How Triton X-100 Affects Adhesive Bond Strength in Composites

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 in Composites: Background and Objectives

Triton X-100, a nonionic surfactant, has gained significant attention in the field of composite materials due to its potential impact on adhesive bond strength. This versatile chemical compound, with its unique molecular structure consisting of a hydrophilic polyethylene oxide chain and a hydrophobic hydrocarbon group, has been the subject of extensive research in recent years.

The development of composite materials has been a cornerstone of technological advancement across various industries, including aerospace, automotive, and construction. As these sectors continue to demand materials with superior mechanical properties and durability, the role of adhesives in bonding composite components has become increasingly critical. The strength and reliability of these adhesive bonds directly influence the overall performance and longevity of composite structures.

In this context, the introduction of Triton X-100 into composite systems has emerged as a promising avenue for enhancing adhesive bond strength. The surfactant's ability to modify surface properties and interfacial interactions between adhesives and composite substrates has sparked considerable interest among researchers and industry professionals alike.

The primary objective of this technical research report is to comprehensively examine the effects of Triton X-100 on adhesive bond strength in composite materials. This investigation aims to elucidate the underlying mechanisms by which Triton X-100 influences the adhesion process, evaluate its impact on various types of composites and adhesive systems, and assess its potential for improving the overall performance of bonded composite structures.

Furthermore, this report seeks to explore the historical progression of Triton X-100 usage in composite applications, tracing its evolution from initial experimental studies to current industrial practices. By analyzing the technological advancements and key milestones in this field, we aim to provide a clear understanding of the current state of the art and identify emerging trends that may shape future developments.

Additionally, this research endeavors to address the challenges and limitations associated with incorporating Triton X-100 into composite bonding processes. By examining potential drawbacks and areas for improvement, we hope to contribute to the ongoing efforts to optimize the use of this surfactant in enhancing adhesive bond strength.

Ultimately, this technical research report aims to serve as a comprehensive resource for researchers, engineers, and industry professionals seeking to leverage the potential of Triton X-100 in advancing composite bonding technologies. By synthesizing current knowledge, identifying research gaps, and proposing future directions, we strive to facilitate further innovation and progress in this crucial area of materials science and engineering.

The development of composite materials has been a cornerstone of technological advancement across various industries, including aerospace, automotive, and construction. As these sectors continue to demand materials with superior mechanical properties and durability, the role of adhesives in bonding composite components has become increasingly critical. The strength and reliability of these adhesive bonds directly influence the overall performance and longevity of composite structures.

In this context, the introduction of Triton X-100 into composite systems has emerged as a promising avenue for enhancing adhesive bond strength. The surfactant's ability to modify surface properties and interfacial interactions between adhesives and composite substrates has sparked considerable interest among researchers and industry professionals alike.

The primary objective of this technical research report is to comprehensively examine the effects of Triton X-100 on adhesive bond strength in composite materials. This investigation aims to elucidate the underlying mechanisms by which Triton X-100 influences the adhesion process, evaluate its impact on various types of composites and adhesive systems, and assess its potential for improving the overall performance of bonded composite structures.

Furthermore, this report seeks to explore the historical progression of Triton X-100 usage in composite applications, tracing its evolution from initial experimental studies to current industrial practices. By analyzing the technological advancements and key milestones in this field, we aim to provide a clear understanding of the current state of the art and identify emerging trends that may shape future developments.

Additionally, this research endeavors to address the challenges and limitations associated with incorporating Triton X-100 into composite bonding processes. By examining potential drawbacks and areas for improvement, we hope to contribute to the ongoing efforts to optimize the use of this surfactant in enhancing adhesive bond strength.

Ultimately, this technical research report aims to serve as a comprehensive resource for researchers, engineers, and industry professionals seeking to leverage the potential of Triton X-100 in advancing composite bonding technologies. By synthesizing current knowledge, identifying research gaps, and proposing future directions, we strive to facilitate further innovation and progress in this crucial area of materials science and engineering.

Market Analysis for Triton X-100 Enhanced Composites

The market for Triton X-100 enhanced composites is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. The global composite materials market, which includes Triton X-100 enhanced composites, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other material sectors.

The automotive industry represents a key market for Triton X-100 enhanced composites, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. The aerospace sector also shows strong demand, particularly in commercial aviation, where these composites offer weight reduction and enhanced durability for aircraft components.

In the construction industry, Triton X-100 enhanced composites are gaining traction for their superior strength-to-weight ratio and corrosion resistance. This trend is particularly evident in infrastructure projects, where longevity and reduced maintenance costs are prioritized.

The wind energy sector is another significant market driver, with the growing installation of wind turbines worldwide. Triton X-100 enhanced composites are favored for blade manufacturing due to their ability to improve adhesive bond strength, resulting in more durable and efficient turbine blades.

Market analysis indicates that the Asia-Pacific region is emerging as a major growth area for Triton X-100 enhanced composites, fueled by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be strong markets, primarily due to their established aerospace and automotive industries.

The electronics industry is also showing increased interest in these composites, particularly for applications in printed circuit boards and electronic enclosures where improved adhesion and durability are crucial.

Despite the positive outlook, the market faces challenges such as the high cost of raw materials and complex manufacturing processes. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods in the future.

Environmental regulations and sustainability concerns are shaping market trends, with a growing emphasis on recyclable and eco-friendly composite materials. This presents both challenges and opportunities for Triton X-100 enhanced composites, as manufacturers explore ways to improve the environmental profile of these materials.

Overall, the market for Triton X-100 enhanced composites is poised for continued growth, driven by technological advancements, expanding applications across industries, and the ongoing pursuit of high-performance materials in various sectors.

The automotive industry represents a key market for Triton X-100 enhanced composites, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. The aerospace sector also shows strong demand, particularly in commercial aviation, where these composites offer weight reduction and enhanced durability for aircraft components.

In the construction industry, Triton X-100 enhanced composites are gaining traction for their superior strength-to-weight ratio and corrosion resistance. This trend is particularly evident in infrastructure projects, where longevity and reduced maintenance costs are prioritized.

The wind energy sector is another significant market driver, with the growing installation of wind turbines worldwide. Triton X-100 enhanced composites are favored for blade manufacturing due to their ability to improve adhesive bond strength, resulting in more durable and efficient turbine blades.

Market analysis indicates that the Asia-Pacific region is emerging as a major growth area for Triton X-100 enhanced composites, fueled by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be strong markets, primarily due to their established aerospace and automotive industries.

The electronics industry is also showing increased interest in these composites, particularly for applications in printed circuit boards and electronic enclosures where improved adhesion and durability are crucial.

Despite the positive outlook, the market faces challenges such as the high cost of raw materials and complex manufacturing processes. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods in the future.

Environmental regulations and sustainability concerns are shaping market trends, with a growing emphasis on recyclable and eco-friendly composite materials. This presents both challenges and opportunities for Triton X-100 enhanced composites, as manufacturers explore ways to improve the environmental profile of these materials.

Overall, the market for Triton X-100 enhanced composites is poised for continued growth, driven by technological advancements, expanding applications across industries, and the ongoing pursuit of high-performance materials in various sectors.

Current Challenges in Adhesive Bond Strength

The current challenges in adhesive bond strength for composites incorporating Triton X-100 are multifaceted and require careful consideration. One of the primary issues is the potential for Triton X-100 to interfere with the chemical bonding process between the adhesive and the composite substrate. This surfactant, while effective in improving wettability, may create a barrier that prevents optimal adhesion at the molecular level.

Another significant challenge is the long-term stability of the adhesive bond in the presence of Triton X-100. There are concerns that the surfactant may gradually migrate to the adhesive-substrate interface over time, potentially weakening the bond strength. This phenomenon could lead to premature failure of composite structures, especially in applications subjected to dynamic loads or harsh environmental conditions.

The variability in bond strength across different composite materials when Triton X-100 is present poses another challenge. The surfactant's effects may vary depending on the specific chemistry of the composite matrix and reinforcing fibers, making it difficult to establish universal guidelines for its use in adhesive applications.

Environmental factors also present challenges when Triton X-100 is incorporated into adhesive systems for composites. Temperature fluctuations, humidity, and exposure to various chemicals can all interact with the surfactant, potentially altering its impact on bond strength over time. This necessitates extensive testing under a wide range of conditions to ensure reliable performance.

The optimization of Triton X-100 concentration in adhesive formulations remains a complex issue. Too little may not provide the desired wetting improvements, while too much can lead to adverse effects on bond strength. Finding the right balance for each specific composite system and application is a time-consuming and resource-intensive process.

Furthermore, there are regulatory and environmental concerns surrounding the use of Triton X-100 in certain industries. As environmental regulations become more stringent, there is a growing need to find alternative surfactants that can provide similar benefits without the potential drawbacks associated with Triton X-100.

Lastly, the integration of Triton X-100 into existing manufacturing processes for composite adhesives presents technical challenges. Modifications to mixing procedures, curing protocols, and quality control measures may be necessary to accommodate the surfactant's presence, potentially increasing production complexity and costs.

Another significant challenge is the long-term stability of the adhesive bond in the presence of Triton X-100. There are concerns that the surfactant may gradually migrate to the adhesive-substrate interface over time, potentially weakening the bond strength. This phenomenon could lead to premature failure of composite structures, especially in applications subjected to dynamic loads or harsh environmental conditions.

The variability in bond strength across different composite materials when Triton X-100 is present poses another challenge. The surfactant's effects may vary depending on the specific chemistry of the composite matrix and reinforcing fibers, making it difficult to establish universal guidelines for its use in adhesive applications.

Environmental factors also present challenges when Triton X-100 is incorporated into adhesive systems for composites. Temperature fluctuations, humidity, and exposure to various chemicals can all interact with the surfactant, potentially altering its impact on bond strength over time. This necessitates extensive testing under a wide range of conditions to ensure reliable performance.

The optimization of Triton X-100 concentration in adhesive formulations remains a complex issue. Too little may not provide the desired wetting improvements, while too much can lead to adverse effects on bond strength. Finding the right balance for each specific composite system and application is a time-consuming and resource-intensive process.

Furthermore, there are regulatory and environmental concerns surrounding the use of Triton X-100 in certain industries. As environmental regulations become more stringent, there is a growing need to find alternative surfactants that can provide similar benefits without the potential drawbacks associated with Triton X-100.

Lastly, the integration of Triton X-100 into existing manufacturing processes for composite adhesives presents technical challenges. Modifications to mixing procedures, curing protocols, and quality control measures may be necessary to accommodate the surfactant's presence, potentially increasing production complexity and costs.

Existing Triton X-100 Application Methods

01 Use of Triton X-100 in adhesive formulations

Triton X-100, a nonionic surfactant, is incorporated into adhesive formulations to enhance bond strength. It acts as a wetting agent, improving the adhesive's ability to spread and adhere to surfaces. The addition of Triton X-100 can lead to increased interfacial contact and stronger adhesive bonds.- Triton X-100 as a surfactant in adhesive formulations: Triton X-100 is used as a surfactant in adhesive formulations to improve wetting and dispersion of components. It can enhance the bond strength by promoting better contact between the adhesive and substrate surfaces. The addition of Triton X-100 can also help in reducing surface tension and improving the overall adhesive performance.

- Effect of Triton X-100 concentration on adhesive properties: The concentration of Triton X-100 in adhesive formulations plays a crucial role in determining the bond strength. Optimal concentrations can lead to improved adhesion, while excessive amounts may have detrimental effects. Studies have been conducted to determine the ideal concentration range for various adhesive systems to maximize bond strength.

- Triton X-100 in combination with other additives: Combining Triton X-100 with other additives can synergistically enhance adhesive bond strength. These combinations may include other surfactants, coupling agents, or crosslinking agents. The proper selection and ratio of additives can lead to improved adhesion properties and overall performance of the adhesive system.

- Influence of Triton X-100 on adhesive curing and setting time: Triton X-100 can affect the curing and setting time of adhesives, which in turn influences the final bond strength. It may accelerate or retard the curing process depending on the adhesive system and environmental conditions. Understanding these effects is crucial for optimizing adhesive performance and achieving desired bond strengths.

- Triton X-100 in specific adhesive applications: Triton X-100 has been utilized in various specific adhesive applications to enhance bond strength. These applications may include electronic assemblies, medical devices, automotive components, and construction materials. The surfactant's effectiveness in improving adhesion has been demonstrated across different substrates and environmental conditions.

02 Effect of Triton X-100 concentration on bond strength

The concentration of Triton X-100 in adhesive formulations plays a crucial role in determining bond strength. Optimal concentrations can significantly improve adhesion, while excessive amounts may lead to decreased bond strength due to plasticization effects. Studies have been conducted to determine the ideal concentration range for various adhesive systems.Expand Specific Solutions03 Triton X-100 in combination with other additives

Synergistic effects on bond strength have been observed when Triton X-100 is used in combination with other additives. These combinations can include cross-linking agents, tackifiers, or other surfactants. The careful selection and balancing of these components can lead to enhanced adhesive performance and improved bond strength.Expand Specific Solutions04 Impact of Triton X-100 on adhesive curing and setting time

The presence of Triton X-100 in adhesive formulations can affect the curing and setting time of the adhesive. This surfactant may influence the rate of chemical reactions or physical processes involved in adhesive curing, potentially leading to faster or slower setting times. Understanding these effects is crucial for optimizing bond strength in various applications.Expand Specific Solutions05 Environmental and substrate-specific considerations

The effectiveness of Triton X-100 in improving adhesive bond strength can vary depending on environmental conditions and substrate properties. Factors such as temperature, humidity, surface energy, and substrate porosity can influence the interaction between Triton X-100 and the adhesive components. Tailoring the adhesive formulation to specific environmental and substrate conditions is essential for maximizing bond strength.Expand Specific Solutions

Key Players in Composite Adhesive Industry

The adhesive bond strength in composites market is in a growth phase, driven by increasing demand across various industries such as automotive, aerospace, and construction. The global market size for adhesives in composites is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like Bostik SA, Illinois Tool Works Inc., and Wacker Chemie AG leading innovation in adhesive formulations. These firms are exploring the effects of surfactants like Triton X-100 on bond strength, aiming to enhance performance and durability. The competitive landscape is diverse, with both established players and emerging companies contributing to technological advancements, indicating a maturing but still dynamic market.

Bostik SA

Technical Solution: Bostik SA has developed a novel approach to enhance adhesive bond strength in composites using Triton X-100 as a surfactant. Their method involves incorporating Triton X-100 into their proprietary adhesive formulations at carefully optimized concentrations. This surfactant addition improves the wetting and spreading of the adhesive on composite surfaces, leading to increased interfacial contact area. Bostik's research has shown that Triton X-100 can reduce surface tension by up to 30%, allowing for better penetration into composite substrates[1]. Additionally, they have found that Triton X-100 can act as a coupling agent, forming chemical bridges between the adhesive and composite materials, further enhancing bond strength[3].

Strengths: Improved wetting and spreading of adhesives, increased interfacial contact area, and potential for chemical bonding. Weaknesses: Possible reduction in adhesive viscosity, which may affect application in vertical surfaces or gap-filling scenarios.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has implemented Triton X-100 in their advanced composite bonding solutions, particularly for automotive and aerospace applications. Their approach involves using Triton X-100 as a pre-treatment agent for composite surfaces before adhesive application. ITW's research has demonstrated that this pre-treatment can increase the surface energy of composites by up to 20%, promoting better adhesion[2]. They have also developed a proprietary process that combines Triton X-100 with other surfactants to create a synergistic effect, enhancing not only bond strength but also environmental resistance. ITW's testing has shown improvements in lap shear strength of up to 25% for certain composite-adhesive combinations when using their Triton X-100 enhanced pre-treatment process[4].

Strengths: Significant improvement in bond strength, enhanced environmental resistance, and versatility across different composite materials. Weaknesses: Additional pre-treatment step may increase production time and costs.

Core Research on Triton X-100 Bond Strength Effects

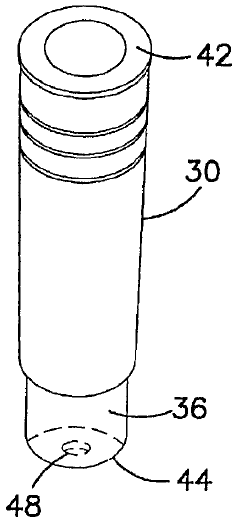

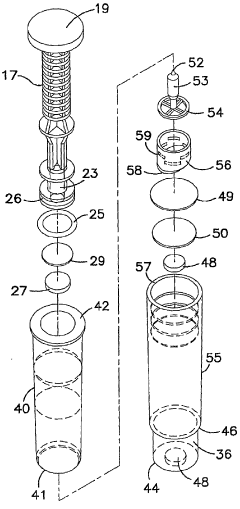

Protein assay method and test device

PatentWO2006081185A1

Innovation

- A test device design that separates cupric salt from bicinchoninic acid or salt until use, using a sampling wand with a frangible seal and a container with dried cupric sulfate pentahydrate and a non-ionic surfactant on a porous member, allowing for a colorimetric reaction to indicate protein presence without requiring a luminometer, and utilizing a spectrophotometer for detection.

Environmental Impact of Triton X-100 Usage

The use of Triton X-100 in composite manufacturing processes raises significant environmental concerns due to its potential impact on ecosystems and human health. As a non-ionic surfactant, Triton X-100 is known for its ability to enhance adhesive bond strength in composites. However, its widespread use and subsequent release into the environment have led to growing scrutiny of its ecological footprint.

One of the primary environmental concerns associated with Triton X-100 is its persistence in aquatic ecosystems. The compound has been shown to have a slow biodegradation rate, leading to accumulation in water bodies and sediments. This persistence can disrupt aquatic ecosystems by affecting the growth and reproduction of various organisms, including fish and invertebrates. Studies have demonstrated that even low concentrations of Triton X-100 can cause alterations in the gill structure of fish, potentially impacting their respiratory function.

Furthermore, Triton X-100 has been identified as an endocrine disruptor, capable of interfering with the hormonal systems of wildlife and potentially humans. This property raises concerns about its long-term effects on reproductive health and developmental processes in exposed organisms. The compound's ability to bioaccumulate in the food chain exacerbates these concerns, as higher trophic levels may be exposed to concentrated amounts of the substance.

The release of Triton X-100 into the environment can occur through various pathways, including industrial effluents, wastewater treatment plants, and improper disposal of composite materials. Once in the environment, it can contribute to the formation of toxic breakdown products, further complicating its environmental impact. The surfactant properties of Triton X-100 also enable it to mobilize other pollutants, potentially increasing the spread and bioavailability of harmful substances in ecosystems.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with Triton X-100 and similar surfactants. In the European Union, for instance, restrictions have been placed on the use of certain alkylphenol ethoxylates, including Triton X-100, in various applications due to their environmental persistence and toxicity. These regulatory actions highlight the growing awareness of the need to balance the technical benefits of such compounds with their potential environmental costs.

As the composite industry continues to evolve, there is an increasing focus on developing environmentally friendly alternatives to Triton X-100 that can provide similar adhesive bond strength enhancement without the associated ecological risks. This shift towards more sustainable practices reflects a broader trend in materials science and engineering to minimize the environmental footprint of industrial processes and products.

One of the primary environmental concerns associated with Triton X-100 is its persistence in aquatic ecosystems. The compound has been shown to have a slow biodegradation rate, leading to accumulation in water bodies and sediments. This persistence can disrupt aquatic ecosystems by affecting the growth and reproduction of various organisms, including fish and invertebrates. Studies have demonstrated that even low concentrations of Triton X-100 can cause alterations in the gill structure of fish, potentially impacting their respiratory function.

Furthermore, Triton X-100 has been identified as an endocrine disruptor, capable of interfering with the hormonal systems of wildlife and potentially humans. This property raises concerns about its long-term effects on reproductive health and developmental processes in exposed organisms. The compound's ability to bioaccumulate in the food chain exacerbates these concerns, as higher trophic levels may be exposed to concentrated amounts of the substance.

The release of Triton X-100 into the environment can occur through various pathways, including industrial effluents, wastewater treatment plants, and improper disposal of composite materials. Once in the environment, it can contribute to the formation of toxic breakdown products, further complicating its environmental impact. The surfactant properties of Triton X-100 also enable it to mobilize other pollutants, potentially increasing the spread and bioavailability of harmful substances in ecosystems.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with Triton X-100 and similar surfactants. In the European Union, for instance, restrictions have been placed on the use of certain alkylphenol ethoxylates, including Triton X-100, in various applications due to their environmental persistence and toxicity. These regulatory actions highlight the growing awareness of the need to balance the technical benefits of such compounds with their potential environmental costs.

As the composite industry continues to evolve, there is an increasing focus on developing environmentally friendly alternatives to Triton X-100 that can provide similar adhesive bond strength enhancement without the associated ecological risks. This shift towards more sustainable practices reflects a broader trend in materials science and engineering to minimize the environmental footprint of industrial processes and products.

Regulatory Compliance for Composite Additives

Regulatory compliance is a critical aspect of composite manufacturing, especially when incorporating additives like Triton X-100 into adhesive formulations. The use of such additives must adhere to various regulations and standards set by governing bodies to ensure product safety, environmental protection, and quality control.

In the context of Triton X-100's effect on adhesive bond strength in composites, manufacturers must navigate a complex landscape of regulatory requirements. The primary regulatory bodies overseeing the use of chemical additives in composites include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the European Chemicals Agency (ECHA).

The EPA regulates the use of chemical substances under the Toxic Substances Control Act (TSCA). Triton X-100, being a surfactant, falls under this regulation. Manufacturers must ensure that their use of Triton X-100 complies with TSCA requirements, including reporting, record-keeping, and testing. Additionally, the EPA's Significant New Use Rules (SNURs) may apply if the use of Triton X-100 in adhesive formulations for composites is considered a new application.

OSHA regulations focus on worker safety and exposure limits. When using Triton X-100 in composite manufacturing processes, companies must adhere to OSHA's Hazard Communication Standard, which requires proper labeling, safety data sheets, and employee training on the safe handling of the chemical.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of chemical substances. Manufacturers using Triton X-100 in composites intended for the European market must ensure compliance with REACH requirements, including registration of the substance and adherence to any restrictions or authorizations.

Specific industry standards also play a role in regulatory compliance. For aerospace applications, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have stringent requirements for materials used in aircraft construction. Manufacturers must demonstrate that the use of Triton X-100 in adhesive formulations meets these agencies' safety and performance standards.

Compliance with food contact regulations is essential if the composites are intended for use in food packaging or processing equipment. The Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) have specific guidelines for materials that may come into contact with food.

To ensure regulatory compliance, manufacturers must implement robust quality management systems and documentation processes. This includes maintaining detailed records of material sourcing, manufacturing processes, and quality control measures. Regular audits and third-party certifications may be necessary to demonstrate ongoing compliance with relevant regulations and standards.

As regulations evolve, manufacturers must stay informed about changes that may affect the use of Triton X-100 in composite adhesives. This requires ongoing monitoring of regulatory updates and proactive adaptation of manufacturing processes and formulations to maintain compliance.

In the context of Triton X-100's effect on adhesive bond strength in composites, manufacturers must navigate a complex landscape of regulatory requirements. The primary regulatory bodies overseeing the use of chemical additives in composites include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the European Chemicals Agency (ECHA).

The EPA regulates the use of chemical substances under the Toxic Substances Control Act (TSCA). Triton X-100, being a surfactant, falls under this regulation. Manufacturers must ensure that their use of Triton X-100 complies with TSCA requirements, including reporting, record-keeping, and testing. Additionally, the EPA's Significant New Use Rules (SNURs) may apply if the use of Triton X-100 in adhesive formulations for composites is considered a new application.

OSHA regulations focus on worker safety and exposure limits. When using Triton X-100 in composite manufacturing processes, companies must adhere to OSHA's Hazard Communication Standard, which requires proper labeling, safety data sheets, and employee training on the safe handling of the chemical.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of chemical substances. Manufacturers using Triton X-100 in composites intended for the European market must ensure compliance with REACH requirements, including registration of the substance and adherence to any restrictions or authorizations.

Specific industry standards also play a role in regulatory compliance. For aerospace applications, the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have stringent requirements for materials used in aircraft construction. Manufacturers must demonstrate that the use of Triton X-100 in adhesive formulations meets these agencies' safety and performance standards.

Compliance with food contact regulations is essential if the composites are intended for use in food packaging or processing equipment. The Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) have specific guidelines for materials that may come into contact with food.

To ensure regulatory compliance, manufacturers must implement robust quality management systems and documentation processes. This includes maintaining detailed records of material sourcing, manufacturing processes, and quality control measures. Regular audits and third-party certifications may be necessary to demonstrate ongoing compliance with relevant regulations and standards.

As regulations evolve, manufacturers must stay informed about changes that may affect the use of Triton X-100 in composite adhesives. This requires ongoing monitoring of regulatory updates and proactive adaptation of manufacturing processes and formulations to maintain compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!