Exploring Dodecane in Coating Technologies

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane Coating Tech Evolution

The evolution of dodecane in coating technologies has been marked by significant advancements and innovations over the past few decades. Initially, dodecane was primarily used as a solvent in various industrial applications, including coatings. However, its potential as a key component in coating formulations began to emerge in the late 1990s, driven by the need for more environmentally friendly and efficient coating solutions.

In the early 2000s, researchers started exploring dodecane's unique properties, such as its low volatility and excellent solvency, which made it an attractive option for slow-drying coatings. This led to the development of novel coating formulations that incorporated dodecane as a primary ingredient, particularly in applications requiring extended working times and improved flow characteristics.

The mid-2000s saw a surge in research focused on dodecane's role in nanocoatings. Scientists discovered that dodecane could be used as a dispersing agent for nanoparticles, enabling the creation of highly uniform and stable nanocoatings. This breakthrough opened up new possibilities for enhancing coating performance, including improved scratch resistance, self-cleaning properties, and enhanced durability.

By the early 2010s, dodecane-based coatings had gained significant traction in the automotive and aerospace industries. The ability of dodecane to form thin, even films made it particularly suitable for high-performance coatings on complex surfaces. Additionally, its low surface tension properties contributed to improved adhesion and coverage, addressing long-standing challenges in these sectors.

The mid-2010s marked a turning point in dodecane coating technology with the advent of smart coatings. Researchers began incorporating dodecane into stimuli-responsive coating systems, where the material's properties could be altered by external factors such as temperature, pH, or light. This innovation led to the development of self-healing coatings and adaptive surface treatments, revolutionizing the field of protective coatings.

In recent years, the focus has shifted towards sustainability and bio-based alternatives. While dodecane itself is a hydrocarbon, efforts have been made to synthesize it from renewable sources. This has resulted in the emergence of bio-based dodecane coatings, aligning with the growing demand for environmentally friendly solutions in the coatings industry.

Looking ahead, the evolution of dodecane in coating technologies is expected to continue, with emphasis on nanotechnology integration, smart coating functionalities, and sustainable production methods. Ongoing research is exploring the potential of dodecane in advanced applications such as energy-efficient building coatings, corrosion-resistant marine coatings, and even biomedical coatings for implants and medical devices.

In the early 2000s, researchers started exploring dodecane's unique properties, such as its low volatility and excellent solvency, which made it an attractive option for slow-drying coatings. This led to the development of novel coating formulations that incorporated dodecane as a primary ingredient, particularly in applications requiring extended working times and improved flow characteristics.

The mid-2000s saw a surge in research focused on dodecane's role in nanocoatings. Scientists discovered that dodecane could be used as a dispersing agent for nanoparticles, enabling the creation of highly uniform and stable nanocoatings. This breakthrough opened up new possibilities for enhancing coating performance, including improved scratch resistance, self-cleaning properties, and enhanced durability.

By the early 2010s, dodecane-based coatings had gained significant traction in the automotive and aerospace industries. The ability of dodecane to form thin, even films made it particularly suitable for high-performance coatings on complex surfaces. Additionally, its low surface tension properties contributed to improved adhesion and coverage, addressing long-standing challenges in these sectors.

The mid-2010s marked a turning point in dodecane coating technology with the advent of smart coatings. Researchers began incorporating dodecane into stimuli-responsive coating systems, where the material's properties could be altered by external factors such as temperature, pH, or light. This innovation led to the development of self-healing coatings and adaptive surface treatments, revolutionizing the field of protective coatings.

In recent years, the focus has shifted towards sustainability and bio-based alternatives. While dodecane itself is a hydrocarbon, efforts have been made to synthesize it from renewable sources. This has resulted in the emergence of bio-based dodecane coatings, aligning with the growing demand for environmentally friendly solutions in the coatings industry.

Looking ahead, the evolution of dodecane in coating technologies is expected to continue, with emphasis on nanotechnology integration, smart coating functionalities, and sustainable production methods. Ongoing research is exploring the potential of dodecane in advanced applications such as energy-efficient building coatings, corrosion-resistant marine coatings, and even biomedical coatings for implants and medical devices.

Market Demand Analysis

The market demand for dodecane in coating technologies has been steadily increasing due to its unique properties and versatile applications. As a long-chain hydrocarbon, dodecane offers excellent solvent characteristics, making it highly valuable in various coating formulations. The global coating industry, valued at over $150 billion, has shown a growing interest in dodecane-based solutions, particularly in sectors such as automotive, aerospace, and industrial coatings.

One of the primary drivers for dodecane's demand in coating technologies is its low volatility and high boiling point. These properties contribute to improved coating performance, especially in applications requiring slow evaporation rates and extended working times. The automotive sector, in particular, has witnessed a surge in demand for dodecane-based coatings due to their ability to provide smooth, high-gloss finishes with enhanced durability.

The aerospace industry has also emerged as a significant consumer of dodecane-based coatings. The need for lightweight, corrosion-resistant, and thermally stable coatings in aircraft manufacturing has led to increased adoption of dodecane-containing formulations. This trend is expected to continue as the aerospace sector focuses on developing more fuel-efficient and environmentally friendly aircraft.

In the industrial coatings segment, dodecane has gained traction due to its compatibility with a wide range of resins and additives. This versatility allows formulators to create coatings with tailored properties, such as improved adhesion, chemical resistance, and weatherability. The growing emphasis on sustainable and eco-friendly coatings has further boosted the demand for dodecane, as it can be derived from renewable sources like plant-based oils.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for dodecane-based coatings, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe remain significant consumers, with a focus on high-performance coatings for specialized applications.

The increasing demand for water-based and low-VOC (volatile organic compound) coatings presents both challenges and opportunities for dodecane in coating technologies. While traditional solvent-based systems may face regulatory pressures, innovative formulations incorporating dodecane as a co-solvent or performance enhancer in water-based systems are gaining attention.

Looking ahead, the market for dodecane in coating technologies is projected to grow at a compound annual growth rate of 4-5% over the next five years. This growth is attributed to ongoing research and development efforts aimed at expanding dodecane's applications in advanced coating systems, such as self-healing coatings and smart coatings with sensing capabilities.

One of the primary drivers for dodecane's demand in coating technologies is its low volatility and high boiling point. These properties contribute to improved coating performance, especially in applications requiring slow evaporation rates and extended working times. The automotive sector, in particular, has witnessed a surge in demand for dodecane-based coatings due to their ability to provide smooth, high-gloss finishes with enhanced durability.

The aerospace industry has also emerged as a significant consumer of dodecane-based coatings. The need for lightweight, corrosion-resistant, and thermally stable coatings in aircraft manufacturing has led to increased adoption of dodecane-containing formulations. This trend is expected to continue as the aerospace sector focuses on developing more fuel-efficient and environmentally friendly aircraft.

In the industrial coatings segment, dodecane has gained traction due to its compatibility with a wide range of resins and additives. This versatility allows formulators to create coatings with tailored properties, such as improved adhesion, chemical resistance, and weatherability. The growing emphasis on sustainable and eco-friendly coatings has further boosted the demand for dodecane, as it can be derived from renewable sources like plant-based oils.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for dodecane-based coatings, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe remain significant consumers, with a focus on high-performance coatings for specialized applications.

The increasing demand for water-based and low-VOC (volatile organic compound) coatings presents both challenges and opportunities for dodecane in coating technologies. While traditional solvent-based systems may face regulatory pressures, innovative formulations incorporating dodecane as a co-solvent or performance enhancer in water-based systems are gaining attention.

Looking ahead, the market for dodecane in coating technologies is projected to grow at a compound annual growth rate of 4-5% over the next five years. This growth is attributed to ongoing research and development efforts aimed at expanding dodecane's applications in advanced coating systems, such as self-healing coatings and smart coatings with sensing capabilities.

Technical Challenges

The exploration of dodecane in coating technologies faces several significant technical challenges that researchers and industry professionals must address. One of the primary obstacles is the volatility of dodecane, which can lead to inconsistent coating performance and reduced shelf life of products. This volatility issue is particularly problematic in applications requiring long-term stability, such as protective coatings for outdoor structures or automotive finishes.

Another major challenge lies in the formulation of dodecane-based coatings to achieve optimal adhesion properties. While dodecane offers excellent spreading characteristics, its non-polar nature can result in poor adhesion to certain substrates, especially those with polar surfaces. This limitation necessitates the development of advanced surface modification techniques or the incorporation of adhesion promoters to enhance the coating's bonding capabilities.

The environmental impact of dodecane-based coatings presents a significant hurdle in their widespread adoption. As a volatile organic compound (VOC), dodecane contributes to air pollution and poses potential health risks. Regulatory pressures and increasing environmental consciousness in the industry demand the development of low-VOC or VOC-free alternatives that maintain the desirable properties of dodecane-based coatings.

Achieving uniform film formation and controlled drying rates with dodecane-containing formulations remains a technical challenge. The rapid evaporation rate of dodecane can lead to surface defects, such as orange peel or pinholes, compromising the coating's aesthetic and protective qualities. Balancing the drying kinetics to ensure proper film formation while maintaining productivity in industrial applications requires sophisticated formulation strategies.

The compatibility of dodecane with other coating components, such as resins, pigments, and additives, presents ongoing challenges in formulation development. Ensuring long-term stability of the coating mixture and preventing phase separation or sedimentation during storage and application is crucial for product quality and performance consistency.

Scaling up production processes for dodecane-based coatings from laboratory to industrial levels introduces additional technical hurdles. Maintaining consistent quality, managing heat transfer during large-scale mixing, and controlling evaporation rates in industrial coating lines require careful engineering and process optimization.

Furthermore, the development of specialized application techniques for dodecane-containing coatings poses challenges in achieving uniform coverage and thickness control. The low surface tension of dodecane can lead to dewetting issues on certain substrates, necessitating the development of tailored application methods or surface preparation techniques to ensure consistent coating quality.

Another major challenge lies in the formulation of dodecane-based coatings to achieve optimal adhesion properties. While dodecane offers excellent spreading characteristics, its non-polar nature can result in poor adhesion to certain substrates, especially those with polar surfaces. This limitation necessitates the development of advanced surface modification techniques or the incorporation of adhesion promoters to enhance the coating's bonding capabilities.

The environmental impact of dodecane-based coatings presents a significant hurdle in their widespread adoption. As a volatile organic compound (VOC), dodecane contributes to air pollution and poses potential health risks. Regulatory pressures and increasing environmental consciousness in the industry demand the development of low-VOC or VOC-free alternatives that maintain the desirable properties of dodecane-based coatings.

Achieving uniform film formation and controlled drying rates with dodecane-containing formulations remains a technical challenge. The rapid evaporation rate of dodecane can lead to surface defects, such as orange peel or pinholes, compromising the coating's aesthetic and protective qualities. Balancing the drying kinetics to ensure proper film formation while maintaining productivity in industrial applications requires sophisticated formulation strategies.

The compatibility of dodecane with other coating components, such as resins, pigments, and additives, presents ongoing challenges in formulation development. Ensuring long-term stability of the coating mixture and preventing phase separation or sedimentation during storage and application is crucial for product quality and performance consistency.

Scaling up production processes for dodecane-based coatings from laboratory to industrial levels introduces additional technical hurdles. Maintaining consistent quality, managing heat transfer during large-scale mixing, and controlling evaporation rates in industrial coating lines require careful engineering and process optimization.

Furthermore, the development of specialized application techniques for dodecane-containing coatings poses challenges in achieving uniform coverage and thickness control. The low surface tension of dodecane can lead to dewetting issues on certain substrates, necessitating the development of tailored application methods or surface preparation techniques to ensure consistent coating quality.

Current Dodecane Solutions

01 Synthesis and production of dodecane

Dodecane can be synthesized through various chemical processes, including the hydrogenation of long-chain alkenes or the Fischer-Tropsch process. It can also be produced from renewable resources such as plant oils or biomass. The synthesis methods often involve catalytic reactions and may require specific reaction conditions to optimize yield and purity.- Synthesis and purification of dodecane: Various methods for synthesizing and purifying dodecane are described. These include catalytic processes, distillation techniques, and chemical reactions to produce high-purity dodecane for industrial applications.

- Use of dodecane in cosmetic and personal care products: Dodecane is utilized as an ingredient in cosmetic and personal care formulations. It serves as an emollient, solvent, or carrier in products such as moisturizers, sunscreens, and hair care items, contributing to improved texture and performance.

- Dodecane in fuel and lubricant applications: Dodecane is employed in fuel and lubricant formulations. It is used as a component in diesel fuel, jet fuel, and various lubricating oils, enhancing performance characteristics such as viscosity and combustion properties.

- Dodecane as a solvent and extraction medium: The use of dodecane as a solvent and extraction medium in various industrial processes is described. It is employed in the extraction of natural products, separation of chemical compounds, and as a reaction medium in organic synthesis.

- Dodecane in polymer and material science applications: Dodecane finds applications in polymer and material science. It is used as a plasticizer, a component in polymer formulations, and in the production of specialty materials with specific properties for various industrial uses.

02 Applications in cosmetics and personal care products

Dodecane is used in various cosmetic and personal care formulations due to its emollient properties and ability to enhance product texture. It can be found in skincare products, hair care formulations, and fragrances. Dodecane helps improve the spreadability of products and can act as a carrier for other active ingredients.Expand Specific Solutions03 Use in industrial lubricants and solvents

Dodecane serves as a component in industrial lubricants and solvents due to its low viscosity and good solvency properties. It is used in metalworking fluids, cutting oils, and as a solvent in various industrial processes. Dodecane's chemical stability and low reactivity make it suitable for these applications.Expand Specific Solutions04 Role in fuel and energy applications

Dodecane is an important component in jet fuels and diesel fuels, contributing to their combustion properties and energy content. It is also studied as a potential biofuel or synthetic fuel component. Research focuses on improving its production from renewable sources and optimizing its performance in various engine types.Expand Specific Solutions05 Analytical and research applications

Dodecane is used as a standard or reference compound in various analytical and research applications. It serves as a model compound for studying hydrocarbon behavior, developing new catalysts, and in chromatography techniques. Dodecane's well-defined properties make it valuable for calibration and method development in scientific research.Expand Specific Solutions

Key Industry Players

The exploration of dodecane in coating technologies is currently in a nascent stage, with the market showing potential for growth as research progresses. The global coating industry, valued at over $150 billion, provides a substantial backdrop for this emerging technology. While the market size for dodecane-specific coatings is not yet clearly defined, it is expected to expand as applications are developed. Technologically, dodecane coatings are still in the early phases of development, with companies like PPG Industries, BASF Coatings, and Henkel AG & Co. KGaA leading research efforts. These industry giants, along with innovative players such as Wanhua Chemical Group and Evonik Operations, are exploring dodecane's potential to enhance coating performance, particularly in areas of durability and environmental sustainability.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed innovative coating technologies incorporating dodecane as a key component. Their approach involves using dodecane as a solvent and dispersing agent in high-performance coatings. The company has engineered a proprietary blend of dodecane with other aliphatic hydrocarbons to create a coating system that offers improved flow, leveling, and substrate wetting properties[1]. This formulation enhances the coating's ability to form a uniform film, resulting in superior surface finish and durability. PPG's dodecane-based coatings also demonstrate excellent resistance to weathering and chemical exposure, making them suitable for a wide range of industrial and automotive applications[3].

Strengths: Enhanced flow and leveling properties, improved durability, and chemical resistance. Weaknesses: Potential environmental concerns due to VOC content, may require specialized application equipment.

BASF Coatings GmbH

Technical Solution: BASF Coatings has integrated dodecane into their eco-friendly coating solutions. Their approach focuses on using dodecane as a bio-based alternative to traditional petroleum-derived solvents. BASF has developed a patented process that combines dodecane with renewable raw materials to create low-VOC, high-performance coatings[2]. This technology utilizes dodecane's excellent solvency and low surface tension to improve pigment dispersion and film formation. The resulting coatings offer enhanced scratch resistance and gloss retention, particularly in automotive clear coats and industrial protective coatings[4]. BASF's dodecane-based formulations also demonstrate improved drying times and reduced energy consumption during the curing process.

Strengths: Eco-friendly formulation, improved scratch resistance, and energy-efficient curing. Weaknesses: Higher production costs compared to conventional coatings, limited availability of bio-based dodecane.

Innovative Dodecane Patents

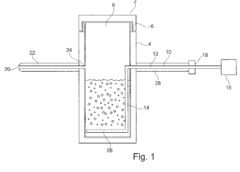

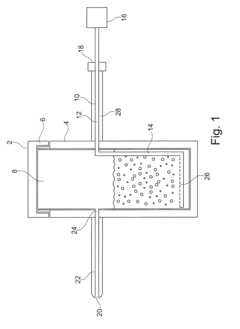

Application device for applying at least one sublimatable condensable compound, in particular of condensable cyclododecane, on surfaces of solid substrates or construction parts and device for determining the quality, in particular of the surface of a solid substrate or component

PatentInactiveEP2829328A1

Innovation

- A device with a heatable material container, gas inlet system, and application line allows for the controlled liquefaction and sublimation of cyclododecane onto surfaces, ensuring a homogeneous coating without crystallization or flocculation, using a heatable cover, flexible gas inlet sections, and a nozzle for precise application.

Aqueous coating material, its preparation and use

PatentInactiveUS20110318495A1

Innovation

- Aqueous coating material with a solubility parameter δ<10 (cal/cm3)1/2 and a specific branching ratio of CH and CH2 groups to CH3 groups, using branched aliphatic hydrocarbons as solvents, and incorporating a wetting agent or dispersant, which minimizes crater formation even in the presence of silicones.

Environmental Impact

The environmental impact of dodecane in coating technologies is a critical consideration for sustainable development and regulatory compliance. Dodecane, a hydrocarbon compound, has both positive and negative effects on the environment when used in coatings.

One of the primary environmental concerns associated with dodecane is its volatile organic compound (VOC) content. VOCs contribute to air pollution and can form ground-level ozone when released into the atmosphere. Coatings containing dodecane may release these compounds during application and curing processes, potentially impacting air quality and human health. However, compared to some other solvents used in coatings, dodecane has a relatively low vapor pressure, which can result in slower evaporation rates and potentially reduced VOC emissions.

Water pollution is another environmental aspect to consider. Although dodecane has low water solubility, improper disposal or accidental spills of coatings containing this compound can lead to contamination of water bodies. This can have adverse effects on aquatic ecosystems and potentially enter the food chain. However, the biodegradability of dodecane is relatively high compared to some other hydrocarbon solvents, which may mitigate long-term environmental persistence.

In terms of resource consumption, dodecane is derived from petroleum, a non-renewable resource. The extraction and processing of petroleum to produce dodecane contribute to carbon emissions and other environmental impacts associated with the fossil fuel industry. However, ongoing research into bio-based alternatives and sustainable production methods may offer more environmentally friendly options in the future.

The use of dodecane in coatings can also have indirect environmental benefits. For instance, coatings that incorporate dodecane may provide enhanced durability and weather resistance to surfaces, potentially extending the lifespan of coated materials. This can lead to reduced resource consumption and waste generation over time, as fewer replacements or repairs are needed.

From a lifecycle perspective, the environmental impact of dodecane in coatings extends beyond its immediate use. The production, transportation, and eventual disposal of coatings containing dodecane all contribute to its overall environmental footprint. Manufacturers and users of these coatings must consider end-of-life management, including proper disposal or recycling methods, to minimize environmental harm.

As environmental regulations become more stringent, there is increasing pressure on the coating industry to develop more sustainable alternatives. This has led to research into low-VOC and VOC-free formulations, as well as the exploration of bio-based solvents that could potentially replace dodecane in certain applications. The ongoing development of green chemistry principles and sustainable coating technologies may provide opportunities to mitigate the environmental impact of dodecane and similar compounds in the future.

One of the primary environmental concerns associated with dodecane is its volatile organic compound (VOC) content. VOCs contribute to air pollution and can form ground-level ozone when released into the atmosphere. Coatings containing dodecane may release these compounds during application and curing processes, potentially impacting air quality and human health. However, compared to some other solvents used in coatings, dodecane has a relatively low vapor pressure, which can result in slower evaporation rates and potentially reduced VOC emissions.

Water pollution is another environmental aspect to consider. Although dodecane has low water solubility, improper disposal or accidental spills of coatings containing this compound can lead to contamination of water bodies. This can have adverse effects on aquatic ecosystems and potentially enter the food chain. However, the biodegradability of dodecane is relatively high compared to some other hydrocarbon solvents, which may mitigate long-term environmental persistence.

In terms of resource consumption, dodecane is derived from petroleum, a non-renewable resource. The extraction and processing of petroleum to produce dodecane contribute to carbon emissions and other environmental impacts associated with the fossil fuel industry. However, ongoing research into bio-based alternatives and sustainable production methods may offer more environmentally friendly options in the future.

The use of dodecane in coatings can also have indirect environmental benefits. For instance, coatings that incorporate dodecane may provide enhanced durability and weather resistance to surfaces, potentially extending the lifespan of coated materials. This can lead to reduced resource consumption and waste generation over time, as fewer replacements or repairs are needed.

From a lifecycle perspective, the environmental impact of dodecane in coatings extends beyond its immediate use. The production, transportation, and eventual disposal of coatings containing dodecane all contribute to its overall environmental footprint. Manufacturers and users of these coatings must consider end-of-life management, including proper disposal or recycling methods, to minimize environmental harm.

As environmental regulations become more stringent, there is increasing pressure on the coating industry to develop more sustainable alternatives. This has led to research into low-VOC and VOC-free formulations, as well as the exploration of bio-based solvents that could potentially replace dodecane in certain applications. The ongoing development of green chemistry principles and sustainable coating technologies may provide opportunities to mitigate the environmental impact of dodecane and similar compounds in the future.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of dodecane in coating technologies. As the use of dodecane expands in various industries, manufacturers and end-users must navigate a complex landscape of regulations to ensure product safety, environmental protection, and legal compliance.

In the United States, the Environmental Protection Agency (EPA) regulates dodecane under the Toxic Substances Control Act (TSCA). Manufacturers and importers are required to comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety protocols when handling dodecane in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of dodecane in coating technologies within EU member states. Companies must register dodecane with the European Chemicals Agency (ECHA) and provide detailed information on its properties, uses, and potential risks. The Classification, Labeling, and Packaging (CLP) regulation further ensures that hazards associated with dodecane are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the registration and management of new chemical substances, including dodecane, through the Measures for Environmental Management of New Chemical Substances. Japan's Chemical Substances Control Law (CSCL) requires manufacturers and importers to notify the government of new chemical substances and comply with safety assessment procedures.

Globally, the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Many countries have adopted GHS principles, which affects the labeling and safety data sheet requirements for dodecane-based coating products.

As environmental concerns grow, regulations are evolving to address volatile organic compound (VOC) emissions. Dodecane, being a VOC, is subject to increasingly stringent emission limits in many jurisdictions. For instance, the California Air Resources Board (CARB) sets strict VOC limits for various coating applications, influencing product formulations and application methods.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach from companies involved in dodecane-based coating technologies. This includes maintaining up-to-date chemical inventories, conducting thorough risk assessments, implementing robust safety measures, and staying informed about regulatory changes across different markets. Failure to comply can result in significant penalties, product recalls, and reputational damage.

In the United States, the Environmental Protection Agency (EPA) regulates dodecane under the Toxic Substances Control Act (TSCA). Manufacturers and importers are required to comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety protocols when handling dodecane in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of dodecane in coating technologies within EU member states. Companies must register dodecane with the European Chemicals Agency (ECHA) and provide detailed information on its properties, uses, and potential risks. The Classification, Labeling, and Packaging (CLP) regulation further ensures that hazards associated with dodecane are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the registration and management of new chemical substances, including dodecane, through the Measures for Environmental Management of New Chemical Substances. Japan's Chemical Substances Control Law (CSCL) requires manufacturers and importers to notify the government of new chemical substances and comply with safety assessment procedures.

Globally, the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Many countries have adopted GHS principles, which affects the labeling and safety data sheet requirements for dodecane-based coating products.

As environmental concerns grow, regulations are evolving to address volatile organic compound (VOC) emissions. Dodecane, being a VOC, is subject to increasingly stringent emission limits in many jurisdictions. For instance, the California Air Resources Board (CARB) sets strict VOC limits for various coating applications, influencing product formulations and application methods.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach from companies involved in dodecane-based coating technologies. This includes maintaining up-to-date chemical inventories, conducting thorough risk assessments, implementing robust safety measures, and staying informed about regulatory changes across different markets. Failure to comply can result in significant penalties, product recalls, and reputational damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!