How Silicone Rubber Influences Next-Gen Communication Devices?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Comms: Background and Objectives

Silicone rubber has emerged as a critical material in the evolution of next-generation communication devices, playing a pivotal role in enhancing their performance, durability, and functionality. The journey of silicone rubber in communications technology dates back to the mid-20th century, with its unique properties making it increasingly indispensable as devices became more sophisticated and demanding.

Initially utilized primarily for its excellent insulating properties, silicone rubber's application in communication devices has expanded significantly over the years. Its resistance to extreme temperatures, moisture, and UV radiation made it an ideal choice for protecting sensitive electronic components in outdoor telecommunications equipment. As mobile communications proliferated, silicone rubber found new applications in sealing and protecting portable devices from environmental factors.

The advent of 5G and IoT technologies has further amplified the importance of silicone rubber in the communications sector. These next-generation networks require a vast array of small cell antennas and sensors, often deployed in challenging environments. Silicone rubber's flexibility, weather resistance, and ability to maintain its properties over a wide temperature range make it an excellent material for encapsulating and protecting these critical components.

In recent years, the focus has shifted towards developing advanced silicone rubber formulations that can meet the specific needs of modern communication devices. These include improved signal transparency for antenna housings, enhanced thermal management properties for heat-generating components, and increased durability to withstand the rigors of constant use and exposure to various environmental conditions.

The overarching goal of silicone rubber research and development in the communications sector is to enable the creation of more reliable, efficient, and compact devices capable of supporting the increasing demands of data transmission and connectivity. This involves not only improving the material's existing properties but also exploring new functionalities such as self-healing capabilities and integration with other advanced materials.

As we look towards the future of communication technologies, including 6G and beyond, the role of silicone rubber is expected to become even more crucial. The objectives for its development include achieving higher levels of miniaturization, improved energy efficiency, and enhanced electromagnetic compatibility. Additionally, there is a growing emphasis on developing sustainable and environmentally friendly silicone rubber formulations to align with global sustainability goals in the tech industry.

Initially utilized primarily for its excellent insulating properties, silicone rubber's application in communication devices has expanded significantly over the years. Its resistance to extreme temperatures, moisture, and UV radiation made it an ideal choice for protecting sensitive electronic components in outdoor telecommunications equipment. As mobile communications proliferated, silicone rubber found new applications in sealing and protecting portable devices from environmental factors.

The advent of 5G and IoT technologies has further amplified the importance of silicone rubber in the communications sector. These next-generation networks require a vast array of small cell antennas and sensors, often deployed in challenging environments. Silicone rubber's flexibility, weather resistance, and ability to maintain its properties over a wide temperature range make it an excellent material for encapsulating and protecting these critical components.

In recent years, the focus has shifted towards developing advanced silicone rubber formulations that can meet the specific needs of modern communication devices. These include improved signal transparency for antenna housings, enhanced thermal management properties for heat-generating components, and increased durability to withstand the rigors of constant use and exposure to various environmental conditions.

The overarching goal of silicone rubber research and development in the communications sector is to enable the creation of more reliable, efficient, and compact devices capable of supporting the increasing demands of data transmission and connectivity. This involves not only improving the material's existing properties but also exploring new functionalities such as self-healing capabilities and integration with other advanced materials.

As we look towards the future of communication technologies, including 6G and beyond, the role of silicone rubber is expected to become even more crucial. The objectives for its development include achieving higher levels of miniaturization, improved energy efficiency, and enhanced electromagnetic compatibility. Additionally, there is a growing emphasis on developing sustainable and environmentally friendly silicone rubber formulations to align with global sustainability goals in the tech industry.

Market Demand Analysis for Advanced Comms Materials

The market demand for advanced communication materials, particularly silicone rubber, is experiencing significant growth driven by the rapid evolution of next-generation communication devices. As 5G and future 6G networks continue to expand, there is an increasing need for materials that can meet the stringent requirements of high-frequency, high-speed data transmission while maintaining durability and reliability.

Silicone rubber has emerged as a crucial material in this landscape due to its unique properties. Its excellent dielectric characteristics, thermal stability, and flexibility make it ideal for various applications in communication devices. The market for silicone rubber in this sector is expected to grow substantially over the next decade, with a compound annual growth rate (CAGR) projected to be in the double digits.

One of the primary drivers of this demand is the proliferation of 5G infrastructure. As countries worldwide invest heavily in 5G rollout, the need for high-performance antenna systems, cable insulation, and protective housings has surged. Silicone rubber's ability to maintain its properties across a wide temperature range and its resistance to environmental factors make it an attractive choice for outdoor communication equipment.

The automotive industry is another significant contributor to the growing demand for silicone rubber in communication devices. With the rise of connected and autonomous vehicles, there is an increasing need for reliable, high-performance materials in automotive communication systems. Silicone rubber's resistance to vibration, heat, and electromagnetic interference positions it as a preferred material for these applications.

Consumer electronics represent another substantial market segment driving demand for silicone rubber in communication devices. As smartphones, tablets, and wearable devices become more advanced, manufacturers are seeking materials that can provide better signal integrity, improved durability, and enhanced user experience. Silicone rubber's properties align well with these requirements, leading to its increased adoption in device components such as antennas, connectors, and protective casings.

The Internet of Things (IoT) and smart home devices are also fueling the demand for silicone rubber in communication materials. As these technologies become more prevalent, there is a growing need for reliable, long-lasting materials that can withstand various environmental conditions while maintaining optimal performance. Silicone rubber's versatility and durability make it an excellent choice for IoT sensors, smart home hubs, and other connected devices.

Looking ahead, the market demand for silicone rubber in next-generation communication devices is expected to continue its upward trajectory. As 6G technology begins to take shape, the requirements for advanced materials will become even more stringent, likely leading to further innovations in silicone rubber formulations and applications. This ongoing development will create new opportunities for material suppliers, device manufacturers, and technology companies operating in the communications sector.

Silicone rubber has emerged as a crucial material in this landscape due to its unique properties. Its excellent dielectric characteristics, thermal stability, and flexibility make it ideal for various applications in communication devices. The market for silicone rubber in this sector is expected to grow substantially over the next decade, with a compound annual growth rate (CAGR) projected to be in the double digits.

One of the primary drivers of this demand is the proliferation of 5G infrastructure. As countries worldwide invest heavily in 5G rollout, the need for high-performance antenna systems, cable insulation, and protective housings has surged. Silicone rubber's ability to maintain its properties across a wide temperature range and its resistance to environmental factors make it an attractive choice for outdoor communication equipment.

The automotive industry is another significant contributor to the growing demand for silicone rubber in communication devices. With the rise of connected and autonomous vehicles, there is an increasing need for reliable, high-performance materials in automotive communication systems. Silicone rubber's resistance to vibration, heat, and electromagnetic interference positions it as a preferred material for these applications.

Consumer electronics represent another substantial market segment driving demand for silicone rubber in communication devices. As smartphones, tablets, and wearable devices become more advanced, manufacturers are seeking materials that can provide better signal integrity, improved durability, and enhanced user experience. Silicone rubber's properties align well with these requirements, leading to its increased adoption in device components such as antennas, connectors, and protective casings.

The Internet of Things (IoT) and smart home devices are also fueling the demand for silicone rubber in communication materials. As these technologies become more prevalent, there is a growing need for reliable, long-lasting materials that can withstand various environmental conditions while maintaining optimal performance. Silicone rubber's versatility and durability make it an excellent choice for IoT sensors, smart home hubs, and other connected devices.

Looking ahead, the market demand for silicone rubber in next-generation communication devices is expected to continue its upward trajectory. As 6G technology begins to take shape, the requirements for advanced materials will become even more stringent, likely leading to further innovations in silicone rubber formulations and applications. This ongoing development will create new opportunities for material suppliers, device manufacturers, and technology companies operating in the communications sector.

Current State and Challenges of Silicone in Comms

Silicone rubber has emerged as a critical material in the development of next-generation communication devices, offering unique properties that address many challenges in the field. Currently, silicone is widely used in various components of communication devices, including antennas, connectors, and protective casings. Its flexibility, durability, and resistance to environmental factors make it an ideal choice for devices that need to withstand harsh conditions.

One of the primary advantages of silicone rubber in communication devices is its excellent dielectric properties. This characteristic allows for efficient signal transmission and minimal interference, which is crucial for maintaining high-quality communications. Additionally, silicone's thermal stability ensures that devices can operate reliably across a wide range of temperatures, from extreme cold to intense heat.

However, the integration of silicone rubber in next-generation communication devices is not without challenges. One significant hurdle is the material's relatively high cost compared to traditional plastics, which can impact the overall production expenses of communication devices. Manufacturers are constantly seeking ways to optimize the use of silicone to balance performance and cost-effectiveness.

Another challenge lies in the processing and manufacturing techniques required for silicone rubber. The material's unique properties, while beneficial for the end product, can make it more difficult to work with during the production phase. This necessitates specialized equipment and expertise, which not all manufacturers possess.

The increasing demand for miniaturization in communication devices presents another obstacle. While silicone rubber can be molded into various shapes and sizes, achieving the level of precision required for some cutting-edge components can be challenging. This is particularly true for devices that incorporate advanced technologies such as 5G and beyond, where every millimeter counts.

Compatibility with other materials used in communication devices is also a concern. Engineers must ensure that silicone rubber interfaces correctly with metals, other polymers, and electronic components without compromising the integrity or performance of the device. This often requires extensive testing and refinement of designs.

Looking ahead, researchers and manufacturers are exploring ways to enhance the properties of silicone rubber further. This includes developing new formulations with improved electrical properties, better adhesion to other materials, and enhanced durability. There is also a focus on creating more environmentally friendly silicone rubber compounds to align with the growing emphasis on sustainability in the tech industry.

One of the primary advantages of silicone rubber in communication devices is its excellent dielectric properties. This characteristic allows for efficient signal transmission and minimal interference, which is crucial for maintaining high-quality communications. Additionally, silicone's thermal stability ensures that devices can operate reliably across a wide range of temperatures, from extreme cold to intense heat.

However, the integration of silicone rubber in next-generation communication devices is not without challenges. One significant hurdle is the material's relatively high cost compared to traditional plastics, which can impact the overall production expenses of communication devices. Manufacturers are constantly seeking ways to optimize the use of silicone to balance performance and cost-effectiveness.

Another challenge lies in the processing and manufacturing techniques required for silicone rubber. The material's unique properties, while beneficial for the end product, can make it more difficult to work with during the production phase. This necessitates specialized equipment and expertise, which not all manufacturers possess.

The increasing demand for miniaturization in communication devices presents another obstacle. While silicone rubber can be molded into various shapes and sizes, achieving the level of precision required for some cutting-edge components can be challenging. This is particularly true for devices that incorporate advanced technologies such as 5G and beyond, where every millimeter counts.

Compatibility with other materials used in communication devices is also a concern. Engineers must ensure that silicone rubber interfaces correctly with metals, other polymers, and electronic components without compromising the integrity or performance of the device. This often requires extensive testing and refinement of designs.

Looking ahead, researchers and manufacturers are exploring ways to enhance the properties of silicone rubber further. This includes developing new formulations with improved electrical properties, better adhesion to other materials, and enhanced durability. There is also a focus on creating more environmentally friendly silicone rubber compounds to align with the growing emphasis on sustainability in the tech industry.

Existing Silicone Solutions for Comms Devices

01 Composition and formulation of silicone rubber

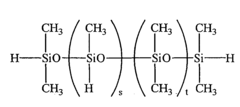

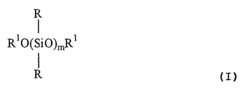

Silicone rubber compositions typically include a base polymer, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as heat resistance, electrical insulation, or flexibility. Various additives may be incorporated to enhance performance characteristics or processing behavior.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the manufacturing process. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating nanoparticles.

- Applications of silicone rubber: Silicone rubber finds wide-ranging applications due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, and consumer products. Its biocompatibility makes it suitable for implants and prosthetics, while its heat resistance is valuable in industrial applications.

- Curing methods for silicone rubber: Various curing methods are employed in the production of silicone rubber, including heat curing, room temperature vulcanization (RTV), and UV curing. Each method affects the final properties of the rubber differently and is chosen based on the specific application requirements and manufacturing constraints.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing with fibers, blending with other elastomers, or incorporating functional fillers. These composites often exhibit improved mechanical strength, thermal conductivity, or specific functional properties.

02 Manufacturing processes for silicone rubber products

Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods such as heat curing or room temperature vulcanization are used to set the rubber.Expand Specific Solutions03 Modifications and improvements to silicone rubber properties

Researchers continually work on enhancing silicone rubber properties through various modifications. This includes incorporating nanofillers, blending with other polymers, or chemically modifying the silicone backbone. Such improvements can lead to increased strength, better thermal stability, or improved chemical resistance.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds widespread use across multiple industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for diverse applications.Expand Specific Solutions05 Environmental and safety considerations in silicone rubber production

The production and use of silicone rubber involve considerations for environmental impact and safety. This includes developing eco-friendly manufacturing processes, ensuring the safety of workers handling the material, and addressing end-of-life disposal or recycling of silicone rubber products. Efforts are made to reduce volatile organic compound emissions and improve overall sustainability.Expand Specific Solutions

Key Players in Silicone and Comms Device Industry

The market for silicone rubber in next-generation communication devices is in a growth phase, driven by increasing demand for 5G infrastructure and IoT devices. The global market size is projected to expand significantly over the next few years. Technologically, silicone rubber solutions are advancing rapidly, with key players like Shin-Etsu Chemical, Wacker Chemie, and Dow Corning leading innovation. These companies are developing high-performance silicone materials with enhanced thermal, electrical, and mechanical properties tailored for 5G and IoT applications. Emerging players like Elkem Silicones and Momentive are also contributing to technological advancements, intensifying competition in this evolving market landscape.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically tailored for next-generation communication devices. Their high-performance silicone elastomers offer excellent electrical insulation properties and thermal stability, crucial for 5G and future 6G applications[1]. The company's silicone rubber materials demonstrate low dielectric loss and high frequency stability, enabling efficient signal transmission in high-frequency ranges up to 110 GHz[2]. Additionally, Shin-Etsu has introduced self-healing silicone rubbers that can recover from physical damage, enhancing the durability of communication devices exposed to harsh environments[3].

Strengths: Superior electrical properties, thermal stability, and self-healing capabilities. Weaknesses: Potentially higher cost compared to traditional materials, may require specialized processing techniques.

Apple, Inc.

Technical Solution: Apple has incorporated advanced silicone rubber technologies in their next-gen communication devices, particularly in their latest iPhone and Apple Watch models. The company utilizes custom-formulated silicone rubber compounds for antenna housings and gaskets, optimizing signal transmission and reception in 5G networks[4]. Apple's approach includes the use of liquid silicone rubber (LSR) injection molding for precise, complex geometries in device components, enhancing both functionality and design aesthetics[5]. Their silicone rubber applications also extend to improving water and dust resistance in communication devices, with specially designed seals and gaskets maintaining an IP68 rating[6].

Strengths: Integration of silicone rubber in cutting-edge consumer electronics, balancing performance and design. Weaknesses: Proprietary nature of technologies may limit broader industry adoption.

Core Innovations in Silicone for Next-Gen Comms

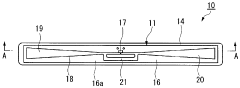

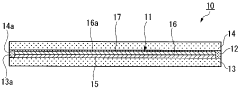

Non-contact data receiver/transmitter

PatentWO2009119828A1

Innovation

- A non-contact data transmitter/receiver design utilizing liquid silicone rubber adhesive and silicone rubber or vulcanized rubber base materials to sandwich the IC tag, ensuring high adhesion and flexibility while preventing chemical and water ingress, and maintaining antenna communication quality.

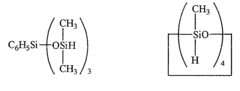

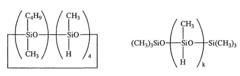

Silicone rubber compositions, their preparation and use

PatentInactiveEP1557446A1

Innovation

- A silicone rubber composition comprising an organopolysiloxane with a degree of polymerization of 100 or higher and at least two silicon-bonded alkenyl groups, combined with wet silica having a specific surface area of 50 m^2/g or larger and a water content of 4% or lower, and an effective curing agent, which inhibits foaming during hot air vulcanization and enhances electrical properties.

Environmental Impact of Silicone in Comms Devices

The environmental impact of silicone rubber in next-generation communication devices is a critical consideration as the industry moves towards more sustainable practices. Silicone rubber, while offering numerous benefits in terms of durability and performance, presents both challenges and opportunities from an environmental perspective.

One of the primary environmental concerns associated with silicone rubber in communication devices is its end-of-life disposal. Unlike many other materials, silicone rubber is not biodegradable and can persist in the environment for extended periods. This longevity, while beneficial for product lifespan, poses challenges for waste management and recycling efforts. However, recent advancements in recycling technologies have shown promise in breaking down silicone rubber into reusable components, potentially mitigating some of these concerns.

The production process of silicone rubber also has environmental implications. The manufacturing of silicone involves energy-intensive processes and the use of various chemicals, which can contribute to greenhouse gas emissions and potential pollution if not properly managed. However, compared to some alternative materials, silicone production generally has a lower environmental footprint, particularly in terms of water usage and toxic byproducts.

On the positive side, the durability and weather resistance of silicone rubber contribute to the longevity of communication devices, potentially reducing the frequency of device replacement and associated electronic waste. This extended lifespan can lead to a reduction in overall resource consumption and waste generation over time.

Furthermore, the thermal stability and electrical insulation properties of silicone rubber enable the development of more energy-efficient communication devices. By improving heat dissipation and reducing power loss, silicone-based components can contribute to lower energy consumption during device operation, indirectly reducing the carbon footprint associated with device usage.

The flexibility of silicone rubber also allows for the design of more compact and lightweight devices, potentially reducing material usage and transportation-related emissions. Additionally, silicone's resistance to extreme temperatures and environmental conditions can lead to fewer device failures in harsh environments, further extending product lifespans and reducing waste.

As the communication industry continues to evolve, there is a growing focus on developing more environmentally friendly silicone formulations. Research into bio-based silicones and improved recycling methods shows promise for further reducing the environmental impact of silicone rubber in future communication devices.

One of the primary environmental concerns associated with silicone rubber in communication devices is its end-of-life disposal. Unlike many other materials, silicone rubber is not biodegradable and can persist in the environment for extended periods. This longevity, while beneficial for product lifespan, poses challenges for waste management and recycling efforts. However, recent advancements in recycling technologies have shown promise in breaking down silicone rubber into reusable components, potentially mitigating some of these concerns.

The production process of silicone rubber also has environmental implications. The manufacturing of silicone involves energy-intensive processes and the use of various chemicals, which can contribute to greenhouse gas emissions and potential pollution if not properly managed. However, compared to some alternative materials, silicone production generally has a lower environmental footprint, particularly in terms of water usage and toxic byproducts.

On the positive side, the durability and weather resistance of silicone rubber contribute to the longevity of communication devices, potentially reducing the frequency of device replacement and associated electronic waste. This extended lifespan can lead to a reduction in overall resource consumption and waste generation over time.

Furthermore, the thermal stability and electrical insulation properties of silicone rubber enable the development of more energy-efficient communication devices. By improving heat dissipation and reducing power loss, silicone-based components can contribute to lower energy consumption during device operation, indirectly reducing the carbon footprint associated with device usage.

The flexibility of silicone rubber also allows for the design of more compact and lightweight devices, potentially reducing material usage and transportation-related emissions. Additionally, silicone's resistance to extreme temperatures and environmental conditions can lead to fewer device failures in harsh environments, further extending product lifespans and reducing waste.

As the communication industry continues to evolve, there is a growing focus on developing more environmentally friendly silicone formulations. Research into bio-based silicones and improved recycling methods shows promise for further reducing the environmental impact of silicone rubber in future communication devices.

Regulatory Landscape for Silicone in Electronics

The regulatory landscape for silicone in electronics is complex and evolving, reflecting the increasing importance of silicone rubber in next-generation communication devices. Regulatory bodies worldwide are adapting their frameworks to address the unique properties and applications of silicone in electronic components.

In the United States, the Federal Communications Commission (FCC) plays a crucial role in regulating electronic devices, including those incorporating silicone rubber. The FCC's regulations focus on electromagnetic compatibility and radio frequency emissions, areas where silicone's dielectric properties can significantly impact device performance. Manufacturers must ensure that silicone-based components comply with FCC standards for electromagnetic interference (EMI) and radiofrequency interference (RFI).

The European Union's regulatory approach is governed by the Radio Equipment Directive (RED) and the Restriction of Hazardous Substances (RoHS) Directive. These regulations set strict standards for the use of materials in electronic devices, including silicone rubber. The RED ensures that radio equipment, which may incorporate silicone components, meets essential requirements for safety and electromagnetic compatibility. The RoHS Directive limits the use of certain hazardous substances in electrical and electronic equipment, impacting the formulation of silicone rubber compounds used in these devices.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Industry and Information Technology (MIIT) oversees regulations for electronic products, including those using silicone rubber. Japan's regulatory landscape is shaped by the Electrical Appliance and Material Safety Law, which sets safety standards for electronic devices and components.

Global harmonization efforts, such as the International Electrotechnical Commission (IEC) standards, are increasingly important in shaping the regulatory landscape for silicone in electronics. These standards aim to create a unified approach to safety, performance, and environmental impact across different regions.

Environmental regulations are also becoming more stringent, affecting the use of silicone in electronics. Regulations like the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) impact the chemical composition of silicone rubber used in electronic devices, pushing manufacturers to develop more environmentally friendly formulations.

As next-generation communication devices continue to evolve, regulatory bodies are likely to update their frameworks to address new applications of silicone rubber. This may include specific regulations for 5G and future 6G technologies, where silicone's unique properties play a crucial role in antenna design and signal transmission. Manufacturers and researchers must stay abreast of these regulatory changes to ensure compliance and optimize the use of silicone rubber in innovative communication devices.

In the United States, the Federal Communications Commission (FCC) plays a crucial role in regulating electronic devices, including those incorporating silicone rubber. The FCC's regulations focus on electromagnetic compatibility and radio frequency emissions, areas where silicone's dielectric properties can significantly impact device performance. Manufacturers must ensure that silicone-based components comply with FCC standards for electromagnetic interference (EMI) and radiofrequency interference (RFI).

The European Union's regulatory approach is governed by the Radio Equipment Directive (RED) and the Restriction of Hazardous Substances (RoHS) Directive. These regulations set strict standards for the use of materials in electronic devices, including silicone rubber. The RED ensures that radio equipment, which may incorporate silicone components, meets essential requirements for safety and electromagnetic compatibility. The RoHS Directive limits the use of certain hazardous substances in electrical and electronic equipment, impacting the formulation of silicone rubber compounds used in these devices.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Industry and Information Technology (MIIT) oversees regulations for electronic products, including those using silicone rubber. Japan's regulatory landscape is shaped by the Electrical Appliance and Material Safety Law, which sets safety standards for electronic devices and components.

Global harmonization efforts, such as the International Electrotechnical Commission (IEC) standards, are increasingly important in shaping the regulatory landscape for silicone in electronics. These standards aim to create a unified approach to safety, performance, and environmental impact across different regions.

Environmental regulations are also becoming more stringent, affecting the use of silicone in electronics. Regulations like the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) impact the chemical composition of silicone rubber used in electronic devices, pushing manufacturers to develop more environmentally friendly formulations.

As next-generation communication devices continue to evolve, regulatory bodies are likely to update their frameworks to address new applications of silicone rubber. This may include specific regulations for 5G and future 6G technologies, where silicone's unique properties play a crucial role in antenna design and signal transmission. Manufacturers and researchers must stay abreast of these regulatory changes to ensure compliance and optimize the use of silicone rubber in innovative communication devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!