Revolutionary Silicone Rubber Techniques for Horticulture

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Horticulture: Background and Objectives

Silicone rubber has emerged as a revolutionary material in the field of horticulture, offering unique properties that address various challenges in plant cultivation and management. The evolution of silicone rubber technology in horticulture can be traced back to the mid-20th century when its potential for agricultural applications was first recognized. Initially used for simple tasks such as waterproofing and sealing, silicone rubber has since undergone significant advancements, leading to its widespread adoption in modern horticultural practices.

The primary objective of incorporating silicone rubber techniques in horticulture is to enhance plant growth, improve crop yields, and streamline cultivation processes. This material's exceptional flexibility, durability, and resistance to extreme temperatures and chemicals make it ideal for creating innovative solutions in greenhouse construction, irrigation systems, and plant support structures. Furthermore, silicone rubber's non-toxic nature and ability to repel water while allowing gas exchange have opened up new possibilities in seed coating and root development technologies.

One of the key drivers behind the development of silicone rubber techniques in horticulture is the growing demand for sustainable and efficient agricultural practices. As global population increases and arable land becomes scarcer, there is an urgent need for technologies that can maximize crop production while minimizing resource consumption. Silicone rubber's unique properties align well with these requirements, offering potential solutions for water conservation, pest control, and climate-adaptive cultivation methods.

The technological evolution in this field has been marked by several significant milestones. Early applications focused on using silicone rubber for creating flexible greenhouse coverings and durable irrigation tubing. As research progressed, more sophisticated applications emerged, such as silicone-based hydrogels for controlled release of nutrients and water to plants. Recent advancements have led to the development of smart silicone materials that can respond to environmental changes, potentially revolutionizing precision agriculture and automated farming systems.

Looking ahead, the future of silicone rubber in horticulture is poised for further innovation. Researchers and industry experts are exploring the integration of nanotechnology with silicone rubber to create multifunctional materials that can not only support plant growth but also monitor and respond to plant health in real-time. Additionally, there is growing interest in developing biodegradable silicone rubber variants to address environmental concerns and promote circular economy principles in agriculture.

As we delve deeper into the potential of silicone rubber in horticulture, it becomes clear that this technology holds immense promise for addressing some of the most pressing challenges in modern agriculture. From enhancing crop resilience to climate change to enabling more efficient use of resources, silicone rubber techniques are set to play a crucial role in shaping the future of sustainable food production and ornamental plant cultivation.

The primary objective of incorporating silicone rubber techniques in horticulture is to enhance plant growth, improve crop yields, and streamline cultivation processes. This material's exceptional flexibility, durability, and resistance to extreme temperatures and chemicals make it ideal for creating innovative solutions in greenhouse construction, irrigation systems, and plant support structures. Furthermore, silicone rubber's non-toxic nature and ability to repel water while allowing gas exchange have opened up new possibilities in seed coating and root development technologies.

One of the key drivers behind the development of silicone rubber techniques in horticulture is the growing demand for sustainable and efficient agricultural practices. As global population increases and arable land becomes scarcer, there is an urgent need for technologies that can maximize crop production while minimizing resource consumption. Silicone rubber's unique properties align well with these requirements, offering potential solutions for water conservation, pest control, and climate-adaptive cultivation methods.

The technological evolution in this field has been marked by several significant milestones. Early applications focused on using silicone rubber for creating flexible greenhouse coverings and durable irrigation tubing. As research progressed, more sophisticated applications emerged, such as silicone-based hydrogels for controlled release of nutrients and water to plants. Recent advancements have led to the development of smart silicone materials that can respond to environmental changes, potentially revolutionizing precision agriculture and automated farming systems.

Looking ahead, the future of silicone rubber in horticulture is poised for further innovation. Researchers and industry experts are exploring the integration of nanotechnology with silicone rubber to create multifunctional materials that can not only support plant growth but also monitor and respond to plant health in real-time. Additionally, there is growing interest in developing biodegradable silicone rubber variants to address environmental concerns and promote circular economy principles in agriculture.

As we delve deeper into the potential of silicone rubber in horticulture, it becomes clear that this technology holds immense promise for addressing some of the most pressing challenges in modern agriculture. From enhancing crop resilience to climate change to enabling more efficient use of resources, silicone rubber techniques are set to play a crucial role in shaping the future of sustainable food production and ornamental plant cultivation.

Market Analysis for Horticultural Silicone Applications

The horticultural silicone market has experienced significant growth in recent years, driven by the increasing adoption of advanced cultivation techniques and the rising demand for high-quality, sustainable agricultural products. Silicone-based materials have found widespread applications in horticulture due to their unique properties, including durability, flexibility, and resistance to extreme temperatures and weather conditions.

The global market for horticultural silicone applications is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the increasing use of silicone-based products in greenhouse construction, irrigation systems, and plant protection. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate during this period, owing to rapid urbanization and the adoption of modern farming practices.

One of the key drivers of market growth is the rising demand for controlled environment agriculture (CEA) and vertical farming systems. Silicone materials play a crucial role in these advanced cultivation methods, providing excellent light transmission, thermal insulation, and moisture control. The greenhouse film segment, which heavily relies on silicone-based materials, is anticipated to dominate the market share, accounting for over 40% of the total revenue.

The increasing focus on sustainable agriculture and water conservation has also boosted the demand for silicone-based irrigation systems. These systems offer improved water efficiency and durability compared to traditional materials, leading to their widespread adoption in both commercial and small-scale farming operations. The irrigation segment is expected to grow at a CAGR of 7.5% during the forecast period.

Plant protection is another area where silicone applications are gaining traction. Silicone-based sprays and coatings provide effective protection against pests, diseases, and environmental stressors while being environmentally friendly. This segment is projected to witness substantial growth, driven by the increasing awareness of sustainable pest management practices and stringent regulations on chemical pesticides.

The market landscape is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development to introduce novel silicone formulations tailored for specific horticultural applications. Collaborations between silicone manufacturers and agricultural research institutions are becoming more common, aiming to develop cutting-edge solutions for the evolving needs of the horticulture industry.

Despite the positive outlook, the market faces challenges such as the high initial cost of silicone-based products and the lack of awareness among small-scale farmers in developing regions. However, ongoing efforts to educate farmers about the long-term benefits of silicone applications and the development of cost-effective solutions are expected to mitigate these challenges in the coming years.

The global market for horticultural silicone applications is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the increasing use of silicone-based products in greenhouse construction, irrigation systems, and plant protection. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate during this period, owing to rapid urbanization and the adoption of modern farming practices.

One of the key drivers of market growth is the rising demand for controlled environment agriculture (CEA) and vertical farming systems. Silicone materials play a crucial role in these advanced cultivation methods, providing excellent light transmission, thermal insulation, and moisture control. The greenhouse film segment, which heavily relies on silicone-based materials, is anticipated to dominate the market share, accounting for over 40% of the total revenue.

The increasing focus on sustainable agriculture and water conservation has also boosted the demand for silicone-based irrigation systems. These systems offer improved water efficiency and durability compared to traditional materials, leading to their widespread adoption in both commercial and small-scale farming operations. The irrigation segment is expected to grow at a CAGR of 7.5% during the forecast period.

Plant protection is another area where silicone applications are gaining traction. Silicone-based sprays and coatings provide effective protection against pests, diseases, and environmental stressors while being environmentally friendly. This segment is projected to witness substantial growth, driven by the increasing awareness of sustainable pest management practices and stringent regulations on chemical pesticides.

The market landscape is characterized by the presence of both established players and innovative startups. Key market players are focusing on research and development to introduce novel silicone formulations tailored for specific horticultural applications. Collaborations between silicone manufacturers and agricultural research institutions are becoming more common, aiming to develop cutting-edge solutions for the evolving needs of the horticulture industry.

Despite the positive outlook, the market faces challenges such as the high initial cost of silicone-based products and the lack of awareness among small-scale farmers in developing regions. However, ongoing efforts to educate farmers about the long-term benefits of silicone applications and the development of cost-effective solutions are expected to mitigate these challenges in the coming years.

Current Challenges in Silicone Rubber Horticultural Use

The use of silicone rubber in horticulture has gained significant traction in recent years due to its unique properties and versatility. However, several challenges persist in its widespread adoption and optimal utilization. One of the primary concerns is the high initial cost associated with silicone rubber products compared to traditional horticultural materials. This cost factor often deters small-scale farmers and hobbyists from embracing this technology, limiting its market penetration.

Another significant challenge lies in the durability and longevity of silicone rubber products in harsh outdoor environments. While silicone rubber is known for its resilience, prolonged exposure to UV radiation, extreme temperatures, and chemical fertilizers can lead to degradation over time. This necessitates the development of more robust formulations that can withstand these environmental stressors without compromising performance.

The environmental impact of silicone rubber production and disposal remains a contentious issue. Although silicone rubber is generally considered inert and non-toxic, the energy-intensive manufacturing process and the lack of biodegradability raise sustainability concerns. The horticultural industry is increasingly seeking eco-friendly alternatives, putting pressure on silicone rubber manufacturers to innovate and improve their environmental footprint.

Customization and adaptability present another hurdle in silicone rubber horticultural applications. Different crops and growing conditions require specific properties in terms of water retention, nutrient delivery, and gas permeability. Developing silicone rubber formulations that can be easily tailored to meet these diverse needs without significant cost implications is an ongoing challenge for researchers and manufacturers.

The integration of silicone rubber with smart farming technologies is an emerging area that faces its own set of challenges. While silicone rubber offers excellent potential for embedding sensors and creating intelligent growing systems, issues related to data accuracy, wireless connectivity, and power supply in outdoor settings need to be addressed to fully leverage this potential.

Lastly, the regulatory landscape surrounding the use of silicone rubber in food production remains complex and varies across different regions. Ensuring compliance with food safety standards and obtaining necessary certifications can be a time-consuming and costly process for manufacturers, potentially slowing down innovation and market expansion in the horticultural sector.

Another significant challenge lies in the durability and longevity of silicone rubber products in harsh outdoor environments. While silicone rubber is known for its resilience, prolonged exposure to UV radiation, extreme temperatures, and chemical fertilizers can lead to degradation over time. This necessitates the development of more robust formulations that can withstand these environmental stressors without compromising performance.

The environmental impact of silicone rubber production and disposal remains a contentious issue. Although silicone rubber is generally considered inert and non-toxic, the energy-intensive manufacturing process and the lack of biodegradability raise sustainability concerns. The horticultural industry is increasingly seeking eco-friendly alternatives, putting pressure on silicone rubber manufacturers to innovate and improve their environmental footprint.

Customization and adaptability present another hurdle in silicone rubber horticultural applications. Different crops and growing conditions require specific properties in terms of water retention, nutrient delivery, and gas permeability. Developing silicone rubber formulations that can be easily tailored to meet these diverse needs without significant cost implications is an ongoing challenge for researchers and manufacturers.

The integration of silicone rubber with smart farming technologies is an emerging area that faces its own set of challenges. While silicone rubber offers excellent potential for embedding sensors and creating intelligent growing systems, issues related to data accuracy, wireless connectivity, and power supply in outdoor settings need to be addressed to fully leverage this potential.

Lastly, the regulatory landscape surrounding the use of silicone rubber in food production remains complex and varies across different regions. Ensuring compliance with food safety standards and obtaining necessary certifications can be a time-consuming and costly process for manufacturers, potentially slowing down innovation and market expansion in the horticultural sector.

Existing Silicone Solutions for Horticulture

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and formulation of silicone rubber: Silicone rubber compositions typically consist of silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or provide additional functionalities.

- Manufacturing processes for silicone rubber products: Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods, such as heat curing or room temperature vulcanization, are crucial steps in the production process.

- Modifications and improvements to silicone rubber properties: Researchers continually work on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of novel fillers or reinforcing agents, and the use of specialized additives to improve specific characteristics such as thermal stability, electrical properties, or chemical resistance.

- Applications of silicone rubber in various industries: Silicone rubber finds widespread use across multiple industries due to its unique properties. It is commonly used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for diverse applications.

- Environmental and safety considerations in silicone rubber production: The production and use of silicone rubber involve considerations related to environmental impact and safety. This includes the development of eco-friendly formulations, reduction of volatile organic compounds, and ensuring compliance with regulatory standards. Efforts are also made to improve the recyclability and biodegradability of silicone rubber products.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be found in various medical devices, implants, prosthetics, and drug delivery systems. The material's properties make it suitable for both short-term and long-term contact with the human body.Expand Specific Solutions04 Silicone rubber in electronic and electrical applications

Silicone rubber is utilized in electronic and electrical applications due to its excellent insulating properties and resistance to extreme temperatures. It can be found in cable insulation, gaskets, seals, and various components in electronic devices. The material's stability and performance in harsh environments make it valuable in this field.Expand Specific Solutions05 Advancements in silicone rubber technology

Ongoing research and development in silicone rubber technology focus on improving its performance, expanding its applications, and addressing environmental concerns. This includes developing new formulations, exploring novel curing methods, and creating silicone rubber composites with enhanced properties for specialized uses.Expand Specific Solutions

Key Players in Horticultural Silicone Industry

The market for revolutionary silicone rubber techniques in horticulture is in its early growth stage, with significant potential for expansion. The global silicone market is projected to reach $18.7 billion by 2025, with the horticultural segment showing promising growth. While the technology is still evolving, key players like Shin-Etsu Chemical, Dow Silicones, and Evonik Operations are driving innovation. These companies are investing heavily in R&D to develop advanced silicone formulations tailored for horticultural applications. The technology's maturity varies, with some applications already commercialized and others still in the research phase. Emerging players such as Guangzhou Baiyun Chemical and Inner Mongolia Sucon Silicone are also contributing to the sector's development, particularly in the Asian market.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber techniques for horticulture, focusing on improving plant growth and crop yields. Their innovative approach includes the creation of silicone-based films and coatings that can be applied to greenhouse structures and agricultural equipment. These materials offer superior light transmission and diffusion properties, enhancing photosynthesis efficiency[1]. Additionally, they have engineered silicone rubber compounds with controlled release mechanisms for fertilizers and pesticides, allowing for more precise and sustainable nutrient delivery to plants[3]. The company has also introduced silicone-based hydrogels that improve water retention in soil, reducing irrigation needs and promoting drought resistance in crops[5].

Strengths: Industry-leading expertise in silicone chemistry, extensive R&D capabilities, and a wide range of applications in agriculture. Weaknesses: Potentially higher costs compared to traditional materials, and the need for specialized application techniques.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered revolutionary silicone rubber techniques for horticulture, focusing on enhancing crop protection and plant growth. Their innovative solutions include silicone-based elastomers that form protective barriers on plant surfaces, improving resistance to pests and diseases while allowing for gas exchange[2]. The company has also developed silicone emulsions that, when applied to soil, enhance water penetration and retention, leading to more efficient irrigation and reduced water consumption[4]. Furthermore, Dow has introduced silicone-based adjuvants that improve the efficacy of agrochemicals by promoting better spreading and adhesion on plant surfaces, resulting in reduced chemical usage and environmental impact[6].

Strengths: Broad portfolio of silicone products, strong global presence, and extensive experience in agricultural applications. Weaknesses: Potential regulatory challenges in some markets and the need for farmer education on new technologies.

Innovative Silicone Rubber Formulations for Plant Growth

Method for hydroponic culture of plant of family asteraceae

PatentActiveEP3479684A1

Innovation

- Hydroponic culture method where 10 to 50% of the tap root's total length is submerged in a nutrient solution, with the rest exposed to gas, promoting root growth and activating rubber synthesis, thereby increasing rubber accumulation in the roots.

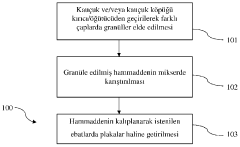

A METHOD OF PRODUCTION OF RUBBER GRANULES USED IN SOILless GARDENING AND GREEN ROOF/FACE APPLICATIONS

PatentInactiveTR201611975A3

Innovation

- The method produces rubber granules of different diameters specifically for soilless gardening and green roof/face applications.

- The production method involves a unique combination of crushing/grinding, mixing, and molding steps to create rubber granules suitable for plant growth.

- The resulting product is made entirely of rubber, without the inclusion of other materials, distinguishing it from existing alternatives.

Environmental Impact of Silicone Rubber in Horticulture

The environmental impact of silicone rubber in horticulture is a critical consideration as the industry adopts revolutionary techniques. Silicone rubber offers numerous benefits for horticultural applications, but its widespread use also raises concerns about potential ecological consequences.

One of the primary environmental advantages of silicone rubber in horticulture is its durability and longevity. Unlike traditional plastic materials, silicone rubber products have a significantly longer lifespan, reducing the frequency of replacement and, consequently, the amount of waste generated. This durability contributes to a decrease in overall resource consumption and waste production in the horticultural sector.

However, the production process of silicone rubber involves the use of various chemicals and energy-intensive methods, which can have negative environmental implications. The extraction of silica, a primary component of silicone rubber, may lead to habitat disruption and soil erosion if not managed responsibly. Additionally, the energy required for processing and manufacturing silicone rubber products contributes to carbon emissions and overall environmental footprint.

In terms of biodegradability, silicone rubber presents a complex challenge. While it does not biodegrade in the traditional sense, it does undergo a slow process of degradation when exposed to environmental factors such as UV radiation and extreme temperatures. This gradual breakdown can result in the release of microparticles into the soil and water systems, potentially affecting local ecosystems and entering the food chain.

On the positive side, silicone rubber's inert nature means it does not leach harmful chemicals into the soil or water, making it a safer option compared to some conventional plastics used in horticulture. This characteristic is particularly beneficial in applications such as irrigation systems and plant containers, where direct contact with soil and water is constant.

The recyclability of silicone rubber is another important environmental consideration. While technically recyclable, the process is complex and not widely available, which can lead to most silicone rubber products ending up in landfills at the end of their life cycle. However, ongoing research and development in recycling technologies may improve this situation in the future.

In the context of water conservation, silicone rubber's application in advanced irrigation systems has shown promising results. These systems can significantly reduce water usage in horticultural operations, contributing to more sustainable water management practices, especially in water-scarce regions.

As the horticultural industry continues to adopt silicone rubber technologies, it is crucial to balance the material's benefits with its potential environmental impacts. Future research should focus on improving the sustainability of silicone rubber production, enhancing its recyclability, and developing eco-friendly alternatives for specific applications where environmental concerns are paramount.

One of the primary environmental advantages of silicone rubber in horticulture is its durability and longevity. Unlike traditional plastic materials, silicone rubber products have a significantly longer lifespan, reducing the frequency of replacement and, consequently, the amount of waste generated. This durability contributes to a decrease in overall resource consumption and waste production in the horticultural sector.

However, the production process of silicone rubber involves the use of various chemicals and energy-intensive methods, which can have negative environmental implications. The extraction of silica, a primary component of silicone rubber, may lead to habitat disruption and soil erosion if not managed responsibly. Additionally, the energy required for processing and manufacturing silicone rubber products contributes to carbon emissions and overall environmental footprint.

In terms of biodegradability, silicone rubber presents a complex challenge. While it does not biodegrade in the traditional sense, it does undergo a slow process of degradation when exposed to environmental factors such as UV radiation and extreme temperatures. This gradual breakdown can result in the release of microparticles into the soil and water systems, potentially affecting local ecosystems and entering the food chain.

On the positive side, silicone rubber's inert nature means it does not leach harmful chemicals into the soil or water, making it a safer option compared to some conventional plastics used in horticulture. This characteristic is particularly beneficial in applications such as irrigation systems and plant containers, where direct contact with soil and water is constant.

The recyclability of silicone rubber is another important environmental consideration. While technically recyclable, the process is complex and not widely available, which can lead to most silicone rubber products ending up in landfills at the end of their life cycle. However, ongoing research and development in recycling technologies may improve this situation in the future.

In the context of water conservation, silicone rubber's application in advanced irrigation systems has shown promising results. These systems can significantly reduce water usage in horticultural operations, contributing to more sustainable water management practices, especially in water-scarce regions.

As the horticultural industry continues to adopt silicone rubber technologies, it is crucial to balance the material's benefits with its potential environmental impacts. Future research should focus on improving the sustainability of silicone rubber production, enhancing its recyclability, and developing eco-friendly alternatives for specific applications where environmental concerns are paramount.

Regulatory Framework for Agricultural Silicone Products

The regulatory framework for agricultural silicone products is a complex and evolving landscape that plays a crucial role in the development and adoption of revolutionary silicone rubber techniques for horticulture. As these innovative technologies continue to emerge, regulatory bodies worldwide are working to establish guidelines that ensure the safety, efficacy, and environmental sustainability of silicone-based agricultural products.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory authority for agricultural chemicals and materials. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), silicone-based products used in agriculture must undergo rigorous testing and registration processes. This includes evaluating their potential impact on human health, non-target organisms, and the environment. The EPA also sets tolerance levels for silicone residues on food crops, ensuring that any products used in horticulture do not pose risks to consumers.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to silicone products used in agriculture. This comprehensive framework requires manufacturers to register their substances and provide detailed safety information. Additionally, the EU's Plant Protection Products Regulation (EC) No 1107/2009 governs the approval of active substances and the authorization of plant protection products, including those containing silicone-based materials.

In Asia, countries like Japan and China have their own regulatory systems for agricultural silicone products. Japan's Ministry of Agriculture, Forestry and Fisheries (MAFF) oversees the registration and use of agricultural chemicals, including silicone-based materials. China's Institute for the Control of Agrochemicals, Ministry of Agriculture (ICAMA) is responsible for pesticide registration, which encompasses certain silicone products used in horticulture.

International organizations also play a role in shaping the regulatory landscape. The Food and Agriculture Organization (FAO) of the United Nations and the World Health Organization (WHO) jointly manage the Codex Alimentarius Commission, which develops international food standards, guidelines, and codes of practice. These standards often influence national regulations regarding the use of silicone products in agriculture.

As the field of silicone rubber techniques for horticulture continues to advance, regulatory frameworks are likely to evolve. There is a growing emphasis on sustainable agriculture and reducing chemical inputs, which may lead to more favorable regulations for silicone-based products that offer environmentally friendly alternatives to traditional agrochemicals. However, regulators must balance innovation with caution, ensuring that new silicone technologies are thoroughly evaluated for long-term safety and environmental impact before widespread adoption.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory authority for agricultural chemicals and materials. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), silicone-based products used in agriculture must undergo rigorous testing and registration processes. This includes evaluating their potential impact on human health, non-target organisms, and the environment. The EPA also sets tolerance levels for silicone residues on food crops, ensuring that any products used in horticulture do not pose risks to consumers.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to silicone products used in agriculture. This comprehensive framework requires manufacturers to register their substances and provide detailed safety information. Additionally, the EU's Plant Protection Products Regulation (EC) No 1107/2009 governs the approval of active substances and the authorization of plant protection products, including those containing silicone-based materials.

In Asia, countries like Japan and China have their own regulatory systems for agricultural silicone products. Japan's Ministry of Agriculture, Forestry and Fisheries (MAFF) oversees the registration and use of agricultural chemicals, including silicone-based materials. China's Institute for the Control of Agrochemicals, Ministry of Agriculture (ICAMA) is responsible for pesticide registration, which encompasses certain silicone products used in horticulture.

International organizations also play a role in shaping the regulatory landscape. The Food and Agriculture Organization (FAO) of the United Nations and the World Health Organization (WHO) jointly manage the Codex Alimentarius Commission, which develops international food standards, guidelines, and codes of practice. These standards often influence national regulations regarding the use of silicone products in agriculture.

As the field of silicone rubber techniques for horticulture continues to advance, regulatory frameworks are likely to evolve. There is a growing emphasis on sustainable agriculture and reducing chemical inputs, which may lead to more favorable regulations for silicone-based products that offer environmentally friendly alternatives to traditional agrochemicals. However, regulators must balance innovation with caution, ensuring that new silicone technologies are thoroughly evaluated for long-term safety and environmental impact before widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!