How to Maximize Silicone Rubber’s Role in Anti-Reflective Coatings?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in AR Coatings: Background and Objectives

Anti-reflective (AR) coatings have become an integral part of various optical applications, ranging from eyewear to solar panels and electronic displays. The quest for improved AR coatings has led researchers and engineers to explore innovative materials, with silicone rubber emerging as a promising candidate. This technological evolution aims to enhance the performance and durability of AR coatings across diverse industries.

Silicone rubber, known for its unique combination of flexibility, thermal stability, and optical properties, has garnered significant attention in the field of AR coatings. Its potential to address longstanding challenges in coating technology, such as adhesion, durability, and environmental resistance, has sparked a wave of research and development efforts globally.

The primary objective of maximizing silicone rubber's role in AR coatings is to leverage its inherent properties to create more effective, long-lasting, and versatile anti-reflective solutions. This involves optimizing the chemical composition, processing techniques, and application methods of silicone-based AR coatings to achieve superior optical performance and mechanical robustness.

One of the key drivers behind this technological pursuit is the growing demand for high-performance optical components in industries such as consumer electronics, automotive, and renewable energy. As these sectors continue to evolve, the need for advanced AR coatings that can withstand harsh environments, maintain optical clarity, and provide consistent performance over extended periods has become increasingly critical.

The integration of silicone rubber into AR coating technology also aligns with broader trends in materials science and sustainable manufacturing. Its potential for reducing environmental impact, improving energy efficiency, and enhancing product longevity makes it an attractive option for companies seeking to develop more sustainable and eco-friendly solutions.

As we delve deeper into the role of silicone rubber in AR coatings, it is essential to consider the historical context of anti-reflective technology and the gradual shift towards more advanced materials. This evolution has been driven by a combination of scientific breakthroughs, technological advancements, and changing market demands, setting the stage for silicone rubber to play a pivotal role in the next generation of AR coatings.

The journey to maximize silicone rubber's potential in this field encompasses a wide range of research areas, including polymer chemistry, surface science, and optical engineering. By exploring these interconnected disciplines, researchers aim to unlock new possibilities for creating AR coatings that offer unprecedented levels of performance, durability, and versatility.

Silicone rubber, known for its unique combination of flexibility, thermal stability, and optical properties, has garnered significant attention in the field of AR coatings. Its potential to address longstanding challenges in coating technology, such as adhesion, durability, and environmental resistance, has sparked a wave of research and development efforts globally.

The primary objective of maximizing silicone rubber's role in AR coatings is to leverage its inherent properties to create more effective, long-lasting, and versatile anti-reflective solutions. This involves optimizing the chemical composition, processing techniques, and application methods of silicone-based AR coatings to achieve superior optical performance and mechanical robustness.

One of the key drivers behind this technological pursuit is the growing demand for high-performance optical components in industries such as consumer electronics, automotive, and renewable energy. As these sectors continue to evolve, the need for advanced AR coatings that can withstand harsh environments, maintain optical clarity, and provide consistent performance over extended periods has become increasingly critical.

The integration of silicone rubber into AR coating technology also aligns with broader trends in materials science and sustainable manufacturing. Its potential for reducing environmental impact, improving energy efficiency, and enhancing product longevity makes it an attractive option for companies seeking to develop more sustainable and eco-friendly solutions.

As we delve deeper into the role of silicone rubber in AR coatings, it is essential to consider the historical context of anti-reflective technology and the gradual shift towards more advanced materials. This evolution has been driven by a combination of scientific breakthroughs, technological advancements, and changing market demands, setting the stage for silicone rubber to play a pivotal role in the next generation of AR coatings.

The journey to maximize silicone rubber's potential in this field encompasses a wide range of research areas, including polymer chemistry, surface science, and optical engineering. By exploring these interconnected disciplines, researchers aim to unlock new possibilities for creating AR coatings that offer unprecedented levels of performance, durability, and versatility.

Market Analysis for AR Coating Applications

The anti-reflective (AR) coating market has experienced significant growth in recent years, driven by increasing demand across various industries. The global AR coating market size was valued at approximately $4.2 billion in 2020 and is projected to reach $6.8 billion by 2026, growing at a CAGR of 8.2% during the forecast period. This growth is primarily attributed to the rising adoption of AR coatings in consumer electronics, automotive, solar panels, and eyewear applications.

In the consumer electronics sector, AR coatings are extensively used in smartphones, tablets, laptops, and televisions to enhance display visibility and reduce glare. The increasing penetration of smartphones and the growing demand for high-quality displays are major factors driving the market growth in this segment. The automotive industry is another key market for AR coatings, with applications in windshields, mirrors, and dashboard displays to improve visibility and safety.

The solar energy sector represents a significant opportunity for AR coating applications. As the global focus on renewable energy intensifies, the demand for solar panels continues to rise. AR coatings play a crucial role in improving the efficiency of solar cells by reducing light reflection and increasing light absorption, thereby enhancing overall energy conversion rates.

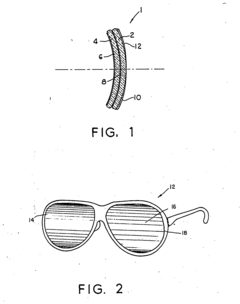

Eyewear is another major application area for AR coatings, with the market benefiting from the growing awareness of eye health and the increasing prevalence of vision-related issues. AR coatings on eyeglass lenses reduce glare, improve visual clarity, and provide UV protection, driving their adoption in both prescription and non-prescription eyewear.

Geographically, Asia Pacific is expected to dominate the AR coating market, owing to the presence of major consumer electronics manufacturers and the rapid growth of the automotive and solar energy sectors in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and increasing investments in research and development.

The integration of silicone rubber in AR coatings presents a promising opportunity to address some of the challenges faced by traditional coating materials. Silicone rubber offers excellent durability, weather resistance, and flexibility, which can enhance the longevity and performance of AR coatings across various applications. As the market continues to evolve, the development of innovative silicone rubber-based AR coating solutions could potentially capture a significant market share and drive further growth in this sector.

In the consumer electronics sector, AR coatings are extensively used in smartphones, tablets, laptops, and televisions to enhance display visibility and reduce glare. The increasing penetration of smartphones and the growing demand for high-quality displays are major factors driving the market growth in this segment. The automotive industry is another key market for AR coatings, with applications in windshields, mirrors, and dashboard displays to improve visibility and safety.

The solar energy sector represents a significant opportunity for AR coating applications. As the global focus on renewable energy intensifies, the demand for solar panels continues to rise. AR coatings play a crucial role in improving the efficiency of solar cells by reducing light reflection and increasing light absorption, thereby enhancing overall energy conversion rates.

Eyewear is another major application area for AR coatings, with the market benefiting from the growing awareness of eye health and the increasing prevalence of vision-related issues. AR coatings on eyeglass lenses reduce glare, improve visual clarity, and provide UV protection, driving their adoption in both prescription and non-prescription eyewear.

Geographically, Asia Pacific is expected to dominate the AR coating market, owing to the presence of major consumer electronics manufacturers and the rapid growth of the automotive and solar energy sectors in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and increasing investments in research and development.

The integration of silicone rubber in AR coatings presents a promising opportunity to address some of the challenges faced by traditional coating materials. Silicone rubber offers excellent durability, weather resistance, and flexibility, which can enhance the longevity and performance of AR coatings across various applications. As the market continues to evolve, the development of innovative silicone rubber-based AR coating solutions could potentially capture a significant market share and drive further growth in this sector.

Current Challenges in Silicone-Based AR Coatings

Despite the promising potential of silicone-based anti-reflective (AR) coatings, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving consistent and uniform coating thickness across large surface areas. Silicone rubber's inherent viscosity and surface tension properties can lead to uneven distribution during application, resulting in optical inconsistencies and reduced anti-reflective efficacy.

Another major challenge lies in enhancing the durability and longevity of silicone-based AR coatings. While silicone rubber offers excellent flexibility and weather resistance, it is susceptible to degradation under prolonged exposure to UV radiation and harsh environmental conditions. This vulnerability can lead to a gradual decline in anti-reflective properties over time, necessitating frequent reapplication or replacement.

Adhesion to various substrate materials presents an ongoing difficulty for silicone-based AR coatings. Ensuring strong and lasting adhesion to diverse surfaces, such as glass, plastics, and metals, without compromising the coating's optical properties remains a complex task. The development of universal or substrate-specific adhesion promoters compatible with silicone formulations is crucial for expanding the application range of these coatings.

The optimization of refractive index matching between the silicone coating and the substrate is another significant challenge. Achieving the ideal refractive index gradient to maximize anti-reflective performance while maintaining the desirable properties of silicone rubber requires careful formulation and often involves the incorporation of nanoparticles or other additives, which can introduce additional complexities in terms of dispersion and long-term stability.

Scalability and cost-effectiveness in manufacturing processes pose substantial hurdles for the widespread adoption of silicone-based AR coatings. Current production methods often involve complex multi-step processes or require specialized equipment, limiting their feasibility for large-scale industrial applications. Developing streamlined, economically viable manufacturing techniques that can maintain coating quality and performance at scale is essential for market penetration.

Lastly, the environmental impact and regulatory compliance of silicone-based AR coatings present ongoing challenges. As global environmental regulations become more stringent, there is a growing need to develop eco-friendly formulations that minimize volatile organic compound (VOC) emissions and ensure easy recyclability or biodegradability at the end of the product lifecycle. Balancing these environmental considerations with the performance requirements of AR coatings adds another layer of complexity to their development and implementation.

Another major challenge lies in enhancing the durability and longevity of silicone-based AR coatings. While silicone rubber offers excellent flexibility and weather resistance, it is susceptible to degradation under prolonged exposure to UV radiation and harsh environmental conditions. This vulnerability can lead to a gradual decline in anti-reflective properties over time, necessitating frequent reapplication or replacement.

Adhesion to various substrate materials presents an ongoing difficulty for silicone-based AR coatings. Ensuring strong and lasting adhesion to diverse surfaces, such as glass, plastics, and metals, without compromising the coating's optical properties remains a complex task. The development of universal or substrate-specific adhesion promoters compatible with silicone formulations is crucial for expanding the application range of these coatings.

The optimization of refractive index matching between the silicone coating and the substrate is another significant challenge. Achieving the ideal refractive index gradient to maximize anti-reflective performance while maintaining the desirable properties of silicone rubber requires careful formulation and often involves the incorporation of nanoparticles or other additives, which can introduce additional complexities in terms of dispersion and long-term stability.

Scalability and cost-effectiveness in manufacturing processes pose substantial hurdles for the widespread adoption of silicone-based AR coatings. Current production methods often involve complex multi-step processes or require specialized equipment, limiting their feasibility for large-scale industrial applications. Developing streamlined, economically viable manufacturing techniques that can maintain coating quality and performance at scale is essential for market penetration.

Lastly, the environmental impact and regulatory compliance of silicone-based AR coatings present ongoing challenges. As global environmental regulations become more stringent, there is a growing need to develop eco-friendly formulations that minimize volatile organic compound (VOC) emissions and ensure easy recyclability or biodegradability at the end of the product lifecycle. Balancing these environmental considerations with the performance requirements of AR coatings adds another layer of complexity to their development and implementation.

Existing Silicone-Based AR Coating Solutions

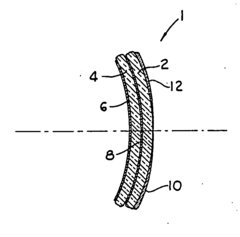

01 Silicone rubber composition for anti-reflective coatings

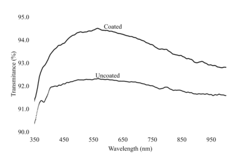

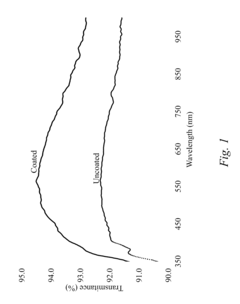

Silicone rubber compositions are formulated with specific additives to create anti-reflective coatings. These compositions often include silica particles, coupling agents, and curing catalysts to achieve the desired optical properties and durability. The resulting coatings can be applied to various substrates to reduce glare and improve light transmission.- Silicone rubber composition for anti-reflective coatings: Silicone rubber compositions are used to create anti-reflective coatings. These compositions typically include silicone polymers, curing agents, and additives that enhance the anti-reflective properties. The coatings can be applied to various surfaces to reduce glare and improve optical performance.

- Nanostructured silicone rubber surfaces for anti-reflection: Nanostructured surfaces made from silicone rubber can provide anti-reflective properties. These surfaces are created by various methods such as etching, molding, or self-assembly techniques. The nanostructures disrupt the reflection of light, reducing glare and improving transparency.

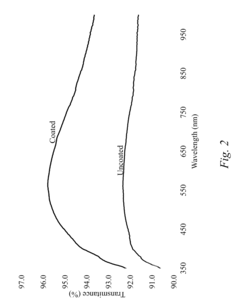

- Silicone rubber anti-reflective films for optical devices: Thin films of silicone rubber with anti-reflective properties are developed for use in optical devices such as lenses, displays, and solar panels. These films are designed to minimize reflection across a wide range of wavelengths, improving the efficiency and performance of the optical devices.

- Incorporation of fillers in silicone rubber for enhanced anti-reflection: Various fillers are incorporated into silicone rubber matrices to enhance anti-reflective properties. These fillers can include nanoparticles, hollow microspheres, or other materials that alter the refractive index of the silicone rubber, resulting in improved anti-reflective characteristics.

- Multi-layer silicone rubber anti-reflective coatings: Multi-layer coatings using silicone rubber are developed to achieve superior anti-reflective properties. These coatings consist of alternating layers of silicone rubber with different refractive indices or compositions, designed to cancel out reflections across a broad spectrum of light.

02 Manufacturing methods for anti-reflective silicone rubber products

Various manufacturing techniques are employed to produce anti-reflective silicone rubber products. These methods may include molding, extrusion, or casting processes, often followed by surface treatments or additional coating steps. The manufacturing process is optimized to ensure uniform distribution of anti-reflective properties throughout the product.Expand Specific Solutions03 Surface modification of silicone rubber for anti-reflective properties

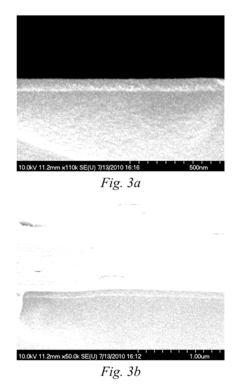

Surface modification techniques are applied to silicone rubber to enhance its anti-reflective properties. These may include plasma treatment, chemical etching, or the application of nanostructured coatings. The modified surface helps to reduce light reflection by creating a gradual change in refractive index between the air and the substrate.Expand Specific Solutions04 Integration of anti-reflective silicone rubber in optical devices

Anti-reflective silicone rubber is incorporated into various optical devices to improve their performance. This includes lenses, displays, solar panels, and other light-sensitive equipment. The integration of silicone rubber helps to reduce glare, enhance clarity, and improve overall optical efficiency in these devices.Expand Specific Solutions05 Durability and environmental resistance of anti-reflective silicone rubber

Formulations and treatments are developed to enhance the durability and environmental resistance of anti-reflective silicone rubber. This includes improving resistance to UV radiation, temperature fluctuations, humidity, and chemical exposure. The goal is to maintain the anti-reflective properties and structural integrity of the silicone rubber over extended periods in various environmental conditions.Expand Specific Solutions

Key Players in Silicone and AR Coating Industries

The anti-reflective coatings market utilizing silicone rubber is in a growth phase, driven by increasing demand in optical and electronic applications. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Dow Silicones Corp., Shin-Etsu Chemical, and Merck Patent GmbH leading innovation. These firms are developing advanced formulations to enhance coating performance and durability. Other key players such as SCHOTT AG and Guardian Glass LLC are integrating these coatings into their product lines, particularly for high-performance glass applications. The competitive landscape is characterized by a mix of established chemical companies and specialized coating manufacturers, with ongoing research focused on improving coating efficiency and environmental sustainability.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced silicone-based anti-reflective coatings for optical applications. Their technology involves a multi-layer coating system that incorporates silicone rubber as a key component. The process begins with a sol-gel derived silica base layer, followed by a silicone rubber intermediate layer, and topped with a nanoporous silica layer[1]. This structure allows for precise control of the refractive index gradient, resulting in excellent anti-reflective properties. The silicone rubber layer acts as a flexible buffer, enhancing durability and reducing stress between layers[3]. SCHOTT's method also includes a plasma treatment step to improve adhesion and stability of the coating[2].

Strengths: Excellent optical performance, enhanced durability, and stress reduction. Weaknesses: Complex multi-step manufacturing process, potentially higher production costs.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has pioneered a novel approach to maximize silicone rubber's role in anti-reflective coatings. Their method involves creating a nanocomposite material by incorporating silica nanoparticles into a silicone rubber matrix[4]. This approach allows for fine-tuning of the refractive index while maintaining the flexibility and durability of silicone rubber. The company has also developed a proprietary surface modification technique for the silica nanoparticles, ensuring better dispersion and bonding within the silicone matrix[5]. Additionally, Dow has implemented a controlled curing process that optimizes the crosslinking density of the silicone rubber, further enhancing the coating's optical and mechanical properties[6].

Strengths: Highly customizable optical properties, excellent durability, and scalable production process. Weaknesses: Potential challenges in achieving uniform nanoparticle dispersion at large scales.

Innovative Silicone Rubber Formulations for AR Coatings

Ophthalmic lens with graded interference coating

PatentInactiveUS20040257525A1

Innovation

- A polymeric ophthalmic lens construction involving a hardcoating on exterior surfaces, followed by an interference layer, and optionally an anti-reflective coating, with the polarizing layer between laminated lens components, allowing for controlled deposition of the interference layer to create aesthetic patterns without compromising protection.

Anti-reflective and Anti-soiling coatings with self-cleaning properties

PatentInactiveUS20170141242A1

Innovation

- Development of silane-based coating compositions that form anti-reflective, anti-soiling, and abrasion-resistant films through a sol-gel process, using a combination of tetraalkoxysilane, organosilane, and organofluorosilane precursors, which are hydrolyzed and cured to create a stable, durable coating with enhanced mechanical and chemical resistance.

Environmental Impact of Silicone-Based AR Coatings

The environmental impact of silicone-based anti-reflective (AR) coatings is a crucial consideration in their development and application. These coatings, while offering significant benefits in optical performance, also present unique environmental challenges and opportunities throughout their lifecycle.

Silicone-based AR coatings generally have a lower environmental footprint compared to traditional inorganic coatings. The production process of silicone materials typically requires less energy and generates fewer emissions than the manufacture of inorganic alternatives. Additionally, silicone-based coatings often allow for thinner application layers, reducing the overall material consumption.

However, the durability of silicone-based AR coatings can be a double-edged sword from an environmental perspective. While their longevity reduces the need for frequent reapplication, potentially lowering long-term resource consumption, it also means that these coatings persist in the environment for extended periods when disposed of improperly.

The end-of-life management of silicone-based AR coatings presents significant challenges. Unlike some organic materials, silicones do not biodegrade easily in natural environments. This persistence raises concerns about potential accumulation in ecosystems, particularly in aquatic environments where discarded coated products may end up.

On the positive side, silicone-based AR coatings can contribute to energy efficiency in various applications. When used on solar panels, for instance, these coatings can enhance light transmission, potentially increasing the panels' efficiency and indirectly reducing the carbon footprint of energy production.

The recyclability of silicone-based AR coatings is an area of ongoing research and development. While pure silicone materials can be recycled, the complex nature of AR coatings, often involving multiple layers and additives, complicates the recycling process. Advances in recycling technologies specific to these materials could significantly improve their environmental profile.

Water consumption and pollution during the manufacturing and application processes of silicone-based AR coatings are also important environmental considerations. While generally less water-intensive than some alternatives, there is still room for improvement in water management practices throughout the coating's lifecycle.

As environmental regulations become more stringent globally, the development of silicone-based AR coatings is increasingly focused on minimizing harmful emissions and waste. This includes efforts to reduce volatile organic compound (VOC) emissions during application and curing, as well as exploring bio-based silicone alternatives to decrease reliance on petroleum-derived raw materials.

Silicone-based AR coatings generally have a lower environmental footprint compared to traditional inorganic coatings. The production process of silicone materials typically requires less energy and generates fewer emissions than the manufacture of inorganic alternatives. Additionally, silicone-based coatings often allow for thinner application layers, reducing the overall material consumption.

However, the durability of silicone-based AR coatings can be a double-edged sword from an environmental perspective. While their longevity reduces the need for frequent reapplication, potentially lowering long-term resource consumption, it also means that these coatings persist in the environment for extended periods when disposed of improperly.

The end-of-life management of silicone-based AR coatings presents significant challenges. Unlike some organic materials, silicones do not biodegrade easily in natural environments. This persistence raises concerns about potential accumulation in ecosystems, particularly in aquatic environments where discarded coated products may end up.

On the positive side, silicone-based AR coatings can contribute to energy efficiency in various applications. When used on solar panels, for instance, these coatings can enhance light transmission, potentially increasing the panels' efficiency and indirectly reducing the carbon footprint of energy production.

The recyclability of silicone-based AR coatings is an area of ongoing research and development. While pure silicone materials can be recycled, the complex nature of AR coatings, often involving multiple layers and additives, complicates the recycling process. Advances in recycling technologies specific to these materials could significantly improve their environmental profile.

Water consumption and pollution during the manufacturing and application processes of silicone-based AR coatings are also important environmental considerations. While generally less water-intensive than some alternatives, there is still room for improvement in water management practices throughout the coating's lifecycle.

As environmental regulations become more stringent globally, the development of silicone-based AR coatings is increasingly focused on minimizing harmful emissions and waste. This includes efforts to reduce volatile organic compound (VOC) emissions during application and curing, as well as exploring bio-based silicone alternatives to decrease reliance on petroleum-derived raw materials.

Durability and Longevity of Silicone AR Coatings

The durability and longevity of silicone-based anti-reflective (AR) coatings are critical factors in their widespread adoption and long-term performance. Silicone rubber's inherent properties, such as excellent weather resistance, UV stability, and flexibility, contribute significantly to the extended lifespan of AR coatings in various applications.

One of the primary advantages of silicone AR coatings is their resistance to environmental degradation. Unlike traditional organic coatings, silicone-based formulations exhibit superior resistance to moisture, temperature fluctuations, and UV radiation. This resilience ensures that the optical properties of the coating remain stable over extended periods, even in harsh outdoor environments.

The chemical structure of silicone rubber plays a crucial role in its durability. The strong Si-O bonds in the silicone backbone provide exceptional thermal stability, allowing the coating to maintain its integrity under extreme temperature conditions. This characteristic is particularly valuable for applications in solar panels and outdoor optical devices, where exposure to intense heat and cold cycles is common.

Furthermore, silicone AR coatings demonstrate excellent adhesion to various substrates, including glass, metals, and plastics. This strong bonding minimizes the risk of delamination or peeling, which are common failure modes in less durable coating systems. The flexibility of silicone rubber also allows the coating to accommodate substrate expansion and contraction without cracking or losing its anti-reflective properties.

The hydrophobic nature of silicone contributes to the coating's self-cleaning properties, reducing the accumulation of dirt and debris on the surface. This feature not only maintains the optical performance of the coating but also reduces the need for frequent cleaning and maintenance, further extending its functional lifespan.

Recent advancements in silicone chemistry have led to the development of hybrid silicone-organic AR coatings. These formulations combine the durability of silicone with the enhanced scratch resistance of organic compounds, addressing one of the few limitations of pure silicone coatings. This synergistic approach results in AR coatings that offer both longevity and improved mechanical robustness.

Long-term studies have demonstrated that silicone AR coatings can maintain their anti-reflective properties for over a decade in outdoor applications, significantly outperforming traditional coating materials. This extended lifespan translates to reduced maintenance costs and improved overall efficiency of optical systems, making silicone-based AR coatings an increasingly attractive option for various industries.

One of the primary advantages of silicone AR coatings is their resistance to environmental degradation. Unlike traditional organic coatings, silicone-based formulations exhibit superior resistance to moisture, temperature fluctuations, and UV radiation. This resilience ensures that the optical properties of the coating remain stable over extended periods, even in harsh outdoor environments.

The chemical structure of silicone rubber plays a crucial role in its durability. The strong Si-O bonds in the silicone backbone provide exceptional thermal stability, allowing the coating to maintain its integrity under extreme temperature conditions. This characteristic is particularly valuable for applications in solar panels and outdoor optical devices, where exposure to intense heat and cold cycles is common.

Furthermore, silicone AR coatings demonstrate excellent adhesion to various substrates, including glass, metals, and plastics. This strong bonding minimizes the risk of delamination or peeling, which are common failure modes in less durable coating systems. The flexibility of silicone rubber also allows the coating to accommodate substrate expansion and contraction without cracking or losing its anti-reflective properties.

The hydrophobic nature of silicone contributes to the coating's self-cleaning properties, reducing the accumulation of dirt and debris on the surface. This feature not only maintains the optical performance of the coating but also reduces the need for frequent cleaning and maintenance, further extending its functional lifespan.

Recent advancements in silicone chemistry have led to the development of hybrid silicone-organic AR coatings. These formulations combine the durability of silicone with the enhanced scratch resistance of organic compounds, addressing one of the few limitations of pure silicone coatings. This synergistic approach results in AR coatings that offer both longevity and improved mechanical robustness.

Long-term studies have demonstrated that silicone AR coatings can maintain their anti-reflective properties for over a decade in outdoor applications, significantly outperforming traditional coating materials. This extended lifespan translates to reduced maintenance costs and improved overall efficiency of optical systems, making silicone-based AR coatings an increasingly attractive option for various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!