Triton X-100-Enhanced Disulfide Bond Formation in Peptide Synthesis

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 in Peptide Synthesis: Background and Objectives

Peptide synthesis has been a cornerstone of biochemical research and pharmaceutical development for decades. The formation of disulfide bonds within peptides is crucial for maintaining their three-dimensional structure and biological activity. However, this process has long been challenging due to the complexity of controlling oxidation reactions in aqueous environments. In recent years, the use of Triton X-100, a nonionic surfactant, has emerged as a promising approach to enhance disulfide bond formation in peptide synthesis.

The background of this research stems from the ongoing need to improve the efficiency and yield of peptide synthesis, particularly in the production of complex, disulfide-rich peptides. Traditional methods often result in low yields, misfolded products, or require harsh oxidizing conditions that can damage sensitive amino acid residues. The introduction of Triton X-100 into the synthesis process represents a significant step towards addressing these limitations.

Triton X-100's potential in peptide synthesis was first recognized in the early 2000s, but it is only in recent years that its full capabilities have begun to be explored. This surfactant creates a unique microenvironment that facilitates the controlled oxidation of cysteine residues, leading to more efficient and precise disulfide bond formation. The hydrophobic nature of Triton X-100 also helps to stabilize peptide intermediates, potentially reducing side reactions and improving overall yield.

The primary objective of research in this area is to develop a robust and widely applicable method for using Triton X-100 to enhance disulfide bond formation in peptide synthesis. This includes optimizing reaction conditions, understanding the mechanism of action, and exploring the scope of peptides that can benefit from this approach. Additionally, researchers aim to integrate this technique into existing peptide synthesis protocols, making it accessible to both academic and industrial laboratories.

Another key goal is to elucidate the molecular interactions between Triton X-100, peptide chains, and oxidizing agents. This understanding is crucial for fine-tuning the process and potentially developing new, more effective surfactants or additives. Furthermore, there is a focus on demonstrating the scalability of Triton X-100-enhanced peptide synthesis, as this is essential for its adoption in large-scale pharmaceutical production.

The research also aims to address potential challenges, such as the removal of Triton X-100 from the final product and its impact on downstream purification processes. As environmental concerns grow, there is an additional objective to assess the ecological impact of using Triton X-100 and to explore more sustainable alternatives that maintain its beneficial properties in peptide synthesis.

The background of this research stems from the ongoing need to improve the efficiency and yield of peptide synthesis, particularly in the production of complex, disulfide-rich peptides. Traditional methods often result in low yields, misfolded products, or require harsh oxidizing conditions that can damage sensitive amino acid residues. The introduction of Triton X-100 into the synthesis process represents a significant step towards addressing these limitations.

Triton X-100's potential in peptide synthesis was first recognized in the early 2000s, but it is only in recent years that its full capabilities have begun to be explored. This surfactant creates a unique microenvironment that facilitates the controlled oxidation of cysteine residues, leading to more efficient and precise disulfide bond formation. The hydrophobic nature of Triton X-100 also helps to stabilize peptide intermediates, potentially reducing side reactions and improving overall yield.

The primary objective of research in this area is to develop a robust and widely applicable method for using Triton X-100 to enhance disulfide bond formation in peptide synthesis. This includes optimizing reaction conditions, understanding the mechanism of action, and exploring the scope of peptides that can benefit from this approach. Additionally, researchers aim to integrate this technique into existing peptide synthesis protocols, making it accessible to both academic and industrial laboratories.

Another key goal is to elucidate the molecular interactions between Triton X-100, peptide chains, and oxidizing agents. This understanding is crucial for fine-tuning the process and potentially developing new, more effective surfactants or additives. Furthermore, there is a focus on demonstrating the scalability of Triton X-100-enhanced peptide synthesis, as this is essential for its adoption in large-scale pharmaceutical production.

The research also aims to address potential challenges, such as the removal of Triton X-100 from the final product and its impact on downstream purification processes. As environmental concerns grow, there is an additional objective to assess the ecological impact of using Triton X-100 and to explore more sustainable alternatives that maintain its beneficial properties in peptide synthesis.

Market Analysis for Enhanced Peptide Synthesis Methods

The market for enhanced peptide synthesis methods, particularly those involving disulfide bond formation, has been experiencing significant growth in recent years. This growth is primarily driven by the increasing demand for peptide-based therapeutics and the need for more efficient and cost-effective synthesis processes. The global peptide therapeutics market, which directly influences the demand for advanced synthesis methods, is projected to reach substantial market value in the coming years.

The pharmaceutical industry remains the largest consumer of peptide synthesis technologies, with a growing emphasis on developing novel peptide-based drugs for various diseases, including cancer, metabolic disorders, and infectious diseases. The use of Triton X-100 in enhancing disulfide bond formation represents a promising advancement in this field, potentially offering improved yield and purity of synthesized peptides.

Biotechnology and research institutions also contribute significantly to the market demand for enhanced peptide synthesis methods. These organizations are continuously seeking innovative techniques to improve the efficiency and scalability of peptide production for both research and commercial applications. The adoption of Triton X-100-enhanced methods could provide a competitive edge in this sector.

The contract manufacturing organization (CMO) segment is another key player in the market for advanced peptide synthesis technologies. As pharmaceutical companies increasingly outsource peptide production, CMOs are investing in cutting-edge synthesis methods to meet the growing demand and maintain their market position. The potential for Triton X-100 to streamline the synthesis process and reduce production costs makes it an attractive option for CMOs looking to optimize their operations.

Geographically, North America and Europe currently dominate the market for peptide synthesis technologies, owing to their well-established pharmaceutical and biotechnology industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investment in life sciences research and the expansion of contract manufacturing services in countries like China and India.

The market for peptide synthesis reagents and equipment is also closely tied to advancements in synthesis methods. Suppliers of these products are likely to benefit from the adoption of Triton X-100-enhanced techniques, as it may create demand for specialized reagents and modified synthesis equipment. This presents opportunities for both established players and new entrants in the reagent and equipment market to develop tailored solutions for this emerging synthesis method.

The pharmaceutical industry remains the largest consumer of peptide synthesis technologies, with a growing emphasis on developing novel peptide-based drugs for various diseases, including cancer, metabolic disorders, and infectious diseases. The use of Triton X-100 in enhancing disulfide bond formation represents a promising advancement in this field, potentially offering improved yield and purity of synthesized peptides.

Biotechnology and research institutions also contribute significantly to the market demand for enhanced peptide synthesis methods. These organizations are continuously seeking innovative techniques to improve the efficiency and scalability of peptide production for both research and commercial applications. The adoption of Triton X-100-enhanced methods could provide a competitive edge in this sector.

The contract manufacturing organization (CMO) segment is another key player in the market for advanced peptide synthesis technologies. As pharmaceutical companies increasingly outsource peptide production, CMOs are investing in cutting-edge synthesis methods to meet the growing demand and maintain their market position. The potential for Triton X-100 to streamline the synthesis process and reduce production costs makes it an attractive option for CMOs looking to optimize their operations.

Geographically, North America and Europe currently dominate the market for peptide synthesis technologies, owing to their well-established pharmaceutical and biotechnology industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investment in life sciences research and the expansion of contract manufacturing services in countries like China and India.

The market for peptide synthesis reagents and equipment is also closely tied to advancements in synthesis methods. Suppliers of these products are likely to benefit from the adoption of Triton X-100-enhanced techniques, as it may create demand for specialized reagents and modified synthesis equipment. This presents opportunities for both established players and new entrants in the reagent and equipment market to develop tailored solutions for this emerging synthesis method.

Current Challenges in Disulfide Bond Formation

Disulfide bond formation in peptide synthesis remains a critical challenge, despite significant advancements in the field. The primary obstacle lies in achieving efficient and selective oxidation of cysteine residues to form the desired disulfide bridges. Traditional methods often result in low yields, side reactions, and the formation of undesired isomers, particularly in complex peptides with multiple cysteine residues.

One of the major challenges is controlling the oxidation process to prevent overoxidation or the formation of scrambled disulfide bonds. The kinetics of disulfide bond formation can be unpredictable, leading to difficulties in optimizing reaction conditions. Additionally, the presence of other reactive functional groups in the peptide sequence can interfere with the oxidation process, further complicating the synthesis.

The choice of oxidizing agents presents another significant challenge. Commonly used reagents such as dimethyl sulfoxide (DMSO) or air oxidation often lack specificity and can lead to side reactions. More selective oxidants like iodine or hydrogen peroxide may offer improved control but can still result in unwanted modifications to other amino acid residues.

Solubility issues pose yet another hurdle in disulfide bond formation. Many peptides, especially those rich in hydrophobic residues, have limited solubility in aqueous media, which are typically preferred for oxidation reactions. This can lead to aggregation or precipitation of the peptide, hindering the formation of the desired disulfide bonds.

The challenge of maintaining the native conformation of the peptide during oxidation is also significant. Improper folding can result in mismatched disulfide pairs, leading to inactive or incorrectly structured peptides. This is particularly problematic for larger peptides or those with complex tertiary structures.

Furthermore, the scalability of disulfide bond formation processes remains a concern. Many successful laboratory-scale methods fail to translate effectively to larger-scale production, limiting their industrial applicability. This scaling issue is often due to the sensitivity of the oxidation reaction to factors such as concentration, temperature, and mixing conditions.

In the context of Triton X-100-enhanced disulfide bond formation, while this approach shows promise in improving the efficiency of the process, it introduces new challenges. The presence of the detergent can affect peptide solubility and conformation, potentially altering the oxidation kinetics and final product structure. Optimizing the concentration of Triton X-100 to balance its beneficial effects with potential drawbacks is a delicate task that requires careful consideration and experimentation.

One of the major challenges is controlling the oxidation process to prevent overoxidation or the formation of scrambled disulfide bonds. The kinetics of disulfide bond formation can be unpredictable, leading to difficulties in optimizing reaction conditions. Additionally, the presence of other reactive functional groups in the peptide sequence can interfere with the oxidation process, further complicating the synthesis.

The choice of oxidizing agents presents another significant challenge. Commonly used reagents such as dimethyl sulfoxide (DMSO) or air oxidation often lack specificity and can lead to side reactions. More selective oxidants like iodine or hydrogen peroxide may offer improved control but can still result in unwanted modifications to other amino acid residues.

Solubility issues pose yet another hurdle in disulfide bond formation. Many peptides, especially those rich in hydrophobic residues, have limited solubility in aqueous media, which are typically preferred for oxidation reactions. This can lead to aggregation or precipitation of the peptide, hindering the formation of the desired disulfide bonds.

The challenge of maintaining the native conformation of the peptide during oxidation is also significant. Improper folding can result in mismatched disulfide pairs, leading to inactive or incorrectly structured peptides. This is particularly problematic for larger peptides or those with complex tertiary structures.

Furthermore, the scalability of disulfide bond formation processes remains a concern. Many successful laboratory-scale methods fail to translate effectively to larger-scale production, limiting their industrial applicability. This scaling issue is often due to the sensitivity of the oxidation reaction to factors such as concentration, temperature, and mixing conditions.

In the context of Triton X-100-enhanced disulfide bond formation, while this approach shows promise in improving the efficiency of the process, it introduces new challenges. The presence of the detergent can affect peptide solubility and conformation, potentially altering the oxidation kinetics and final product structure. Optimizing the concentration of Triton X-100 to balance its beneficial effects with potential drawbacks is a delicate task that requires careful consideration and experimentation.

Triton X-100 Enhancement: Current Methodologies

01 Use of Triton X-100 in protein analysis

Triton X-100 is utilized in various protein analysis techniques, including the study of disulfide bond formation. It can help in solubilizing proteins and maintaining their native structure, which is crucial for analyzing disulfide bonds. The detergent properties of Triton X-100 aid in the extraction and purification of proteins, facilitating the investigation of disulfide bond formation in different experimental setups.- Use of Triton X-100 in protein analysis: Triton X-100 is utilized in various protein analysis techniques, including the study of disulfide bond formation. It can help in solubilizing proteins and maintaining their native structure, which is crucial for analyzing disulfide bonds. The detergent properties of Triton X-100 make it useful in protein extraction and purification processes.

- Disulfide bond formation in recombinant protein production: In the production of recombinant proteins, controlling disulfide bond formation is essential for proper protein folding and function. Triton X-100 can be used in buffer systems to facilitate the correct formation of disulfide bonds during protein expression and purification processes. This is particularly important for proteins that rely on disulfide bonds for their structural integrity.

- Triton X-100 in membrane protein studies: Triton X-100 is employed in the study of membrane proteins, including those with disulfide bonds. It can help in solubilizing membrane proteins while preserving their native structure, allowing for the analysis of disulfide bond formation and protein-protein interactions in membrane-associated proteins.

- Redox conditions for disulfide bond formation: The formation of disulfide bonds can be influenced by redox conditions. Triton X-100 may be used in buffer systems that control the redox environment, facilitating the formation or breaking of disulfide bonds as needed. This is important in protein folding studies and in the development of biotechnological processes involving disulfide-rich proteins.

- Analytical techniques for studying disulfide bonds: Various analytical techniques are used to study disulfide bond formation, and Triton X-100 can play a role in sample preparation or analysis. These techniques may include mass spectrometry, chromatography, and electrophoresis methods that are optimized for the analysis of proteins containing disulfide bonds.

02 Disulfide bond formation in recombinant protein production

In the production of recombinant proteins, controlling disulfide bond formation is crucial for proper protein folding and function. Triton X-100 can be used in the process to help maintain protein solubility and prevent aggregation during the formation of disulfide bonds. This is particularly important in the expression and purification of proteins with multiple disulfide bonds.Expand Specific Solutions03 Triton X-100 in membrane protein studies

Triton X-100 is employed in the study of membrane proteins, including those with disulfide bonds. It helps in the solubilization and extraction of membrane proteins while preserving their structure. This allows for the analysis of disulfide bond formation and its role in membrane protein function and stability.Expand Specific Solutions04 Redox conditions and disulfide bond formation

The formation of disulfide bonds is influenced by redox conditions. Triton X-100 can be used in combination with reducing and oxidizing agents to control the redox environment during protein folding and disulfide bond formation. This approach is useful in studying the kinetics and mechanisms of disulfide bond formation in various proteins.Expand Specific Solutions05 Analytical techniques for disulfide bond detection

Various analytical techniques are employed to detect and characterize disulfide bonds in proteins. Triton X-100 can be used in sample preparation for these techniques, such as mass spectrometry, electrophoresis, and chromatography. It helps in maintaining protein solubility and preventing non-specific interactions during analysis, leading to more accurate detection and characterization of disulfide bonds.Expand Specific Solutions

Key Players in Peptide Synthesis Industry

The research on Triton X-100-enhanced disulfide bond formation in peptide synthesis is in a relatively early stage of development, with the market still emerging. The competitive landscape is characterized by a mix of established pharmaceutical companies, biotechnology firms, and academic institutions. Key players like MorphoSys AG, Hybio Pharmaceutical, and Rein Therapeutics are actively involved in peptide-related research and development. The technology's maturity is progressing, with companies such as Lonza and Evonik Operations contributing to advancements in peptide synthesis techniques. While the market size is not yet substantial, there is growing interest in this field due to its potential applications in drug discovery and development.

Lonza Ltd.

Technical Solution: Lonza has developed an innovative approach to enhance disulfide bond formation in peptide synthesis using Triton X-100. Their method involves incorporating Triton X-100 into the oxidation buffer, which significantly improves the efficiency of disulfide bond formation. The surfactant properties of Triton X-100 help to solubilize and stabilize peptides during the oxidation process, leading to higher yields and purer products[1]. Lonza's technique also includes optimized reaction conditions, such as pH control and temperature regulation, to further enhance the formation of correct disulfide bonds[3]. This method has been successfully applied to the synthesis of complex peptides with multiple disulfide bonds, demonstrating its versatility and effectiveness in pharmaceutical and biotechnology applications[5].

Strengths: Improved efficiency and yield in disulfide bond formation, versatility for complex peptides, and enhanced product purity. Weaknesses: Potential challenges in removing Triton X-100 from final products and possible limitations for certain peptide sequences.

Evonik Operations GmbH

Technical Solution: Evonik has developed a proprietary technology for Triton X-100-enhanced disulfide bond formation in peptide synthesis. Their approach utilizes a controlled oxidation process in the presence of Triton X-100, which acts as a mild detergent to prevent peptide aggregation during folding[2]. The company has optimized the concentration of Triton X-100 and other reaction parameters to achieve efficient disulfide bond formation while minimizing side reactions. Evonik's method also incorporates a novel purification strategy to remove Triton X-100 from the final peptide product, ensuring high purity and biocompatibility[4]. This technology has been successfully applied to the production of various therapeutic peptides, demonstrating its potential for large-scale manufacturing[6].

Strengths: Efficient disulfide bond formation, reduced peptide aggregation, and effective purification strategy. Weaknesses: May require additional purification steps and potential limitations in scalability for certain peptides.

Core Innovations in Disulfide Bond Formation

Rapid processing and direct testing of saliva biomarkers

PatentPendingUS20240133896A1

Innovation

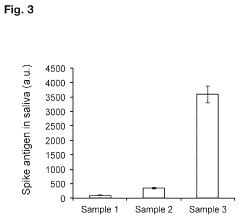

- A saliva treatment composition comprising a mixture of non-ionic detergents, such as Triton X-100 and Polysorbate 20, is used to inactivate viruses and improve the sensitivity and consistency of saliva tests, combined with methods like mechanical admixing and centrifugation for sample processing, enabling reliable analysis of biomarkers like SARS-CoV-2 antigens and antibodies.

Decellurisation processes for making bioprotheses

PatentWO2005118014A2

Innovation

- A method involving the use of ionic and non-ionic detergents to decellularize tissue, removing non-structural proteins and cell debris, which reduces calcification and immunogenicity, and includes a process for treating tissue with detergents like sodium dodecyl sulfate and Triton X-100 to create a decellularized, sterilized, and immunologically reduced tissue product.

Safety and Environmental Considerations of Triton X-100

Triton X-100, a widely used nonionic surfactant in peptide synthesis, presents several safety and environmental considerations that must be carefully addressed. The compound is classified as harmful if swallowed and can cause serious eye damage, necessitating proper handling protocols in laboratory settings. Personal protective equipment, including gloves, safety goggles, and lab coats, should be mandatory when working with Triton X-100.

From an environmental perspective, Triton X-100 poses significant concerns due to its persistence and potential for bioaccumulation. The compound is not readily biodegradable and has been shown to have toxic effects on aquatic organisms, particularly at higher concentrations. Its octylphenol ethoxylate structure contributes to its environmental persistence, with potential long-term impacts on ecosystems.

Regulatory bodies, including the European Chemicals Agency (ECHA), have classified Triton X-100 as a substance of very high concern (SVHC) due to its endocrine-disrupting properties. This classification has led to restrictions on its use in certain applications and increased scrutiny in research settings. Researchers must be aware of these regulatory constraints and consider alternative surfactants where possible.

Proper disposal of Triton X-100 and associated waste is crucial to minimize environmental impact. Incineration at high temperatures is often recommended for complete destruction of the compound. However, this process can lead to the formation of toxic byproducts, necessitating advanced emission control systems. Alternatively, advanced oxidation processes or membrane filtration techniques may be employed for wastewater treatment containing Triton X-100.

In the context of peptide synthesis, researchers should evaluate the necessity of Triton X-100 and explore potential alternatives with improved safety and environmental profiles. Green chemistry principles, such as the use of bio-based surfactants or enzyme-mediated synthesis methods, may offer more sustainable approaches to disulfide bond formation in peptides.

Risk assessment and management strategies should be implemented in laboratories using Triton X-100. This includes regular safety training for personnel, proper storage and handling procedures, and the development of spill response protocols. Additionally, monitoring of workplace exposure levels and environmental release should be conducted to ensure compliance with regulatory standards and minimize potential health and ecological risks.

From an environmental perspective, Triton X-100 poses significant concerns due to its persistence and potential for bioaccumulation. The compound is not readily biodegradable and has been shown to have toxic effects on aquatic organisms, particularly at higher concentrations. Its octylphenol ethoxylate structure contributes to its environmental persistence, with potential long-term impacts on ecosystems.

Regulatory bodies, including the European Chemicals Agency (ECHA), have classified Triton X-100 as a substance of very high concern (SVHC) due to its endocrine-disrupting properties. This classification has led to restrictions on its use in certain applications and increased scrutiny in research settings. Researchers must be aware of these regulatory constraints and consider alternative surfactants where possible.

Proper disposal of Triton X-100 and associated waste is crucial to minimize environmental impact. Incineration at high temperatures is often recommended for complete destruction of the compound. However, this process can lead to the formation of toxic byproducts, necessitating advanced emission control systems. Alternatively, advanced oxidation processes or membrane filtration techniques may be employed for wastewater treatment containing Triton X-100.

In the context of peptide synthesis, researchers should evaluate the necessity of Triton X-100 and explore potential alternatives with improved safety and environmental profiles. Green chemistry principles, such as the use of bio-based surfactants or enzyme-mediated synthesis methods, may offer more sustainable approaches to disulfide bond formation in peptides.

Risk assessment and management strategies should be implemented in laboratories using Triton X-100. This includes regular safety training for personnel, proper storage and handling procedures, and the development of spill response protocols. Additionally, monitoring of workplace exposure levels and environmental release should be conducted to ensure compliance with regulatory standards and minimize potential health and ecological risks.

Scalability and Industrial Applications

The scalability and industrial applications of Triton X-100-enhanced disulfide bond formation in peptide synthesis present significant opportunities for large-scale production and commercial utilization. This technique's potential for scaling up is particularly promising due to its ability to improve the efficiency and yield of disulfide bond formation, a critical step in the synthesis of many biologically active peptides and proteins.

In industrial settings, the use of Triton X-100 as a catalyst for disulfide bond formation can lead to substantial improvements in production processes. The enhanced reaction kinetics and increased yield can translate to reduced production times and lower costs, making it an attractive option for pharmaceutical and biotechnology companies engaged in peptide-based drug development.

The scalability of this method is further supported by the relatively low cost and wide availability of Triton X-100. As a non-ionic surfactant, it is already used in various industrial applications, which means that existing supply chains and handling protocols can be readily adapted for its use in peptide synthesis. This ease of integration into current manufacturing processes can significantly reduce the barriers to adoption for large-scale production.

From an industrial perspective, the Triton X-100-enhanced method offers several advantages. It can be applied to a wide range of peptides and proteins, making it versatile for different product lines. The improved yield and purity of the final products can also lead to higher-quality pharmaceuticals and research reagents, potentially expanding market opportunities and increasing product value.

However, scaling up this technique for industrial applications does present some challenges. Ensuring consistent performance across larger batch sizes and maintaining product quality during scale-up are critical considerations. Additionally, regulatory compliance for the use of Triton X-100 in pharmaceutical production processes may require thorough validation studies and documentation.

Despite these challenges, the potential for this technique to revolutionize industrial peptide synthesis is significant. It could enable the production of complex peptides and proteins at scales previously deemed impractical or economically unfeasible. This, in turn, could accelerate the development and commercialization of new peptide-based therapeutics and diagnostic tools.

As the demand for peptide-based drugs continues to grow, the industrial applications of this enhanced synthesis method are likely to expand. It may find use not only in the pharmaceutical industry but also in the production of peptides for research, cosmetics, and food additives. The scalability of the process could also make it valuable for the production of peptide-based materials and bioengineering applications.

In industrial settings, the use of Triton X-100 as a catalyst for disulfide bond formation can lead to substantial improvements in production processes. The enhanced reaction kinetics and increased yield can translate to reduced production times and lower costs, making it an attractive option for pharmaceutical and biotechnology companies engaged in peptide-based drug development.

The scalability of this method is further supported by the relatively low cost and wide availability of Triton X-100. As a non-ionic surfactant, it is already used in various industrial applications, which means that existing supply chains and handling protocols can be readily adapted for its use in peptide synthesis. This ease of integration into current manufacturing processes can significantly reduce the barriers to adoption for large-scale production.

From an industrial perspective, the Triton X-100-enhanced method offers several advantages. It can be applied to a wide range of peptides and proteins, making it versatile for different product lines. The improved yield and purity of the final products can also lead to higher-quality pharmaceuticals and research reagents, potentially expanding market opportunities and increasing product value.

However, scaling up this technique for industrial applications does present some challenges. Ensuring consistent performance across larger batch sizes and maintaining product quality during scale-up are critical considerations. Additionally, regulatory compliance for the use of Triton X-100 in pharmaceutical production processes may require thorough validation studies and documentation.

Despite these challenges, the potential for this technique to revolutionize industrial peptide synthesis is significant. It could enable the production of complex peptides and proteins at scales previously deemed impractical or economically unfeasible. This, in turn, could accelerate the development and commercialization of new peptide-based therapeutics and diagnostic tools.

As the demand for peptide-based drugs continues to grow, the industrial applications of this enhanced synthesis method are likely to expand. It may find use not only in the pharmaceutical industry but also in the production of peptides for research, cosmetics, and food additives. The scalability of the process could also make it valuable for the production of peptide-based materials and bioengineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!