methods, such as sonication or freeze-thaw cycles, to enhance its disruption efficiency. This synergistic approach can improve the overall yield and quality of extracted proteins or other cellular components.Expand Specific Solutions04 Temperature effects on Triton X-100 disruption efficiency

The temperature at which Triton X-100 is used can significantly impact its disruption efficiency. Optimal temperatures may vary depending on the specific application and target molecules, with some processes benefiting from elevated temperatures while others require lower temperatures to maintain protein stability.Expand Specific Solutions05 Triton X-100 in membrane protein solubilization

Triton X-100 is particularly effective in solubilizing membrane proteins due to its ability to disrupt lipid-protein interactions. Its disruption efficiency makes it a valuable tool in studying and isolating membrane-associated proteins, which are often challenging to work with using other methods.Expand Specific Solutions

Key Players in Biofilm Control Industry

The competitive landscape for evaluating Triton X-100 in biofilm disruption efficiency is in a developing stage, with growing market potential as biofilm-related issues gain prominence across industries. The market size is expanding, driven by increasing applications in healthcare, industrial, and environmental sectors. Technologically, the field is advancing rapidly, with companies like Takeda Pharmaceutical, Novozymes, and F. Hoffmann-La Roche leading research efforts. These firms, along with academic institutions such as the German Cancer Research Center and East China Normal University, are contributing to the maturation of biofilm disruption techniques. The involvement of diverse players, from pharmaceutical giants to specialized biotechnology firms, indicates a competitive and innovative environment in this niche but growing field.

Novozymes A/S

Technical Solution: Novozymes has developed an enzymatic approach to enhance the biofilm disruption efficiency of Triton X-100. Their method combines Triton X-100 with specific enzymes that target the extracellular polymeric substances (EPS) in biofilms. The company has identified a cocktail of enzymes, including proteases, polysaccharidases, and DNases, that work synergistically with Triton X-100 to break down the biofilm matrix. In their formulation, Triton X-100 is typically used at a concentration of 0.1-0.5%, while the enzyme cocktail is added at carefully optimized ratios. This combination has shown to increase biofilm removal efficiency by up to 40% compared to Triton X-100 alone in various industrial and medical applications[7][8].

Strengths: Highly effective against a wide range of biofilm types due to the targeted enzymatic action. Potentially allows for lower concentrations of Triton X-100 to be used. Weaknesses: Enzymes may be sensitive to environmental conditions, potentially limiting the application range. Higher production costs compared to non-enzymatic methods.

F. Hoffmann-La Roche Ltd.

Technical Solution: Roche has developed a novel approach to evaluate Triton X-100's biofilm disruption efficiency in the context of medical device cleaning and sterilization. Their method involves a combination of in vitro biofilm models and advanced imaging techniques. Roche uses a range of clinically relevant bacterial strains to form biofilms on various medical device materials. They then apply Triton X-100 at concentrations ranging from 0.1% to 2%, both alone and in combination with other cleaning agents. The efficacy is evaluated using confocal microscopy with live/dead staining, as well as quantitative culture methods. Additionally, Roche has developed a high-throughput screening platform that allows for rapid testing of multiple Triton X-100 formulations against different biofilm types[9][10].

Strengths: Highly relevant to medical applications, providing data directly applicable to device cleaning protocols. The high-throughput screening allows for rapid optimization of Triton X-100 use. Weaknesses: May be less applicable to non-medical biofilms or environmental applications. The complexity of the evaluation system may make it challenging to translate results to real-world scenarios.

Triton X-100 Mechanism in Biofilm Disruption

Triton X-100-enhanced biochar immobilized microbial material as well as preparation method and application of biochar immobilized microbial material

PatentActiveCN105695443A

Innovation

- The nonionic surfactant TrionX-100 is used to modify the biochar surface to enhance the binding force and adsorption capacity between biochar and microorganisms, and improve the removal efficiency of biochar-immobilized microbial materials.

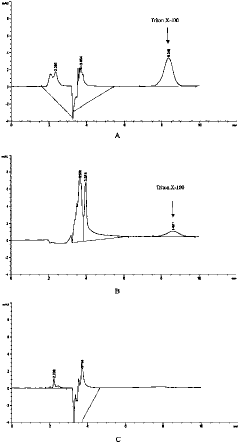

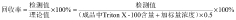

High performance liquid chromatography detection method of Triton X-100 content

PatentActiveCN104215718A

Innovation

- High-performance liquid chromatography detection of Triton X-100 is carried out using a chromatographic column with a pore diameter of 30 nm, which avoids sample pretreatment and directly detects the Triton X-100 content in biological products, using a C18 chromatographic column, methanol-water solution mobile phase and Specific detection conditions.

Environmental Impact of Triton X-100

The environmental impact of Triton X-100 in biofilm disruption applications is a critical consideration for its widespread use. This non-ionic surfactant, while effective in breaking down biofilms, poses significant ecological concerns due to its persistence and potential toxicity in aquatic ecosystems.

Triton X-100 is known for its slow biodegradation rate, with studies indicating that it can persist in the environment for extended periods. This persistence leads to accumulation in water bodies, potentially affecting aquatic life at various trophic levels. Research has shown that Triton X-100 can cause acute toxicity to fish, invertebrates, and algae, even at relatively low concentrations.

The surfactant's ability to disrupt cell membranes, which makes it effective against biofilms, also contributes to its toxicity in non-target organisms. It can interfere with the respiratory functions of aquatic organisms and disrupt their endocrine systems. Furthermore, Triton X-100 has been observed to enhance the bioavailability of other pollutants in aquatic environments, potentially exacerbating the impact of existing contaminants.

In wastewater treatment plants, the presence of Triton X-100 can affect the efficiency of biological treatment processes. It may inhibit the growth and activity of beneficial microorganisms responsible for breaking down organic matter, thus compromising the overall treatment efficacy. This can lead to increased operational costs and reduced water quality in effluent streams.

The environmental fate of Triton X-100 is also a concern. When released into water bodies, it can adsorb to sediments and organic matter, creating a reservoir of the compound that can be slowly released over time. This prolonged exposure increases the risk of chronic effects on aquatic ecosystems and may lead to bioaccumulation in the food chain.

Regulatory bodies in various countries have recognized the environmental risks associated with Triton X-100 and similar alkylphenol ethoxylates. As a result, there have been initiatives to phase out or restrict their use in certain applications. The European Union, for instance, has implemented regulations limiting the use of nonylphenol ethoxylates, a closely related group of compounds, in various products.

Given these environmental concerns, research efforts are increasingly focused on developing alternative biofilm disruption agents that offer similar efficacy but with reduced ecological impact. Biodegradable surfactants, enzymatic treatments, and physical disruption methods are being explored as potential substitutes for Triton X-100 in biofilm management strategies.

Triton X-100 is known for its slow biodegradation rate, with studies indicating that it can persist in the environment for extended periods. This persistence leads to accumulation in water bodies, potentially affecting aquatic life at various trophic levels. Research has shown that Triton X-100 can cause acute toxicity to fish, invertebrates, and algae, even at relatively low concentrations.

The surfactant's ability to disrupt cell membranes, which makes it effective against biofilms, also contributes to its toxicity in non-target organisms. It can interfere with the respiratory functions of aquatic organisms and disrupt their endocrine systems. Furthermore, Triton X-100 has been observed to enhance the bioavailability of other pollutants in aquatic environments, potentially exacerbating the impact of existing contaminants.

In wastewater treatment plants, the presence of Triton X-100 can affect the efficiency of biological treatment processes. It may inhibit the growth and activity of beneficial microorganisms responsible for breaking down organic matter, thus compromising the overall treatment efficacy. This can lead to increased operational costs and reduced water quality in effluent streams.

The environmental fate of Triton X-100 is also a concern. When released into water bodies, it can adsorb to sediments and organic matter, creating a reservoir of the compound that can be slowly released over time. This prolonged exposure increases the risk of chronic effects on aquatic ecosystems and may lead to bioaccumulation in the food chain.

Regulatory bodies in various countries have recognized the environmental risks associated with Triton X-100 and similar alkylphenol ethoxylates. As a result, there have been initiatives to phase out or restrict their use in certain applications. The European Union, for instance, has implemented regulations limiting the use of nonylphenol ethoxylates, a closely related group of compounds, in various products.

Given these environmental concerns, research efforts are increasingly focused on developing alternative biofilm disruption agents that offer similar efficacy but with reduced ecological impact. Biodegradable surfactants, enzymatic treatments, and physical disruption methods are being explored as potential substitutes for Triton X-100 in biofilm management strategies.

Regulatory Framework for Surfactant Use

The regulatory framework for surfactant use in biofilm disruption applications, particularly concerning Triton X-100, is a complex and evolving landscape. Regulatory bodies worldwide have established guidelines and restrictions on the use of surfactants in various industries, including healthcare, food processing, and environmental remediation.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating surfactants under the Toxic Substances Control Act (TSCA). Triton X-100, being a non-ionic surfactant, falls under this regulatory purview. The EPA requires manufacturers and importers to submit premanufacture notices and comply with reporting, record-keeping, and testing requirements. Additionally, the Food and Drug Administration (FDA) regulates the use of surfactants in food contact materials and medical devices, which may include biofilm disruption applications.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to surfactants like Triton X-100. Under REACH, companies must register chemicals they manufacture or import in quantities over one tonne per year. The European Chemicals Agency (ECHA) manages this process and assesses the potential risks associated with these substances.

In Asia, countries like Japan and South Korea have their own chemical regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require registration and risk assessment of surfactants used in various applications, including biofilm disruption.

Environmental concerns have led to increased scrutiny of surfactants' biodegradability and ecotoxicity. Many regulatory bodies now require extensive environmental impact assessments before approving surfactants for use. Triton X-100, being a non-biodegradable surfactant, faces particular challenges in this regard.

Occupational health and safety regulations also play a significant role in the use of surfactants like Triton X-100 in industrial settings. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling these chemicals.

As research into biofilm disruption continues to advance, regulatory frameworks are likely to evolve. Emerging concerns about antimicrobial resistance and the potential for surfactants to contribute to this issue may lead to more stringent regulations in the future. Companies developing biofilm disruption technologies using Triton X-100 or similar surfactants must stay abreast of these regulatory changes and adapt their strategies accordingly.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating surfactants under the Toxic Substances Control Act (TSCA). Triton X-100, being a non-ionic surfactant, falls under this regulatory purview. The EPA requires manufacturers and importers to submit premanufacture notices and comply with reporting, record-keeping, and testing requirements. Additionally, the Food and Drug Administration (FDA) regulates the use of surfactants in food contact materials and medical devices, which may include biofilm disruption applications.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to surfactants like Triton X-100. Under REACH, companies must register chemicals they manufacture or import in quantities over one tonne per year. The European Chemicals Agency (ECHA) manages this process and assesses the potential risks associated with these substances.

In Asia, countries like Japan and South Korea have their own chemical regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require registration and risk assessment of surfactants used in various applications, including biofilm disruption.

Environmental concerns have led to increased scrutiny of surfactants' biodegradability and ecotoxicity. Many regulatory bodies now require extensive environmental impact assessments before approving surfactants for use. Triton X-100, being a non-biodegradable surfactant, faces particular challenges in this regard.

Occupational health and safety regulations also play a significant role in the use of surfactants like Triton X-100 in industrial settings. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and safety protocols for workers handling these chemicals.

As research into biofilm disruption continues to advance, regulatory frameworks are likely to evolve. Emerging concerns about antimicrobial resistance and the potential for surfactants to contribute to this issue may lead to more stringent regulations in the future. Companies developing biofilm disruption technologies using Triton X-100 or similar surfactants must stay abreast of these regulatory changes and adapt their strategies accordingly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!