Examining the Shift from LDPE to Eco-Alternatives

LDPE Evolution and Eco-Transition Goals

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its commercial introduction in the 1930s. Its versatility, low cost, and ease of processing have made it ubiquitous in packaging, consumer goods, and various industrial applications. However, the environmental concerns associated with traditional plastics have led to a growing demand for eco-friendly alternatives.

The evolution of LDPE began with its discovery by Imperial Chemical Industries in 1933. Initially used for electrical wire insulation during World War II, LDPE quickly found its way into numerous applications due to its flexibility, toughness, and chemical resistance. Over the decades, improvements in production techniques and the development of different grades have expanded its utility across industries.

Despite its widespread use, LDPE faces significant challenges in the current environmental landscape. The persistence of plastic waste in ecosystems, concerns over microplastic pollution, and the depletion of fossil resources used in LDPE production have all contributed to a shift in focus towards more sustainable alternatives. This transition is driven by both consumer demand and regulatory pressures, with many countries implementing policies to reduce single-use plastics and promote recycling.

The eco-transition goals for LDPE alternatives are multifaceted. Primarily, there is a push for materials that maintain the beneficial properties of LDPE while addressing its environmental shortcomings. This includes developing biodegradable or compostable plastics, enhancing recycling technologies for existing LDPE products, and exploring bio-based alternatives derived from renewable resources.

One key objective is to create materials that can degrade safely in natural environments or industrial composting facilities, reducing the long-term environmental impact. Another goal is to improve the recyclability of LDPE and its alternatives, aiming for a circular economy model where materials can be reused multiple times without significant quality loss.

The transition also aims to reduce the carbon footprint associated with plastic production. This involves not only the development of bio-based materials but also the optimization of manufacturing processes to minimize energy consumption and emissions. Additionally, there is a focus on creating materials that can maintain food safety and product integrity while using less material overall, addressing concerns about resource efficiency.

As the industry moves forward, the goals extend beyond material properties to encompass the entire lifecycle of products. This holistic approach considers factors such as sourcing of raw materials, energy consumption during production, transportation impacts, and end-of-life management. The ultimate aim is to create a sustainable plastics ecosystem that balances environmental concerns with the practical needs of modern society.

Eco-Alternative Demand Analysis

The shift from Low-Density Polyethylene (LDPE) to eco-alternatives has been driven by a growing demand for sustainable packaging solutions across various industries. This demand is fueled by increasing environmental awareness among consumers, stringent regulations on plastic usage, and corporate sustainability initiatives.

In the food and beverage sector, there is a significant push for eco-friendly packaging alternatives. Major companies are committing to reduce their plastic footprint, leading to a surge in demand for biodegradable and compostable materials. The market for these alternatives in food packaging is expected to grow substantially in the coming years, as consumers show a preference for products with environmentally responsible packaging.

The personal care and cosmetics industry is another key driver of eco-alternative demand. With consumers becoming more conscious of the environmental impact of their purchases, brands are responding by adopting sustainable packaging solutions. This has led to an increased interest in materials such as recycled plastics, bioplastics, and paper-based alternatives to traditional LDPE packaging.

E-commerce and retail sectors are also contributing to the demand for eco-alternatives. As online shopping continues to grow, there is a parallel increase in the need for sustainable packaging solutions. Many e-commerce companies are exploring options like recyclable mailers, biodegradable bubble wrap, and paper-based void fill to replace traditional plastic packaging materials.

The agricultural sector presents another significant market for eco-alternatives. There is a growing demand for biodegradable mulch films and plant pots, which can reduce plastic waste in farming practices. This shift is supported by both environmental concerns and the potential for improved soil health.

In the industrial packaging sector, there is an increasing focus on circular economy principles. This has led to a rise in demand for recyclable and reusable packaging solutions, as well as those made from recycled content. Many businesses are looking to replace LDPE-based shrink wraps and stretch films with more sustainable alternatives.

The healthcare industry, while traditionally reliant on plastic packaging for sterility and durability, is also exploring eco-friendly options. There is a growing interest in bioplastics and other sustainable materials that can meet the stringent requirements of medical packaging while reducing environmental impact.

Overall, the demand for eco-alternatives to LDPE is driven by a combination of consumer preferences, regulatory pressures, and corporate sustainability goals. This trend is expected to continue, with the global market for sustainable packaging projected to grow significantly in the coming years.

Eco-Plastic Challenges and Limitations

While eco-friendly alternatives to LDPE offer promising solutions for reducing plastic pollution, they face several challenges and limitations that hinder their widespread adoption. One of the primary obstacles is the higher production cost associated with these materials. Eco-plastics often require more complex manufacturing processes and specialized equipment, leading to increased expenses that are ultimately passed on to consumers. This price differential makes it difficult for eco-alternatives to compete with traditional LDPE in price-sensitive markets.

Performance and durability issues also pose significant challenges for eco-plastics. Many biodegradable and compostable alternatives struggle to match the strength, flexibility, and barrier properties of LDPE. This can limit their applicability in certain packaging applications, particularly those requiring long shelf life or protection against moisture and oxygen. Additionally, some eco-plastics may degrade prematurely under certain environmental conditions, compromising product integrity and safety.

The lack of standardized disposal and recycling infrastructure for eco-plastics presents another major hurdle. While these materials are designed to be more environmentally friendly, they often require specific conditions for proper decomposition or recycling. Many existing waste management systems are not equipped to handle these materials effectively, leading to potential contamination of conventional plastic recycling streams or improper disposal in landfills where they may not biodegrade as intended.

Consumer awareness and acceptance of eco-plastic alternatives remain limited, creating barriers to market penetration. Many consumers are unfamiliar with the properties and proper disposal methods for these materials, leading to confusion and potential misuse. Furthermore, there is often skepticism about the environmental claims made by manufacturers, particularly in light of greenwashing concerns.

Technical limitations in the production of eco-plastics also present challenges. Scaling up production to meet global demand while maintaining consistent quality and properties can be difficult. Additionally, the sourcing of raw materials for some bio-based plastics may compete with food production or lead to other environmental concerns, such as deforestation or increased water usage.

Regulatory hurdles and the lack of unified global standards for eco-plastics further complicate their adoption. Different regions may have varying definitions and requirements for biodegradability and compostability, creating confusion in the market and hindering international trade. The absence of clear labeling and certification standards also makes it challenging for consumers and businesses to make informed choices about eco-plastic products.

Current Eco-Alternative Solutions

01 Biodegradable LDPE composites

Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's ability to decompose in the environment, addressing concerns about plastic pollution.- Biodegradable LDPE composites: Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's degradability while maintaining its desirable properties. This approach aims to address the issue of plastic waste accumulation in the environment.

- Recycling and upcycling of LDPE: Innovative methods for recycling and upcycling LDPE to minimize its environmental footprint. These techniques include chemical recycling, mechanical recycling, and the transformation of LDPE waste into value-added products. By promoting circular economy principles, these approaches aim to reduce the amount of LDPE ending up in landfills or the environment.

- LDPE alternatives and substitutes: Research and development of environmentally friendly alternatives to LDPE. This includes the creation of bio-based polymers, compostable materials, and other sustainable substitutes that can replace LDPE in various applications while offering similar performance characteristics and reduced environmental impact.

- Reduction of LDPE usage: Strategies and technologies aimed at reducing the overall consumption of LDPE. This involves designing products that use less material, developing reusable alternatives, and implementing policies to discourage single-use LDPE products. The goal is to minimize the production and disposal of LDPE, thereby lessening its environmental impact.

- LDPE waste management and disposal: Improved methods for managing and disposing of LDPE waste to mitigate its environmental impact. This includes advanced sorting technologies, efficient collection systems, and environmentally sound disposal techniques. The focus is on preventing LDPE from entering ecosystems and reducing its long-term environmental effects.

02 Recycling and upcycling of LDPE

Innovative methods for recycling and upcycling LDPE to minimize waste and environmental impact. These processes involve converting waste LDPE into valuable products or materials, reducing the amount of plastic that ends up in landfills or the environment.Expand Specific Solutions03 LDPE alternatives and substitutes

Research and development of environmentally friendly alternatives and substitutes for LDPE. These materials aim to provide similar properties to LDPE while offering improved biodegradability or reduced environmental impact.Expand Specific Solutions04 Reduction of LDPE environmental footprint

Techniques and processes to reduce the environmental footprint of LDPE production and use. This includes optimizing manufacturing processes, reducing energy consumption, and minimizing emissions associated with LDPE production and disposal.Expand Specific Solutions05 LDPE waste management and disposal

Improved methods for managing and disposing of LDPE waste to minimize environmental impact. These approaches focus on efficient collection, sorting, and treatment of LDPE waste to prevent pollution and promote sustainable waste management practices.Expand Specific Solutions

Key Eco-Plastic Industry Players

The shift from LDPE to eco-alternatives is gaining momentum in a maturing industry, driven by increasing environmental concerns and regulatory pressures. The market size for sustainable packaging solutions is expanding rapidly, with major players like Dow Global Technologies, ExxonMobil Chemical, and SABIC Global Technologies leading the charge. These companies are investing heavily in R&D to develop bio-based and recyclable alternatives. The technology is progressing, with innovations in biodegradable polymers and advanced recycling techniques. However, the eco-alternatives market is still in its growth phase, with challenges in scalability and cost-effectiveness compared to traditional LDPE. Smaller players and academic institutions are also contributing to technological advancements, indicating a dynamic and competitive landscape.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Innovative Eco-Plastic Technologies

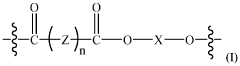

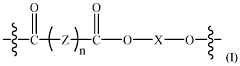

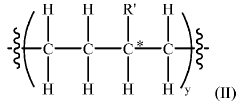

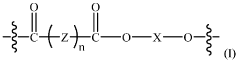

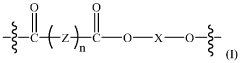

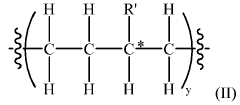

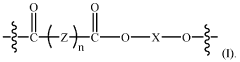

- Development of repeatedly recyclable polymer mimics (RR-PM) of LDPE, which are created from a reaction product of difunctional oligomers and linkers obtained through depolymerization of used articles, allowing for repeated recycling with minimal loss of properties and reduced need for virgin materials.

- A repeatedly recyclable polymer mimic (RR-PM) of LLDPE is created through a reaction product of difunctional oligomers and linkers obtained from depolymerized articles, allowing for repeated recycling with minimal loss of material quality and reduced need for virgin materials, achieved by liquefying and repolymerizing the RR-PM in a closed-loop process.

Environmental Impact Assessment

The shift from Low-Density Polyethylene (LDPE) to eco-alternatives has significant environmental implications that warrant careful assessment. This transition is primarily driven by the growing awareness of plastic pollution and the need for more sustainable packaging solutions.

LDPE, while versatile and widely used, contributes to long-term environmental degradation due to its non-biodegradable nature. It persists in ecosystems for hundreds of years, leading to accumulation in landfills and oceans. The production of LDPE also relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change.

Eco-alternatives, on the other hand, offer potential environmental benefits. Biodegradable and compostable materials, such as polylactic acid (PLA) derived from renewable resources, can significantly reduce plastic waste accumulation. These materials break down more rapidly under specific conditions, minimizing long-term environmental impact.

However, the environmental impact of eco-alternatives is not uniformly positive. The production of some bio-based plastics may require intensive agricultural practices, potentially leading to increased land use, water consumption, and the use of fertilizers and pesticides. This could result in unintended consequences such as deforestation or competition with food crops.

Recycling infrastructure also plays a crucial role in the environmental assessment. While LDPE recycling systems are well-established in many regions, the recycling processes for newer eco-alternatives may not be as developed. This could lead to these materials ending up in landfills or contaminating existing recycling streams if not properly managed.

Energy consumption and carbon footprint throughout the lifecycle of these materials must be considered. While eco-alternatives may have lower end-of-life impacts, their production processes might be more energy-intensive compared to traditional LDPE manufacturing. A comprehensive life cycle assessment is necessary to accurately compare the overall environmental impact of LDPE and its eco-friendly counterparts.

Water pollution is another critical factor. LDPE contributes to microplastic pollution in aquatic ecosystems, whereas some eco-alternatives may have reduced impact in this regard. However, the potential leaching of chemicals from biodegradable plastics during decomposition needs further study to ensure they do not introduce new forms of water contamination.

In conclusion, while the shift from LDPE to eco-alternatives presents promising opportunities for reducing environmental impact, it requires careful consideration of various factors. A holistic approach, considering production methods, disposal practices, and overall lifecycle impacts, is essential to ensure that the transition truly benefits the environment in the long term.

Regulatory Framework for Eco-Plastics

The regulatory framework for eco-plastics is rapidly evolving as governments and international organizations respond to the growing environmental concerns associated with traditional plastics like LDPE. This shift is driven by the need to reduce plastic pollution, minimize carbon footprints, and promote sustainable practices in the packaging industry.

At the international level, the United Nations Environment Programme (UNEP) has been instrumental in setting global standards and guidelines for sustainable plastic use. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste, effectively regulating its international trade and disposal.

In the European Union, the Single-Use Plastics Directive (SUP) has set ambitious targets for reducing plastic waste and promoting the use of eco-alternatives. This directive bans certain single-use plastic items and sets recycling targets for others, encouraging the development and adoption of more sustainable materials.

The United States has seen a patchwork of state-level regulations, with California leading the way through its Plastic Pollution Prevention and Packaging Producer Responsibility Act. This legislation aims to reduce single-use plastic packaging and foodware by 25% by 2032 and ensures that remaining items are recyclable or compostable.

In Asia, countries like Japan and South Korea have implemented extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their plastic products, including disposal and recycling. China's ban on importing plastic waste has also had a significant global impact, forcing many countries to reassess their plastic waste management strategies.

Emerging economies are also taking steps to regulate eco-plastics. India, for instance, has banned single-use plastics and is promoting the use of biodegradable alternatives. Similarly, several African nations have implemented bans on plastic bags, encouraging the use of eco-friendly substitutes.

These regulatory frameworks are not only focusing on banning or limiting traditional plastics but are also setting standards for eco-alternatives. Certifications and labeling requirements for biodegradable and compostable plastics are becoming more stringent to prevent greenwashing and ensure that eco-alternatives truly deliver on their environmental promises.

As the shift from LDPE to eco-alternatives gains momentum, we can expect regulatory frameworks to become more comprehensive and harmonized across regions. This will likely include stricter lifecycle assessments, standardized testing methods for biodegradability and compostability, and more robust recycling and waste management infrastructures to support the transition to eco-plastics.