How to Enhance Silicone Rubber's UV Resistance?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Resistance Challenges

Silicone rubber, despite its numerous advantageous properties, faces significant challenges when exposed to ultraviolet (UV) radiation. The primary issue lies in the material's susceptibility to photo-oxidation, which can lead to degradation of its physical and mechanical properties over time. This degradation manifests as surface cracking, discoloration, and a reduction in tensile strength and elongation at break.

One of the main challenges in enhancing UV resistance is the inherent chemical structure of silicone rubber. The Si-O-Si backbone, while providing excellent thermal stability and flexibility, is vulnerable to UV-induced scission. This process can lead to chain breakage and subsequent formation of free radicals, which further propagate the degradation process.

Another significant challenge is the balance between UV resistance and other desirable properties of silicone rubber. Incorporating UV stabilizers or absorbers can improve UV resistance but may negatively impact other characteristics such as transparency, electrical properties, or processability. Finding the right balance without compromising the material's overall performance is a complex task that requires careful formulation and testing.

The outdoor application of silicone rubber products presents additional challenges. Exposure to varying environmental conditions, including temperature fluctuations, humidity, and pollutants, can exacerbate UV-induced degradation. These factors can work synergistically with UV radiation, accelerating the deterioration process and making it difficult to predict long-term performance accurately.

Furthermore, the development of effective UV-resistant additives specifically tailored for silicone rubber is an ongoing challenge. While many UV stabilizers exist for organic polymers, their compatibility and effectiveness in silicone systems can be limited. This necessitates the development of novel additives or modification techniques that are chemically compatible with the silicone matrix and can provide long-lasting protection without migration or leaching.

The testing and validation of UV resistance improvements also pose significant challenges. Accelerated weathering tests, while useful, may not always accurately reflect real-world performance. Developing standardized testing protocols that correlate well with actual outdoor exposure is crucial for reliable product development and quality assurance.

Lastly, the cost-effectiveness of UV resistance enhancement solutions remains a challenge. High-performance UV stabilizers or surface treatment technologies can significantly increase production costs, potentially limiting their widespread adoption in price-sensitive applications. Striking a balance between improved UV resistance and economic viability is essential for commercial success in the silicone rubber industry.

One of the main challenges in enhancing UV resistance is the inherent chemical structure of silicone rubber. The Si-O-Si backbone, while providing excellent thermal stability and flexibility, is vulnerable to UV-induced scission. This process can lead to chain breakage and subsequent formation of free radicals, which further propagate the degradation process.

Another significant challenge is the balance between UV resistance and other desirable properties of silicone rubber. Incorporating UV stabilizers or absorbers can improve UV resistance but may negatively impact other characteristics such as transparency, electrical properties, or processability. Finding the right balance without compromising the material's overall performance is a complex task that requires careful formulation and testing.

The outdoor application of silicone rubber products presents additional challenges. Exposure to varying environmental conditions, including temperature fluctuations, humidity, and pollutants, can exacerbate UV-induced degradation. These factors can work synergistically with UV radiation, accelerating the deterioration process and making it difficult to predict long-term performance accurately.

Furthermore, the development of effective UV-resistant additives specifically tailored for silicone rubber is an ongoing challenge. While many UV stabilizers exist for organic polymers, their compatibility and effectiveness in silicone systems can be limited. This necessitates the development of novel additives or modification techniques that are chemically compatible with the silicone matrix and can provide long-lasting protection without migration or leaching.

The testing and validation of UV resistance improvements also pose significant challenges. Accelerated weathering tests, while useful, may not always accurately reflect real-world performance. Developing standardized testing protocols that correlate well with actual outdoor exposure is crucial for reliable product development and quality assurance.

Lastly, the cost-effectiveness of UV resistance enhancement solutions remains a challenge. High-performance UV stabilizers or surface treatment technologies can significantly increase production costs, potentially limiting their widespread adoption in price-sensitive applications. Striking a balance between improved UV resistance and economic viability is essential for commercial success in the silicone rubber industry.

Market Demand Analysis

The market demand for UV-resistant silicone rubber has been steadily increasing across various industries due to the material's unique properties and the growing awareness of UV radiation's detrimental effects. Silicone rubber is widely used in outdoor applications, aerospace, automotive, construction, and electronics industries, where exposure to UV radiation is a significant concern.

In the automotive sector, the demand for UV-resistant silicone rubber is driven by the need for durable exterior components, such as weatherstripping, gaskets, and seals. As vehicles are exposed to harsh environmental conditions, including prolonged sunlight, manufacturers are seeking materials that can maintain their integrity and appearance over extended periods.

The construction industry represents another significant market for UV-resistant silicone rubber. With the increasing use of silicone sealants and adhesives in building facades, roofing, and glazing systems, there is a growing demand for products that can withstand long-term UV exposure without degradation. This is particularly important in regions with high solar radiation levels, where traditional materials may fail prematurely.

In the aerospace industry, UV-resistant silicone rubber is crucial for applications such as window seals, door seals, and other exterior components of aircraft. The extreme conditions encountered during flight, including high-altitude UV exposure, necessitate materials with superior UV resistance to ensure safety and longevity.

The electronics industry is also driving demand for UV-resistant silicone rubber, particularly in outdoor electronic enclosures, solar panel installations, and LED lighting systems. As electronic devices become more prevalent in outdoor environments, the need for protective materials that can withstand UV radiation while maintaining their electrical insulation properties has increased.

Market analysts project that the global UV-resistant silicone rubber market will experience substantial growth in the coming years. This growth is attributed to the expanding applications in emerging technologies, such as electric vehicles, renewable energy systems, and smart city infrastructure, all of which require materials capable of withstanding prolonged UV exposure.

Furthermore, the increasing focus on sustainability and environmental regulations is expected to boost the demand for UV-resistant silicone rubber. As industries seek alternatives to traditional materials that may contain harmful chemicals or have shorter lifespans, silicone rubber with enhanced UV resistance presents an attractive option due to its durability and potential for reducing waste through longer product lifecycles.

In the automotive sector, the demand for UV-resistant silicone rubber is driven by the need for durable exterior components, such as weatherstripping, gaskets, and seals. As vehicles are exposed to harsh environmental conditions, including prolonged sunlight, manufacturers are seeking materials that can maintain their integrity and appearance over extended periods.

The construction industry represents another significant market for UV-resistant silicone rubber. With the increasing use of silicone sealants and adhesives in building facades, roofing, and glazing systems, there is a growing demand for products that can withstand long-term UV exposure without degradation. This is particularly important in regions with high solar radiation levels, where traditional materials may fail prematurely.

In the aerospace industry, UV-resistant silicone rubber is crucial for applications such as window seals, door seals, and other exterior components of aircraft. The extreme conditions encountered during flight, including high-altitude UV exposure, necessitate materials with superior UV resistance to ensure safety and longevity.

The electronics industry is also driving demand for UV-resistant silicone rubber, particularly in outdoor electronic enclosures, solar panel installations, and LED lighting systems. As electronic devices become more prevalent in outdoor environments, the need for protective materials that can withstand UV radiation while maintaining their electrical insulation properties has increased.

Market analysts project that the global UV-resistant silicone rubber market will experience substantial growth in the coming years. This growth is attributed to the expanding applications in emerging technologies, such as electric vehicles, renewable energy systems, and smart city infrastructure, all of which require materials capable of withstanding prolonged UV exposure.

Furthermore, the increasing focus on sustainability and environmental regulations is expected to boost the demand for UV-resistant silicone rubber. As industries seek alternatives to traditional materials that may contain harmful chemicals or have shorter lifespans, silicone rubber with enhanced UV resistance presents an attractive option due to its durability and potential for reducing waste through longer product lifecycles.

Current UV Protection

Current UV protection strategies for silicone rubber primarily focus on incorporating UV stabilizers and absorbers into the material matrix. One of the most common approaches is the addition of inorganic fillers such as titanium dioxide (TiO2) and zinc oxide (ZnO). These particles effectively scatter and absorb UV radiation, preventing it from penetrating deeper into the silicone rubber structure. The concentration and particle size of these fillers are crucial factors in determining their effectiveness.

Another widely used method is the incorporation of organic UV stabilizers, such as hindered amine light stabilizers (HALS) and benzophenones. HALS work by scavenging free radicals generated during UV exposure, while benzophenones absorb UV radiation and dissipate it as heat. These organic additives are often used in combination with inorganic fillers to provide comprehensive protection against UV degradation.

Surface treatments and coatings represent another approach to enhancing UV resistance. UV-resistant coatings, typically based on acrylic or polyurethane formulations, can be applied to the silicone rubber surface to create a protective barrier. These coatings often contain additional UV absorbers and stabilizers to further improve their protective properties.

Recent advancements in nanotechnology have led to the development of nanocomposite materials for UV protection. Nanoparticles of materials such as cerium oxide (CeO2) and graphene oxide have shown promising results in improving the UV resistance of silicone rubber. These nanoparticles offer the advantage of high UV absorption efficiency while maintaining the optical clarity of the material.

Researchers are also exploring the potential of reactive UV stabilizers that can be chemically bonded to the silicone rubber matrix. This approach aims to prevent the migration and leaching of stabilizers over time, ensuring long-term UV protection. Additionally, the use of synergistic combinations of different UV stabilizers and absorbers is being investigated to achieve enhanced protection across a broader spectrum of UV wavelengths.

Despite these advancements, current UV protection methods for silicone rubber still face challenges. The incorporation of high concentrations of additives can negatively impact the material's mechanical properties and transparency. Moreover, the long-term effectiveness of UV stabilizers remains a concern, as they can degrade or leach out of the material over time, especially under harsh environmental conditions.

Ongoing research is focused on developing more efficient and durable UV protection strategies. This includes the exploration of novel materials with intrinsic UV-resistant properties, as well as the optimization of existing additives and their integration methods. The goal is to achieve a balance between effective UV protection and the preservation of silicone rubber's desirable properties, ensuring its long-term performance in various applications exposed to UV radiation.

Another widely used method is the incorporation of organic UV stabilizers, such as hindered amine light stabilizers (HALS) and benzophenones. HALS work by scavenging free radicals generated during UV exposure, while benzophenones absorb UV radiation and dissipate it as heat. These organic additives are often used in combination with inorganic fillers to provide comprehensive protection against UV degradation.

Surface treatments and coatings represent another approach to enhancing UV resistance. UV-resistant coatings, typically based on acrylic or polyurethane formulations, can be applied to the silicone rubber surface to create a protective barrier. These coatings often contain additional UV absorbers and stabilizers to further improve their protective properties.

Recent advancements in nanotechnology have led to the development of nanocomposite materials for UV protection. Nanoparticles of materials such as cerium oxide (CeO2) and graphene oxide have shown promising results in improving the UV resistance of silicone rubber. These nanoparticles offer the advantage of high UV absorption efficiency while maintaining the optical clarity of the material.

Researchers are also exploring the potential of reactive UV stabilizers that can be chemically bonded to the silicone rubber matrix. This approach aims to prevent the migration and leaching of stabilizers over time, ensuring long-term UV protection. Additionally, the use of synergistic combinations of different UV stabilizers and absorbers is being investigated to achieve enhanced protection across a broader spectrum of UV wavelengths.

Despite these advancements, current UV protection methods for silicone rubber still face challenges. The incorporation of high concentrations of additives can negatively impact the material's mechanical properties and transparency. Moreover, the long-term effectiveness of UV stabilizers remains a concern, as they can degrade or leach out of the material over time, especially under harsh environmental conditions.

Ongoing research is focused on developing more efficient and durable UV protection strategies. This includes the exploration of novel materials with intrinsic UV-resistant properties, as well as the optimization of existing additives and their integration methods. The goal is to achieve a balance between effective UV protection and the preservation of silicone rubber's desirable properties, ensuring its long-term performance in various applications exposed to UV radiation.

Existing UV Solutions

01 UV-resistant additives for silicone rubber

Various additives can be incorporated into silicone rubber formulations to enhance UV resistance. These may include UV absorbers, antioxidants, and stabilizers that protect the polymer structure from degradation caused by UV radiation. Such additives can significantly improve the longevity and performance of silicone rubber products exposed to sunlight or other UV sources.- UV-resistant additives in silicone rubber: Incorporating UV-resistant additives into silicone rubber formulations can significantly enhance their resistance to ultraviolet radiation. These additives, such as UV absorbers and light stabilizers, help prevent degradation of the silicone material when exposed to sunlight. This approach extends the lifespan of silicone rubber products used in outdoor applications.

- Surface modification techniques: Various surface modification techniques can be applied to silicone rubber to improve its UV resistance. These methods include plasma treatment, chemical grafting, and the application of protective coatings. Such modifications create a barrier that shields the underlying silicone material from UV radiation, enhancing its durability in outdoor environments.

- Nanoparticle reinforcement: Incorporating nanoparticles into silicone rubber matrices can enhance UV resistance. Nanoparticles such as titanium dioxide, zinc oxide, or silica can effectively scatter and absorb UV radiation, protecting the silicone rubber from degradation. This approach also often improves other mechanical properties of the material.

- Silicone rubber blends and copolymers: Developing blends or copolymers of silicone rubber with other UV-resistant polymers can enhance overall UV resistance. This approach combines the beneficial properties of silicone rubber with the UV stability of other materials, resulting in a composite that offers improved performance in high UV exposure environments.

- Optimized curing and crosslinking processes: Improving the curing and crosslinking processes of silicone rubber can enhance its UV resistance. Techniques such as high-temperature vulcanization, electron beam curing, or the use of specific catalysts can create a more tightly crosslinked structure that is less susceptible to UV-induced degradation. This results in silicone rubber products with improved longevity under UV exposure.

02 Surface treatment techniques for UV protection

Surface treatments can be applied to silicone rubber to improve its UV resistance. These may include coatings, plasma treatments, or chemical modifications of the surface layer. Such treatments create a protective barrier that absorbs or reflects UV radiation, preventing it from penetrating and damaging the underlying silicone rubber material.Expand Specific Solutions03 Silicone rubber composites with enhanced UV stability

Developing composite materials by blending silicone rubber with other UV-resistant polymers or inorganic particles can improve overall UV resistance. These composites may incorporate materials such as titanium dioxide, zinc oxide, or specialized polymer blends that synergistically enhance the UV stability of the final product.Expand Specific Solutions04 Molecular structure modifications for UV resistance

Altering the molecular structure of silicone rubber through chemical modifications or copolymerization can inherently improve its UV resistance. This may involve introducing UV-stable functional groups or creating cross-linked structures that are less susceptible to UV-induced degradation.Expand Specific Solutions05 Testing and evaluation methods for UV resistance

Developing and standardizing testing protocols to evaluate the UV resistance of silicone rubber materials is crucial. These methods may include accelerated weathering tests, spectroscopic analysis, and long-term outdoor exposure studies to accurately assess and predict the UV stability of silicone rubber products under various environmental conditions.Expand Specific Solutions

Key Industry Players

The UV resistance enhancement of silicone rubber is a critical technological challenge in an industry that is rapidly evolving. The market for UV-resistant silicone rubber is expanding, driven by increasing demand in sectors such as construction, automotive, and electronics. Major players like Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie are at the forefront of this technology, investing heavily in R&D to improve UV resistance. The market is in a growth phase, with emerging companies and research institutions also contributing to innovations. While the basic technology is mature, ongoing research focuses on developing advanced formulations and additives to enhance UV stability further, indicating a dynamic and competitive landscape.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber formulations with enhanced UV resistance. Their approach involves incorporating specialized UV absorbers and light stabilizers into the silicone matrix. The company has introduced a series of UV-resistant silicone grades, such as their KE-7611-U, which exhibits excellent weatherability and maintains its physical properties even after prolonged UV exposure[1]. They have also developed a proprietary crosslinking technology that creates a more stable polymer network, further improving the material's resistance to UV degradation[2]. Additionally, Shin-Etsu has implemented surface modification techniques, including the application of UV-resistant coatings, to provide an extra layer of protection against harmful radiation[3].

Strengths: Industry-leading expertise in silicone technology, comprehensive product range, and strong R&D capabilities. Weaknesses: Potentially higher costs due to advanced formulations and specialized additives.

Kaneka Corp.

Technical Solution: Kaneka Corporation has made significant strides in enhancing silicone rubber's UV resistance through their innovative material science approach. They have developed a series of silicone elastomers with integrated UV stabilizers that are chemically bonded to the silicone backbone, providing long-lasting protection against UV degradation[7]. Kaneka's technology also includes the use of specialized silica fillers that not only reinforce the rubber but also contribute to UV scattering and absorption. Their KANEKA MS Polymer™ technology, while not a traditional silicone, offers hybrid materials with excellent UV resistance that can be used in conjunction with silicone rubbers for enhanced performance[8]. Additionally, Kaneka has explored the use of nano-scale cerium oxide particles as UV absorbers in silicone formulations, significantly improving the material's weatherability[9].

Strengths: Innovative hybrid materials, strong focus on nanotechnology integration. Weaknesses: Some solutions may be more suitable for specific niche applications rather than general-purpose use.

Core UV Innovations

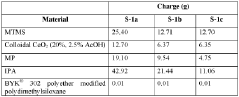

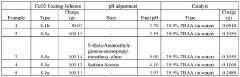

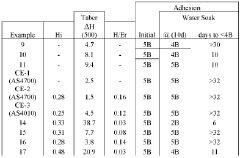

Abrasion resistant coating composition with inorganic metal oxides

PatentWO2018102510A1

Innovation

- A coating system comprising a curable silicone hardcoat with inorganic UV-absorbing materials such as cerium oxide, titanium oxide, or zinc oxide, and a catalyst like tetrabutylammonium carboxylate, which controls the concentration of these components to achieve excellent weatherability and abrasion resistance while maintaining optical clarity and adhesion.

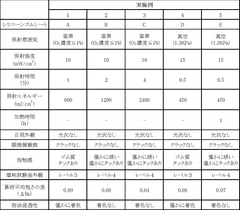

Method for photo-hardening silicone rubber surface, and molded silicone rubber

PatentWO2017150074A1

Innovation

- Irradiating the silicone rubber surface with vacuum ultraviolet light of 200 nm or less at specific energy levels to form an oxidized layer through photo-oxidation, which enhances abrasion resistance without altering the surface gloss or texture, and optionally aging the material at low temperatures to further harden the surface.

Environmental Impact

The environmental impact of enhancing silicone rubber's UV resistance is a critical consideration in the development and application of this technology. UV-resistant silicone rubber offers improved durability and longevity, potentially reducing the frequency of replacement and disposal of products made from this material. This can lead to a decrease in overall waste generation and resource consumption.

However, the process of enhancing UV resistance often involves the incorporation of additional chemicals or additives into the silicone rubber matrix. These additives, such as UV absorbers or stabilizers, may have their own environmental implications. Some UV stabilizers have been found to persist in the environment and bioaccumulate in organisms, raising concerns about their long-term ecological effects.

The production of UV-resistant silicone rubber may require additional energy and resources compared to standard silicone rubber manufacturing. This increased energy consumption could contribute to higher carbon emissions if not offset by renewable energy sources or improved production efficiencies.

On the positive side, enhanced UV resistance can extend the lifespan of outdoor applications, such as solar panel components, building materials, and automotive parts. This longevity can indirectly contribute to environmental protection by reducing the need for frequent replacements and the associated manufacturing and transportation impacts.

The end-of-life disposal of UV-resistant silicone rubber is another important environmental consideration. While silicone rubber is generally considered inert and non-toxic, the additives used for UV resistance may complicate recycling processes or introduce potential contaminants if not properly managed.

In marine environments, UV-resistant silicone rubber used in various applications may contribute less to microplastic pollution due to its enhanced durability. This could potentially reduce the impact on marine ecosystems compared to less durable materials that degrade more rapidly under UV exposure.

As environmental regulations become more stringent, the development of UV-resistant silicone rubber must also focus on eco-friendly additives and production methods. Research into bio-based UV stabilizers and green chemistry approaches for enhancing UV resistance is gaining traction, aiming to minimize the environmental footprint of these materials throughout their lifecycle.

However, the process of enhancing UV resistance often involves the incorporation of additional chemicals or additives into the silicone rubber matrix. These additives, such as UV absorbers or stabilizers, may have their own environmental implications. Some UV stabilizers have been found to persist in the environment and bioaccumulate in organisms, raising concerns about their long-term ecological effects.

The production of UV-resistant silicone rubber may require additional energy and resources compared to standard silicone rubber manufacturing. This increased energy consumption could contribute to higher carbon emissions if not offset by renewable energy sources or improved production efficiencies.

On the positive side, enhanced UV resistance can extend the lifespan of outdoor applications, such as solar panel components, building materials, and automotive parts. This longevity can indirectly contribute to environmental protection by reducing the need for frequent replacements and the associated manufacturing and transportation impacts.

The end-of-life disposal of UV-resistant silicone rubber is another important environmental consideration. While silicone rubber is generally considered inert and non-toxic, the additives used for UV resistance may complicate recycling processes or introduce potential contaminants if not properly managed.

In marine environments, UV-resistant silicone rubber used in various applications may contribute less to microplastic pollution due to its enhanced durability. This could potentially reduce the impact on marine ecosystems compared to less durable materials that degrade more rapidly under UV exposure.

As environmental regulations become more stringent, the development of UV-resistant silicone rubber must also focus on eco-friendly additives and production methods. Research into bio-based UV stabilizers and green chemistry approaches for enhancing UV resistance is gaining traction, aiming to minimize the environmental footprint of these materials throughout their lifecycle.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of UV-resistant silicone rubber products. As manufacturers and researchers strive to enhance the UV resistance of silicone rubber, they must navigate a complex landscape of regulations and standards across different industries and regions.

In the United States, the Food and Drug Administration (FDA) regulates silicone rubber materials used in food contact applications and medical devices. For UV-resistant silicone rubber intended for these purposes, compliance with FDA regulations is essential. This includes adherence to specific guidelines outlined in 21 CFR 177.2600 for rubber articles intended for repeated use in food contact applications.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of chemicals in silicone rubber formulations, including UV stabilizers and additives. Manufacturers must ensure that all substances used in their UV-resistant silicone rubber products are registered and comply with REACH requirements.

For automotive applications, UV-resistant silicone rubber components must meet stringent industry standards. These include SAE J2527 for accelerated exposure of automotive exterior materials using a controlled irradiance xenon-arc apparatus, which evaluates the UV resistance of materials used in automotive exteriors.

In the construction industry, ASTM D1149 standard test method for rubber deterioration - surface ozone cracking in a chamber is often used to assess the ozone and UV resistance of silicone rubber materials used in building and construction applications.

The aerospace industry has its own set of rigorous standards for UV-resistant materials. NASA's Technical Standard NASA-STD-6016A, which covers standard materials and processes requirements for spacecraft, includes specifications for UV-resistant materials used in space applications.

Environmental regulations also impact the development of UV-resistant silicone rubber. Many regions have restrictions on volatile organic compounds (VOCs) and other potentially harmful substances that may be used in UV stabilizers or additives. Manufacturers must consider these regulations when formulating their products.

As the demand for sustainable and eco-friendly materials grows, new regulations are emerging that focus on the environmental impact of materials throughout their lifecycle. This includes considerations for the recyclability and end-of-life disposal of UV-resistant silicone rubber products.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to product development and testing. Manufacturers must invest in rigorous quality control processes and documentation to demonstrate compliance with applicable standards and regulations. This often involves extensive testing, certification, and ongoing monitoring to ensure continued compliance as regulations evolve.

In the United States, the Food and Drug Administration (FDA) regulates silicone rubber materials used in food contact applications and medical devices. For UV-resistant silicone rubber intended for these purposes, compliance with FDA regulations is essential. This includes adherence to specific guidelines outlined in 21 CFR 177.2600 for rubber articles intended for repeated use in food contact applications.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of chemicals in silicone rubber formulations, including UV stabilizers and additives. Manufacturers must ensure that all substances used in their UV-resistant silicone rubber products are registered and comply with REACH requirements.

For automotive applications, UV-resistant silicone rubber components must meet stringent industry standards. These include SAE J2527 for accelerated exposure of automotive exterior materials using a controlled irradiance xenon-arc apparatus, which evaluates the UV resistance of materials used in automotive exteriors.

In the construction industry, ASTM D1149 standard test method for rubber deterioration - surface ozone cracking in a chamber is often used to assess the ozone and UV resistance of silicone rubber materials used in building and construction applications.

The aerospace industry has its own set of rigorous standards for UV-resistant materials. NASA's Technical Standard NASA-STD-6016A, which covers standard materials and processes requirements for spacecraft, includes specifications for UV-resistant materials used in space applications.

Environmental regulations also impact the development of UV-resistant silicone rubber. Many regions have restrictions on volatile organic compounds (VOCs) and other potentially harmful substances that may be used in UV stabilizers or additives. Manufacturers must consider these regulations when formulating their products.

As the demand for sustainable and eco-friendly materials grows, new regulations are emerging that focus on the environmental impact of materials throughout their lifecycle. This includes considerations for the recyclability and end-of-life disposal of UV-resistant silicone rubber products.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to product development and testing. Manufacturers must invest in rigorous quality control processes and documentation to demonstrate compliance with applicable standards and regulations. This often involves extensive testing, certification, and ongoing monitoring to ensure continued compliance as regulations evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!