Exploring Advanced Silicone Rubber Dielectric Properties

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Dielectric Evolution and Objectives

Silicone rubber has been a subject of extensive research and development in the field of dielectric materials since its introduction in the mid-20th century. The evolution of silicone rubber as a dielectric material has been driven by the increasing demand for high-performance insulators in various industries, including electronics, power transmission, and aerospace.

Initially, silicone rubber was primarily valued for its thermal stability and resistance to environmental factors. However, as technology advanced, researchers began to explore its potential as a dielectric material. The 1960s and 1970s saw significant advancements in understanding the molecular structure of silicone rubber and its impact on dielectric properties. This period marked the beginning of tailoring silicone rubber compositions to enhance specific dielectric characteristics.

The 1980s and 1990s witnessed a surge in research focused on improving the dielectric strength and breakdown resistance of silicone rubber. This was largely driven by the growing needs of the power industry for more reliable insulation materials. Concurrently, the electronics industry's rapid growth led to increased interest in silicone rubber's potential for miniaturization and high-frequency applications.

Entering the 21st century, the focus shifted towards developing advanced composite silicone rubber materials. By incorporating various fillers and additives, researchers aimed to create materials with enhanced dielectric properties, such as increased permittivity and reduced dielectric loss. This period also saw the emergence of nanocomposite silicone rubbers, offering unprecedented control over material properties at the molecular level.

The current technological landscape demands silicone rubber dielectrics with increasingly sophisticated properties. Key objectives in this field include developing materials with ultra-high breakdown strength, low dielectric loss at high frequencies, and improved thermal conductivity while maintaining excellent electrical insulation. There is also a growing emphasis on creating environmentally friendly and sustainable silicone rubber dielectrics.

Looking forward, the objectives for silicone rubber dielectric research are multifaceted. One primary goal is to push the boundaries of dielectric strength, aiming for materials that can withstand extreme electrical stresses in compact designs. Another critical objective is to develop silicone rubber dielectrics with adaptive or smart properties, capable of responding to environmental changes or electrical stresses dynamically.

Furthermore, there is a strong focus on enhancing the long-term reliability and durability of silicone rubber dielectrics, particularly in harsh environments. This includes improving resistance to partial discharge, electrical treeing, and thermal degradation. The integration of silicone rubber dielectrics with emerging technologies, such as flexible electronics and high-power wireless charging systems, also presents exciting research opportunities.

Initially, silicone rubber was primarily valued for its thermal stability and resistance to environmental factors. However, as technology advanced, researchers began to explore its potential as a dielectric material. The 1960s and 1970s saw significant advancements in understanding the molecular structure of silicone rubber and its impact on dielectric properties. This period marked the beginning of tailoring silicone rubber compositions to enhance specific dielectric characteristics.

The 1980s and 1990s witnessed a surge in research focused on improving the dielectric strength and breakdown resistance of silicone rubber. This was largely driven by the growing needs of the power industry for more reliable insulation materials. Concurrently, the electronics industry's rapid growth led to increased interest in silicone rubber's potential for miniaturization and high-frequency applications.

Entering the 21st century, the focus shifted towards developing advanced composite silicone rubber materials. By incorporating various fillers and additives, researchers aimed to create materials with enhanced dielectric properties, such as increased permittivity and reduced dielectric loss. This period also saw the emergence of nanocomposite silicone rubbers, offering unprecedented control over material properties at the molecular level.

The current technological landscape demands silicone rubber dielectrics with increasingly sophisticated properties. Key objectives in this field include developing materials with ultra-high breakdown strength, low dielectric loss at high frequencies, and improved thermal conductivity while maintaining excellent electrical insulation. There is also a growing emphasis on creating environmentally friendly and sustainable silicone rubber dielectrics.

Looking forward, the objectives for silicone rubber dielectric research are multifaceted. One primary goal is to push the boundaries of dielectric strength, aiming for materials that can withstand extreme electrical stresses in compact designs. Another critical objective is to develop silicone rubber dielectrics with adaptive or smart properties, capable of responding to environmental changes or electrical stresses dynamically.

Furthermore, there is a strong focus on enhancing the long-term reliability and durability of silicone rubber dielectrics, particularly in harsh environments. This includes improving resistance to partial discharge, electrical treeing, and thermal degradation. The integration of silicone rubber dielectrics with emerging technologies, such as flexible electronics and high-power wireless charging systems, also presents exciting research opportunities.

Market Analysis for High-Performance Dielectrics

The market for high-performance dielectrics, particularly those based on advanced silicone rubber, is experiencing significant growth driven by the increasing demand for reliable and efficient electrical insulation materials across various industries. The global market for high-performance dielectrics is projected to reach substantial value in the coming years, with silicone rubber-based materials playing a crucial role in this expansion.

The automotive sector represents a key market for advanced silicone rubber dielectrics, particularly in electric and hybrid vehicles. As the automotive industry continues its shift towards electrification, the demand for high-performance insulation materials in battery systems, power electronics, and electric motors is surging. Silicone rubber dielectrics offer excellent thermal stability, electrical insulation properties, and resistance to environmental factors, making them ideal for these applications.

In the electronics industry, the miniaturization trend and the need for higher performance in devices are driving the demand for advanced dielectric materials. Silicone rubber dielectrics are increasingly used in semiconductor manufacturing, printed circuit boards, and electronic components due to their superior electrical properties and thermal management capabilities.

The renewable energy sector, particularly solar and wind power generation, is another significant market for high-performance dielectrics. As renewable energy installations continue to grow globally, the demand for reliable insulation materials in power transmission and distribution systems is increasing. Silicone rubber dielectrics offer excellent weatherability and long-term performance, making them suitable for outdoor applications in harsh environments.

The aerospace and defense industries also present substantial opportunities for advanced silicone rubber dielectrics. These materials are used in various applications, including radar systems, communication equipment, and aircraft electrical systems, where high reliability and performance under extreme conditions are critical.

In the medical device industry, silicone rubber dielectrics are gaining traction due to their biocompatibility and excellent electrical insulation properties. Applications include implantable medical devices, diagnostic equipment, and surgical tools, where the materials' performance and safety are paramount.

The Asia-Pacific region is expected to be the fastest-growing market for high-performance dielectrics, driven by rapid industrialization, increasing electronics manufacturing, and growing investments in renewable energy infrastructure. North America and Europe are also significant markets, with a focus on advanced technologies and stringent regulations driving the adoption of high-performance dielectric materials.

As the demand for high-performance dielectrics continues to grow, manufacturers are investing in research and development to enhance the properties of silicone rubber-based materials. This includes improving their dielectric strength, reducing losses, and enhancing their thermal and mechanical properties to meet the evolving requirements of various industries.

The automotive sector represents a key market for advanced silicone rubber dielectrics, particularly in electric and hybrid vehicles. As the automotive industry continues its shift towards electrification, the demand for high-performance insulation materials in battery systems, power electronics, and electric motors is surging. Silicone rubber dielectrics offer excellent thermal stability, electrical insulation properties, and resistance to environmental factors, making them ideal for these applications.

In the electronics industry, the miniaturization trend and the need for higher performance in devices are driving the demand for advanced dielectric materials. Silicone rubber dielectrics are increasingly used in semiconductor manufacturing, printed circuit boards, and electronic components due to their superior electrical properties and thermal management capabilities.

The renewable energy sector, particularly solar and wind power generation, is another significant market for high-performance dielectrics. As renewable energy installations continue to grow globally, the demand for reliable insulation materials in power transmission and distribution systems is increasing. Silicone rubber dielectrics offer excellent weatherability and long-term performance, making them suitable for outdoor applications in harsh environments.

The aerospace and defense industries also present substantial opportunities for advanced silicone rubber dielectrics. These materials are used in various applications, including radar systems, communication equipment, and aircraft electrical systems, where high reliability and performance under extreme conditions are critical.

In the medical device industry, silicone rubber dielectrics are gaining traction due to their biocompatibility and excellent electrical insulation properties. Applications include implantable medical devices, diagnostic equipment, and surgical tools, where the materials' performance and safety are paramount.

The Asia-Pacific region is expected to be the fastest-growing market for high-performance dielectrics, driven by rapid industrialization, increasing electronics manufacturing, and growing investments in renewable energy infrastructure. North America and Europe are also significant markets, with a focus on advanced technologies and stringent regulations driving the adoption of high-performance dielectric materials.

As the demand for high-performance dielectrics continues to grow, manufacturers are investing in research and development to enhance the properties of silicone rubber-based materials. This includes improving their dielectric strength, reducing losses, and enhancing their thermal and mechanical properties to meet the evolving requirements of various industries.

Current Challenges in Silicone Rubber Dielectrics

Despite the widespread use of silicone rubber as a dielectric material in various applications, several challenges persist in optimizing its properties for advanced electrical and electronic systems. One of the primary issues is the inherent trade-off between dielectric strength and flexibility. As silicone rubber compositions are modified to enhance their dielectric strength, they often become less flexible, which can limit their applicability in certain scenarios where both high electrical insulation and mechanical flexibility are required.

Another significant challenge lies in improving the thermal conductivity of silicone rubber dielectrics. While silicone rubber exhibits excellent thermal stability, its thermal conductivity is relatively low. This can lead to heat accumulation in high-power applications, potentially compromising the material's dielectric properties and overall performance. Researchers are actively exploring methods to enhance thermal conductivity without sacrificing other desirable characteristics of silicone rubber.

The long-term stability of silicone rubber dielectrics under extreme conditions remains a concern. Exposure to high electric fields, elevated temperatures, and harsh environmental factors can lead to gradual degradation of the material's dielectric properties. This degradation may manifest as increased leakage current, reduced breakdown strength, or changes in permittivity over time. Developing silicone rubber formulations that maintain their dielectric integrity under such demanding conditions is an ongoing challenge for materials scientists and engineers.

Furthermore, the presence of impurities and structural defects in silicone rubber can significantly impact its dielectric performance. These imperfections can act as charge trapping sites or initiate partial discharges, leading to premature failure of the insulation system. Improving manufacturing processes to minimize impurities and developing advanced characterization techniques to detect and mitigate structural defects are crucial areas of research.

The integration of silicone rubber dielectrics with other materials in composite structures presents additional challenges. Achieving strong interfacial bonding between silicone rubber and other components, such as electrodes or reinforcing fillers, is essential for maintaining the integrity of the dielectric system. However, the chemical inertness of silicone rubber can make it difficult to achieve robust adhesion without compromising its dielectric properties.

Lastly, there is a growing need to develop environmentally friendly and sustainable silicone rubber dielectrics. This includes exploring bio-based alternatives for certain components, reducing the use of potentially harmful additives, and improving the recyclability of silicone rubber materials at the end of their lifecycle. Balancing these sustainability goals with the stringent performance requirements of advanced dielectric applications remains a significant challenge in the field.

Another significant challenge lies in improving the thermal conductivity of silicone rubber dielectrics. While silicone rubber exhibits excellent thermal stability, its thermal conductivity is relatively low. This can lead to heat accumulation in high-power applications, potentially compromising the material's dielectric properties and overall performance. Researchers are actively exploring methods to enhance thermal conductivity without sacrificing other desirable characteristics of silicone rubber.

The long-term stability of silicone rubber dielectrics under extreme conditions remains a concern. Exposure to high electric fields, elevated temperatures, and harsh environmental factors can lead to gradual degradation of the material's dielectric properties. This degradation may manifest as increased leakage current, reduced breakdown strength, or changes in permittivity over time. Developing silicone rubber formulations that maintain their dielectric integrity under such demanding conditions is an ongoing challenge for materials scientists and engineers.

Furthermore, the presence of impurities and structural defects in silicone rubber can significantly impact its dielectric performance. These imperfections can act as charge trapping sites or initiate partial discharges, leading to premature failure of the insulation system. Improving manufacturing processes to minimize impurities and developing advanced characterization techniques to detect and mitigate structural defects are crucial areas of research.

The integration of silicone rubber dielectrics with other materials in composite structures presents additional challenges. Achieving strong interfacial bonding between silicone rubber and other components, such as electrodes or reinforcing fillers, is essential for maintaining the integrity of the dielectric system. However, the chemical inertness of silicone rubber can make it difficult to achieve robust adhesion without compromising its dielectric properties.

Lastly, there is a growing need to develop environmentally friendly and sustainable silicone rubber dielectrics. This includes exploring bio-based alternatives for certain components, reducing the use of potentially harmful additives, and improving the recyclability of silicone rubber materials at the end of their lifecycle. Balancing these sustainability goals with the stringent performance requirements of advanced dielectric applications remains a significant challenge in the field.

State-of-the-Art Silicone Rubber Dielectric Solutions

01 Composition of silicone rubber for improved dielectric properties

Silicone rubber compositions can be modified to enhance their dielectric properties. This may involve incorporating specific fillers, additives, or modifying the base polymer structure. These modifications can lead to improved electrical insulation, increased dielectric strength, or tailored dielectric constants for specific applications.- Composition of silicone rubber for improved dielectric properties: Silicone rubber compositions can be modified to enhance their dielectric properties. This may involve incorporating specific fillers, additives, or modifying the base polymer structure. These modifications can lead to improved insulation performance, increased dielectric strength, and better overall electrical characteristics of the silicone rubber material.

- Dielectric constant control in silicone rubber: Methods for controlling and adjusting the dielectric constant of silicone rubber materials are explored. This can involve the use of specific additives, varying the crosslinking density, or incorporating nanoparticles. By fine-tuning the dielectric constant, the material's performance in various electrical applications can be optimized.

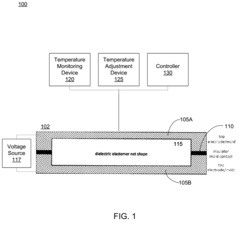

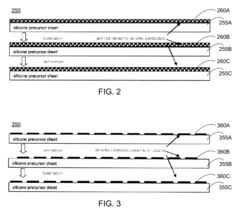

- Silicone rubber composites for enhanced dielectric properties: Composite materials based on silicone rubber are developed to achieve superior dielectric properties. These composites may incorporate various fillers such as ceramic particles, carbon nanotubes, or other polymeric materials. The resulting composites can exhibit improved dielectric strength, reduced dielectric loss, and enhanced overall electrical performance.

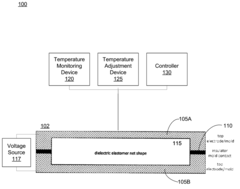

- Temperature-dependent dielectric behavior of silicone rubber: The dielectric properties of silicone rubber can vary with temperature. Research focuses on understanding and controlling these temperature-dependent characteristics. This includes developing silicone rubber formulations that maintain stable dielectric properties across a wide temperature range, which is crucial for applications in extreme environments.

- Measurement and characterization of silicone rubber dielectric properties: Techniques and methods for accurately measuring and characterizing the dielectric properties of silicone rubber are developed. This includes advanced testing procedures, specialized equipment, and analytical methods to evaluate parameters such as dielectric constant, dissipation factor, and breakdown strength. These measurements are crucial for quality control and material development in electrical applications.

02 Influence of fillers on dielectric properties of silicone rubber

The addition of various fillers to silicone rubber can significantly impact its dielectric properties. Fillers such as silica, metal oxides, or ceramic particles can be used to adjust the dielectric constant, improve breakdown strength, or enhance thermal conductivity while maintaining good electrical insulation.Expand Specific Solutions03 Temperature dependence of silicone rubber's dielectric properties

The dielectric properties of silicone rubber can vary with temperature. Understanding and controlling this temperature dependence is crucial for applications in extreme environments. Formulations can be developed to maintain stable dielectric properties across a wide temperature range.Expand Specific Solutions04 Silicone rubber composites for specialized dielectric applications

Silicone rubber can be combined with other materials to create composites with unique dielectric properties. These composites may offer advantages such as improved flexibility, better thermal management, or enhanced electrical performance for specific applications like high-voltage insulation or electromagnetic shielding.Expand Specific Solutions05 Measurement and characterization of silicone rubber dielectric properties

Accurate measurement and characterization of the dielectric properties of silicone rubber are essential for quality control and product development. Various techniques and instruments can be used to assess parameters such as dielectric constant, dissipation factor, and breakdown strength under different conditions.Expand Specific Solutions

Key Players in Advanced Dielectric Materials

The exploration of advanced silicone rubber dielectric properties is currently in a growth phase, with increasing market demand driven by applications in electronics, automotive, and energy sectors. The global market size for silicone rubber is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with key players like Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie AG leading innovation. These companies are investing heavily in R&D to enhance dielectric properties, focusing on improving insulation, thermal stability, and flexibility. Academic institutions such as Sichuan University and the Chinese Academy of Science are also contributing to fundamental research, potentially accelerating technological breakthroughs in this domain.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds with enhanced dielectric properties. Their research focuses on optimizing the molecular structure of silicone polymers to achieve higher breakdown strength and lower dielectric loss. They have introduced a novel cross-linking technique that improves the thermal stability of the material while maintaining excellent electrical insulation properties[1]. Their silicone rubber formulations incorporate specially designed fillers that enhance the dielectric constant without compromising flexibility. Recent advancements include the development of self-healing silicone dielectrics that can recover from electrical breakdown events, significantly extending the lifespan of insulation systems[2].

Strengths: Industry-leading expertise in silicone chemistry, wide range of customizable formulations, and strong R&D capabilities. Weaknesses: Higher cost compared to traditional dielectrics, and potential limitations in extreme high-voltage applications.

Wacker Chemie AG

Technical Solution: Wacker Chemie has pioneered the development of silicone elastomers with tailored dielectric properties for high-voltage applications. Their approach involves the synthesis of novel silicone copolymers with precisely controlled side-chain functionalities that enhance polarizability and reduce dielectric loss[3]. They have also developed a proprietary manufacturing process that ensures uniform dispersion of nano-scale fillers, resulting in improved dielectric strength and reduced space charge accumulation. Wacker's latest innovation is a series of silicone rubber compounds with adaptive dielectric properties that respond to changes in electric field strength, providing optimal insulation performance across a wide range of operating conditions[4].

Strengths: Extensive experience in silicone technology, strong patent portfolio, and global manufacturing capabilities. Weaknesses: Relatively high production costs and potential scalability issues for some advanced formulations.

Breakthrough Innovations in Dielectric Properties

Enhancing dielectric constants of elastomers using electric fields

PatentActiveUS20170133118A1

Innovation

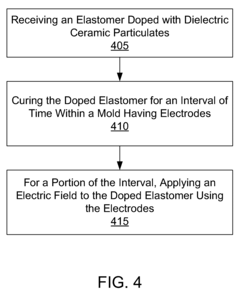

- An enhanced elastomer molding process involving electrodes and a cavity, where dielectric ceramic particulates are inserted and subjected to an electric field near the material's melting point and Curie temperature, increasing the dielectric constant while maintaining elasticity.

High dielectric insulating silicone rubber composition and electric field relaxation layer

PatentWO2018193705A1

Innovation

- A high dielectric insulating silicone rubber composition comprising organopolysiloxane, thermal black, reinforcing fumed silica, and a curing agent, with specific formulations to achieve a dielectric constant of 10 or more, a dielectric loss tangent of 0.1 or less, and a volume resistivity of 1.0×10^13 to 1.0×10^17 Ω·cm, ensuring excellent electric field relaxation and reliability.

Environmental Impact of Silicone Rubber Dielectrics

The environmental impact of silicone rubber dielectrics is a crucial consideration in the development and application of advanced materials. Silicone rubber, known for its excellent dielectric properties, has become increasingly prevalent in various industries, including electronics, power transmission, and automotive sectors. However, its widespread use raises important questions about its long-term effects on the environment.

One of the primary environmental concerns associated with silicone rubber dielectrics is their persistence in ecosystems. Unlike many organic materials, silicone rubbers do not readily biodegrade, potentially leading to accumulation in landfills and natural environments. This persistence can have far-reaching consequences for wildlife and ecosystems, as the material may fragment into smaller particles over time, potentially entering food chains and water systems.

The production process of silicone rubber dielectrics also contributes to environmental impact. The manufacturing of these materials often involves energy-intensive processes and the use of various chemicals, some of which may have harmful effects if released into the environment. Additionally, the extraction of raw materials, particularly silica and methyl chloride, can lead to habitat disruption and resource depletion if not managed sustainably.

On the positive side, silicone rubber dielectrics offer several environmental benefits that may offset some of their negative impacts. Their durability and resistance to degradation mean that products using these materials often have longer lifespans, reducing the need for frequent replacements and potentially decreasing overall waste generation. Furthermore, the excellent insulating properties of silicone rubber can contribute to energy efficiency in electrical systems, potentially reducing energy consumption and associated carbon emissions.

The end-of-life management of silicone rubber dielectrics presents both challenges and opportunities. While recycling these materials can be complex due to their chemical structure, advancements in recycling technologies are opening new possibilities for material recovery. Innovative approaches, such as chemical recycling and the use of silicone rubber as a filler in other materials, are being explored to minimize waste and promote circular economy principles.

As the demand for high-performance dielectric materials continues to grow, it is essential to consider the full lifecycle environmental impact of silicone rubber dielectrics. This includes not only their production and use but also their disposal and potential for recycling or repurposing. Ongoing research into more environmentally friendly alternatives and improved manufacturing processes is crucial for mitigating the environmental footprint of these materials while maintaining their valuable properties.

One of the primary environmental concerns associated with silicone rubber dielectrics is their persistence in ecosystems. Unlike many organic materials, silicone rubbers do not readily biodegrade, potentially leading to accumulation in landfills and natural environments. This persistence can have far-reaching consequences for wildlife and ecosystems, as the material may fragment into smaller particles over time, potentially entering food chains and water systems.

The production process of silicone rubber dielectrics also contributes to environmental impact. The manufacturing of these materials often involves energy-intensive processes and the use of various chemicals, some of which may have harmful effects if released into the environment. Additionally, the extraction of raw materials, particularly silica and methyl chloride, can lead to habitat disruption and resource depletion if not managed sustainably.

On the positive side, silicone rubber dielectrics offer several environmental benefits that may offset some of their negative impacts. Their durability and resistance to degradation mean that products using these materials often have longer lifespans, reducing the need for frequent replacements and potentially decreasing overall waste generation. Furthermore, the excellent insulating properties of silicone rubber can contribute to energy efficiency in electrical systems, potentially reducing energy consumption and associated carbon emissions.

The end-of-life management of silicone rubber dielectrics presents both challenges and opportunities. While recycling these materials can be complex due to their chemical structure, advancements in recycling technologies are opening new possibilities for material recovery. Innovative approaches, such as chemical recycling and the use of silicone rubber as a filler in other materials, are being explored to minimize waste and promote circular economy principles.

As the demand for high-performance dielectric materials continues to grow, it is essential to consider the full lifecycle environmental impact of silicone rubber dielectrics. This includes not only their production and use but also their disposal and potential for recycling or repurposing. Ongoing research into more environmentally friendly alternatives and improved manufacturing processes is crucial for mitigating the environmental footprint of these materials while maintaining their valuable properties.

Standardization and Testing Protocols

Standardization and testing protocols play a crucial role in ensuring the reliability and consistency of advanced silicone rubber dielectric properties. These protocols provide a framework for evaluating and comparing different silicone rubber formulations, enabling researchers and manufacturers to make informed decisions about material selection and optimization.

One of the primary challenges in standardizing testing protocols for silicone rubber dielectrics is the wide range of applications and operating conditions these materials encounter. To address this, international organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM) have developed comprehensive standards that cover various aspects of dielectric testing.

Key standardized tests for silicone rubber dielectrics include dielectric strength measurements, which assess the material's ability to withstand high electric fields without breakdown. These tests typically involve applying a gradually increasing voltage across a sample until electrical failure occurs. The IEC 60243 standard, for instance, provides detailed guidelines for conducting dielectric strength tests on solid insulating materials.

Another critical parameter is the dielectric constant, which quantifies the material's ability to store electrical energy. Standardized methods for measuring dielectric constant include the parallel plate capacitor technique and the coaxial probe method. The ASTM D150 standard outlines procedures for determining the dielectric properties of solid electrical insulating materials at various frequencies.

Dissipation factor testing is also essential for evaluating the energy losses within the dielectric material. This property is particularly important for high-frequency applications. The IEC 60250 standard provides guidelines for measuring the dissipation factor and permittivity of electrical insulating materials.

To ensure the long-term performance of silicone rubber dielectrics, accelerated aging tests are conducted. These tests simulate the effects of environmental factors such as temperature, humidity, and electrical stress over extended periods. The IEEE 1-2000 standard offers recommendations for accelerated aging and lifetime estimation of solid electrical insulating materials.

As the field of advanced silicone rubber dielectrics continues to evolve, testing protocols must adapt to new developments. For instance, the increasing use of nanocomposites in silicone rubber formulations has led to the development of specialized testing methods to evaluate the impact of nanoparticles on dielectric properties.

Efforts are ongoing to harmonize testing standards across different regions and industries. This harmonization aims to facilitate global trade and ensure consistent quality benchmarks for silicone rubber dielectrics. Additionally, there is a growing emphasis on developing non-destructive testing methods that allow for in-situ evaluation of dielectric properties in finished products.

One of the primary challenges in standardizing testing protocols for silicone rubber dielectrics is the wide range of applications and operating conditions these materials encounter. To address this, international organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM) have developed comprehensive standards that cover various aspects of dielectric testing.

Key standardized tests for silicone rubber dielectrics include dielectric strength measurements, which assess the material's ability to withstand high electric fields without breakdown. These tests typically involve applying a gradually increasing voltage across a sample until electrical failure occurs. The IEC 60243 standard, for instance, provides detailed guidelines for conducting dielectric strength tests on solid insulating materials.

Another critical parameter is the dielectric constant, which quantifies the material's ability to store electrical energy. Standardized methods for measuring dielectric constant include the parallel plate capacitor technique and the coaxial probe method. The ASTM D150 standard outlines procedures for determining the dielectric properties of solid electrical insulating materials at various frequencies.

Dissipation factor testing is also essential for evaluating the energy losses within the dielectric material. This property is particularly important for high-frequency applications. The IEC 60250 standard provides guidelines for measuring the dissipation factor and permittivity of electrical insulating materials.

To ensure the long-term performance of silicone rubber dielectrics, accelerated aging tests are conducted. These tests simulate the effects of environmental factors such as temperature, humidity, and electrical stress over extended periods. The IEEE 1-2000 standard offers recommendations for accelerated aging and lifetime estimation of solid electrical insulating materials.

As the field of advanced silicone rubber dielectrics continues to evolve, testing protocols must adapt to new developments. For instance, the increasing use of nanocomposites in silicone rubber formulations has led to the development of specialized testing methods to evaluate the impact of nanoparticles on dielectric properties.

Efforts are ongoing to harmonize testing standards across different regions and industries. This harmonization aims to facilitate global trade and ensure consistent quality benchmarks for silicone rubber dielectrics. Additionally, there is a growing emphasis on developing non-destructive testing methods that allow for in-situ evaluation of dielectric properties in finished products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!