Silicone Rubber: The Future of Water-Repellent Textures

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution and Objectives

Silicone rubber has a rich history dating back to the 1940s when it was first developed as a versatile synthetic elastomer. Initially used in aerospace and military applications, its unique properties quickly garnered attention across various industries. The evolution of silicone rubber has been marked by continuous improvements in its formulation, processing techniques, and application methods.

In the early stages, silicone rubber was primarily valued for its thermal stability and electrical insulation properties. As research progressed, scientists discovered its exceptional water-repellent characteristics, opening up new avenues for exploration. The 1960s and 1970s saw significant advancements in silicone chemistry, leading to the development of more specialized grades with enhanced hydrophobicity.

The turn of the millennium brought about a renewed focus on nanotechnology, which has played a crucial role in refining the water-repellent properties of silicone rubber. By incorporating nanoparticles and creating micro-structured surfaces, researchers have been able to achieve superhydrophobic effects, mimicking natural water-repellent surfaces like lotus leaves.

Recent years have witnessed a surge in interest in biomimetic approaches, where the intricate structures found in nature are replicated to enhance the water-repellent properties of silicone rubber. This has led to the development of self-cleaning surfaces and advanced coatings with unprecedented levels of water resistance.

The current objectives in silicone rubber research for water-repellent textures are multifaceted. One primary goal is to improve the durability and longevity of water-repellent coatings, ensuring they maintain their effectiveness under various environmental conditions and mechanical stresses. Another key objective is to develop environmentally friendly formulations that reduce the reliance on potentially harmful chemicals while maintaining superior performance.

Researchers are also focusing on creating multi-functional silicone rubber materials that combine water repellency with other desirable properties such as antimicrobial activity, UV resistance, and self-healing capabilities. This holistic approach aims to produce versatile materials suitable for a wide range of applications, from textiles and construction to electronics and medical devices.

Furthermore, there is a growing emphasis on scalability and cost-effectiveness in the production of water-repellent silicone rubber textures. The goal is to transition cutting-edge laboratory discoveries into commercially viable products that can be mass-produced without compromising their performance or environmental sustainability.

In the early stages, silicone rubber was primarily valued for its thermal stability and electrical insulation properties. As research progressed, scientists discovered its exceptional water-repellent characteristics, opening up new avenues for exploration. The 1960s and 1970s saw significant advancements in silicone chemistry, leading to the development of more specialized grades with enhanced hydrophobicity.

The turn of the millennium brought about a renewed focus on nanotechnology, which has played a crucial role in refining the water-repellent properties of silicone rubber. By incorporating nanoparticles and creating micro-structured surfaces, researchers have been able to achieve superhydrophobic effects, mimicking natural water-repellent surfaces like lotus leaves.

Recent years have witnessed a surge in interest in biomimetic approaches, where the intricate structures found in nature are replicated to enhance the water-repellent properties of silicone rubber. This has led to the development of self-cleaning surfaces and advanced coatings with unprecedented levels of water resistance.

The current objectives in silicone rubber research for water-repellent textures are multifaceted. One primary goal is to improve the durability and longevity of water-repellent coatings, ensuring they maintain their effectiveness under various environmental conditions and mechanical stresses. Another key objective is to develop environmentally friendly formulations that reduce the reliance on potentially harmful chemicals while maintaining superior performance.

Researchers are also focusing on creating multi-functional silicone rubber materials that combine water repellency with other desirable properties such as antimicrobial activity, UV resistance, and self-healing capabilities. This holistic approach aims to produce versatile materials suitable for a wide range of applications, from textiles and construction to electronics and medical devices.

Furthermore, there is a growing emphasis on scalability and cost-effectiveness in the production of water-repellent silicone rubber textures. The goal is to transition cutting-edge laboratory discoveries into commercially viable products that can be mass-produced without compromising their performance or environmental sustainability.

Market Demand Analysis for Hydrophobic Materials

The market demand for hydrophobic materials, particularly silicone rubber with water-repellent textures, has been experiencing significant growth across various industries. This surge is driven by the increasing need for durable, weather-resistant, and low-maintenance materials in sectors such as construction, automotive, electronics, and consumer goods.

In the construction industry, there is a rising demand for water-repellent coatings and sealants to protect buildings from moisture damage and improve energy efficiency. Silicone rubber-based products are gaining traction due to their superior water-repellent properties and long-lasting performance. The automotive sector is another key market, with manufacturers seeking hydrophobic materials for windshields, side mirrors, and body coatings to enhance visibility and reduce maintenance requirements.

The electronics industry is witnessing a growing adoption of hydrophobic materials, especially in the production of smartphones, tablets, and wearable devices. These materials provide essential protection against water damage and improve device longevity. Consumer goods, including outdoor gear, sportswear, and household items, are also driving the demand for water-repellent textures to enhance product functionality and durability.

Environmental concerns and sustainability trends are influencing market dynamics, with a shift towards eco-friendly hydrophobic materials. This has led to increased research and development efforts in bio-based and recyclable silicone rubber formulations. The healthcare sector is emerging as a promising market for hydrophobic materials, with applications in medical devices, implants, and protective equipment.

The global market for hydrophobic coatings is projected to grow steadily, with Asia-Pacific region leading in terms of market share and growth rate. Factors such as rapid industrialization, urbanization, and increasing disposable income in emerging economies are contributing to this trend. North America and Europe remain significant markets, driven by technological advancements and stringent regulations promoting the use of high-performance materials.

Key market players are focusing on product innovation and strategic partnerships to gain a competitive edge. The development of advanced silicone rubber formulations with enhanced water-repellent properties and improved durability is a primary focus area. Additionally, there is a growing emphasis on customization to meet specific industry requirements and expand application areas.

Despite the positive outlook, challenges such as high production costs and technical limitations in certain applications persist. However, ongoing research in nanotechnology and surface engineering is expected to address these issues and unlock new opportunities for silicone rubber-based water-repellent textures.

In the construction industry, there is a rising demand for water-repellent coatings and sealants to protect buildings from moisture damage and improve energy efficiency. Silicone rubber-based products are gaining traction due to their superior water-repellent properties and long-lasting performance. The automotive sector is another key market, with manufacturers seeking hydrophobic materials for windshields, side mirrors, and body coatings to enhance visibility and reduce maintenance requirements.

The electronics industry is witnessing a growing adoption of hydrophobic materials, especially in the production of smartphones, tablets, and wearable devices. These materials provide essential protection against water damage and improve device longevity. Consumer goods, including outdoor gear, sportswear, and household items, are also driving the demand for water-repellent textures to enhance product functionality and durability.

Environmental concerns and sustainability trends are influencing market dynamics, with a shift towards eco-friendly hydrophobic materials. This has led to increased research and development efforts in bio-based and recyclable silicone rubber formulations. The healthcare sector is emerging as a promising market for hydrophobic materials, with applications in medical devices, implants, and protective equipment.

The global market for hydrophobic coatings is projected to grow steadily, with Asia-Pacific region leading in terms of market share and growth rate. Factors such as rapid industrialization, urbanization, and increasing disposable income in emerging economies are contributing to this trend. North America and Europe remain significant markets, driven by technological advancements and stringent regulations promoting the use of high-performance materials.

Key market players are focusing on product innovation and strategic partnerships to gain a competitive edge. The development of advanced silicone rubber formulations with enhanced water-repellent properties and improved durability is a primary focus area. Additionally, there is a growing emphasis on customization to meet specific industry requirements and expand application areas.

Despite the positive outlook, challenges such as high production costs and technical limitations in certain applications persist. However, ongoing research in nanotechnology and surface engineering is expected to address these issues and unlock new opportunities for silicone rubber-based water-repellent textures.

Current Challenges in Water-Repellent Technologies

Water-repellent technologies have made significant strides in recent years, yet several challenges persist in achieving optimal performance and widespread adoption. One of the primary obstacles is the durability of water-repellent coatings. Many current solutions suffer from degradation over time, especially when exposed to harsh environmental conditions or frequent use. This limitation restricts their application in outdoor settings or high-wear scenarios.

Another significant challenge lies in the environmental impact of traditional water-repellent materials. Many conventional treatments rely on fluorinated compounds, which have raised concerns due to their persistence in the environment and potential health risks. The industry is under pressure to develop eco-friendly alternatives that maintain high performance without compromising sustainability.

Scalability and cost-effectiveness present additional hurdles. While advanced water-repellent technologies show promise in laboratory settings, translating these innovations into large-scale, economically viable production processes remains challenging. This gap between research and commercial application slows the widespread adoption of cutting-edge solutions.

The versatility of water-repellent treatments across diverse substrates and materials is another area requiring improvement. Current technologies often perform well on specific surfaces but struggle to maintain effectiveness across a broad range of materials, limiting their universal applicability.

Transparency and aesthetic considerations pose challenges in certain applications, particularly in consumer products and architectural uses. Achieving water repellency without altering the appearance or optical properties of the underlying material is crucial for wider acceptance in these sectors.

The development of multifunctional coatings that combine water repellency with other desirable properties, such as self-cleaning, anti-fogging, or antimicrobial capabilities, represents a complex challenge. Integrating these functionalities without compromising the core water-repellent performance requires sophisticated material engineering and nanotechnology approaches.

Lastly, the long-term stability and resistance to chemical degradation of water-repellent surfaces remain areas of ongoing research. Enhancing the chemical resilience of these materials, particularly against oils, solvents, and other potentially damaging substances, is crucial for expanding their application in industrial and high-performance settings.

Another significant challenge lies in the environmental impact of traditional water-repellent materials. Many conventional treatments rely on fluorinated compounds, which have raised concerns due to their persistence in the environment and potential health risks. The industry is under pressure to develop eco-friendly alternatives that maintain high performance without compromising sustainability.

Scalability and cost-effectiveness present additional hurdles. While advanced water-repellent technologies show promise in laboratory settings, translating these innovations into large-scale, economically viable production processes remains challenging. This gap between research and commercial application slows the widespread adoption of cutting-edge solutions.

The versatility of water-repellent treatments across diverse substrates and materials is another area requiring improvement. Current technologies often perform well on specific surfaces but struggle to maintain effectiveness across a broad range of materials, limiting their universal applicability.

Transparency and aesthetic considerations pose challenges in certain applications, particularly in consumer products and architectural uses. Achieving water repellency without altering the appearance or optical properties of the underlying material is crucial for wider acceptance in these sectors.

The development of multifunctional coatings that combine water repellency with other desirable properties, such as self-cleaning, anti-fogging, or antimicrobial capabilities, represents a complex challenge. Integrating these functionalities without compromising the core water-repellent performance requires sophisticated material engineering and nanotechnology approaches.

Lastly, the long-term stability and resistance to chemical degradation of water-repellent surfaces remain areas of ongoing research. Enhancing the chemical resilience of these materials, particularly against oils, solvents, and other potentially damaging substances, is crucial for expanding their application in industrial and high-performance settings.

Existing Water-Repellent Silicone Solutions

01 Silicone rubber composition with water-repellent additives

Silicone rubber formulations can be enhanced with water-repellent additives such as fluorinated compounds or silane-based materials. These additives improve the hydrophobicity of the silicone rubber surface, making it more resistant to water penetration and increasing its overall water-repellent properties.- Silicone rubber composition with water-repellent additives: Silicone rubber compositions can be enhanced with water-repellent additives to improve their hydrophobic properties. These additives may include fluorinated compounds or silane-based materials that increase the surface tension and create a water-repellent barrier. The resulting silicone rubber exhibits improved water resistance and durability in wet conditions.

- Surface modification techniques for silicone rubber: Various surface modification techniques can be applied to silicone rubber to enhance its water-repellent properties. These may include plasma treatment, chemical etching, or the application of nanocoatings. Such modifications alter the surface structure and chemistry of the silicone rubber, leading to increased hydrophobicity and improved water-repellent performance.

- Incorporation of silica or other fillers: The addition of silica or other fillers to silicone rubber formulations can enhance their water-repellent properties. These fillers can modify the surface roughness and create a micro-textured surface that increases water contact angle and promotes water repellency. The type and concentration of fillers can be optimized to achieve the desired level of water repellency.

- Crosslinking and curing methods for water-repellent silicone rubber: Specific crosslinking and curing methods can be employed to enhance the water-repellent properties of silicone rubber. These may include the use of particular catalysts, curing agents, or processing conditions that promote the formation of a highly hydrophobic surface structure. The optimization of these methods can lead to silicone rubber with superior water-repellent characteristics.

- Blending silicone rubber with other polymers: Blending silicone rubber with other polymers or elastomers can create composite materials with enhanced water-repellent properties. These blends may combine the inherent properties of silicone rubber with the hydrophobic characteristics of other materials, resulting in a synergistic effect that improves overall water repellency and performance in wet environments.

02 Surface modification techniques for silicone rubber

Various surface modification techniques can be applied to silicone rubber to enhance its water-repellent properties. These may include plasma treatment, chemical etching, or the application of specialized coatings. Such modifications alter the surface structure or chemistry of the silicone rubber, improving its ability to repel water.Expand Specific Solutions03 Incorporation of nanoparticles in silicone rubber

The addition of nanoparticles, such as silica or metal oxides, to silicone rubber can significantly enhance its water-repellent properties. These nanoparticles create a rough surface texture at the microscopic level, which increases the contact angle with water droplets and promotes water repellency.Expand Specific Solutions04 Crosslinking agents for improved water repellency

Specific crosslinking agents can be used in the formulation of silicone rubber to enhance its water-repellent properties. These agents create a more tightly bound network within the rubber, reducing the ability of water molecules to penetrate the material and improving overall water repellency.Expand Specific Solutions05 Silicone rubber blends with other polymers

Blending silicone rubber with other polymers, such as fluoropolymers or polyurethanes, can result in composite materials with enhanced water-repellent properties. These blends combine the beneficial properties of multiple materials to create a more effective water-repellent silicone rubber product.Expand Specific Solutions

Key Players in Silicone Rubber Industry

The silicone rubber water-repellent textures market is in a growth phase, driven by increasing demand across industries like automotive, electronics, and construction. The global market size is projected to expand significantly in the coming years. Technologically, silicone rubber formulations are advancing, with major players like Shin-Etsu Chemical, Dow Silicones, and Evonik Operations leading innovation. These companies are developing enhanced water-repellent properties, durability, and eco-friendly formulations. While the core technology is mature, ongoing research focuses on improving performance and sustainability. Emerging players like Zhejiang Xinan Chemical and DNF Co. are also contributing to technological advancements, intensifying competition in this dynamic market.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has pioneered a novel approach to water-repellent silicone rubber textures by developing a proprietary silicone elastomer with self-healing properties. Their technology incorporates dynamic covalent bonds within the silicone network, allowing the material to repair micro-damages and maintain its water-repellent characteristics over time[2]. The company has also introduced a gradient-structure design in their silicone rubber formulation, where the surface layer exhibits extreme hydrophobicity while the bulk material retains its elastomeric properties[4]. This approach ensures both excellent water repellency and mechanical stability. Furthermore, Shin-Etsu has developed a bio-inspired surface patterning technique that mimics the lotus leaf structure, enhancing the water-repellent performance through a combination of chemical composition and physical surface topology[6].

Strengths: Self-healing properties, excellent durability, and bio-inspired design. Weaknesses: Complex manufacturing process and potentially higher cost compared to traditional silicone rubbers.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has developed advanced silicone rubber formulations with enhanced water-repellent properties. Their technology involves incorporating fluorosilicone compounds into the silicone rubber matrix, resulting in a superhydrophobic surface with a contact angle exceeding 150 degrees[1]. This formulation also includes nano-sized silica particles, which create a hierarchical surface structure that further enhances water repellency[3]. The company has implemented a cross-linking process that improves the durability of the water-repellent coating, allowing it to maintain its properties even after prolonged exposure to harsh environmental conditions[5]. Additionally, Dow Silicones has developed a spray-on application method that enables easy and uniform coating of complex geometries, making it suitable for a wide range of industrial and consumer applications[7].

Strengths: Superior water repellency, enhanced durability, and versatile application method. Weaknesses: Potentially higher production costs and limited compatibility with certain substrates.

Innovations in Silicone Rubber Hydrophobicity

Durable water repellent glass surface

PatentInactiveEP0545201B2

Innovation

- A sol-gel applied silica primer layer is combined with a perfluoroalkylalkyl silane to create a thin, durable non-wetting surface, where the silica primer is deposited using an anhydrous solvent and the perfluoroalkylalkyl silane forms a second layer, enhancing water repellency and lubricity.

Room temperature crosslinking, one component silicone rubber formulation with hydrophobic silica

PatentInactiveUS6956080B2

Innovation

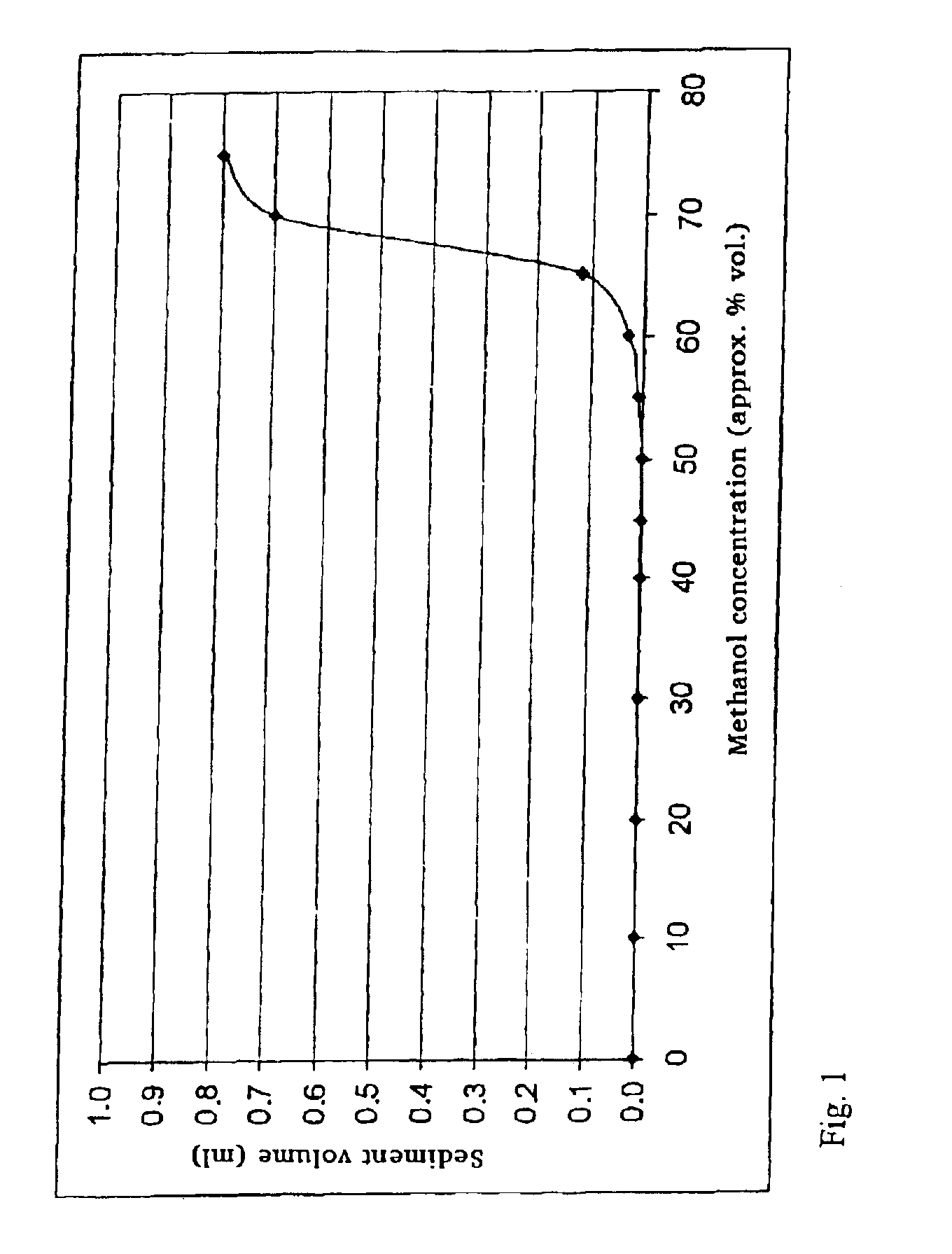

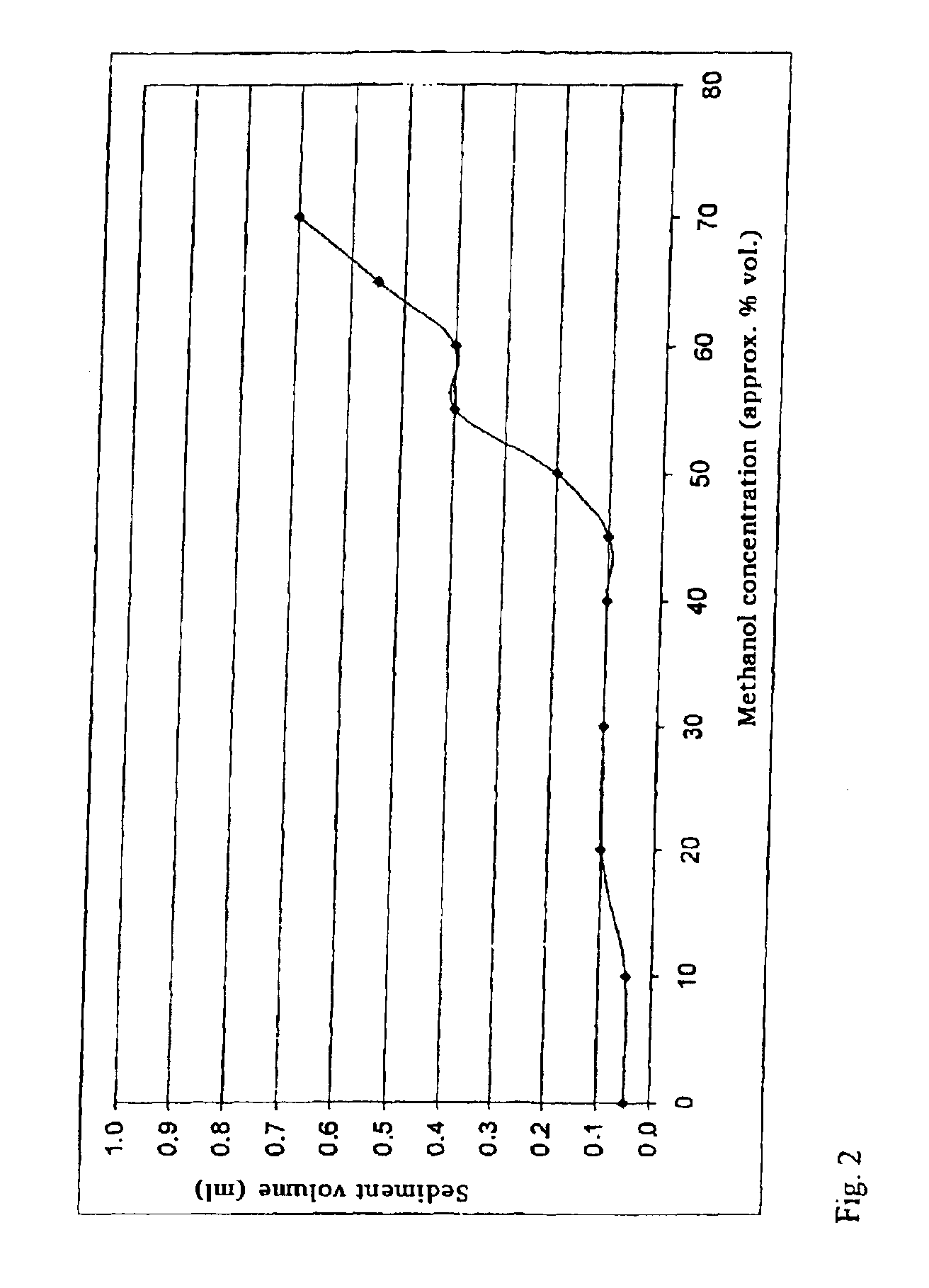

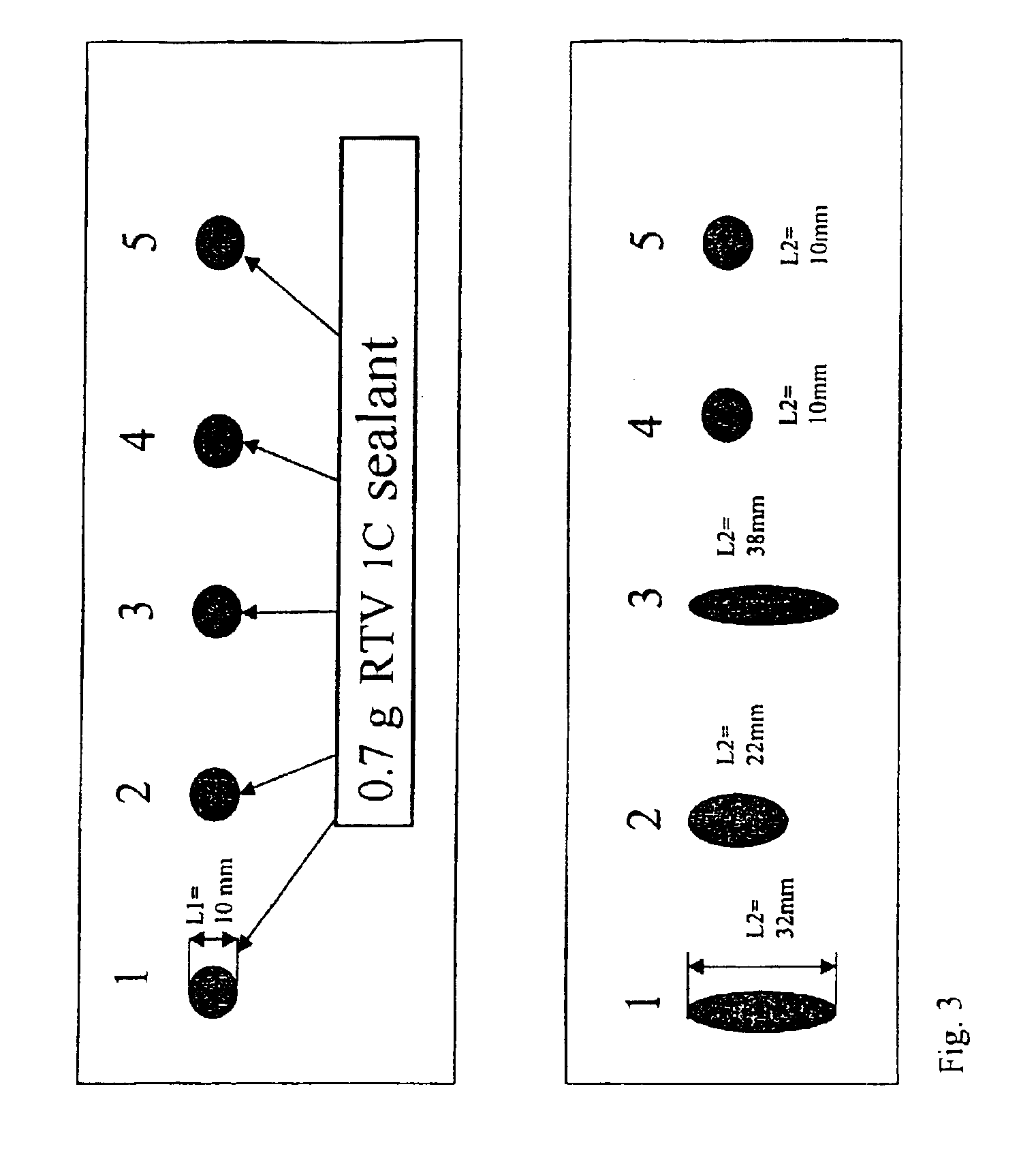

- A room temperature crosslinking, one-component silicone rubber formulation using hydrophobic silica with specific properties such as high carbon content, methanol wettability, and reflectance, combined with an organopolysiloxane, to achieve improved mechanical and rheological properties while maintaining storage stability.

Environmental Impact of Silicone-Based Materials

The environmental impact of silicone-based materials, particularly silicone rubber, is a complex and multifaceted issue that requires careful consideration. Silicone rubber, known for its water-repellent properties, has gained popularity in various industries due to its durability and versatility. However, its widespread use has raised concerns about its long-term effects on the environment.

One of the primary environmental considerations is the production process of silicone rubber. The manufacturing of silicone-based materials involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. Additionally, the extraction of raw materials, such as silica and methyl chloride, can lead to habitat destruction and ecosystem disruption if not managed responsibly.

Silicone rubber's durability, while beneficial for product longevity, poses challenges for waste management. These materials are not biodegradable and can persist in the environment for extended periods. When improperly disposed of, silicone rubber products can contribute to pollution in landfills and marine environments. Microplastics derived from the breakdown of silicone-based materials have been detected in various ecosystems, raising concerns about their potential impact on wildlife and food chains.

However, it is important to note that silicone rubber also offers some environmental benefits. Its water-repellent properties can contribute to energy efficiency in buildings and reduce the need for harmful chemical treatments in certain applications. The long lifespan of silicone products can also lead to reduced waste generation compared to less durable alternatives.

Recycling silicone rubber presents both challenges and opportunities. While traditional recycling methods are not always suitable for silicone-based materials, innovative technologies are emerging to address this issue. Chemical recycling processes and the development of biodegradable silicone alternatives show promise in mitigating the environmental impact of these materials.

The water-repellent nature of silicone rubber also raises questions about its interaction with aquatic ecosystems. While it can prevent water absorption and reduce the growth of harmful microorganisms in certain applications, there are concerns about its potential to interfere with natural water cycles and aquatic habitats if released into the environment.

As research continues, a more comprehensive understanding of the environmental impact of silicone-based materials is emerging. This knowledge is crucial for developing sustainable practices in the production, use, and disposal of silicone rubber products. Future innovations in this field will likely focus on improving the environmental profile of silicone materials while maintaining their beneficial properties.

One of the primary environmental considerations is the production process of silicone rubber. The manufacturing of silicone-based materials involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. Additionally, the extraction of raw materials, such as silica and methyl chloride, can lead to habitat destruction and ecosystem disruption if not managed responsibly.

Silicone rubber's durability, while beneficial for product longevity, poses challenges for waste management. These materials are not biodegradable and can persist in the environment for extended periods. When improperly disposed of, silicone rubber products can contribute to pollution in landfills and marine environments. Microplastics derived from the breakdown of silicone-based materials have been detected in various ecosystems, raising concerns about their potential impact on wildlife and food chains.

However, it is important to note that silicone rubber also offers some environmental benefits. Its water-repellent properties can contribute to energy efficiency in buildings and reduce the need for harmful chemical treatments in certain applications. The long lifespan of silicone products can also lead to reduced waste generation compared to less durable alternatives.

Recycling silicone rubber presents both challenges and opportunities. While traditional recycling methods are not always suitable for silicone-based materials, innovative technologies are emerging to address this issue. Chemical recycling processes and the development of biodegradable silicone alternatives show promise in mitigating the environmental impact of these materials.

The water-repellent nature of silicone rubber also raises questions about its interaction with aquatic ecosystems. While it can prevent water absorption and reduce the growth of harmful microorganisms in certain applications, there are concerns about its potential to interfere with natural water cycles and aquatic habitats if released into the environment.

As research continues, a more comprehensive understanding of the environmental impact of silicone-based materials is emerging. This knowledge is crucial for developing sustainable practices in the production, use, and disposal of silicone rubber products. Future innovations in this field will likely focus on improving the environmental profile of silicone materials while maintaining their beneficial properties.

Regulatory Framework for Silicone Rubber Applications

The regulatory framework for silicone rubber applications is a complex and evolving landscape that plays a crucial role in shaping the development and adoption of water-repellent textures. As silicone rubber continues to gain prominence in various industries, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and quality standards.

In the United States, the Food and Drug Administration (FDA) oversees the use of silicone rubber in food contact applications and medical devices. The FDA has established specific regulations under 21 CFR 177.2600 for silicone rubber intended for repeated use in contact with food. These regulations outline the permissible raw materials, manufacturing processes, and testing requirements to ensure the safety of silicone rubber products in food-related applications.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and use of silicone rubber. Under REACH, manufacturers and importers must register substances used in silicone rubber production and provide safety data. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive restricts the use of certain hazardous materials in electrical and electronic equipment, which may impact silicone rubber applications in these sectors.

In the automotive industry, silicone rubber components must comply with various international standards, such as those set by the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards address performance, durability, and safety requirements for silicone rubber parts used in vehicles.

Environmental regulations also play a significant role in shaping the silicone rubber industry. Many countries have implemented regulations to control volatile organic compound (VOC) emissions during the manufacturing process of silicone rubber products. For instance, the U.S. Environmental Protection Agency (EPA) has established National Emission Standards for Hazardous Air Pollutants (NESHAP) that apply to certain silicone rubber production facilities.

As the applications of silicone rubber in water-repellent textures continue to expand, regulatory bodies are likely to develop more specific guidelines. This may include standards for testing the longevity and effectiveness of water-repellent properties, as well as regulations addressing the potential environmental impact of silicone rubber coatings in various applications.

The global nature of the silicone rubber industry necessitates harmonization efforts between different regulatory frameworks. Organizations such as the International Organization for Standardization (ISO) are working to develop unified standards that can be adopted across multiple jurisdictions, facilitating international trade and ensuring consistent quality and safety standards worldwide.

In the United States, the Food and Drug Administration (FDA) oversees the use of silicone rubber in food contact applications and medical devices. The FDA has established specific regulations under 21 CFR 177.2600 for silicone rubber intended for repeated use in contact with food. These regulations outline the permissible raw materials, manufacturing processes, and testing requirements to ensure the safety of silicone rubber products in food-related applications.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and use of silicone rubber. Under REACH, manufacturers and importers must register substances used in silicone rubber production and provide safety data. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive restricts the use of certain hazardous materials in electrical and electronic equipment, which may impact silicone rubber applications in these sectors.

In the automotive industry, silicone rubber components must comply with various international standards, such as those set by the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards address performance, durability, and safety requirements for silicone rubber parts used in vehicles.

Environmental regulations also play a significant role in shaping the silicone rubber industry. Many countries have implemented regulations to control volatile organic compound (VOC) emissions during the manufacturing process of silicone rubber products. For instance, the U.S. Environmental Protection Agency (EPA) has established National Emission Standards for Hazardous Air Pollutants (NESHAP) that apply to certain silicone rubber production facilities.

As the applications of silicone rubber in water-repellent textures continue to expand, regulatory bodies are likely to develop more specific guidelines. This may include standards for testing the longevity and effectiveness of water-repellent properties, as well as regulations addressing the potential environmental impact of silicone rubber coatings in various applications.

The global nature of the silicone rubber industry necessitates harmonization efforts between different regulatory frameworks. Organizations such as the International Organization for Standardization (ISO) are working to develop unified standards that can be adopted across multiple jurisdictions, facilitating international trade and ensuring consistent quality and safety standards worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!