Exploring Silicone Rubber's Role in Smart Grid Networks

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Grid Silicone Evolution

The evolution of silicone rubber in smart grid networks has been marked by significant technological advancements and innovative applications. Initially, silicone rubber was primarily used for its excellent insulating properties in traditional power transmission and distribution systems. However, as smart grid technology emerged, the role of silicone rubber expanded dramatically.

In the early stages of smart grid development, silicone rubber found its place in sensor technologies. Its flexibility and durability made it an ideal material for encapsulating various types of sensors used in monitoring grid performance. These sensors, protected by silicone rubber, could withstand harsh environmental conditions while providing accurate data on voltage fluctuations, temperature changes, and other critical parameters.

As smart grids became more sophisticated, the demand for advanced materials in power electronics increased. Silicone rubber's thermal management properties made it an excellent choice for heat dissipation in smart transformers and inverters. Its ability to maintain stability over a wide temperature range ensured the reliability of these crucial components in the evolving grid infrastructure.

The integration of renewable energy sources into smart grids presented new challenges, which silicone rubber helped address. In solar panel applications, silicone-based sealants and encapsulants improved the longevity and efficiency of photovoltaic cells. For wind turbines, silicone rubber components enhanced the durability of blade edges and electrical connections, contributing to increased energy production and reduced maintenance needs.

As smart grids became more interconnected, the importance of reliable communication systems grew. Silicone rubber played a vital role in protecting fiber optic cables and other communication infrastructure from environmental factors, ensuring uninterrupted data transmission across the grid. This was crucial for real-time monitoring and control of energy distribution.

Recent developments have seen silicone rubber being incorporated into smart materials with self-healing properties. These advanced composites can automatically repair minor damage, significantly extending the lifespan of grid components and reducing maintenance costs. Additionally, researchers are exploring the potential of silicone-based dielectric elastomers for energy harvesting applications within smart grids, potentially turning the grid infrastructure itself into a source of additional power.

The ongoing evolution of silicone rubber in smart grid networks continues to push the boundaries of material science and electrical engineering. As grid technologies advance, silicone rubber is expected to play an even more critical role in enhancing efficiency, reliability, and sustainability in our power systems.

In the early stages of smart grid development, silicone rubber found its place in sensor technologies. Its flexibility and durability made it an ideal material for encapsulating various types of sensors used in monitoring grid performance. These sensors, protected by silicone rubber, could withstand harsh environmental conditions while providing accurate data on voltage fluctuations, temperature changes, and other critical parameters.

As smart grids became more sophisticated, the demand for advanced materials in power electronics increased. Silicone rubber's thermal management properties made it an excellent choice for heat dissipation in smart transformers and inverters. Its ability to maintain stability over a wide temperature range ensured the reliability of these crucial components in the evolving grid infrastructure.

The integration of renewable energy sources into smart grids presented new challenges, which silicone rubber helped address. In solar panel applications, silicone-based sealants and encapsulants improved the longevity and efficiency of photovoltaic cells. For wind turbines, silicone rubber components enhanced the durability of blade edges and electrical connections, contributing to increased energy production and reduced maintenance needs.

As smart grids became more interconnected, the importance of reliable communication systems grew. Silicone rubber played a vital role in protecting fiber optic cables and other communication infrastructure from environmental factors, ensuring uninterrupted data transmission across the grid. This was crucial for real-time monitoring and control of energy distribution.

Recent developments have seen silicone rubber being incorporated into smart materials with self-healing properties. These advanced composites can automatically repair minor damage, significantly extending the lifespan of grid components and reducing maintenance costs. Additionally, researchers are exploring the potential of silicone-based dielectric elastomers for energy harvesting applications within smart grids, potentially turning the grid infrastructure itself into a source of additional power.

The ongoing evolution of silicone rubber in smart grid networks continues to push the boundaries of material science and electrical engineering. As grid technologies advance, silicone rubber is expected to play an even more critical role in enhancing efficiency, reliability, and sustainability in our power systems.

Market Demand Analysis

The market demand for silicone rubber in smart grid networks is experiencing significant growth, driven by the increasing adoption of smart grid technologies worldwide. As power distribution systems evolve to become more intelligent, efficient, and resilient, the unique properties of silicone rubber make it an ideal material for various applications within this sector.

One of the primary drivers of market demand is the need for improved insulation and protection of electrical components in smart grid infrastructure. Silicone rubber's excellent dielectric properties, coupled with its resistance to environmental factors such as UV radiation, ozone, and extreme temperatures, make it highly suitable for outdoor applications in power transmission and distribution systems. This has led to a growing demand for silicone rubber-based insulators, cable accessories, and protective coatings.

The smart grid market is also witnessing a surge in demand for sensors and monitoring devices, where silicone rubber plays a crucial role. Its flexibility, durability, and ability to withstand harsh conditions make it an ideal material for encapsulating sensitive electronic components used in smart meters, fault detectors, and other monitoring equipment. This trend is expected to continue as utilities invest in more advanced monitoring and control systems to enhance grid reliability and efficiency.

Furthermore, the increasing focus on renewable energy integration into smart grids is creating new opportunities for silicone rubber applications. Solar panel installations, wind turbines, and energy storage systems all require weather-resistant and durable materials for sealing, bonding, and insulation. Silicone rubber's ability to maintain its properties over long periods, even in extreme weather conditions, makes it a preferred choice for these applications.

The automotive sector's shift towards electric vehicles (EVs) and the associated charging infrastructure is another significant factor driving the demand for silicone rubber in smart grid networks. As EV charging stations become an integral part of smart grid systems, there is a growing need for reliable insulation and sealing materials that can withstand frequent use and varying environmental conditions.

In terms of market size, the global smart grid market is projected to grow substantially in the coming years, with a corresponding increase in demand for silicone rubber products. Regions such as North America, Europe, and Asia-Pacific are expected to lead this growth, driven by government initiatives to modernize power infrastructure and increase renewable energy adoption.

However, it's important to note that the market demand is not without challenges. The relatively higher cost of silicone rubber compared to some alternative materials may limit its adoption in certain applications. Additionally, the development of new materials with similar properties could potentially compete with silicone rubber in some market segments.

One of the primary drivers of market demand is the need for improved insulation and protection of electrical components in smart grid infrastructure. Silicone rubber's excellent dielectric properties, coupled with its resistance to environmental factors such as UV radiation, ozone, and extreme temperatures, make it highly suitable for outdoor applications in power transmission and distribution systems. This has led to a growing demand for silicone rubber-based insulators, cable accessories, and protective coatings.

The smart grid market is also witnessing a surge in demand for sensors and monitoring devices, where silicone rubber plays a crucial role. Its flexibility, durability, and ability to withstand harsh conditions make it an ideal material for encapsulating sensitive electronic components used in smart meters, fault detectors, and other monitoring equipment. This trend is expected to continue as utilities invest in more advanced monitoring and control systems to enhance grid reliability and efficiency.

Furthermore, the increasing focus on renewable energy integration into smart grids is creating new opportunities for silicone rubber applications. Solar panel installations, wind turbines, and energy storage systems all require weather-resistant and durable materials for sealing, bonding, and insulation. Silicone rubber's ability to maintain its properties over long periods, even in extreme weather conditions, makes it a preferred choice for these applications.

The automotive sector's shift towards electric vehicles (EVs) and the associated charging infrastructure is another significant factor driving the demand for silicone rubber in smart grid networks. As EV charging stations become an integral part of smart grid systems, there is a growing need for reliable insulation and sealing materials that can withstand frequent use and varying environmental conditions.

In terms of market size, the global smart grid market is projected to grow substantially in the coming years, with a corresponding increase in demand for silicone rubber products. Regions such as North America, Europe, and Asia-Pacific are expected to lead this growth, driven by government initiatives to modernize power infrastructure and increase renewable energy adoption.

However, it's important to note that the market demand is not without challenges. The relatively higher cost of silicone rubber compared to some alternative materials may limit its adoption in certain applications. Additionally, the development of new materials with similar properties could potentially compete with silicone rubber in some market segments.

Silicone Rubber Challenges

Silicone rubber, while offering numerous advantages in smart grid applications, faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the material's susceptibility to environmental degradation. Exposure to ultraviolet radiation, ozone, and extreme temperatures can lead to deterioration of the rubber's physical properties over time, potentially compromising its insulating capabilities and mechanical strength.

Another critical challenge lies in the electrical properties of silicone rubber. While it generally exhibits good dielectric strength, its electrical conductivity can increase under certain conditions, such as high humidity or contamination. This phenomenon, known as surface tracking, can lead to electrical failures and reduced reliability in smart grid components.

The manufacturing process of silicone rubber for smart grid applications also presents challenges. Achieving consistent quality and uniformity in large-scale production can be difficult, particularly when incorporating additives to enhance specific properties. Variations in the curing process or the distribution of fillers can result in inconsistent performance across different batches or components.

Silicone rubber's relatively high cost compared to traditional materials like EPDM or PVC is another significant hurdle. The economic feasibility of using silicone rubber in large-scale smart grid infrastructure projects often comes into question, especially in regions with budget constraints or developing economies.

The integration of smart functionalities into silicone rubber components poses additional challenges. Embedding sensors, conductive elements, or other smart features while maintaining the material's core properties requires advanced manufacturing techniques and careful material engineering. Balancing the incorporation of these smart elements with the rubber's insulating and mechanical properties is a complex task that demands ongoing research and development.

Recycling and end-of-life management of silicone rubber products used in smart grids is another area of concern. The material's durability, while advantageous during its service life, makes it challenging to recycle or dispose of in an environmentally friendly manner. Developing efficient recycling processes for silicone rubber components from smart grid networks is crucial for sustainable implementation.

Lastly, the long-term performance and reliability of silicone rubber in smart grid applications remain areas of uncertainty. As smart grids evolve and face new environmental and operational challenges, the ability of silicone rubber to maintain its properties and functionality over extended periods needs continuous evaluation and improvement.

Another critical challenge lies in the electrical properties of silicone rubber. While it generally exhibits good dielectric strength, its electrical conductivity can increase under certain conditions, such as high humidity or contamination. This phenomenon, known as surface tracking, can lead to electrical failures and reduced reliability in smart grid components.

The manufacturing process of silicone rubber for smart grid applications also presents challenges. Achieving consistent quality and uniformity in large-scale production can be difficult, particularly when incorporating additives to enhance specific properties. Variations in the curing process or the distribution of fillers can result in inconsistent performance across different batches or components.

Silicone rubber's relatively high cost compared to traditional materials like EPDM or PVC is another significant hurdle. The economic feasibility of using silicone rubber in large-scale smart grid infrastructure projects often comes into question, especially in regions with budget constraints or developing economies.

The integration of smart functionalities into silicone rubber components poses additional challenges. Embedding sensors, conductive elements, or other smart features while maintaining the material's core properties requires advanced manufacturing techniques and careful material engineering. Balancing the incorporation of these smart elements with the rubber's insulating and mechanical properties is a complex task that demands ongoing research and development.

Recycling and end-of-life management of silicone rubber products used in smart grids is another area of concern. The material's durability, while advantageous during its service life, makes it challenging to recycle or dispose of in an environmentally friendly manner. Developing efficient recycling processes for silicone rubber components from smart grid networks is crucial for sustainable implementation.

Lastly, the long-term performance and reliability of silicone rubber in smart grid applications remain areas of uncertainty. As smart grids evolve and face new environmental and operational challenges, the ability of silicone rubber to maintain its properties and functionality over extended periods needs continuous evaluation and improvement.

Current Silicone Solutions

01 Composition and formulation of silicone rubber

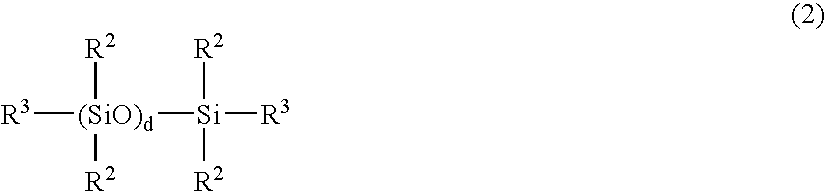

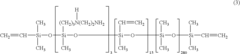

Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing properties.- Composition and formulation of silicone rubber: Silicone rubber compositions typically include a base polymer, curing agents, fillers, and additives. The formulation can be adjusted to achieve specific properties such as heat resistance, electrical insulation, or flexibility. Various methods of preparing and processing silicone rubber compounds are employed to optimize performance for different applications.

- Curing and vulcanization processes: Silicone rubber undergoes curing or vulcanization processes to achieve its final properties. This can involve heat-activated curing, room temperature vulcanization (RTV), or UV-curing methods. The choice of curing process and agents affects the final characteristics of the silicone rubber, such as hardness, elasticity, and chemical resistance.

- Modification and reinforcement techniques: Various techniques are used to modify and reinforce silicone rubber, including the incorporation of nanoparticles, fibers, or other polymers. These modifications can enhance mechanical strength, thermal stability, or introduce specific functionalities like self-healing properties or improved adhesion to other materials.

- Specialized silicone rubber formulations: Specialized silicone rubber formulations are developed for specific applications such as medical devices, automotive parts, or electronic components. These formulations may include additives for improved biocompatibility, flame retardancy, or electrical conductivity, tailoring the silicone rubber to meet industry-specific requirements.

- Processing and manufacturing methods: Various processing and manufacturing methods are employed for silicone rubber products, including injection molding, extrusion, compression molding, and 3D printing. Each method requires specific formulation adjustments and process parameters to ensure optimal product quality and performance. Innovations in manufacturing techniques continue to expand the possibilities for complex silicone rubber components.

02 Manufacturing processes for silicone rubber products

Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods, such as heat curing or room temperature vulcanization, are crucial steps in the production process.Expand Specific Solutions03 Modifications and improvements to silicone rubber properties

Researchers continually work on enhancing silicone rubber properties through various modifications. This includes incorporating nanoparticles, blending with other polymers, or chemically modifying the silicone backbone. Such improvements can lead to enhanced mechanical strength, thermal stability, or specific functionalities like self-healing or conductivity.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds widespread use across multiple industries due to its unique properties. It is commonly used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, chemical resistance, and durability make it suitable for diverse applications.Expand Specific Solutions05 Environmental considerations and sustainability of silicone rubber

As environmental concerns grow, there is increasing focus on the sustainability aspects of silicone rubber. This includes developing bio-based silicone materials, improving recycling methods for silicone products, and assessing the environmental impact of silicone rubber throughout its lifecycle. Efforts are being made to create more eco-friendly formulations and production processes.Expand Specific Solutions

Key Industry Players

The smart grid network market is in a growth phase, driven by increasing demand for efficient energy management and grid modernization. The global market size is projected to expand significantly in the coming years, with major players like State Grid Corporation of China and Apple Inc. investing heavily in this technology. The technical maturity varies across different aspects of smart grid networks, with some components like advanced metering infrastructure being relatively mature, while others like grid-scale energy storage are still evolving. Companies such as Shin-Etsu Chemical, Wacker Chemie, and Momentive Performance Materials are at the forefront of developing silicone rubber materials crucial for smart grid applications, leveraging their expertise in material science to enhance grid reliability and performance.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has made significant contributions to the development of silicone rubber materials for smart grid networks. Their KE series of silicone rubber compounds offers excellent electrical properties and thermal stability, making them suitable for a wide range of smart grid components[10]. Shin-Etsu has developed specialized silicone rubber formulations that provide enhanced tracking and erosion resistance, crucial for outdoor insulation applications in smart grids exposed to harsh environmental conditions[11]. The company has also introduced optically clear silicone rubber materials that can be used in smart meters and display devices within the smart grid ecosystem, combining electrical insulation with optical transparency[12]. Additionally, Shin-Etsu's research into liquid silicone rubber (LSR) technology has led to the development of complex-shaped components for smart grid connectors and seals, offering improved design flexibility and automated manufacturing processes[13].

Strengths: Wide range of specialized silicone rubber formulations, strong focus on material innovation. Weaknesses: May need to expand application-specific solutions to compete with more focused smart grid technology providers.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced silicone rubber compounds specifically designed for smart grid applications. Their ELASTOSIL® line of products offers excellent electrical insulation properties and long-term stability under various environmental conditions. These materials are engineered to withstand high temperatures, UV radiation, and electrical stress, making them ideal for outdoor use in smart grid infrastructure[1]. Wacker's silicone rubber compounds also feature self-healing properties, which can automatically repair minor damage caused by electrical discharges, enhancing the overall reliability of smart grid components[2]. The company has also introduced conductive silicone rubber formulations that can be used in electromagnetic shielding applications within smart grid networks, helping to protect sensitive electronic components from interference[3].

Strengths: Superior electrical insulation, long-term stability, and self-healing properties. Weaknesses: Higher cost compared to traditional materials, which may limit adoption in price-sensitive markets.

Innovative Silicone Tech

Silicone rubber composition and vulcanized object

PatentWO2016136275A1

Innovation

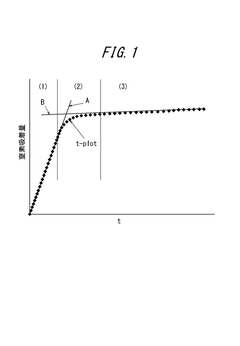

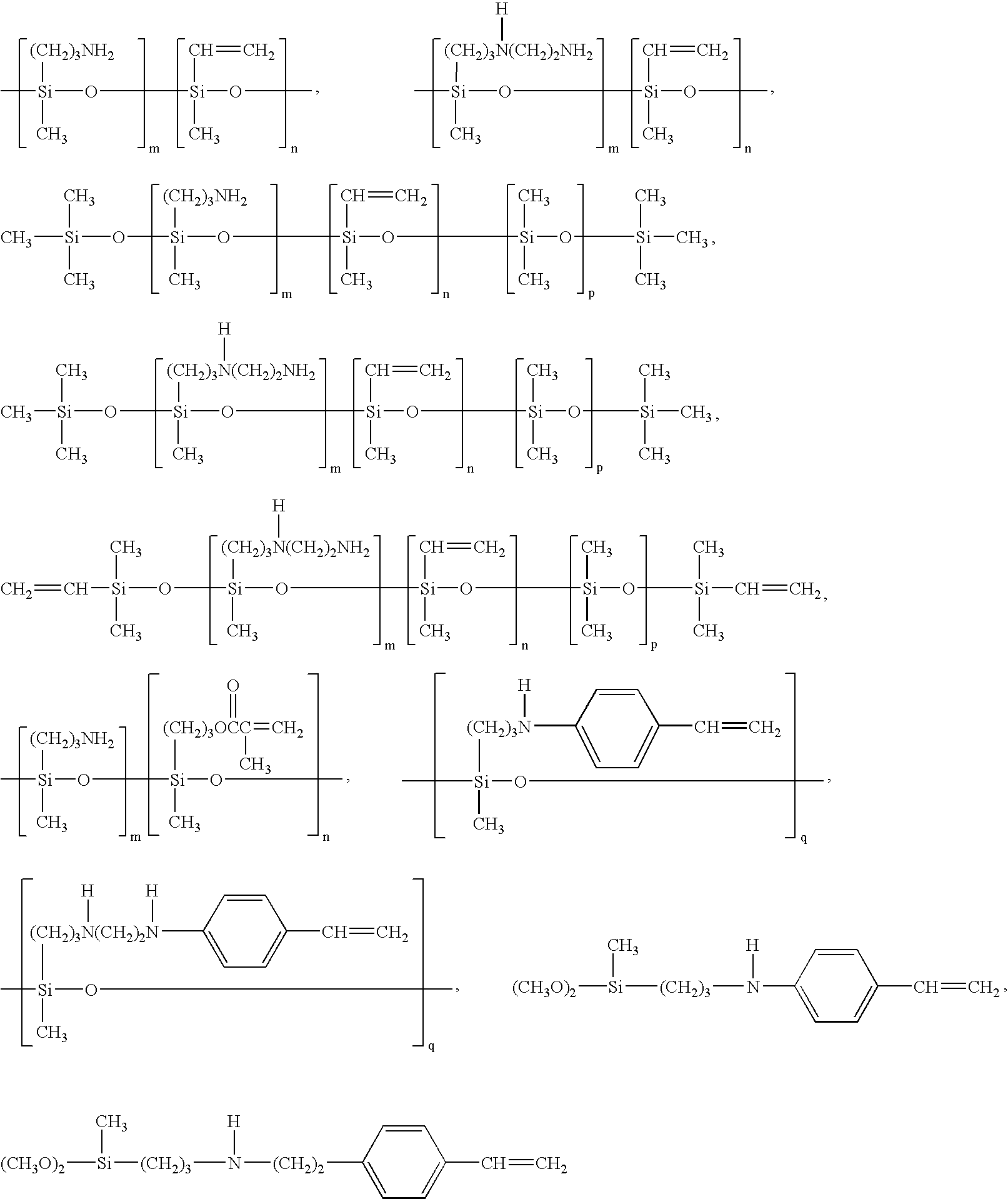

- Incorporating a fibrous carbon nanostructure with specific properties, such as an upwardly convex t-plot from nitrogen adsorption isotherm, and average diameters between 2-10 nm, along with graphite, to enhance conductivity while minimizing hardness increase.

Anti-tracking silicone rubber composition and power cable using the same

PatentInactiveUS6890662B2

Innovation

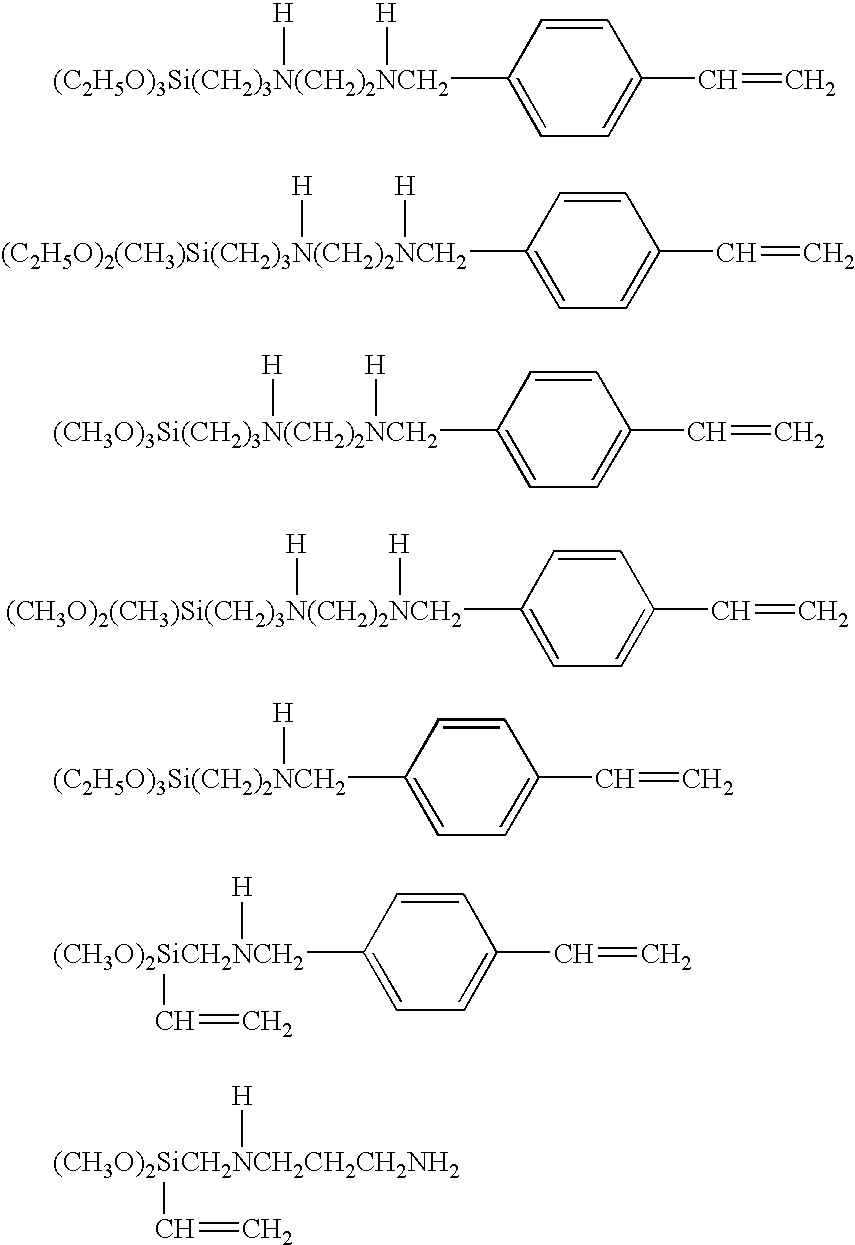

- A silicone rubber composition comprising organopolysiloxane components, microparticulate silica, platinum or platinum compounds, and an organosilicon compound with a nitrogenous organic group and unsaturated hydrocarbon group, along with a curing agent, which improves tracking resistance without using aluminum hydroxide, enhancing mechanical strength and electrical insulation.

Environmental Impact

The integration of silicone rubber in smart grid networks has significant environmental implications that warrant careful consideration. As a key component in various electrical insulation and protection applications, silicone rubber's environmental impact extends throughout its lifecycle, from production to disposal.

During the manufacturing process, silicone rubber production generally requires less energy compared to traditional rubber materials, resulting in a lower carbon footprint. The raw materials used in silicone rubber production, primarily silica and methyl chloride, are abundant and have relatively low environmental impact in their extraction. However, the process does involve the use of certain chemicals that require proper handling and disposal to prevent environmental contamination.

In its application within smart grid networks, silicone rubber contributes to improved energy efficiency and grid reliability. Its excellent electrical insulation properties help reduce energy losses in transmission and distribution systems, indirectly lowering overall energy consumption and associated greenhouse gas emissions. Additionally, the long lifespan and durability of silicone rubber components reduce the frequency of replacements, minimizing waste generation and resource consumption over time.

Silicone rubber's resistance to extreme temperatures, UV radiation, and harsh weather conditions makes it particularly suitable for outdoor applications in smart grid infrastructure. This resilience translates to reduced maintenance requirements and longer service life, further contributing to resource conservation and waste reduction. Moreover, its ability to withstand environmental stressors without degrading helps prevent the leaching of harmful substances into the surrounding ecosystem.

At the end of its life cycle, silicone rubber presents both challenges and opportunities from an environmental perspective. While it is not biodegradable, silicone rubber can be recycled through specialized processes. These recycling methods, although not yet widely implemented, offer the potential to recover valuable materials and reduce the environmental burden associated with disposal. However, the current limited availability of silicone rubber recycling facilities means that a significant portion still ends up in landfills or incineration plants.

The fire-resistant properties of silicone rubber also play a crucial role in environmental protection. By reducing the risk of electrical fires in smart grid components, it helps prevent the release of toxic fumes and pollutants that would otherwise result from burning electrical equipment. This aspect is particularly important in densely populated urban areas where the environmental and health impacts of such incidents can be severe.

In conclusion, while silicone rubber offers several environmental benefits in its application within smart grid networks, its overall environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on further improving its eco-friendly characteristics, including enhancing recyclability and exploring bio-based alternatives for certain components. As smart grid technologies continue to evolve, the environmental profile of silicone rubber will likely remain a key consideration in its widespread adoption and long-term sustainability.

During the manufacturing process, silicone rubber production generally requires less energy compared to traditional rubber materials, resulting in a lower carbon footprint. The raw materials used in silicone rubber production, primarily silica and methyl chloride, are abundant and have relatively low environmental impact in their extraction. However, the process does involve the use of certain chemicals that require proper handling and disposal to prevent environmental contamination.

In its application within smart grid networks, silicone rubber contributes to improved energy efficiency and grid reliability. Its excellent electrical insulation properties help reduce energy losses in transmission and distribution systems, indirectly lowering overall energy consumption and associated greenhouse gas emissions. Additionally, the long lifespan and durability of silicone rubber components reduce the frequency of replacements, minimizing waste generation and resource consumption over time.

Silicone rubber's resistance to extreme temperatures, UV radiation, and harsh weather conditions makes it particularly suitable for outdoor applications in smart grid infrastructure. This resilience translates to reduced maintenance requirements and longer service life, further contributing to resource conservation and waste reduction. Moreover, its ability to withstand environmental stressors without degrading helps prevent the leaching of harmful substances into the surrounding ecosystem.

At the end of its life cycle, silicone rubber presents both challenges and opportunities from an environmental perspective. While it is not biodegradable, silicone rubber can be recycled through specialized processes. These recycling methods, although not yet widely implemented, offer the potential to recover valuable materials and reduce the environmental burden associated with disposal. However, the current limited availability of silicone rubber recycling facilities means that a significant portion still ends up in landfills or incineration plants.

The fire-resistant properties of silicone rubber also play a crucial role in environmental protection. By reducing the risk of electrical fires in smart grid components, it helps prevent the release of toxic fumes and pollutants that would otherwise result from burning electrical equipment. This aspect is particularly important in densely populated urban areas where the environmental and health impacts of such incidents can be severe.

In conclusion, while silicone rubber offers several environmental benefits in its application within smart grid networks, its overall environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on further improving its eco-friendly characteristics, including enhancing recyclability and exploring bio-based alternatives for certain components. As smart grid technologies continue to evolve, the environmental profile of silicone rubber will likely remain a key consideration in its widespread adoption and long-term sustainability.

Regulatory Framework

The regulatory framework surrounding the integration of silicone rubber in smart grid networks is a complex and evolving landscape. As smart grid technologies continue to advance, regulatory bodies are adapting their policies to ensure the safe, efficient, and reliable implementation of these systems.

At the federal level, the Federal Energy Regulatory Commission (FERC) plays a crucial role in overseeing the development of smart grid infrastructure. FERC has established guidelines for the use of advanced materials, including silicone rubber, in grid components. These guidelines focus on ensuring the reliability and resilience of the power system, with specific attention to the durability and performance of materials under various environmental conditions.

The North American Electric Reliability Corporation (NERC) has also developed standards that impact the use of silicone rubber in smart grid applications. NERC's Critical Infrastructure Protection (CIP) standards address cybersecurity concerns, which extend to the materials used in grid components. Silicone rubber's potential to enhance the security and reliability of smart grid networks must be demonstrated in compliance with these standards.

State-level regulations further shape the landscape for silicone rubber adoption in smart grids. Public Utility Commissions (PUCs) in various states have established guidelines for grid modernization projects, which often include specifications for materials used in infrastructure upgrades. These regulations may influence the selection of silicone rubber-based components, particularly in areas prone to extreme weather conditions or environmental challenges.

Environmental regulations also play a significant role in the regulatory framework. The Environmental Protection Agency (EPA) has set standards for the manufacturing and disposal of materials used in electrical infrastructure. Silicone rubber's environmental impact, including its production process and end-of-life management, must be considered in light of these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidance for the use of silicone rubber in smart grid applications. These standards often inform domestic regulations and industry practices, ensuring a level of global consistency in the approach to material selection and implementation.

As the smart grid landscape continues to evolve, regulatory bodies are likely to refine their frameworks to address emerging technologies and materials. This may include specific provisions for the use of advanced polymers like silicone rubber, particularly as their benefits in enhancing grid resilience and efficiency become more apparent. Stakeholders in the smart grid sector must remain vigilant and adaptable to these regulatory changes to ensure compliance and maximize the potential of silicone rubber in grid modernization efforts.

At the federal level, the Federal Energy Regulatory Commission (FERC) plays a crucial role in overseeing the development of smart grid infrastructure. FERC has established guidelines for the use of advanced materials, including silicone rubber, in grid components. These guidelines focus on ensuring the reliability and resilience of the power system, with specific attention to the durability and performance of materials under various environmental conditions.

The North American Electric Reliability Corporation (NERC) has also developed standards that impact the use of silicone rubber in smart grid applications. NERC's Critical Infrastructure Protection (CIP) standards address cybersecurity concerns, which extend to the materials used in grid components. Silicone rubber's potential to enhance the security and reliability of smart grid networks must be demonstrated in compliance with these standards.

State-level regulations further shape the landscape for silicone rubber adoption in smart grids. Public Utility Commissions (PUCs) in various states have established guidelines for grid modernization projects, which often include specifications for materials used in infrastructure upgrades. These regulations may influence the selection of silicone rubber-based components, particularly in areas prone to extreme weather conditions or environmental challenges.

Environmental regulations also play a significant role in the regulatory framework. The Environmental Protection Agency (EPA) has set standards for the manufacturing and disposal of materials used in electrical infrastructure. Silicone rubber's environmental impact, including its production process and end-of-life management, must be considered in light of these regulations.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide additional guidance for the use of silicone rubber in smart grid applications. These standards often inform domestic regulations and industry practices, ensuring a level of global consistency in the approach to material selection and implementation.

As the smart grid landscape continues to evolve, regulatory bodies are likely to refine their frameworks to address emerging technologies and materials. This may include specific provisions for the use of advanced polymers like silicone rubber, particularly as their benefits in enhancing grid resilience and efficiency become more apparent. Stakeholders in the smart grid sector must remain vigilant and adaptable to these regulatory changes to ensure compliance and maximize the potential of silicone rubber in grid modernization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!