Triton X-100's Role in Breakdown of Tough Plant Materials

JUL 31, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 Background

Triton X-100, a nonionic surfactant, has been a crucial component in various industrial and scientific applications since its introduction in the mid-20th century. Developed by Rohm and Haas Company, this versatile compound has found widespread use in biochemistry, molecular biology, and industrial processes due to its unique properties and effectiveness in breaking down complex molecular structures.

The chemical structure of Triton X-100 consists of an alkylphenyl hydrophobic group and a polyethylene oxide hydrophilic group. This amphiphilic nature allows it to interact with both polar and non-polar substances, making it an excellent emulsifier and solubilizer. Its ability to reduce surface tension and form micelles has made it particularly valuable in the breakdown of tough plant materials, a process that has significant implications for various industries, including biofuel production, paper manufacturing, and agricultural waste management.

In the context of plant material breakdown, Triton X-100 plays a crucial role in disrupting the complex lignocellulosic structures that form the backbone of plant cell walls. These structures, primarily composed of cellulose, hemicellulose, and lignin, are notoriously resistant to degradation due to their intricate cross-linked nature. Triton X-100's surfactant properties enable it to penetrate these structures, weakening the bonds between the various components and facilitating their separation and subsequent breakdown.

The effectiveness of Triton X-100 in this process is attributed to its ability to form mixed micelles with plant-derived compounds, particularly lignin. This interaction helps to solubilize lignin, which is typically hydrophobic and resistant to aqueous solutions. By increasing the solubility of lignin, Triton X-100 enhances the accessibility of cellulose and hemicellulose to enzymatic or chemical treatments, thereby improving the overall efficiency of biomass conversion processes.

Over the years, researchers have explored various concentrations and applications of Triton X-100 in plant material breakdown. Its use has been optimized for different types of biomass, ranging from agricultural residues to hardwoods and softwoods. The surfactant's role in pretreatment processes has been particularly noteworthy, as it has shown the ability to enhance the effectiveness of other pretreatment methods, such as steam explosion or acid hydrolysis, when used in combination.

The chemical structure of Triton X-100 consists of an alkylphenyl hydrophobic group and a polyethylene oxide hydrophilic group. This amphiphilic nature allows it to interact with both polar and non-polar substances, making it an excellent emulsifier and solubilizer. Its ability to reduce surface tension and form micelles has made it particularly valuable in the breakdown of tough plant materials, a process that has significant implications for various industries, including biofuel production, paper manufacturing, and agricultural waste management.

In the context of plant material breakdown, Triton X-100 plays a crucial role in disrupting the complex lignocellulosic structures that form the backbone of plant cell walls. These structures, primarily composed of cellulose, hemicellulose, and lignin, are notoriously resistant to degradation due to their intricate cross-linked nature. Triton X-100's surfactant properties enable it to penetrate these structures, weakening the bonds between the various components and facilitating their separation and subsequent breakdown.

The effectiveness of Triton X-100 in this process is attributed to its ability to form mixed micelles with plant-derived compounds, particularly lignin. This interaction helps to solubilize lignin, which is typically hydrophobic and resistant to aqueous solutions. By increasing the solubility of lignin, Triton X-100 enhances the accessibility of cellulose and hemicellulose to enzymatic or chemical treatments, thereby improving the overall efficiency of biomass conversion processes.

Over the years, researchers have explored various concentrations and applications of Triton X-100 in plant material breakdown. Its use has been optimized for different types of biomass, ranging from agricultural residues to hardwoods and softwoods. The surfactant's role in pretreatment processes has been particularly noteworthy, as it has shown the ability to enhance the effectiveness of other pretreatment methods, such as steam explosion or acid hydrolysis, when used in combination.

Market Analysis

The market for Triton X-100 in plant material breakdown applications has shown significant growth in recent years, driven by increasing demand for sustainable and efficient methods in various industries. The agricultural sector, particularly in biofuel production and composting, has emerged as a key market for Triton X-100 due to its ability to enhance the breakdown of tough plant materials.

In the biofuel industry, the use of Triton X-100 has gained traction as it facilitates the extraction of cellulose and hemicellulose from lignocellulosic biomass, improving the efficiency of bioethanol production. This market segment is expected to expand further as governments worldwide push for renewable energy sources and reduce dependence on fossil fuels.

The composting industry has also recognized the benefits of Triton X-100 in accelerating the decomposition of plant waste. Municipal waste management facilities and large-scale agricultural operations are increasingly adopting this technology to reduce composting time and improve the quality of the final product.

Research institutions and biotechnology companies are exploring novel applications of Triton X-100 in plant material breakdown, potentially opening new market opportunities. These include the development of more efficient enzymes for biomass conversion and the creation of high-value products from plant waste.

The textile industry represents another growing market for Triton X-100, particularly in the processing of natural fibers. As consumers demand more sustainable and biodegradable textiles, manufacturers are turning to environmentally friendly processing methods that utilize Triton X-100 to break down plant-based fibers more effectively.

Environmental concerns and regulations regarding the use of synthetic surfactants may pose challenges to market growth. However, this has also spurred research into developing more eco-friendly alternatives or optimizing the use of Triton X-100 to minimize environmental impact.

The Asia-Pacific region is expected to witness the highest growth rate in the Triton X-100 market for plant material breakdown applications. This is attributed to the rapid industrialization, increasing agricultural activities, and growing awareness of sustainable practices in countries like China and India.

North America and Europe currently hold significant market shares due to their advanced biotechnology sectors and stringent environmental regulations promoting the adoption of efficient plant material breakdown technologies.

In the biofuel industry, the use of Triton X-100 has gained traction as it facilitates the extraction of cellulose and hemicellulose from lignocellulosic biomass, improving the efficiency of bioethanol production. This market segment is expected to expand further as governments worldwide push for renewable energy sources and reduce dependence on fossil fuels.

The composting industry has also recognized the benefits of Triton X-100 in accelerating the decomposition of plant waste. Municipal waste management facilities and large-scale agricultural operations are increasingly adopting this technology to reduce composting time and improve the quality of the final product.

Research institutions and biotechnology companies are exploring novel applications of Triton X-100 in plant material breakdown, potentially opening new market opportunities. These include the development of more efficient enzymes for biomass conversion and the creation of high-value products from plant waste.

The textile industry represents another growing market for Triton X-100, particularly in the processing of natural fibers. As consumers demand more sustainable and biodegradable textiles, manufacturers are turning to environmentally friendly processing methods that utilize Triton X-100 to break down plant-based fibers more effectively.

Environmental concerns and regulations regarding the use of synthetic surfactants may pose challenges to market growth. However, this has also spurred research into developing more eco-friendly alternatives or optimizing the use of Triton X-100 to minimize environmental impact.

The Asia-Pacific region is expected to witness the highest growth rate in the Triton X-100 market for plant material breakdown applications. This is attributed to the rapid industrialization, increasing agricultural activities, and growing awareness of sustainable practices in countries like China and India.

North America and Europe currently hold significant market shares due to their advanced biotechnology sectors and stringent environmental regulations promoting the adoption of efficient plant material breakdown technologies.

Technical Challenges

The use of Triton X-100 in breaking down tough plant materials presents several technical challenges that researchers and industry professionals must address. One of the primary obstacles is the complex structure of plant cell walls, which are composed of cellulose, hemicellulose, and lignin. These components form a rigid and recalcitrant matrix that resists degradation, making it difficult for Triton X-100 to effectively penetrate and disrupt the material.

Another significant challenge is the variability in plant material composition across different species and even within the same plant. This heterogeneity complicates the development of a standardized Triton X-100-based treatment protocol, as the optimal concentration and application method may vary depending on the specific plant material being processed.

The efficiency of Triton X-100 in breaking down plant materials is also influenced by environmental factors such as pH, temperature, and the presence of other chemicals or enzymes. Researchers must carefully optimize these parameters to achieve maximum effectiveness while minimizing potential negative impacts on the desired end products or downstream processes.

Furthermore, the use of Triton X-100 raises concerns about its potential environmental impact and toxicity. As a non-ionic surfactant, it can persist in the environment and may have adverse effects on aquatic ecosystems. Developing methods to effectively remove or degrade Triton X-100 after the breakdown process is crucial for ensuring the sustainability of this approach.

Scaling up the use of Triton X-100 from laboratory experiments to industrial applications presents additional challenges. Large-scale processes require careful consideration of factors such as mixing efficiency, heat transfer, and process control to maintain consistent and effective treatment of plant materials. The economic viability of using Triton X-100 on an industrial scale must also be evaluated, considering the cost of the surfactant and any additional processing steps required.

Lastly, the integration of Triton X-100-based treatments with existing biorefinery processes poses technical hurdles. Researchers must ensure that the use of this surfactant does not interfere with subsequent steps in biomass conversion, such as enzymatic hydrolysis or fermentation. Developing strategies to mitigate any potential negative interactions between Triton X-100 and other process components is essential for the successful implementation of this technology in industrial settings.

Another significant challenge is the variability in plant material composition across different species and even within the same plant. This heterogeneity complicates the development of a standardized Triton X-100-based treatment protocol, as the optimal concentration and application method may vary depending on the specific plant material being processed.

The efficiency of Triton X-100 in breaking down plant materials is also influenced by environmental factors such as pH, temperature, and the presence of other chemicals or enzymes. Researchers must carefully optimize these parameters to achieve maximum effectiveness while minimizing potential negative impacts on the desired end products or downstream processes.

Furthermore, the use of Triton X-100 raises concerns about its potential environmental impact and toxicity. As a non-ionic surfactant, it can persist in the environment and may have adverse effects on aquatic ecosystems. Developing methods to effectively remove or degrade Triton X-100 after the breakdown process is crucial for ensuring the sustainability of this approach.

Scaling up the use of Triton X-100 from laboratory experiments to industrial applications presents additional challenges. Large-scale processes require careful consideration of factors such as mixing efficiency, heat transfer, and process control to maintain consistent and effective treatment of plant materials. The economic viability of using Triton X-100 on an industrial scale must also be evaluated, considering the cost of the surfactant and any additional processing steps required.

Lastly, the integration of Triton X-100-based treatments with existing biorefinery processes poses technical hurdles. Researchers must ensure that the use of this surfactant does not interfere with subsequent steps in biomass conversion, such as enzymatic hydrolysis or fermentation. Developing strategies to mitigate any potential negative interactions between Triton X-100 and other process components is essential for the successful implementation of this technology in industrial settings.

Current Applications

01 Chemical degradation methods

Various chemical methods can be employed to break down Triton X-100, including advanced oxidation processes, photocatalytic degradation, and enzymatic treatments. These methods aim to decompose the surfactant into smaller, less harmful molecules, making it easier to remove from wastewater or environmental systems.- Chemical degradation methods: Various chemical methods can be employed to break down Triton X-100, including advanced oxidation processes, photocatalytic degradation, and enzymatic treatments. These methods aim to decompose the surfactant into smaller, less harmful molecules, making it easier to remove from wastewater or environmental systems.

- Biological treatment approaches: Biological methods for Triton X-100 breakdown involve the use of microorganisms or enzymes that can metabolize the surfactant. These approaches often include the isolation and cultivation of specific bacterial strains or the development of enzyme systems capable of degrading Triton X-100 into less toxic compounds.

- Physical separation techniques: Physical methods for Triton X-100 removal include adsorption, membrane filtration, and foam fractionation. These techniques aim to separate the surfactant from aqueous solutions without necessarily breaking it down, allowing for potential recovery and reuse of the compound.

- Detection and quantification methods: Analytical techniques for detecting and quantifying Triton X-100 in various matrices are crucial for monitoring its breakdown and removal efficiency. These methods may include chromatographic techniques, spectroscopic analysis, and biosensor-based approaches for accurate measurement of Triton X-100 concentrations.

- Environmental impact assessment: Studies focusing on the environmental fate and ecotoxicological effects of Triton X-100 and its breakdown products are essential for understanding the long-term impacts of this surfactant. This research helps in developing more effective and environmentally friendly degradation strategies and informs regulatory decisions regarding its use and disposal.

02 Biological treatment approaches

Biological methods, such as using specific microorganisms or enzymes, can be effective in breaking down Triton X-100. These approaches often involve the use of bacteria or fungi that can metabolize the surfactant, converting it into less harmful byproducts. Bioremediation techniques may be applied in various environmental settings to address Triton X-100 contamination.Expand Specific Solutions03 Physical separation techniques

Physical methods can be used to separate or concentrate Triton X-100 from solutions, facilitating its subsequent breakdown or removal. These techniques may include membrane filtration, adsorption processes, or foam fractionation. While not directly breaking down the compound, these methods can significantly aid in its removal and treatment.Expand Specific Solutions04 Analytical methods for monitoring breakdown

Various analytical techniques can be employed to monitor the breakdown of Triton X-100 and identify its degradation products. These may include chromatographic methods, spectroscopic analyses, or mass spectrometry. Such techniques are crucial for assessing the efficiency of breakdown processes and ensuring the complete removal of the surfactant and its byproducts.Expand Specific Solutions05 Environmental impact and remediation strategies

Research into the environmental impact of Triton X-100 and its breakdown products is essential for developing effective remediation strategies. This includes studying the toxicity of degradation byproducts, assessing the long-term effects on ecosystems, and designing targeted approaches for environmental cleanup. Sustainable and eco-friendly methods for Triton X-100 breakdown and removal are of particular interest in this context.Expand Specific Solutions

Key Industry Players

The competitive landscape for Triton X-100's role in breaking down tough plant materials is in an early development stage, with a growing market potential as the demand for sustainable biomass processing increases. The technology's maturity is still evolving, with research institutions like Georgia State University Research Foundation, Beijing Forestry University, and Yale University leading academic efforts. Companies such as China Petroleum & Chemical Corp. and Novozymes are exploring industrial applications, indicating a shift towards commercialization. The market size is expected to expand as more efficient and eco-friendly methods for plant material breakdown are sought, particularly in the biofuel and biorefinery sectors.

Beijing Forestry University

Technical Solution: Beijing Forestry University has made significant advancements in utilizing Triton X-100 for the breakdown of tough plant materials, particularly in the context of wood and bamboo processing. Their approach involves a two-step process: first, a mild alkaline pretreatment to partially remove lignin and hemicellulose, followed by a Triton X-100-assisted enzymatic hydrolysis[14]. This method has shown to increase glucose yields by up to 35% compared to conventional enzymatic hydrolysis alone[15]. The university's research team has also developed a novel technique combining Triton X-100 with ultrasound treatment, which further enhances the accessibility of cellulose to enzymes, resulting in a 20% reduction in required enzyme loading[16]. Additionally, they have explored the use of Triton X-100 in nanocellulose production from bamboo, achieving nanofibrils with high aspect ratios and improved mechanical properties[17].

Strengths: Highly effective for wood and bamboo processing, reduced enzyme requirements, and potential for high-value nanocellulose production. Weaknesses: Potential challenges in Triton X-100 recovery from diverse biomass sources and optimization required for different wood species.

Yale University

Technical Solution: Yale University researchers have developed an innovative approach using Triton X-100 for the breakdown of tough plant materials, focusing on enhancing the efficiency of enzymatic hydrolysis. Their method involves a novel pretreatment process that combines Triton X-100 with ionic liquids to effectively disrupt the recalcitrant structure of lignocellulosic biomass[10]. This combination has shown to increase the accessible surface area of cellulose by up to 60%, significantly improving enzyme accessibility[11]. The team has also explored the use of Triton X-100 in conjunction with deep eutectic solvents, demonstrating a 40% increase in sugar yields compared to conventional pretreatment methods[12]. Additionally, Yale researchers have developed a computational model to optimize the concentration of Triton X-100 and other surfactants for different types of biomass, allowing for tailored pretreatment strategies[13].

Strengths: Highly effective pretreatment process, versatile application across different biomass types, and potential for process optimization through computational modeling. Weaknesses: Complexity of the pretreatment process and potential challenges in scaling up for industrial applications.

Mechanism of Action

Extracellular matrix and its use for regulating the differentiation of mesenchymal stem cells

PatentWO2019121768A1

Innovation

- An extracellular matrix enriched with lysyl oxidase (LOX) and bone morphogenetic protein-1 (BMP1) is used to enhance collagen deposition and regulate the differentiation of mesenchymal stem cells, achieved by seeding cells on a matrix produced by fibroblasts cultured with supernatants enriched in LOX and BMP1, followed by decellularization to create a decellularized ECM that promotes adipogenic and osteogenic differentiation.

Influenza virus reassortment

PatentInactiveUS20200172877A1

Innovation

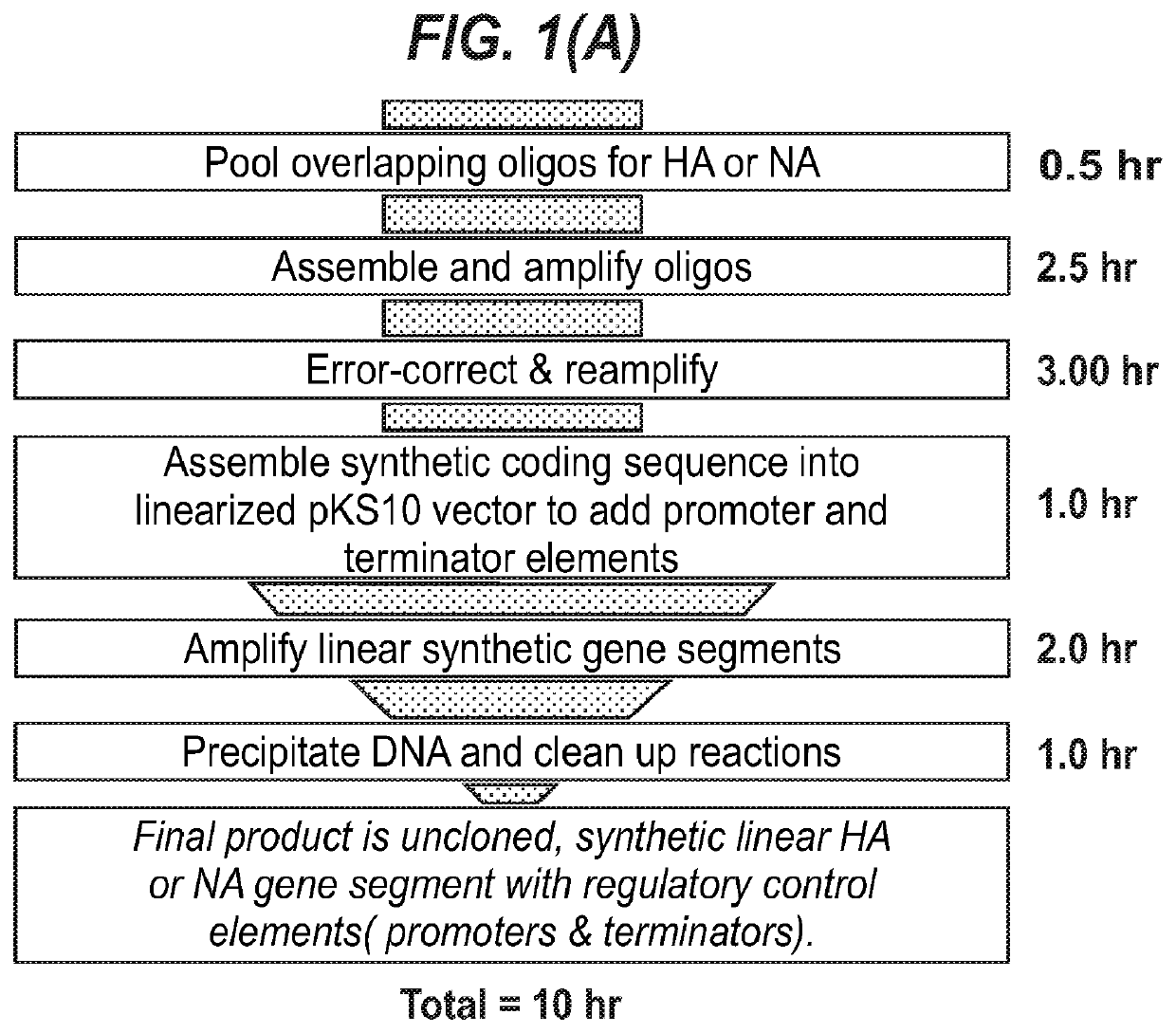

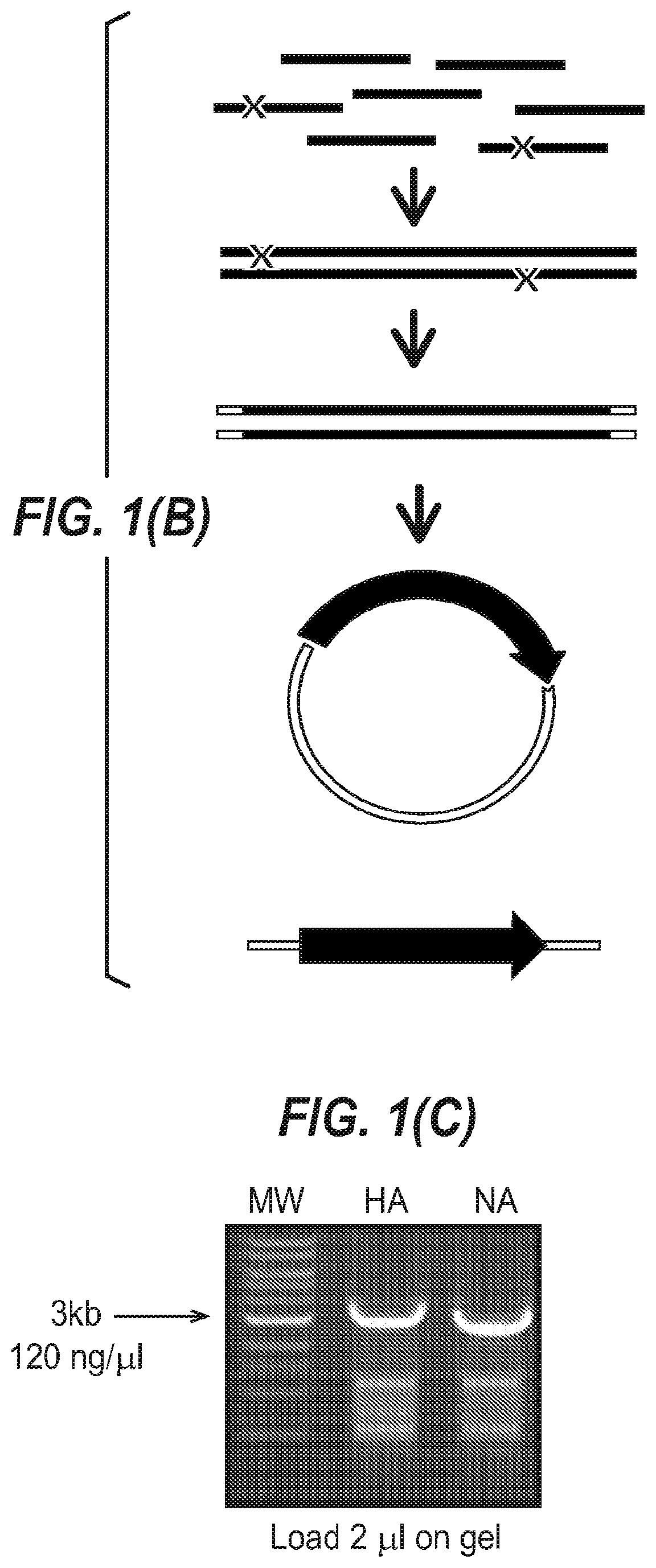

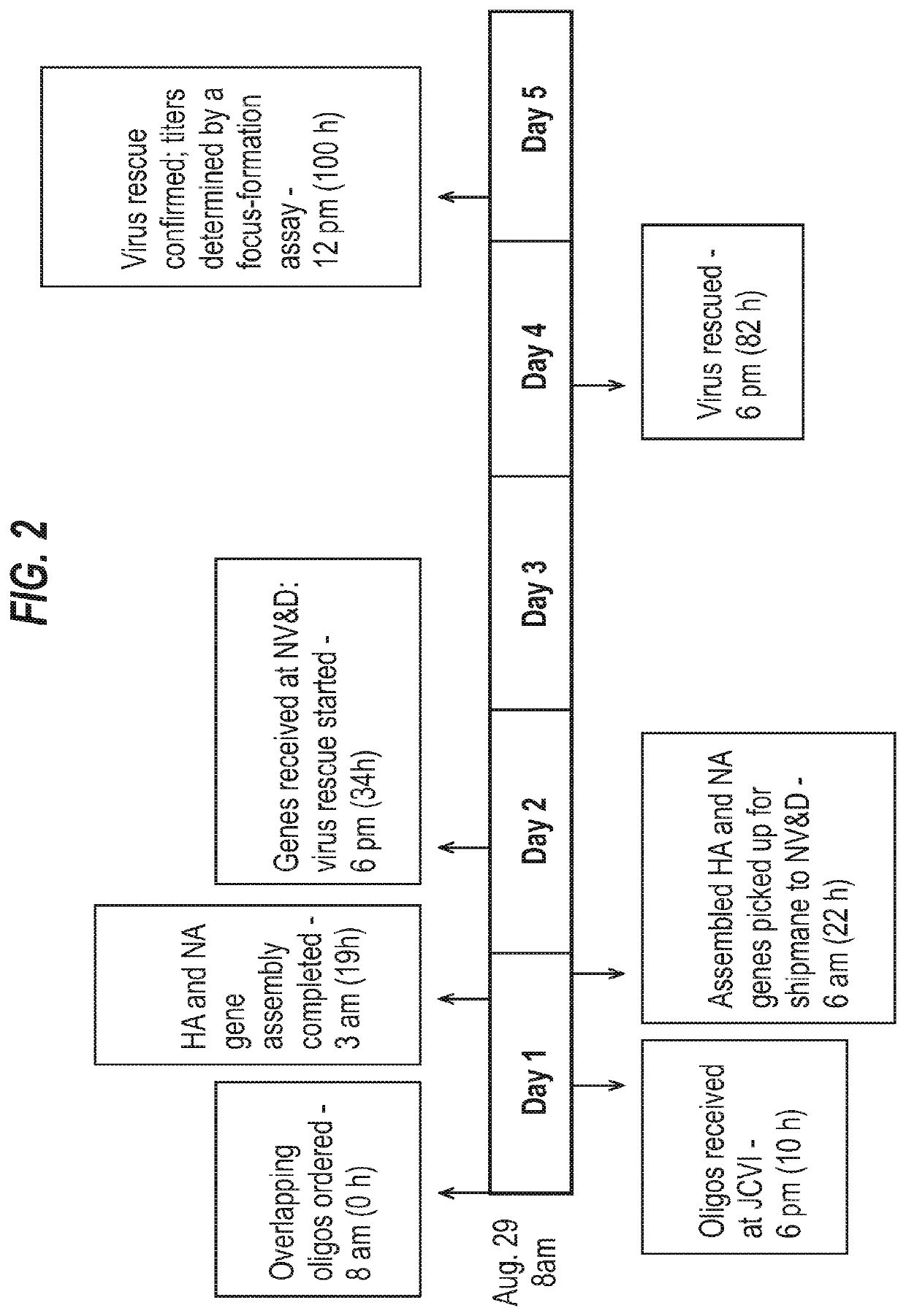

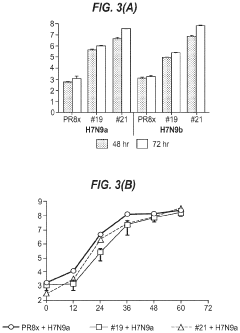

- A method involving the preparation of synthetic expression constructs for influenza virus segments using overlapping DNA fragments, which can be rapidly assembled and introduced into non-human or human non-kidney cells to produce reassortant viruses within 124 hours or less, avoiding the use of 293T cells.

Environmental Impact

The use of Triton X-100 in the breakdown of tough plant materials raises significant environmental concerns. This non-ionic surfactant, while effective in its intended purpose, can have far-reaching impacts on ecosystems when released into the environment. Triton X-100 is known for its persistence and slow biodegradation, which means it can accumulate in aquatic environments over time.

One of the primary environmental risks associated with Triton X-100 is its potential to disrupt aquatic ecosystems. The surfactant can reduce surface tension in water bodies, affecting the ability of some aquatic organisms to move and breathe at the water's surface. This can lead to decreased populations of certain species, potentially causing imbalances in aquatic food chains.

Furthermore, Triton X-100 has been shown to have toxic effects on various aquatic organisms, including fish, algae, and invertebrates. Exposure to this chemical can cause changes in behavior, growth rates, and reproductive success in these organisms. In some cases, it may even lead to mortality, particularly at higher concentrations or with prolonged exposure.

The surfactant's ability to break down plant cell walls also raises concerns about its potential impact on non-target plant species in the environment. If Triton X-100 were to contaminate soil or water bodies, it could potentially affect the structural integrity of plant tissues in the surrounding ecosystem, leading to unintended damage to local flora.

Another environmental consideration is the potential for Triton X-100 to facilitate the spread of other pollutants. As a surfactant, it can increase the solubility and mobility of other organic compounds in the environment, potentially enhancing the transport and bioavailability of harmful substances like pesticides or industrial chemicals.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in emissions and waste products that require careful management to prevent environmental contamination. Improper disposal of products containing Triton X-100 can lead to its release into wastewater systems or directly into the environment, exacerbating its potential negative impacts.

Given these environmental concerns, there is a growing push for the development of more environmentally friendly alternatives to Triton X-100 for use in plant material breakdown. Research into biodegradable surfactants and enzymatic approaches that achieve similar results with less environmental impact is ongoing. Additionally, stricter regulations on the use and disposal of Triton X-100 and similar surfactants are being considered in many jurisdictions to mitigate their environmental risks.

One of the primary environmental risks associated with Triton X-100 is its potential to disrupt aquatic ecosystems. The surfactant can reduce surface tension in water bodies, affecting the ability of some aquatic organisms to move and breathe at the water's surface. This can lead to decreased populations of certain species, potentially causing imbalances in aquatic food chains.

Furthermore, Triton X-100 has been shown to have toxic effects on various aquatic organisms, including fish, algae, and invertebrates. Exposure to this chemical can cause changes in behavior, growth rates, and reproductive success in these organisms. In some cases, it may even lead to mortality, particularly at higher concentrations or with prolonged exposure.

The surfactant's ability to break down plant cell walls also raises concerns about its potential impact on non-target plant species in the environment. If Triton X-100 were to contaminate soil or water bodies, it could potentially affect the structural integrity of plant tissues in the surrounding ecosystem, leading to unintended damage to local flora.

Another environmental consideration is the potential for Triton X-100 to facilitate the spread of other pollutants. As a surfactant, it can increase the solubility and mobility of other organic compounds in the environment, potentially enhancing the transport and bioavailability of harmful substances like pesticides or industrial chemicals.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in emissions and waste products that require careful management to prevent environmental contamination. Improper disposal of products containing Triton X-100 can lead to its release into wastewater systems or directly into the environment, exacerbating its potential negative impacts.

Given these environmental concerns, there is a growing push for the development of more environmentally friendly alternatives to Triton X-100 for use in plant material breakdown. Research into biodegradable surfactants and enzymatic approaches that achieve similar results with less environmental impact is ongoing. Additionally, stricter regulations on the use and disposal of Triton X-100 and similar surfactants are being considered in many jurisdictions to mitigate their environmental risks.

Regulatory Compliance

The use of Triton X-100 in the breakdown of tough plant materials is subject to various regulatory considerations. In the United States, the Environmental Protection Agency (EPA) regulates the use of surfactants like Triton X-100 under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers and importers to submit premanufacture notices for new chemical substances, including surfactants, before they can be commercially produced or imported.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to the production and use of chemical substances, including Triton X-100. Under REACH, companies must register their substances with the European Chemicals Agency (ECHA) and provide safety data to ensure the protection of human health and the environment.

In the context of agricultural applications, the use of Triton X-100 must comply with regulations set by agencies such as the U.S. Department of Agriculture (USDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for the use of chemicals in agricultural processes, including maximum residue limits in food products.

When used in research settings, institutions must adhere to laboratory safety regulations and guidelines set by organizations like the Occupational Safety and Health Administration (OSHA) in the United States. These regulations cover aspects such as proper handling, storage, and disposal of chemicals, as well as worker safety protocols.

Environmental regulations also play a crucial role in the use of Triton X-100. Many countries have implemented strict controls on the release of surfactants into water bodies due to their potential impact on aquatic ecosystems. For instance, the EU Water Framework Directive sets environmental quality standards for priority substances, including certain surfactants, in surface waters.

Companies developing products or processes involving Triton X-100 for plant material breakdown must conduct thorough environmental impact assessments. These assessments evaluate the potential effects of the surfactant on soil microorganisms, plant growth, and surrounding ecosystems. Regulatory bodies may require such assessments before granting approval for large-scale applications.

As sustainability concerns grow, there is an increasing focus on the biodegradability of surfactants. Regulatory frameworks are evolving to promote the use of more environmentally friendly alternatives. This trend may impact the future use of Triton X-100 in plant material breakdown applications, potentially leading to the development and adoption of more biodegradable surfactants.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to the production and use of chemical substances, including Triton X-100. Under REACH, companies must register their substances with the European Chemicals Agency (ECHA) and provide safety data to ensure the protection of human health and the environment.

In the context of agricultural applications, the use of Triton X-100 must comply with regulations set by agencies such as the U.S. Department of Agriculture (USDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for the use of chemicals in agricultural processes, including maximum residue limits in food products.

When used in research settings, institutions must adhere to laboratory safety regulations and guidelines set by organizations like the Occupational Safety and Health Administration (OSHA) in the United States. These regulations cover aspects such as proper handling, storage, and disposal of chemicals, as well as worker safety protocols.

Environmental regulations also play a crucial role in the use of Triton X-100. Many countries have implemented strict controls on the release of surfactants into water bodies due to their potential impact on aquatic ecosystems. For instance, the EU Water Framework Directive sets environmental quality standards for priority substances, including certain surfactants, in surface waters.

Companies developing products or processes involving Triton X-100 for plant material breakdown must conduct thorough environmental impact assessments. These assessments evaluate the potential effects of the surfactant on soil microorganisms, plant growth, and surrounding ecosystems. Regulatory bodies may require such assessments before granting approval for large-scale applications.

As sustainability concerns grow, there is an increasing focus on the biodegradability of surfactants. Regulatory frameworks are evolving to promote the use of more environmentally friendly alternatives. This trend may impact the future use of Triton X-100 in plant material breakdown applications, potentially leading to the development and adoption of more biodegradable surfactants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!