Silicone Rubber: Creating Next-Gen Flexible Electronics

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution and Objectives

Silicone rubber has undergone a remarkable evolution since its inception in the 1940s. Initially developed as a high-performance elastomer for industrial applications, it has steadily expanded its reach into various sectors, including electronics. The journey of silicone rubber in flexible electronics began in the late 1990s when researchers recognized its potential for creating bendable and stretchable electronic devices.

The primary objective in the field of silicone rubber for next-generation flexible electronics is to develop materials that can seamlessly integrate electronic functionality with the flexibility and durability of silicone elastomers. This goal encompasses several key aspects, including enhancing the electrical conductivity of silicone-based composites, improving the adhesion between silicone and conductive materials, and developing novel manufacturing techniques for complex, multi-layered flexible electronic structures.

One of the critical milestones in this technological evolution was the development of conductive silicone composites. By incorporating conductive fillers such as carbon nanotubes, silver nanoparticles, or graphene into silicone matrices, researchers have created materials that maintain the desirable mechanical properties of silicone while exhibiting electrical conductivity. This breakthrough has paved the way for stretchable circuits, sensors, and electrodes.

Another significant advancement has been the improvement of silicone's compatibility with traditional electronic materials. Techniques such as plasma treatment and the development of specialized coupling agents have enhanced the adhesion between silicone and metals or other polymers, enabling the creation of more robust and reliable flexible electronic devices.

The evolution of manufacturing processes has also played a crucial role in advancing silicone-based flexible electronics. Innovations in 3D printing, screen printing, and roll-to-roll processing have made it possible to fabricate complex, multi-layered structures with precise control over material deposition and device architecture.

Looking forward, the objectives for silicone rubber in flexible electronics are ambitious and multifaceted. Researchers aim to develop self-healing silicone composites that can autonomously repair damage, ensuring longer device lifespans. There is also a push towards creating biocompatible and biodegradable silicone-based electronics for medical and environmental applications. Additionally, efforts are underway to improve the energy efficiency and power density of silicone-based energy storage and harvesting devices, such as flexible batteries and solar cells.

The ultimate goal is to create a new generation of electronic devices that are not only flexible and stretchable but also seamlessly integrate with our environment and bodies. This vision encompasses wearable health monitors, soft robotics, and adaptive smart surfaces, all powered by advanced silicone rubber technologies.

The primary objective in the field of silicone rubber for next-generation flexible electronics is to develop materials that can seamlessly integrate electronic functionality with the flexibility and durability of silicone elastomers. This goal encompasses several key aspects, including enhancing the electrical conductivity of silicone-based composites, improving the adhesion between silicone and conductive materials, and developing novel manufacturing techniques for complex, multi-layered flexible electronic structures.

One of the critical milestones in this technological evolution was the development of conductive silicone composites. By incorporating conductive fillers such as carbon nanotubes, silver nanoparticles, or graphene into silicone matrices, researchers have created materials that maintain the desirable mechanical properties of silicone while exhibiting electrical conductivity. This breakthrough has paved the way for stretchable circuits, sensors, and electrodes.

Another significant advancement has been the improvement of silicone's compatibility with traditional electronic materials. Techniques such as plasma treatment and the development of specialized coupling agents have enhanced the adhesion between silicone and metals or other polymers, enabling the creation of more robust and reliable flexible electronic devices.

The evolution of manufacturing processes has also played a crucial role in advancing silicone-based flexible electronics. Innovations in 3D printing, screen printing, and roll-to-roll processing have made it possible to fabricate complex, multi-layered structures with precise control over material deposition and device architecture.

Looking forward, the objectives for silicone rubber in flexible electronics are ambitious and multifaceted. Researchers aim to develop self-healing silicone composites that can autonomously repair damage, ensuring longer device lifespans. There is also a push towards creating biocompatible and biodegradable silicone-based electronics for medical and environmental applications. Additionally, efforts are underway to improve the energy efficiency and power density of silicone-based energy storage and harvesting devices, such as flexible batteries and solar cells.

The ultimate goal is to create a new generation of electronic devices that are not only flexible and stretchable but also seamlessly integrate with our environment and bodies. This vision encompasses wearable health monitors, soft robotics, and adaptive smart surfaces, all powered by advanced silicone rubber technologies.

Flexible Electronics Market Analysis

The flexible electronics market has been experiencing significant growth and transformation, driven by advancements in materials science, particularly in the field of silicone rubber. This market segment encompasses a wide range of applications, including wearable devices, foldable displays, smart textiles, and medical sensors. The demand for flexible electronic products has been steadily increasing due to their unique properties, such as bendability, stretchability, and conformability to various surfaces.

Market research indicates that the global flexible electronics market is poised for substantial expansion in the coming years. This growth is attributed to several factors, including the rising adoption of Internet of Things (IoT) devices, increasing consumer demand for lightweight and portable electronic products, and the growing integration of flexible electronics in healthcare and automotive industries. The market is also benefiting from ongoing research and development efforts aimed at improving the performance and durability of flexible electronic components.

One of the key drivers of market growth is the increasing demand for wearable technology. Smartwatches, fitness trackers, and health monitoring devices are becoming increasingly popular among consumers, fueling the need for flexible and comfortable electronic solutions. The healthcare sector, in particular, is showing a strong interest in flexible electronics for applications such as remote patient monitoring and implantable medical devices.

The automotive industry is another significant contributor to the flexible electronics market. As vehicles become more technologically advanced, there is a growing need for flexible displays, touch panels, and sensors that can be seamlessly integrated into curved surfaces and unconventional form factors. This trend is expected to accelerate with the development of autonomous and electric vehicles, which require advanced sensing and display technologies.

In terms of regional market dynamics, Asia-Pacific is emerging as a key player in the flexible electronics industry. Countries like China, South Korea, and Japan are investing heavily in research and manufacturing capabilities for flexible electronic components. North America and Europe are also significant markets, with a focus on innovation and high-end applications in sectors such as aerospace and defense.

Despite the positive outlook, the flexible electronics market faces certain challenges. These include the high cost of materials and manufacturing processes, which can limit widespread adoption in price-sensitive markets. Additionally, there are technical hurdles to overcome, such as improving the long-term reliability and performance of flexible electronic devices under various environmental conditions.

Market research indicates that the global flexible electronics market is poised for substantial expansion in the coming years. This growth is attributed to several factors, including the rising adoption of Internet of Things (IoT) devices, increasing consumer demand for lightweight and portable electronic products, and the growing integration of flexible electronics in healthcare and automotive industries. The market is also benefiting from ongoing research and development efforts aimed at improving the performance and durability of flexible electronic components.

One of the key drivers of market growth is the increasing demand for wearable technology. Smartwatches, fitness trackers, and health monitoring devices are becoming increasingly popular among consumers, fueling the need for flexible and comfortable electronic solutions. The healthcare sector, in particular, is showing a strong interest in flexible electronics for applications such as remote patient monitoring and implantable medical devices.

The automotive industry is another significant contributor to the flexible electronics market. As vehicles become more technologically advanced, there is a growing need for flexible displays, touch panels, and sensors that can be seamlessly integrated into curved surfaces and unconventional form factors. This trend is expected to accelerate with the development of autonomous and electric vehicles, which require advanced sensing and display technologies.

In terms of regional market dynamics, Asia-Pacific is emerging as a key player in the flexible electronics industry. Countries like China, South Korea, and Japan are investing heavily in research and manufacturing capabilities for flexible electronic components. North America and Europe are also significant markets, with a focus on innovation and high-end applications in sectors such as aerospace and defense.

Despite the positive outlook, the flexible electronics market faces certain challenges. These include the high cost of materials and manufacturing processes, which can limit widespread adoption in price-sensitive markets. Additionally, there are technical hurdles to overcome, such as improving the long-term reliability and performance of flexible electronic devices under various environmental conditions.

Silicone Rubber Tech Challenges

Silicone rubber, a versatile elastomer, faces several technical challenges in its application to next-generation flexible electronics. One of the primary obstacles is achieving consistent electrical conductivity while maintaining the material's inherent flexibility. Traditional methods of incorporating conductive elements often compromise the rubber's elasticity or lead to uneven distribution of conductivity.

Another significant challenge lies in the integration of silicone rubber with other electronic components. The material's surface properties can make it difficult to achieve strong adhesion with metallic conductors or other rigid electronic elements. This integration issue is critical for creating seamless, durable flexible electronic devices that can withstand repeated bending and stretching.

The thermal management of silicone rubber-based electronics presents another hurdle. As electronic components generate heat during operation, efficient heat dissipation becomes crucial. However, silicone rubber's inherent thermal insulation properties can lead to localized heating, potentially affecting the performance and lifespan of embedded electronic components.

Durability and long-term stability of silicone rubber electronics under various environmental conditions pose additional challenges. Exposure to UV radiation, extreme temperatures, and humidity can degrade the material's properties over time, potentially leading to device failure or reduced performance. Developing silicone rubber formulations that maintain their electrical and mechanical properties under these conditions is essential for creating reliable flexible electronics.

Scalability and manufacturing processes present further technical hurdles. Current production methods for integrating electronic functionality into silicone rubber often involve complex, multi-step processes that are difficult to scale up for mass production. Developing efficient, cost-effective manufacturing techniques that can produce consistent results at scale is crucial for the widespread adoption of silicone rubber-based flexible electronics.

Lastly, the challenge of achieving high-resolution patterning and miniaturization in silicone rubber electronics cannot be overlooked. Traditional lithographic techniques used in rigid electronics are not directly applicable to soft, stretchable substrates. Developing new patterning methods that can create fine, precise conductive traces and circuits on silicone rubber surfaces is essential for advancing the capabilities of flexible electronic devices.

Another significant challenge lies in the integration of silicone rubber with other electronic components. The material's surface properties can make it difficult to achieve strong adhesion with metallic conductors or other rigid electronic elements. This integration issue is critical for creating seamless, durable flexible electronic devices that can withstand repeated bending and stretching.

The thermal management of silicone rubber-based electronics presents another hurdle. As electronic components generate heat during operation, efficient heat dissipation becomes crucial. However, silicone rubber's inherent thermal insulation properties can lead to localized heating, potentially affecting the performance and lifespan of embedded electronic components.

Durability and long-term stability of silicone rubber electronics under various environmental conditions pose additional challenges. Exposure to UV radiation, extreme temperatures, and humidity can degrade the material's properties over time, potentially leading to device failure or reduced performance. Developing silicone rubber formulations that maintain their electrical and mechanical properties under these conditions is essential for creating reliable flexible electronics.

Scalability and manufacturing processes present further technical hurdles. Current production methods for integrating electronic functionality into silicone rubber often involve complex, multi-step processes that are difficult to scale up for mass production. Developing efficient, cost-effective manufacturing techniques that can produce consistent results at scale is crucial for the widespread adoption of silicone rubber-based flexible electronics.

Lastly, the challenge of achieving high-resolution patterning and miniaturization in silicone rubber electronics cannot be overlooked. Traditional lithographic techniques used in rigid electronics are not directly applicable to soft, stretchable substrates. Developing new patterning methods that can create fine, precise conductive traces and circuits on silicone rubber surfaces is essential for advancing the capabilities of flexible electronic devices.

Current Flexible Electronics Solutions

01 Silicone rubber composition for improved flexibility

Specific silicone rubber compositions can be formulated to enhance flexibility. These compositions may include various additives, fillers, or cross-linking agents that contribute to the overall flexibility of the silicone rubber. The careful selection and balance of these components can result in silicone rubber with superior flexibility properties.- Silicone rubber composition for improved flexibility: Specific silicone rubber compositions can be formulated to enhance flexibility. These compositions may include various additives, fillers, or cross-linking agents that contribute to the overall flexibility of the silicone rubber. The careful selection and balance of these components can result in silicone rubber with improved elasticity and flexibility for various applications.

- Heat-curable silicone rubber with enhanced flexibility: Heat-curable silicone rubber formulations can be designed to achieve improved flexibility. These formulations often involve specific curing agents, catalysts, or processing conditions that promote the formation of a flexible silicone rubber network. The resulting material exhibits enhanced flexibility while maintaining other desirable properties of silicone rubber.

- Silicone rubber blends for flexibility enhancement: Blending different types of silicone rubbers or incorporating other elastomeric materials can lead to improved flexibility. These blends may combine the beneficial properties of multiple components to achieve a silicone rubber with enhanced flexibility. The careful selection of blend ratios and compatibilizers can result in a material with optimized flexibility for specific applications.

- Modification of silicone rubber structure for flexibility: The molecular structure of silicone rubber can be modified to enhance flexibility. This may involve altering the backbone structure, side groups, or cross-linking density of the silicone polymer. Such modifications can lead to a more flexible silicone rubber while maintaining other essential properties like thermal stability and chemical resistance.

- Additives for improving silicone rubber flexibility: Various additives can be incorporated into silicone rubber formulations to enhance flexibility. These may include plasticizers, softeners, or specific types of fillers that contribute to the overall flexibility of the material. The careful selection and dosage of these additives can result in silicone rubber with improved flexibility for diverse applications.

02 Heat treatment to enhance silicone rubber flexibility

Heat treatment processes can be applied to silicone rubber to improve its flexibility. This may involve controlled heating and cooling cycles that modify the molecular structure of the silicone rubber, resulting in increased flexibility. The specific temperature, duration, and cooling rate can be optimized for different silicone rubber formulations.Expand Specific Solutions03 Incorporation of plasticizers for increased flexibility

The addition of plasticizers to silicone rubber formulations can significantly enhance flexibility. These additives work by increasing the space between polymer chains, reducing intermolecular forces, and allowing for greater movement. The type and amount of plasticizer can be tailored to achieve the desired level of flexibility while maintaining other important properties of the silicone rubber.Expand Specific Solutions04 Blending with other elastomers for improved flexibility

Silicone rubber can be blended with other elastomers to create composite materials with enhanced flexibility. This approach combines the unique properties of silicone rubber with the flexibility characteristics of other elastomers. The ratio of silicone to other elastomers, as well as the blending process, can be optimized to achieve the desired flexibility while maintaining other important properties.Expand Specific Solutions05 Modification of silicone polymer structure

The flexibility of silicone rubber can be improved by modifying the structure of the silicone polymer itself. This may involve altering the molecular weight, introducing specific functional groups, or changing the degree of cross-linking. These modifications can be achieved through various synthesis techniques or post-processing methods, resulting in silicone rubber with tailored flexibility properties.Expand Specific Solutions

Key Silicone Rubber Manufacturers

The market for silicone rubber in flexible electronics is rapidly evolving, currently in a growth phase with increasing demand and technological advancements. The global market size for flexible electronics is projected to expand significantly in the coming years, driven by applications in consumer electronics, healthcare, and automotive sectors. While the technology is maturing, there's still room for innovation, particularly in enhancing durability and performance. Key players like Shin-Etsu Chemical, Wacker Chemie, and Dow Corning are leading the field, with research institutions such as Arizona State University and Huazhong University of Science & Technology contributing to technological progress. Companies like Apple and IBM are also exploring applications, indicating the technology's potential for mainstream adoption.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically designed for flexible electronics. Their proprietary formulations incorporate nano-sized silica particles to enhance mechanical strength while maintaining flexibility[1]. The company has also introduced self-healing silicone rubbers that can recover from cuts and tears, improving the durability of flexible devices[2]. Additionally, Shin-Etsu has developed highly transparent silicone rubbers with excellent light transmission properties, suitable for flexible displays and touch panels[3]. Their materials demonstrate stable electrical properties under repeated bending and stretching, with some formulations maintaining conductivity at strains up to 100%[4].

Strengths: Industry-leading expertise in silicone chemistry, wide range of specialized formulations, strong R&D capabilities. Weaknesses: Higher cost compared to conventional materials, potential scalability challenges for some advanced formulations.

Apple, Inc.

Technical Solution: Apple has been investing heavily in flexible electronics research, particularly focusing on integrating silicone rubber into their devices. They have developed a proprietary silicone-based elastomer that can be used as a protective and functional layer in flexible displays[5]. This material offers high durability, excellent optical clarity, and the ability to withstand repeated folding and unfolding cycles. Apple has also patented a method for creating stretchable circuit boards using silicone rubber as a substrate, allowing for seamless integration of electronic components into flexible form factors[6]. Furthermore, the company is exploring the use of silicone-based sensors for health monitoring applications in wearable devices, leveraging the material's biocompatibility and conformability to skin[7].

Strengths: Vast resources for R&D, strong integration capabilities, established supply chain. Weaknesses: Primarily focused on consumer electronics applications, potential limitations in sharing technologies due to proprietary nature.

Silicone Rubber Innovations

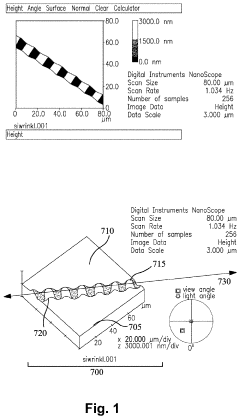

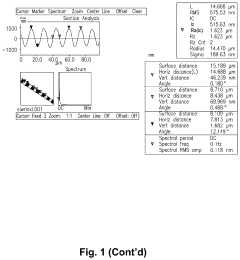

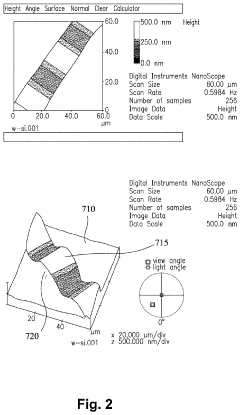

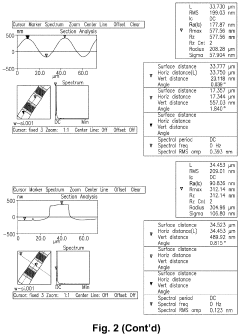

Stretchable Form of Single Crystal Silicon for High Performance Electronics on Rubber Substrates

PatentActiveUS20200013720A1

Innovation

- Development of stretchable semiconductors and electronic devices with curved internal surfaces bonded to flexible substrates, allowing for elongation, compression, and deformation without mechanical failure, using techniques like prestraining elastic substrates and transferring semiconductor elements to form bent structures.

Electrically conductive member having expandable wiring

PatentWO2012028686A2

Innovation

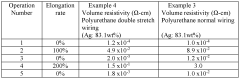

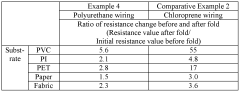

- An electrically conductive member is created using a mixture of polyurethane dispersion and conductive particles applied to a flexible substrate, allowing for high elongation rates without the need for adhesives, maintaining conductivity even when stretched beyond conventional limits.

Environmental Impact Assessment

The environmental impact of silicone rubber in next-generation flexible electronics is a critical consideration as this technology advances. Silicone rubber, while offering numerous benefits for flexible electronics, also presents potential environmental challenges throughout its lifecycle.

During the production phase, the manufacturing of silicone rubber involves the use of various chemicals and energy-intensive processes. The extraction of silica, a primary raw material, can lead to habitat disruption and soil erosion. Additionally, the synthesis of silicone polymers often requires the use of organic solvents and catalysts, which may contribute to air and water pollution if not properly managed.

In the usage phase, silicone rubber-based flexible electronics demonstrate several positive environmental attributes. Their durability and flexibility can lead to longer product lifespans, potentially reducing electronic waste. The low power consumption of many flexible electronic devices also contributes to energy efficiency, aligning with global efforts to reduce carbon emissions.

However, the end-of-life stage presents significant environmental challenges. Silicone rubber is not biodegradable and can persist in the environment for extended periods. While it is theoretically recyclable, the complex integration of silicone with other electronic components often makes recycling difficult and economically unfeasible. This can result in increased electronic waste, contributing to landfill accumulation and potential soil and water contamination.

The production of flexible electronics using silicone rubber may also involve the use of rare earth elements and other scarce materials. The extraction and processing of these resources can have substantial environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

To mitigate these environmental concerns, researchers and manufacturers are exploring several avenues. These include developing more environmentally friendly production processes, improving the recyclability of silicone-based electronics, and investigating bio-based alternatives to traditional silicone rubber. Additionally, efforts are being made to design products with easier disassembly and material recovery in mind, potentially facilitating more effective recycling and reducing electronic waste.

As the field of flexible electronics continues to evolve, it is crucial to balance technological advancements with environmental stewardship. This requires ongoing research into sustainable materials, improved manufacturing processes, and innovative recycling technologies. By addressing these environmental challenges, the industry can work towards creating truly sustainable next-generation flexible electronics that minimize ecological impact while maximizing technological benefits.

During the production phase, the manufacturing of silicone rubber involves the use of various chemicals and energy-intensive processes. The extraction of silica, a primary raw material, can lead to habitat disruption and soil erosion. Additionally, the synthesis of silicone polymers often requires the use of organic solvents and catalysts, which may contribute to air and water pollution if not properly managed.

In the usage phase, silicone rubber-based flexible electronics demonstrate several positive environmental attributes. Their durability and flexibility can lead to longer product lifespans, potentially reducing electronic waste. The low power consumption of many flexible electronic devices also contributes to energy efficiency, aligning with global efforts to reduce carbon emissions.

However, the end-of-life stage presents significant environmental challenges. Silicone rubber is not biodegradable and can persist in the environment for extended periods. While it is theoretically recyclable, the complex integration of silicone with other electronic components often makes recycling difficult and economically unfeasible. This can result in increased electronic waste, contributing to landfill accumulation and potential soil and water contamination.

The production of flexible electronics using silicone rubber may also involve the use of rare earth elements and other scarce materials. The extraction and processing of these resources can have substantial environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

To mitigate these environmental concerns, researchers and manufacturers are exploring several avenues. These include developing more environmentally friendly production processes, improving the recyclability of silicone-based electronics, and investigating bio-based alternatives to traditional silicone rubber. Additionally, efforts are being made to design products with easier disassembly and material recovery in mind, potentially facilitating more effective recycling and reducing electronic waste.

As the field of flexible electronics continues to evolve, it is crucial to balance technological advancements with environmental stewardship. This requires ongoing research into sustainable materials, improved manufacturing processes, and innovative recycling technologies. By addressing these environmental challenges, the industry can work towards creating truly sustainable next-generation flexible electronics that minimize ecological impact while maximizing technological benefits.

Durability and Lifecycle Analysis

Durability and lifecycle analysis are critical aspects in the development of next-generation flexible electronics using silicone rubber. The inherent flexibility and stretchability of silicone rubber make it an attractive material for wearable devices and other applications requiring conformable electronics. However, these same properties also present unique challenges in terms of long-term performance and reliability.

One of the primary concerns in the durability of silicone rubber-based flexible electronics is the potential for mechanical fatigue. Repeated stretching and bending can lead to the formation of microcracks in the conductive elements embedded within the silicone matrix. These microcracks can propagate over time, eventually causing device failure. To address this issue, researchers have been exploring various strategies, including the development of self-healing materials and the incorporation of strain-relieving structures.

Environmental factors also play a significant role in the lifecycle of silicone rubber electronics. Exposure to UV radiation, moisture, and temperature fluctuations can degrade the material properties over time. This degradation can manifest as changes in elasticity, color, or even chemical composition. Consequently, the development of protective coatings and encapsulation techniques has become an essential area of research to enhance the environmental resistance of these devices.

The integration of electronic components with silicone rubber substrates introduces additional durability concerns. Adhesion between the silicone and rigid electronic components can weaken over time, leading to delamination and device failure. Researchers are investigating novel bonding techniques and interface materials to improve the long-term stability of these hybrid structures.

From a lifecycle perspective, the recyclability and end-of-life management of silicone rubber electronics present both challenges and opportunities. While silicone rubber itself is not biodegradable, it can be recycled through specialized processes. However, the presence of embedded electronic components complicates the recycling process. Efforts are underway to develop design strategies that facilitate easier disassembly and material recovery at the end of a device's useful life.

The durability and lifecycle performance of silicone rubber-based flexible electronics are also influenced by the manufacturing processes used in their production. Techniques such as 3D printing and soft lithography offer new possibilities for creating complex, multi-material structures with enhanced durability. However, these processes must be optimized to ensure consistent material properties and minimize defects that could compromise long-term reliability.

One of the primary concerns in the durability of silicone rubber-based flexible electronics is the potential for mechanical fatigue. Repeated stretching and bending can lead to the formation of microcracks in the conductive elements embedded within the silicone matrix. These microcracks can propagate over time, eventually causing device failure. To address this issue, researchers have been exploring various strategies, including the development of self-healing materials and the incorporation of strain-relieving structures.

Environmental factors also play a significant role in the lifecycle of silicone rubber electronics. Exposure to UV radiation, moisture, and temperature fluctuations can degrade the material properties over time. This degradation can manifest as changes in elasticity, color, or even chemical composition. Consequently, the development of protective coatings and encapsulation techniques has become an essential area of research to enhance the environmental resistance of these devices.

The integration of electronic components with silicone rubber substrates introduces additional durability concerns. Adhesion between the silicone and rigid electronic components can weaken over time, leading to delamination and device failure. Researchers are investigating novel bonding techniques and interface materials to improve the long-term stability of these hybrid structures.

From a lifecycle perspective, the recyclability and end-of-life management of silicone rubber electronics present both challenges and opportunities. While silicone rubber itself is not biodegradable, it can be recycled through specialized processes. However, the presence of embedded electronic components complicates the recycling process. Efforts are underway to develop design strategies that facilitate easier disassembly and material recovery at the end of a device's useful life.

The durability and lifecycle performance of silicone rubber-based flexible electronics are also influenced by the manufacturing processes used in their production. Techniques such as 3D printing and soft lithography offer new possibilities for creating complex, multi-material structures with enhanced durability. However, these processes must be optimized to ensure consistent material properties and minimize defects that could compromise long-term reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!