Innovative Silicone Rubber Use in Luxury Goods Production

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Luxury Goods: Background and Objectives

Silicone rubber has emerged as a revolutionary material in the luxury goods industry, offering a unique combination of versatility, durability, and aesthetic appeal. The evolution of this synthetic polymer dates back to the 1940s, with its initial applications primarily in industrial and medical fields. However, over the past few decades, silicone rubber has found its way into high-end consumer products, particularly in the luxury sector.

The luxury goods market has always been driven by innovation, exclusivity, and superior quality. As consumer preferences shift towards more sustainable and technologically advanced products, luxury brands are constantly seeking new materials and manufacturing techniques to maintain their competitive edge. Silicone rubber, with its exceptional properties, has become a material of choice for many luxury goods manufacturers.

The primary objective of researching innovative silicone rubber applications in luxury goods production is to explore new possibilities for product design, enhance performance characteristics, and create unique sensory experiences for consumers. This research aims to push the boundaries of traditional luxury materials, offering alternatives that can potentially outperform conventional options in terms of durability, flexibility, and customization potential.

One of the key drivers behind this research is the growing demand for sustainable and eco-friendly luxury products. Silicone rubber, being inert and recyclable, aligns well with the sustainability goals of many luxury brands. By developing innovative applications of silicone rubber, companies can address environmental concerns while maintaining the high standards expected in the luxury market.

The technical evolution of silicone rubber has seen significant advancements in recent years. Improved formulations have led to enhanced properties such as increased heat resistance, better color stability, and improved tactile qualities. These developments have opened up new avenues for its application in luxury goods, ranging from high-end watches and jewelry to fashion accessories and home decor items.

As the luxury market continues to evolve, there is a growing trend towards personalization and unique experiences. Silicone rubber's moldability and ability to be infused with various textures and colors make it an ideal material for creating bespoke luxury items. This aligns perfectly with the luxury sector's move towards offering more personalized and exclusive products to discerning consumers.

The research into innovative silicone rubber applications also aims to address some of the challenges faced by traditional luxury materials. For instance, silicone rubber's resistance to environmental factors such as UV radiation, extreme temperatures, and moisture makes it a promising alternative to certain natural materials that may degrade over time. This durability factor is particularly crucial in maintaining the longevity and value of luxury goods.

The luxury goods market has always been driven by innovation, exclusivity, and superior quality. As consumer preferences shift towards more sustainable and technologically advanced products, luxury brands are constantly seeking new materials and manufacturing techniques to maintain their competitive edge. Silicone rubber, with its exceptional properties, has become a material of choice for many luxury goods manufacturers.

The primary objective of researching innovative silicone rubber applications in luxury goods production is to explore new possibilities for product design, enhance performance characteristics, and create unique sensory experiences for consumers. This research aims to push the boundaries of traditional luxury materials, offering alternatives that can potentially outperform conventional options in terms of durability, flexibility, and customization potential.

One of the key drivers behind this research is the growing demand for sustainable and eco-friendly luxury products. Silicone rubber, being inert and recyclable, aligns well with the sustainability goals of many luxury brands. By developing innovative applications of silicone rubber, companies can address environmental concerns while maintaining the high standards expected in the luxury market.

The technical evolution of silicone rubber has seen significant advancements in recent years. Improved formulations have led to enhanced properties such as increased heat resistance, better color stability, and improved tactile qualities. These developments have opened up new avenues for its application in luxury goods, ranging from high-end watches and jewelry to fashion accessories and home decor items.

As the luxury market continues to evolve, there is a growing trend towards personalization and unique experiences. Silicone rubber's moldability and ability to be infused with various textures and colors make it an ideal material for creating bespoke luxury items. This aligns perfectly with the luxury sector's move towards offering more personalized and exclusive products to discerning consumers.

The research into innovative silicone rubber applications also aims to address some of the challenges faced by traditional luxury materials. For instance, silicone rubber's resistance to environmental factors such as UV radiation, extreme temperatures, and moisture makes it a promising alternative to certain natural materials that may degrade over time. This durability factor is particularly crucial in maintaining the longevity and value of luxury goods.

Market Analysis for Silicone-Based Luxury Products

The luxury goods market has shown a growing interest in innovative materials that can enhance product quality, durability, and uniqueness. Silicone rubber, traditionally used in industrial applications, has emerged as a potential game-changer in the luxury sector. Market analysis reveals a significant opportunity for silicone-based luxury products, driven by consumer demand for high-performance, sustainable, and versatile materials.

The global luxury goods market, valued at approximately $1.2 trillion in 2021, is projected to grow at a CAGR of 5-6% over the next five years. Within this market, there is an increasing focus on material innovation, with silicone rubber presenting a promising avenue for product differentiation. Luxury brands are exploring silicone's unique properties, such as its flexibility, durability, and resistance to extreme temperatures and chemicals, to create novel product offerings.

Consumer trends indicate a shift towards more practical and resilient luxury items, particularly in accessories, wearables, and home goods. Silicone-based luxury products align well with these preferences, offering a combination of high-end aesthetics and functional benefits. Market research suggests that consumers are willing to pay a premium for luxury items that incorporate innovative materials, with 68% of luxury consumers expressing interest in products that offer enhanced durability and versatility.

The potential market for silicone-based luxury products spans several categories. In the accessories segment, silicone rubber is being explored for high-end watch straps, jewelry, and handbag components. The wearable technology sector, a rapidly growing niche within luxury goods, is also leveraging silicone's properties for smart accessories and fitness trackers. Additionally, the home goods and interior design markets are showing interest in silicone-based luxury items for their unique tactile qualities and customization potential.

Geographically, the market for silicone-based luxury products is expected to see strong growth in Asia-Pacific, particularly in China and Japan, where there is a high appetite for innovative luxury goods. North America and Europe are also significant markets, with consumers in these regions showing increasing interest in sustainable and technologically advanced luxury items.

However, challenges exist in market penetration. Luxury brands must overcome the perception of silicone as a non-premium material and educate consumers on its advanced properties. Marketing strategies will need to focus on highlighting the material's innovative aspects, sustainability credentials, and enhanced user experience to justify premium pricing.

In conclusion, the market analysis for silicone-based luxury products reveals a promising opportunity for growth and innovation in the luxury goods sector. By leveraging the unique properties of silicone rubber, luxury brands can create differentiated products that meet evolving consumer demands for performance, sustainability, and exclusivity.

The global luxury goods market, valued at approximately $1.2 trillion in 2021, is projected to grow at a CAGR of 5-6% over the next five years. Within this market, there is an increasing focus on material innovation, with silicone rubber presenting a promising avenue for product differentiation. Luxury brands are exploring silicone's unique properties, such as its flexibility, durability, and resistance to extreme temperatures and chemicals, to create novel product offerings.

Consumer trends indicate a shift towards more practical and resilient luxury items, particularly in accessories, wearables, and home goods. Silicone-based luxury products align well with these preferences, offering a combination of high-end aesthetics and functional benefits. Market research suggests that consumers are willing to pay a premium for luxury items that incorporate innovative materials, with 68% of luxury consumers expressing interest in products that offer enhanced durability and versatility.

The potential market for silicone-based luxury products spans several categories. In the accessories segment, silicone rubber is being explored for high-end watch straps, jewelry, and handbag components. The wearable technology sector, a rapidly growing niche within luxury goods, is also leveraging silicone's properties for smart accessories and fitness trackers. Additionally, the home goods and interior design markets are showing interest in silicone-based luxury items for their unique tactile qualities and customization potential.

Geographically, the market for silicone-based luxury products is expected to see strong growth in Asia-Pacific, particularly in China and Japan, where there is a high appetite for innovative luxury goods. North America and Europe are also significant markets, with consumers in these regions showing increasing interest in sustainable and technologically advanced luxury items.

However, challenges exist in market penetration. Luxury brands must overcome the perception of silicone as a non-premium material and educate consumers on its advanced properties. Marketing strategies will need to focus on highlighting the material's innovative aspects, sustainability credentials, and enhanced user experience to justify premium pricing.

In conclusion, the market analysis for silicone-based luxury products reveals a promising opportunity for growth and innovation in the luxury goods sector. By leveraging the unique properties of silicone rubber, luxury brands can create differentiated products that meet evolving consumer demands for performance, sustainability, and exclusivity.

Current Challenges in Silicone Rubber Luxury Applications

The luxury goods industry faces several challenges in incorporating silicone rubber into high-end products. One of the primary obstacles is achieving the desired level of quality and aesthetics that luxury consumers expect. Silicone rubber, while versatile and durable, often lacks the premium look and feel associated with traditional luxury materials like leather, precious metals, or fine fabrics. Manufacturers struggle to replicate the tactile sensations and visual appeal of these materials using silicone rubber, which can sometimes be perceived as less sophisticated or lower quality.

Another significant challenge is the integration of silicone rubber with other luxury materials. Luxury goods often combine multiple high-end components, and ensuring seamless compatibility between silicone rubber and materials like gold, diamonds, or exotic leathers presents technical difficulties. Issues such as adhesion, color matching, and maintaining structural integrity over time need to be addressed to meet the exacting standards of luxury brands.

Customization and personalization are crucial in the luxury sector, and silicone rubber poses challenges in this regard. Traditional luxury materials can be easily embossed, engraved, or otherwise customized, while silicone rubber requires different techniques to achieve similar effects. Developing methods to create intricate designs, patterns, or personalized elements on silicone rubber surfaces that match the sophistication of luxury goods is an ongoing challenge for manufacturers.

Durability and aging are also concerns when using silicone rubber in luxury applications. While silicone rubber is known for its resilience, ensuring that it maintains its appearance and properties over extended periods, especially when exposed to various environmental factors, is crucial for luxury products that are often considered long-term investments.

The environmental impact of silicone rubber production and disposal is another challenge that luxury brands must address. As sustainability becomes increasingly important to consumers, particularly in the luxury sector, finding eco-friendly alternatives or improving the sustainability of silicone rubber manufacturing processes is a pressing issue.

Lastly, there is the challenge of perception and marketing. Luxury brands must overcome potential consumer skepticism about the use of silicone rubber in high-end products. Educating customers about the benefits and innovative applications of silicone rubber while maintaining the allure and exclusivity associated with luxury goods requires careful branding and communication strategies.

Another significant challenge is the integration of silicone rubber with other luxury materials. Luxury goods often combine multiple high-end components, and ensuring seamless compatibility between silicone rubber and materials like gold, diamonds, or exotic leathers presents technical difficulties. Issues such as adhesion, color matching, and maintaining structural integrity over time need to be addressed to meet the exacting standards of luxury brands.

Customization and personalization are crucial in the luxury sector, and silicone rubber poses challenges in this regard. Traditional luxury materials can be easily embossed, engraved, or otherwise customized, while silicone rubber requires different techniques to achieve similar effects. Developing methods to create intricate designs, patterns, or personalized elements on silicone rubber surfaces that match the sophistication of luxury goods is an ongoing challenge for manufacturers.

Durability and aging are also concerns when using silicone rubber in luxury applications. While silicone rubber is known for its resilience, ensuring that it maintains its appearance and properties over extended periods, especially when exposed to various environmental factors, is crucial for luxury products that are often considered long-term investments.

The environmental impact of silicone rubber production and disposal is another challenge that luxury brands must address. As sustainability becomes increasingly important to consumers, particularly in the luxury sector, finding eco-friendly alternatives or improving the sustainability of silicone rubber manufacturing processes is a pressing issue.

Lastly, there is the challenge of perception and marketing. Luxury brands must overcome potential consumer skepticism about the use of silicone rubber in high-end products. Educating customers about the benefits and innovative applications of silicone rubber while maintaining the allure and exclusivity associated with luxury goods requires careful branding and communication strategies.

Existing Silicone Solutions in Luxury Goods Production

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness. Such modifications allow for the customization of silicone rubber for various applications.

- Silicone rubber in medical and healthcare applications: Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be found in medical devices, implants, prosthetics, and various healthcare products. The material's properties make it suitable for long-term contact with human tissue and bodily fluids.

- Silicone rubber in electronic and electrical applications: Silicone rubber is utilized in various electronic and electrical applications due to its excellent insulating properties and resistance to extreme temperatures. It can be found in cable insulation, gaskets, seals, and other components in electronic devices and electrical systems. The material's stability and durability contribute to the reliability of these applications.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. These combinations can improve characteristics such as tear strength, abrasion resistance, or chemical resistance. The resulting materials find applications in industries ranging from automotive to aerospace.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare products due to its biocompatibility, flexibility, and durability. Applications include medical implants, prosthetics, drug delivery systems, and various medical devices. Special formulations may be developed to meet specific medical requirements such as antimicrobial properties or controlled drug release.Expand Specific Solutions04 Silicone rubber in industrial and consumer products

Silicone rubber finds extensive use in industrial and consumer products due to its unique combination of properties. It is used in automotive parts, electrical insulation, cookware, sealants, and various household items. The material's heat resistance, electrical insulation properties, and durability make it suitable for a wide range of applications.Expand Specific Solutions05 Advanced processing techniques for silicone rubber

Advanced processing techniques are being developed to enhance the manufacturing and performance of silicone rubber products. These may include novel curing methods, precision molding techniques, or the integration of silicone rubber with other materials to create composite structures. Such advancements aim to improve product quality, reduce production costs, or enable new applications.Expand Specific Solutions

Key Players in Silicone and Luxury Goods Industries

The research on innovative silicone rubber use in luxury goods production is in a growth phase, with increasing market size and technological advancements. The global silicone market is expanding, driven by demand in various industries, including luxury goods. Key players like Shin-Etsu Chemical, Wacker Chemie, and Dow Silicones are leading the technological development, with a focus on enhancing material properties and performance. Companies such as Momentive Performance Materials and Evonik Operations are also contributing to the competitive landscape, pushing for more sophisticated silicone applications. The technology is maturing, with ongoing research at institutions like Beijing University of Chemical Technology and Shandong University, indicating potential for further innovations in luxury goods manufacturing.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed innovative silicone rubber compounds specifically tailored for luxury goods production. Their advanced formulations offer enhanced durability and aesthetic properties, including a unique soft-touch feel and improved color stability[1]. The company has introduced a new line of silicone elastomers that provide excellent resistance to environmental factors such as UV radiation and extreme temperatures, making them ideal for high-end outdoor accessories[2]. Additionally, Shin-Etsu has pioneered a proprietary cross-linking technology that allows for intricate molding and shaping of silicone parts, enabling luxury brands to create complex and detailed designs previously unattainable with traditional materials[3].

Strengths: Superior material properties, extensive R&D capabilities, and a wide range of customizable solutions. Weaknesses: Higher cost compared to conventional materials, which may limit adoption in some market segments.

Wacker Chemie AG

Technical Solution: Wacker Chemie has developed ELASTOSIL® LR 3003/60, a liquid silicone rubber specifically designed for luxury goods production. This material offers excellent transparency and can be easily pigmented to achieve vibrant, long-lasting colors[4]. The company has also introduced SILPURAN® silicone elastomers, which provide biocompatibility and skin-friendliness, making them suitable for wearable luxury items[5]. Wacker's innovative SEMICOSIL® range combines the properties of silicone rubber with those of thermoplastics, allowing for the creation of unique textures and finishes in luxury products[6]. Furthermore, their ELASTOSIL® Film technology enables the production of ultra-thin, flexible silicone sheets that can be used in high-end fashion and accessories[7].

Strengths: Wide range of specialized silicone products, strong focus on sustainability, and extensive technical support. Weaknesses: May face challenges in scaling production to meet increasing demand in the luxury sector.

Innovative Silicone Rubber Formulations and Processes

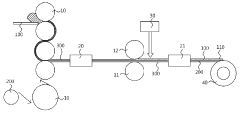

A synthetic leather using silicone rubber

PatentActiveKR1020170066940A

Innovation

- A method involving direct coating of uncured silicone on fabric using a roller or knife, followed by patterning with a heat roller and a secondary coating of a surface treatment agent, eliminating the need for release paper and peeling, and utilizing a mixture of addition and peroxide cure type silicones to enhance properties.

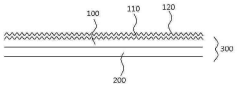

Artificial leather having excellent rubbing fastness and method for manufacturing same

PatentWO2015046917A1

Innovation

- The use of solvent-free liquid silicone rubber as an impregnation material for a non-woven fabric with microfine fibers, combined with a disperse dyeing process, simplifies the manufacturing process and enhances friction fastness without the need for organic solvents, improving both dry and wet friction resistance.

Sustainability Aspects of Silicone in Luxury Goods

The integration of silicone rubber in luxury goods production presents a unique opportunity to enhance sustainability practices within the industry. Silicone rubber, known for its durability and versatility, offers several environmental advantages over traditional materials used in luxury items.

One of the primary sustainability benefits of silicone rubber is its longevity. Luxury goods made with silicone components tend to have extended lifespans, reducing the need for frequent replacements and minimizing waste generation. This durability aligns well with the luxury sector's emphasis on quality and longevity, contributing to a more sustainable consumption model.

Silicone rubber's resistance to degradation from environmental factors such as UV radiation, extreme temperatures, and moisture further enhances its sustainability profile. This resilience ensures that luxury products maintain their appearance and functionality over time, reducing the likelihood of premature disposal and the associated environmental impact.

The production process of silicone rubber also offers sustainability advantages. Compared to some traditional materials used in luxury goods, silicone manufacturing typically requires less energy and water, resulting in a lower carbon footprint. Additionally, silicone production generates fewer byproducts and waste materials, contributing to a cleaner manufacturing process.

Recyclability is another key aspect of silicone's sustainability in luxury goods. While not as widely recycled as some other materials, silicone can be repurposed or recycled at the end of its life cycle. Innovative recycling technologies are emerging, allowing for the recovery and reuse of silicone materials, further reducing the environmental impact of luxury products.

The non-toxic nature of silicone rubber is particularly relevant in the context of luxury goods, which often come into direct contact with the skin. Unlike some synthetic materials that may release harmful chemicals over time, silicone remains stable and safe for long-term use, aligning with growing consumer demand for health-conscious and environmentally friendly products.

Furthermore, the versatility of silicone rubber allows for innovative design approaches that can reduce material usage and improve overall product efficiency. This adaptability enables luxury brands to create more streamlined, resource-efficient products without compromising on quality or aesthetics.

As the luxury industry faces increasing pressure to adopt more sustainable practices, the incorporation of silicone rubber presents a viable solution. By leveraging the material's inherent sustainability benefits, luxury brands can enhance their environmental credentials while maintaining the high standards of quality and performance expected by their discerning clientele.

One of the primary sustainability benefits of silicone rubber is its longevity. Luxury goods made with silicone components tend to have extended lifespans, reducing the need for frequent replacements and minimizing waste generation. This durability aligns well with the luxury sector's emphasis on quality and longevity, contributing to a more sustainable consumption model.

Silicone rubber's resistance to degradation from environmental factors such as UV radiation, extreme temperatures, and moisture further enhances its sustainability profile. This resilience ensures that luxury products maintain their appearance and functionality over time, reducing the likelihood of premature disposal and the associated environmental impact.

The production process of silicone rubber also offers sustainability advantages. Compared to some traditional materials used in luxury goods, silicone manufacturing typically requires less energy and water, resulting in a lower carbon footprint. Additionally, silicone production generates fewer byproducts and waste materials, contributing to a cleaner manufacturing process.

Recyclability is another key aspect of silicone's sustainability in luxury goods. While not as widely recycled as some other materials, silicone can be repurposed or recycled at the end of its life cycle. Innovative recycling technologies are emerging, allowing for the recovery and reuse of silicone materials, further reducing the environmental impact of luxury products.

The non-toxic nature of silicone rubber is particularly relevant in the context of luxury goods, which often come into direct contact with the skin. Unlike some synthetic materials that may release harmful chemicals over time, silicone remains stable and safe for long-term use, aligning with growing consumer demand for health-conscious and environmentally friendly products.

Furthermore, the versatility of silicone rubber allows for innovative design approaches that can reduce material usage and improve overall product efficiency. This adaptability enables luxury brands to create more streamlined, resource-efficient products without compromising on quality or aesthetics.

As the luxury industry faces increasing pressure to adopt more sustainable practices, the incorporation of silicone rubber presents a viable solution. By leveraging the material's inherent sustainability benefits, luxury brands can enhance their environmental credentials while maintaining the high standards of quality and performance expected by their discerning clientele.

Consumer Perception of Silicone in Luxury Products

Consumer perception of silicone in luxury products has evolved significantly over the years, influenced by technological advancements, marketing strategies, and changing consumer preferences. Initially, silicone was often associated with lower-quality, mass-produced items, which created a barrier for its acceptance in the luxury goods sector. However, as innovative applications of silicone rubber have emerged, consumer attitudes have begun to shift.

One of the key factors driving this change is the unique properties of silicone rubber, such as its durability, flexibility, and resistance to extreme temperatures. These characteristics have allowed luxury brands to create products that offer enhanced functionality without compromising on aesthetics. For instance, high-end watchmakers have incorporated silicone components into their timepieces, promoting improved accuracy and longevity.

The tactile experience of silicone has also played a crucial role in shaping consumer perception. Many luxury consumers appreciate the soft, smooth texture of silicone, which can provide a comfortable and luxurious feel. This has led to its use in various accessories, from watch straps to handbag linings, where the material's sensory qualities enhance the overall product experience.

Sustainability concerns have further influenced consumer attitudes towards silicone in luxury goods. As eco-conscious consumers seek more environmentally friendly options, silicone's durability and potential for recycling have become attractive features. Luxury brands that emphasize the longevity and recyclability of their silicone-based products have found resonance with this growing segment of environmentally aware customers.

However, challenges remain in fully integrating silicone into the luxury market. Some consumers still associate the material with lower-end products, necessitating careful marketing and education efforts by luxury brands. The key lies in highlighting the innovative applications and superior performance of high-quality silicone rubber, distinguishing it from its more common counterparts.

The perception of silicone in luxury products also varies across different product categories. While it may be readily accepted in technical luxury items like watches or high-performance accessories, its use in traditional luxury categories such as jewelry or haute couture fashion may face more resistance. Brands must navigate these varying perceptions carefully, tailoring their approach to each specific product line and target audience.

As luxury brands continue to innovate with silicone rubber, consumer perception is likely to evolve further. The success of silicone in luxury goods will depend on brands' ability to communicate its benefits effectively, integrate it seamlessly into high-end designs, and align its use with the values of luxury consumers, particularly in terms of quality, exclusivity, and sustainability.

One of the key factors driving this change is the unique properties of silicone rubber, such as its durability, flexibility, and resistance to extreme temperatures. These characteristics have allowed luxury brands to create products that offer enhanced functionality without compromising on aesthetics. For instance, high-end watchmakers have incorporated silicone components into their timepieces, promoting improved accuracy and longevity.

The tactile experience of silicone has also played a crucial role in shaping consumer perception. Many luxury consumers appreciate the soft, smooth texture of silicone, which can provide a comfortable and luxurious feel. This has led to its use in various accessories, from watch straps to handbag linings, where the material's sensory qualities enhance the overall product experience.

Sustainability concerns have further influenced consumer attitudes towards silicone in luxury goods. As eco-conscious consumers seek more environmentally friendly options, silicone's durability and potential for recycling have become attractive features. Luxury brands that emphasize the longevity and recyclability of their silicone-based products have found resonance with this growing segment of environmentally aware customers.

However, challenges remain in fully integrating silicone into the luxury market. Some consumers still associate the material with lower-end products, necessitating careful marketing and education efforts by luxury brands. The key lies in highlighting the innovative applications and superior performance of high-quality silicone rubber, distinguishing it from its more common counterparts.

The perception of silicone in luxury products also varies across different product categories. While it may be readily accepted in technical luxury items like watches or high-performance accessories, its use in traditional luxury categories such as jewelry or haute couture fashion may face more resistance. Brands must navigate these varying perceptions carefully, tailoring their approach to each specific product line and target audience.

As luxury brands continue to innovate with silicone rubber, consumer perception is likely to evolve further. The success of silicone in luxury goods will depend on brands' ability to communicate its benefits effectively, integrate it seamlessly into high-end designs, and align its use with the values of luxury consumers, particularly in terms of quality, exclusivity, and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!