Triton X-100 Effect on Surface Tension in Microfluidics Devices

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 Background

Triton X-100, a nonionic surfactant, has been widely used in various scientific and industrial applications since its introduction in the mid-20th century. Its chemical structure consists of a hydrophilic polyethylene oxide chain and a hydrophobic aromatic hydrocarbon group, making it an effective surface-active agent. This unique molecular composition allows Triton X-100 to significantly alter the surface tension of liquids, a property that has found particular relevance in microfluidic devices.

The development of Triton X-100 can be traced back to the broader field of surfactant chemistry, which gained momentum in the 1940s and 1950s. As industrial processes and scientific research demanded more sophisticated control over liquid properties, Triton X-100 emerged as a versatile solution. Its ability to reduce surface tension without the ionic interactions associated with other surfactants made it particularly valuable in sensitive applications.

In the context of microfluidics, Triton X-100's role became increasingly prominent as the field evolved from its nascent stages in the 1990s to its current status as a cornerstone of many biotechnological and analytical processes. The miniaturization of fluid handling systems in microfluidic devices presented unique challenges related to surface tension and fluid behavior at the microscale. Triton X-100's capacity to modulate these properties made it an invaluable tool for researchers and engineers working in this domain.

The surfactant's impact on surface tension is particularly crucial in microfluidic devices, where the high surface-area-to-volume ratio amplifies the importance of interfacial phenomena. By reducing surface tension, Triton X-100 facilitates the formation and manipulation of droplets, enhances wetting of channel surfaces, and helps prevent the adsorption of biomolecules to device walls. These effects collectively contribute to improved flow characteristics, more precise control over fluid dynamics, and enhanced overall performance of microfluidic systems.

Over the years, the application of Triton X-100 in microfluidics has expanded beyond its primary role as a surface tension modifier. Researchers have explored its potential in stabilizing emulsions, improving mixing efficiency in microchannel reactors, and enhancing the sensitivity of biosensors integrated into microfluidic platforms. The surfactant's compatibility with a wide range of biological samples has also made it valuable in applications such as cell lysis and protein solubilization within microfluidic devices.

As the field of microfluidics continues to advance, understanding the nuanced effects of Triton X-100 on surface tension and other fluid properties remains a critical area of research. The ongoing exploration of its behavior at different concentrations, in various solvent systems, and under diverse flow conditions continues to yield insights that drive innovation in microfluidic device design and functionality.

The development of Triton X-100 can be traced back to the broader field of surfactant chemistry, which gained momentum in the 1940s and 1950s. As industrial processes and scientific research demanded more sophisticated control over liquid properties, Triton X-100 emerged as a versatile solution. Its ability to reduce surface tension without the ionic interactions associated with other surfactants made it particularly valuable in sensitive applications.

In the context of microfluidics, Triton X-100's role became increasingly prominent as the field evolved from its nascent stages in the 1990s to its current status as a cornerstone of many biotechnological and analytical processes. The miniaturization of fluid handling systems in microfluidic devices presented unique challenges related to surface tension and fluid behavior at the microscale. Triton X-100's capacity to modulate these properties made it an invaluable tool for researchers and engineers working in this domain.

The surfactant's impact on surface tension is particularly crucial in microfluidic devices, where the high surface-area-to-volume ratio amplifies the importance of interfacial phenomena. By reducing surface tension, Triton X-100 facilitates the formation and manipulation of droplets, enhances wetting of channel surfaces, and helps prevent the adsorption of biomolecules to device walls. These effects collectively contribute to improved flow characteristics, more precise control over fluid dynamics, and enhanced overall performance of microfluidic systems.

Over the years, the application of Triton X-100 in microfluidics has expanded beyond its primary role as a surface tension modifier. Researchers have explored its potential in stabilizing emulsions, improving mixing efficiency in microchannel reactors, and enhancing the sensitivity of biosensors integrated into microfluidic platforms. The surfactant's compatibility with a wide range of biological samples has also made it valuable in applications such as cell lysis and protein solubilization within microfluidic devices.

As the field of microfluidics continues to advance, understanding the nuanced effects of Triton X-100 on surface tension and other fluid properties remains a critical area of research. The ongoing exploration of its behavior at different concentrations, in various solvent systems, and under diverse flow conditions continues to yield insights that drive innovation in microfluidic device design and functionality.

Microfluidics Market Analysis

The microfluidics market has experienced significant growth in recent years, driven by advancements in technology and increasing applications across various industries. The global microfluidics market size was valued at approximately $20 billion in 2020 and is projected to reach $50 billion by 2026, growing at a CAGR of over 16% during the forecast period.

The healthcare and life sciences sectors dominate the microfluidics market, accounting for the largest share of revenue. This is primarily due to the widespread adoption of microfluidic devices in drug discovery, point-of-care diagnostics, and genomics research. The pharmaceutical industry, in particular, has embraced microfluidic technologies for high-throughput screening and drug development processes, leading to more efficient and cost-effective drug discovery pipelines.

In recent years, there has been a notable surge in demand for microfluidic devices in the field of diagnostics, especially for point-of-care testing. The COVID-19 pandemic has further accelerated this trend, with microfluidic-based rapid testing kits playing a crucial role in disease detection and management. This has led to increased investment and research in microfluidic technologies for infectious disease diagnostics.

The academic and research sector also contributes significantly to the microfluidics market, with universities and research institutions continuously exploring new applications and pushing the boundaries of microfluidic technology. This has resulted in a steady stream of innovations and potential commercial applications, further fueling market growth.

Geographically, North America holds the largest share of the microfluidics market, followed by Europe and Asia-Pacific. The United States, in particular, is a major hub for microfluidics research and development, with numerous startups and established companies driving innovation in the field. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to increasing healthcare expenditure, growing research activities, and rising adoption of microfluidic technologies in countries like China, Japan, and South Korea.

Key players in the microfluidics market include Danaher Corporation, Thermo Fisher Scientific, Bio-Rad Laboratories, and Illumina, among others. These companies are actively investing in research and development to expand their product portfolios and maintain their competitive edge in the market.

The healthcare and life sciences sectors dominate the microfluidics market, accounting for the largest share of revenue. This is primarily due to the widespread adoption of microfluidic devices in drug discovery, point-of-care diagnostics, and genomics research. The pharmaceutical industry, in particular, has embraced microfluidic technologies for high-throughput screening and drug development processes, leading to more efficient and cost-effective drug discovery pipelines.

In recent years, there has been a notable surge in demand for microfluidic devices in the field of diagnostics, especially for point-of-care testing. The COVID-19 pandemic has further accelerated this trend, with microfluidic-based rapid testing kits playing a crucial role in disease detection and management. This has led to increased investment and research in microfluidic technologies for infectious disease diagnostics.

The academic and research sector also contributes significantly to the microfluidics market, with universities and research institutions continuously exploring new applications and pushing the boundaries of microfluidic technology. This has resulted in a steady stream of innovations and potential commercial applications, further fueling market growth.

Geographically, North America holds the largest share of the microfluidics market, followed by Europe and Asia-Pacific. The United States, in particular, is a major hub for microfluidics research and development, with numerous startups and established companies driving innovation in the field. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to increasing healthcare expenditure, growing research activities, and rising adoption of microfluidic technologies in countries like China, Japan, and South Korea.

Key players in the microfluidics market include Danaher Corporation, Thermo Fisher Scientific, Bio-Rad Laboratories, and Illumina, among others. These companies are actively investing in research and development to expand their product portfolios and maintain their competitive edge in the market.

Surface Tension Challenges

Surface tension plays a critical role in microfluidic devices, influencing fluid behavior and device performance. However, several challenges arise when dealing with surface tension in these miniaturized systems. One of the primary issues is the difficulty in controlling and manipulating surface tension precisely, which can lead to inconsistent fluid flow and droplet formation.

The high surface-area-to-volume ratio in microfluidic channels amplifies the effects of surface tension, making it a dominant force at the microscale. This can result in capillary effects that interfere with desired fluid dynamics, causing issues such as flow instability, bubble formation, and uneven wetting of channel surfaces. These phenomena can significantly impact the accuracy and reliability of microfluidic operations, particularly in applications requiring precise fluid control.

Another challenge is the variability of surface tension across different materials and surface treatments used in microfluidic device fabrication. The interaction between the fluid and channel walls can vary depending on the substrate material, surface roughness, and chemical properties, leading to inconsistent behavior across different devices or even within the same device over time.

The presence of surfactants, such as Triton X-100, introduces additional complexities in managing surface tension. While surfactants can be used to modify surface tension, their effects are not always uniform or predictable in microfluidic environments. The dynamic nature of surfactant adsorption and desorption at interfaces can lead to temporal variations in surface tension, complicating the design and operation of microfluidic systems.

Temperature fluctuations pose another challenge, as surface tension is temperature-dependent. Even small changes in temperature can significantly alter surface tension, affecting fluid behavior and potentially disrupting microfluidic processes. Maintaining consistent temperature control throughout the device becomes crucial for reproducible results.

The integration of multiple fluids with different surface tensions in a single microfluidic device presents further challenges. Interfaces between immiscible fluids can create additional complexities, such as Marangoni effects, which can disrupt desired flow patterns and mixing processes.

Scaling effects also contribute to surface tension challenges in microfluidics. As device dimensions decrease, the relative importance of surface tension increases, often outweighing other forces like gravity. This scaling behavior necessitates careful consideration of surface tension effects in device design and operation, particularly when transitioning from macro to microscale systems.

Addressing these surface tension challenges requires a multidisciplinary approach, combining expertise in fluid dynamics, materials science, and surface chemistry. Innovative solutions, such as advanced surface treatments, dynamic control of surface properties, and novel channel geometries, are being explored to overcome these obstacles and enhance the performance and reliability of microfluidic devices.

The high surface-area-to-volume ratio in microfluidic channels amplifies the effects of surface tension, making it a dominant force at the microscale. This can result in capillary effects that interfere with desired fluid dynamics, causing issues such as flow instability, bubble formation, and uneven wetting of channel surfaces. These phenomena can significantly impact the accuracy and reliability of microfluidic operations, particularly in applications requiring precise fluid control.

Another challenge is the variability of surface tension across different materials and surface treatments used in microfluidic device fabrication. The interaction between the fluid and channel walls can vary depending on the substrate material, surface roughness, and chemical properties, leading to inconsistent behavior across different devices or even within the same device over time.

The presence of surfactants, such as Triton X-100, introduces additional complexities in managing surface tension. While surfactants can be used to modify surface tension, their effects are not always uniform or predictable in microfluidic environments. The dynamic nature of surfactant adsorption and desorption at interfaces can lead to temporal variations in surface tension, complicating the design and operation of microfluidic systems.

Temperature fluctuations pose another challenge, as surface tension is temperature-dependent. Even small changes in temperature can significantly alter surface tension, affecting fluid behavior and potentially disrupting microfluidic processes. Maintaining consistent temperature control throughout the device becomes crucial for reproducible results.

The integration of multiple fluids with different surface tensions in a single microfluidic device presents further challenges. Interfaces between immiscible fluids can create additional complexities, such as Marangoni effects, which can disrupt desired flow patterns and mixing processes.

Scaling effects also contribute to surface tension challenges in microfluidics. As device dimensions decrease, the relative importance of surface tension increases, often outweighing other forces like gravity. This scaling behavior necessitates careful consideration of surface tension effects in device design and operation, particularly when transitioning from macro to microscale systems.

Addressing these surface tension challenges requires a multidisciplinary approach, combining expertise in fluid dynamics, materials science, and surface chemistry. Innovative solutions, such as advanced surface treatments, dynamic control of surface properties, and novel channel geometries, are being explored to overcome these obstacles and enhance the performance and reliability of microfluidic devices.

Current Triton X-100 Solutions

01 Measurement and control of surface tension

Triton X-100 is used in various applications where precise control and measurement of surface tension are crucial. Techniques and devices are developed to accurately measure and manipulate the surface tension of solutions containing Triton X-100, which is important in fields such as materials science, chemistry, and biotechnology.- Measurement and control of surface tension: Triton X-100 is used in various applications where precise control and measurement of surface tension are crucial. This includes the development of sensors, analytical instruments, and methods for determining surface tension in different environments and conditions.

- Formulation of cleaning and detergent compositions: Triton X-100 is incorporated into cleaning and detergent formulations to enhance their surface-active properties. Its ability to lower surface tension improves the wetting and spreading capabilities of these products, making them more effective in various cleaning applications.

- Emulsification and stabilization in industrial processes: The surface tension-lowering properties of Triton X-100 make it valuable in emulsification and stabilization processes across various industries. It is used to create stable emulsions, suspensions, and dispersions in applications such as polymer production, oil recovery, and pharmaceutical formulations.

- Enhancement of biological and biochemical assays: Triton X-100's ability to modify surface tension is utilized in biological and biochemical assays. It aids in cell lysis, protein extraction, and membrane permeabilization, improving the efficiency and accuracy of various analytical techniques and experimental procedures.

- Modification of surface properties in material science: In material science and engineering, Triton X-100 is employed to modify surface properties of materials. Its surface tension-altering capabilities are used in the development of coatings, adhesives, and surface treatments to enhance wettability, adhesion, and other surface-related characteristics.

02 Formulation of cleaning and detergent solutions

Triton X-100 is utilized in the formulation of cleaning and detergent solutions due to its surface-active properties. Its ability to lower surface tension is exploited to enhance the cleaning efficiency of these solutions, making them more effective in removing dirt, oils, and other contaminants from various surfaces.Expand Specific Solutions03 Emulsification and stabilization in industrial processes

The surface tension-lowering properties of Triton X-100 make it valuable in emulsification and stabilization processes across various industries. It is used to create stable emulsions, suspensions, and dispersions in applications such as cosmetics, pharmaceuticals, and food processing.Expand Specific Solutions04 Enhancement of material properties and performance

Triton X-100 is employed to modify surface properties of materials, enhancing their performance in specific applications. By altering surface tension, it can improve wetting, adhesion, and other surface-related properties of materials used in coatings, films, and composite materials.Expand Specific Solutions05 Biological and biochemical applications

In biological and biochemical research, Triton X-100 is used for its ability to modify cell membrane permeability and solubilize proteins. Its surface tension-altering properties are crucial in techniques such as cell lysis, protein extraction, and membrane protein studies.Expand Specific Solutions

Key Microfluidics Players

The competitive landscape for "Triton X-100 Effect on Surface Tension in Microfluidics Devices" is in an early growth stage, with increasing market potential as microfluidics applications expand. The market size is moderate but growing, driven by advancements in lab-on-a-chip technologies and point-of-care diagnostics. Technical maturity varies among key players. Agilent Technologies and IBM lead in commercial applications, while academic institutions like Zhejiang University of Technology and University of Birmingham contribute significant research. Companies like GlobalFoundries and LG Energy Solution are exploring niche applications, indicating a diversifying field with opportunities for innovation and specialization.

Agilent Technologies, Inc.

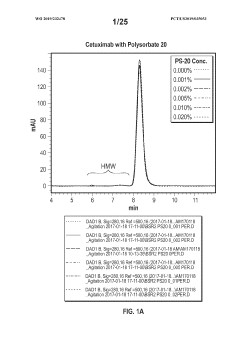

Technical Solution: Agilent Technologies has developed advanced microfluidic devices that utilize Triton X-100 to manipulate surface tension. Their approach involves integrating precise concentrations of Triton X-100 into microfluidic channels to control fluid flow and droplet formation. By fine-tuning the surfactant concentration, they achieve optimal surface tension reduction for various applications, including DNA sequencing and protein analysis. Agilent's microfluidic chips incorporate specialized surface treatments and channel geometries that work synergistically with Triton X-100 to enhance fluid handling and reduce sample volumes[1][3]. Their technology enables precise control over droplet size and stability, crucial for high-throughput screening and single-cell analysis applications.

Strengths: Precise control over surface tension, reduced sample volumes, and enhanced droplet stability. Weaknesses: Potential for surfactant interference in certain biochemical assays and limited compatibility with some biomolecules.

The Regents of the University of California

Technical Solution: The University of California has pioneered research on the effects of Triton X-100 in microfluidic devices, focusing on its impact on surface tension and fluid dynamics. Their approach involves systematic studies of Triton X-100 concentrations and their effects on various microfluidic operations. They have developed novel microfluidic chip designs that leverage Triton X-100's surface tension modulation properties to enhance mixing, separation, and droplet generation processes. Their research has shown that controlled addition of Triton X-100 can reduce surface tension by up to 70% in certain microfluidic configurations, significantly improving fluid control and reducing the occurrence of unwanted droplet coalescence[2][5]. The university's work has also explored the use of Triton X-100 in conjunction with other surfactants to create tailored surface tension profiles within microfluidic channels.

Strengths: Comprehensive understanding of Triton X-100 behavior in microfluidics, innovative chip designs for enhanced performance. Weaknesses: Potential scalability issues for industrial applications, need for further optimization in complex biological systems.

Triton X-100 Innovations

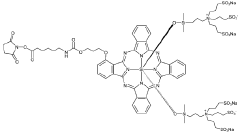

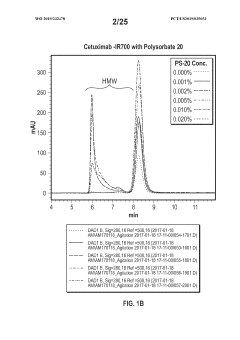

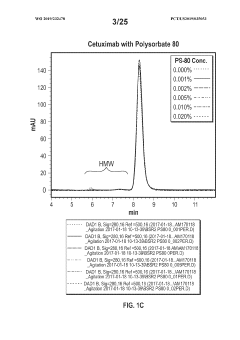

Phthalocyanine dye conjugate compositions

PatentWO2019232478A1

Innovation

- Incorporating stabilizing agents like non-ionic surfactants (e.g., polysorbate 80, polyethylene glycol) and protectants (e.g., trehalose) into the conjugate formulations to reduce aggregation and maintain stability and activity.

Environmental Impact

The use of Triton X-100 in microfluidic devices raises significant environmental concerns due to its potential impact on aquatic ecosystems. As a non-ionic surfactant, Triton X-100 can persist in the environment and accumulate in water bodies, potentially causing harm to aquatic organisms. When released into the environment, it can reduce surface tension in natural water systems, affecting the behavior of aquatic insects and other organisms that rely on surface tension for survival.

The biodegradation of Triton X-100 is relatively slow, with a half-life ranging from 20 to 40 days in aquatic environments. This persistence allows it to spread and potentially affect a wide range of ecosystems. Studies have shown that Triton X-100 can be toxic to various aquatic species, including fish, algae, and invertebrates, even at low concentrations. The toxicity is primarily attributed to its ability to disrupt cell membranes, leading to cellular damage and potential death of organisms.

Furthermore, Triton X-100 has been found to enhance the bioavailability of other pollutants in aquatic environments. It can increase the solubility of hydrophobic organic compounds, potentially making them more accessible to aquatic organisms and exacerbating their toxic effects. This synergistic effect with other pollutants is a significant concern for environmental regulators and ecologists.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in emissions and waste that can impact air and water quality. Improper disposal of microfluidic devices containing Triton X-100 can lead to its release into the environment, particularly if not handled as hazardous waste.

To mitigate these environmental risks, researchers and industry professionals are exploring alternative surfactants with lower environmental impacts. Some promising alternatives include biosurfactants produced by microorganisms, which are generally more biodegradable and less toxic. Additionally, efforts are being made to develop closed-loop systems in microfluidic applications to minimize the release of Triton X-100 into the environment.

Regulatory bodies are also taking notice of the environmental concerns associated with Triton X-100. In some regions, there are discussions about implementing stricter regulations on its use and disposal. This regulatory pressure may drive innovation in the development of more environmentally friendly alternatives for microfluidic applications.

The biodegradation of Triton X-100 is relatively slow, with a half-life ranging from 20 to 40 days in aquatic environments. This persistence allows it to spread and potentially affect a wide range of ecosystems. Studies have shown that Triton X-100 can be toxic to various aquatic species, including fish, algae, and invertebrates, even at low concentrations. The toxicity is primarily attributed to its ability to disrupt cell membranes, leading to cellular damage and potential death of organisms.

Furthermore, Triton X-100 has been found to enhance the bioavailability of other pollutants in aquatic environments. It can increase the solubility of hydrophobic organic compounds, potentially making them more accessible to aquatic organisms and exacerbating their toxic effects. This synergistic effect with other pollutants is a significant concern for environmental regulators and ecologists.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in emissions and waste that can impact air and water quality. Improper disposal of microfluidic devices containing Triton X-100 can lead to its release into the environment, particularly if not handled as hazardous waste.

To mitigate these environmental risks, researchers and industry professionals are exploring alternative surfactants with lower environmental impacts. Some promising alternatives include biosurfactants produced by microorganisms, which are generally more biodegradable and less toxic. Additionally, efforts are being made to develop closed-loop systems in microfluidic applications to minimize the release of Triton X-100 into the environment.

Regulatory bodies are also taking notice of the environmental concerns associated with Triton X-100. In some regions, there are discussions about implementing stricter regulations on its use and disposal. This regulatory pressure may drive innovation in the development of more environmentally friendly alternatives for microfluidic applications.

Regulatory Considerations

The use of Triton X-100 in microfluidic devices necessitates careful consideration of regulatory frameworks and compliance requirements. As a surfactant with wide-ranging applications, Triton X-100 falls under the purview of several regulatory bodies, each with specific guidelines governing its use in scientific and industrial settings.

In the United States, the Environmental Protection Agency (EPA) regulates Triton X-100 under the Toxic Substances Control Act (TSCA). Manufacturers and researchers must adhere to reporting requirements and safety standards set forth by the EPA when handling this substance. Additionally, the Food and Drug Administration (FDA) oversees the use of Triton X-100 in applications that may come into contact with food or pharmaceutical products, requiring thorough documentation and testing to ensure safety.

European regulations, particularly REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), impose stringent controls on the use of Triton X-100. Researchers and manufacturers must register the substance and provide comprehensive safety data before it can be used in significant quantities. The European Chemicals Agency (ECHA) maintains a database of registered substances, including Triton X-100, which provides valuable information on its properties and potential risks.

In the context of microfluidic devices, regulatory considerations extend beyond the surfactant itself to encompass the entire device and its intended application. Medical devices incorporating Triton X-100 must comply with regulations such as the EU Medical Device Regulation (MDR) or the FDA's medical device regulations, depending on the target market. These regulations mandate rigorous testing, risk assessment, and quality management systems to ensure device safety and efficacy.

Environmental regulations also play a crucial role in the use of Triton X-100 in microfluidic devices. Many jurisdictions have strict guidelines on the disposal of surfactants and other chemicals used in laboratory settings. Researchers and manufacturers must implement proper waste management protocols to prevent environmental contamination and comply with local and national environmental protection laws.

Occupational health and safety regulations further impact the use of Triton X-100 in research and manufacturing environments. Organizations such as OSHA in the United States and EU-OSHA in Europe provide guidelines on safe handling, personal protective equipment, and exposure limits for workers dealing with surfactants and other potentially hazardous substances.

As the field of microfluidics continues to evolve, regulatory frameworks are likely to adapt to address new applications and potential risks. Researchers and manufacturers working with Triton X-100 in microfluidic devices must stay informed about regulatory changes and emerging guidelines to ensure ongoing compliance and responsible use of this versatile surfactant.

In the United States, the Environmental Protection Agency (EPA) regulates Triton X-100 under the Toxic Substances Control Act (TSCA). Manufacturers and researchers must adhere to reporting requirements and safety standards set forth by the EPA when handling this substance. Additionally, the Food and Drug Administration (FDA) oversees the use of Triton X-100 in applications that may come into contact with food or pharmaceutical products, requiring thorough documentation and testing to ensure safety.

European regulations, particularly REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), impose stringent controls on the use of Triton X-100. Researchers and manufacturers must register the substance and provide comprehensive safety data before it can be used in significant quantities. The European Chemicals Agency (ECHA) maintains a database of registered substances, including Triton X-100, which provides valuable information on its properties and potential risks.

In the context of microfluidic devices, regulatory considerations extend beyond the surfactant itself to encompass the entire device and its intended application. Medical devices incorporating Triton X-100 must comply with regulations such as the EU Medical Device Regulation (MDR) or the FDA's medical device regulations, depending on the target market. These regulations mandate rigorous testing, risk assessment, and quality management systems to ensure device safety and efficacy.

Environmental regulations also play a crucial role in the use of Triton X-100 in microfluidic devices. Many jurisdictions have strict guidelines on the disposal of surfactants and other chemicals used in laboratory settings. Researchers and manufacturers must implement proper waste management protocols to prevent environmental contamination and comply with local and national environmental protection laws.

Occupational health and safety regulations further impact the use of Triton X-100 in research and manufacturing environments. Organizations such as OSHA in the United States and EU-OSHA in Europe provide guidelines on safe handling, personal protective equipment, and exposure limits for workers dealing with surfactants and other potentially hazardous substances.

As the field of microfluidics continues to evolve, regulatory frameworks are likely to adapt to address new applications and potential risks. Researchers and manufacturers working with Triton X-100 in microfluidic devices must stay informed about regulatory changes and emerging guidelines to ensure ongoing compliance and responsible use of this versatile surfactant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!