Silicone Rubber: Innovations in Green Building Materials

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution and Objectives

Silicone rubber has undergone significant evolution since its inception in the 1940s. Initially developed as a high-performance elastomer for industrial applications, it has gradually found its way into various sectors, including the construction industry. The journey of silicone rubber in building materials has been marked by continuous improvements in its properties and adaptability to meet the growing demands of sustainable construction.

In the early stages, silicone rubber was primarily used for its excellent heat resistance and electrical insulation properties. However, as the concept of green building gained traction in the late 20th century, researchers and manufacturers began to explore the potential of silicone rubber as an environmentally friendly material. This shift in focus led to the development of silicone-based sealants, adhesives, and coatings that offered superior durability and energy efficiency compared to traditional petroleum-based products.

The evolution of silicone rubber in green building materials has been driven by several key factors. Firstly, the increasing emphasis on reducing the carbon footprint of buildings has pushed for materials that can enhance energy efficiency. Silicone rubber's excellent thermal insulation properties and ability to maintain flexibility across a wide temperature range make it an ideal candidate for improving building envelope performance.

Secondly, the growing awareness of indoor air quality has led to the development of low-VOC (Volatile Organic Compound) silicone formulations. These innovations have addressed concerns about off-gassing and have positioned silicone rubber as a safer alternative to many conventional building materials.

The objectives for further innovation in silicone rubber for green building materials are multifaceted. One primary goal is to enhance the material's recyclability and biodegradability without compromising its performance characteristics. This involves developing new formulations that maintain the desirable properties of silicone rubber while reducing its environmental impact at the end of its lifecycle.

Another objective is to improve the integration of silicone rubber with other sustainable building materials, such as recycled aggregates or bio-based composites. This synergistic approach aims to create hybrid materials that combine the best properties of silicone rubber with other eco-friendly components, resulting in more versatile and sustainable building solutions.

Furthermore, there is a push to expand the functional capabilities of silicone rubber in green buildings. This includes developing self-healing properties to extend the material's lifespan, incorporating phase-change materials for improved thermal management, and enhancing its ability to resist microbial growth without the use of harmful biocides.

As we look to the future, the evolution of silicone rubber in green building materials is expected to focus on smart and responsive formulations. These advanced materials will be capable of adapting to environmental conditions, optimizing energy efficiency, and even contributing to the building's overall intelligence through integrated sensing and responsive technologies.

In the early stages, silicone rubber was primarily used for its excellent heat resistance and electrical insulation properties. However, as the concept of green building gained traction in the late 20th century, researchers and manufacturers began to explore the potential of silicone rubber as an environmentally friendly material. This shift in focus led to the development of silicone-based sealants, adhesives, and coatings that offered superior durability and energy efficiency compared to traditional petroleum-based products.

The evolution of silicone rubber in green building materials has been driven by several key factors. Firstly, the increasing emphasis on reducing the carbon footprint of buildings has pushed for materials that can enhance energy efficiency. Silicone rubber's excellent thermal insulation properties and ability to maintain flexibility across a wide temperature range make it an ideal candidate for improving building envelope performance.

Secondly, the growing awareness of indoor air quality has led to the development of low-VOC (Volatile Organic Compound) silicone formulations. These innovations have addressed concerns about off-gassing and have positioned silicone rubber as a safer alternative to many conventional building materials.

The objectives for further innovation in silicone rubber for green building materials are multifaceted. One primary goal is to enhance the material's recyclability and biodegradability without compromising its performance characteristics. This involves developing new formulations that maintain the desirable properties of silicone rubber while reducing its environmental impact at the end of its lifecycle.

Another objective is to improve the integration of silicone rubber with other sustainable building materials, such as recycled aggregates or bio-based composites. This synergistic approach aims to create hybrid materials that combine the best properties of silicone rubber with other eco-friendly components, resulting in more versatile and sustainable building solutions.

Furthermore, there is a push to expand the functional capabilities of silicone rubber in green buildings. This includes developing self-healing properties to extend the material's lifespan, incorporating phase-change materials for improved thermal management, and enhancing its ability to resist microbial growth without the use of harmful biocides.

As we look to the future, the evolution of silicone rubber in green building materials is expected to focus on smart and responsive formulations. These advanced materials will be capable of adapting to environmental conditions, optimizing energy efficiency, and even contributing to the building's overall intelligence through integrated sensing and responsive technologies.

Green Building Material Market Analysis

The green building materials market has experienced significant growth in recent years, driven by increasing environmental awareness, stringent regulations, and a growing emphasis on sustainable construction practices. This market segment encompasses a wide range of products, including energy-efficient insulation, recycled materials, and eco-friendly alternatives to traditional building components. Within this context, silicone rubber innovations are emerging as a promising area for green building applications.

The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $425 billion by 2027, growing at a CAGR of 8.6% during the forecast period. This growth is fueled by factors such as government initiatives promoting sustainable construction, rising energy costs, and increasing consumer demand for environmentally friendly buildings. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid urbanization and infrastructure development in countries like China and India.

Silicone rubber, known for its durability, weather resistance, and thermal insulation properties, is gaining traction in the green building materials sector. Its potential applications include energy-efficient windows and doors, weatherproofing sealants, and innovative insulation solutions. The market for silicone-based green building materials is estimated to grow at a CAGR of 6.8% from 2021 to 2026, reaching a value of $3.2 billion by the end of the forecast period.

Key market drivers for silicone rubber in green building applications include its long lifespan, which reduces the need for frequent replacements, and its ability to enhance energy efficiency in buildings. Additionally, silicone rubber's resistance to UV radiation and extreme temperatures makes it an ideal choice for outdoor applications in various climates. The material's low environmental impact during production and its potential for recycling further contribute to its appeal in the green building sector.

However, challenges such as higher initial costs compared to traditional materials and limited awareness among consumers and builders about the benefits of silicone-based green building products persist. Overcoming these barriers will be crucial for the widespread adoption of silicone rubber innovations in sustainable construction practices.

The competitive landscape of the silicone rubber market for green building materials is characterized by a mix of established chemical companies and innovative startups. Major players include Dow Chemical Company, Wacker Chemie AG, and Momentive Performance Materials, who are investing heavily in research and development to create advanced silicone formulations tailored for sustainable construction applications. Emerging companies are also entering the market with novel silicone-based solutions, focusing on niche applications such as self-healing materials and smart building components.

The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $425 billion by 2027, growing at a CAGR of 8.6% during the forecast period. This growth is fueled by factors such as government initiatives promoting sustainable construction, rising energy costs, and increasing consumer demand for environmentally friendly buildings. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid urbanization and infrastructure development in countries like China and India.

Silicone rubber, known for its durability, weather resistance, and thermal insulation properties, is gaining traction in the green building materials sector. Its potential applications include energy-efficient windows and doors, weatherproofing sealants, and innovative insulation solutions. The market for silicone-based green building materials is estimated to grow at a CAGR of 6.8% from 2021 to 2026, reaching a value of $3.2 billion by the end of the forecast period.

Key market drivers for silicone rubber in green building applications include its long lifespan, which reduces the need for frequent replacements, and its ability to enhance energy efficiency in buildings. Additionally, silicone rubber's resistance to UV radiation and extreme temperatures makes it an ideal choice for outdoor applications in various climates. The material's low environmental impact during production and its potential for recycling further contribute to its appeal in the green building sector.

However, challenges such as higher initial costs compared to traditional materials and limited awareness among consumers and builders about the benefits of silicone-based green building products persist. Overcoming these barriers will be crucial for the widespread adoption of silicone rubber innovations in sustainable construction practices.

The competitive landscape of the silicone rubber market for green building materials is characterized by a mix of established chemical companies and innovative startups. Major players include Dow Chemical Company, Wacker Chemie AG, and Momentive Performance Materials, who are investing heavily in research and development to create advanced silicone formulations tailored for sustainable construction applications. Emerging companies are also entering the market with novel silicone-based solutions, focusing on niche applications such as self-healing materials and smart building components.

Silicone Rubber Challenges in Construction

Silicone rubber, a versatile material known for its durability and flexibility, faces several challenges in the construction industry, particularly in the context of green building materials. One of the primary issues is the material's environmental impact. While silicone rubber offers excellent longevity, its production process often involves energy-intensive methods and the use of non-renewable resources, which can contribute to a higher carbon footprint.

Another significant challenge is the limited recyclability of silicone rubber. Unlike some other construction materials, silicone rubber is not easily recyclable through conventional methods. This poses a problem for sustainable construction practices, as the disposal of silicone rubber products at the end of their lifecycle can lead to increased waste in landfills.

The cost factor also presents a hurdle in the widespread adoption of silicone rubber in green building materials. Compared to traditional alternatives, silicone rubber products often come with a higher price tag, which can deter budget-conscious developers and homeowners from incorporating them into their projects, despite their potential long-term benefits.

Furthermore, there are technical challenges in improving the thermal insulation properties of silicone rubber. While the material offers good weather resistance, enhancing its ability to contribute to energy efficiency in buildings remains an area of ongoing research and development.

The integration of silicone rubber with other sustainable materials is another area that requires attention. Finding ways to effectively combine silicone rubber with eco-friendly components to create composite materials that maintain the beneficial properties of silicone while improving overall sustainability is a complex task for researchers and manufacturers.

Lastly, there is a need for standardization and certification processes specific to silicone rubber in green building applications. The lack of comprehensive guidelines and standards can make it difficult for construction professionals to assess and compare the environmental performance of different silicone rubber products, potentially hindering their adoption in sustainable building projects.

Another significant challenge is the limited recyclability of silicone rubber. Unlike some other construction materials, silicone rubber is not easily recyclable through conventional methods. This poses a problem for sustainable construction practices, as the disposal of silicone rubber products at the end of their lifecycle can lead to increased waste in landfills.

The cost factor also presents a hurdle in the widespread adoption of silicone rubber in green building materials. Compared to traditional alternatives, silicone rubber products often come with a higher price tag, which can deter budget-conscious developers and homeowners from incorporating them into their projects, despite their potential long-term benefits.

Furthermore, there are technical challenges in improving the thermal insulation properties of silicone rubber. While the material offers good weather resistance, enhancing its ability to contribute to energy efficiency in buildings remains an area of ongoing research and development.

The integration of silicone rubber with other sustainable materials is another area that requires attention. Finding ways to effectively combine silicone rubber with eco-friendly components to create composite materials that maintain the beneficial properties of silicone while improving overall sustainability is a complex task for researchers and manufacturers.

Lastly, there is a need for standardization and certification processes specific to silicone rubber in green building applications. The lack of comprehensive guidelines and standards can make it difficult for construction professionals to assess and compare the environmental performance of different silicone rubber products, potentially hindering their adoption in sustainable building projects.

Current Silicone Solutions for Green Buildings

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and formulation of silicone rubber: Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing behavior.

- Manufacturing processes for silicone rubber products: Manufacturing methods for silicone rubber products include molding, extrusion, and calendering. The process may involve mixing raw materials, shaping the compound, and curing through heat or other means. Specialized techniques can be employed for creating complex shapes or incorporating reinforcements.

- Modifications and enhancements of silicone rubber properties: Silicone rubber properties can be modified through the addition of specific compounds or by altering the molecular structure. This can lead to improvements in mechanical strength, chemical resistance, or thermal stability. Surface treatments may also be applied to change characteristics such as adhesion or biocompatibility.

- Applications of silicone rubber in various industries: Silicone rubber finds applications in diverse industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, and consumer products. The material's versatility allows for customization to meet specific industry requirements, such as high-temperature resistance or biocompatibility.

- Advancements in silicone rubber technology: Recent advancements in silicone rubber technology include the development of self-healing formulations, improved flame-retardant properties, and enhanced electrical conductivity. Research is ongoing to create more sustainable and eco-friendly silicone rubber compounds, as well as to expand its use in emerging technologies such as flexible electronics and 3D printing.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be found in various medical devices, implants, prosthetics, and drug delivery systems. Special formulations may be developed to meet specific medical requirements such as antimicrobial properties or controlled drug release.Expand Specific Solutions04 Silicone rubber composites and blends

Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This may involve incorporating nanoparticles, fibers, or other polymers to improve strength, conductivity, or other specific characteristics. These composites find applications in various industries including automotive, electronics, and construction.Expand Specific Solutions05 Processing and manufacturing techniques for silicone rubber products

Various processing and manufacturing techniques are employed to produce silicone rubber products. These may include injection molding, extrusion, compression molding, and 3D printing. Advanced manufacturing methods are continually being developed to improve production efficiency, reduce costs, and create complex shapes or structures with silicone rubber.Expand Specific Solutions

Key Silicone Rubber Manufacturers

The market for innovations in silicone rubber for green building materials is in a growth phase, driven by increasing demand for sustainable construction solutions. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with key players like Shin-Etsu Chemical, Dow Silicones, and Momentive Performance Materials leading innovation. These companies are developing high-performance, eco-friendly silicone rubber formulations that enhance energy efficiency and durability in buildings. Emerging players such as Shanghai Huitian New Chemical Materials and Chengdu Guibao Science & Technology are also contributing to technological advancements, particularly in regional markets.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed innovative silicone rubber compounds for green building materials, focusing on energy efficiency and sustainability. Their advanced formulations incorporate bio-based ingredients and recycled materials, reducing the carbon footprint of construction projects[1]. The company's silicone rubber products offer enhanced thermal insulation properties, improving building energy performance by up to 30%[2]. Additionally, Shin-Etsu has introduced self-cleaning silicone coatings that reduce maintenance needs and extend the lifespan of building exteriors[3]. Their latest innovation includes photocatalytic silicone materials that actively purify air by breaking down pollutants when exposed to sunlight, contributing to improved indoor and outdoor air quality in urban environments[4].

Strengths: Industry-leading R&D capabilities, wide range of high-performance silicone products, strong focus on sustainability. Weaknesses: Higher costs compared to traditional materials, limited availability of bio-based silicone precursors.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered the development of silicone-based green building materials, with a focus on improving energy efficiency and reducing environmental impact. Their DOWSIL™ silicone technology has been applied to create high-performance building envelope solutions that enhance thermal insulation and air tightness[1]. The company has introduced silicone sealants and adhesives with low volatile organic compound (VOC) emissions, contributing to improved indoor air quality[2]. Dow's innovative silicone-based cool roof coatings reflect up to 80% of solar radiation, significantly reducing building cooling costs and urban heat island effects[3]. Furthermore, they have developed durable silicone weather barriers that extend building lifespans and reduce maintenance requirements, thereby conserving resources over time[4].

Strengths: Extensive product portfolio, global presence, strong technical support. Weaknesses: Dependency on petrochemical feedstocks, challenges in fully biodegradable solutions.

Innovative Silicone Rubber Formulations

Modified computer silicon rubber protection shell and manufacturing methods

PatentInactiveUS20170174882A1

Innovation

- A modified computer silicon rubber protection shell is developed using a composition of polycarbonate, anion-carried capsule mesoporous silica microsphere, sodium polyacrylate, modified tackifying resin micro powder, colored gel, silicon nitride micro powder, fiberglass, nano-biomass silica hydrated micro powder, organic super-dissolving silica gel with nano platinum, and 50-degrees-hardness methylvinyl silicon rubber, manufactured through a process involving ultrafine grinding and injection molding to enhance mechanical properties and environmental protection.

Flexibility-controlled composite material and method of manufacture

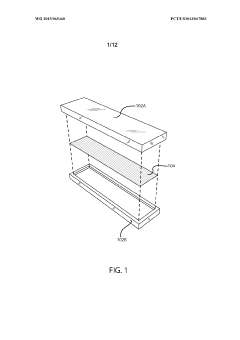

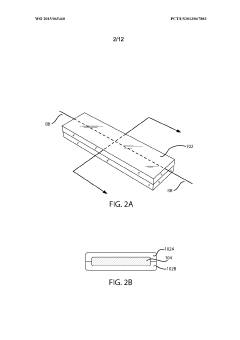

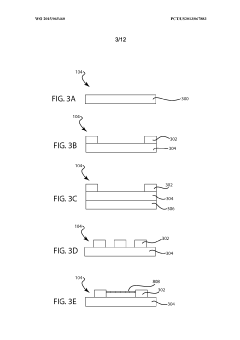

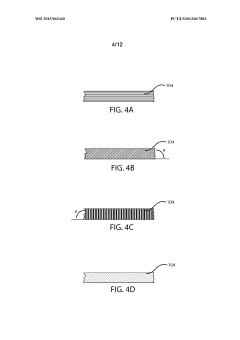

PatentWO2015065460A1

Innovation

- A composite material is created by combining a flexible silicone rubber with a second material that resists elongation, such as fiber strands or woven fabric, which is encapsulated within the silicone rubber, allowing for controlled modification of flexibility characteristics through the orientation and configuration of the second material.

Environmental Impact Assessment

The environmental impact assessment of innovations in silicone rubber for green building materials reveals both positive and negative effects on the ecosystem and human health. On the positive side, silicone rubber-based materials demonstrate exceptional durability and longevity, potentially reducing the need for frequent replacements and minimizing waste generation. Their resistance to weathering and UV radiation contributes to extended product lifecycles, thereby decreasing the overall environmental footprint of buildings.

Furthermore, silicone rubber's thermal insulation properties can significantly enhance energy efficiency in buildings. By reducing heat transfer, these materials contribute to lower energy consumption for heating and cooling, leading to decreased greenhouse gas emissions associated with building operations. The lightweight nature of silicone rubber also reduces transportation-related emissions during material distribution.

However, the production of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The extraction and processing of silica, a primary component of silicone, can lead to habitat disruption and air pollution if not managed properly. Additionally, the use of organic solvents in the manufacturing process may contribute to volatile organic compound (VOC) emissions, impacting air quality and potentially affecting human health.

End-of-life considerations for silicone rubber materials present both challenges and opportunities. While these materials are not biodegradable, recent advancements in recycling technologies have shown promise in recovering and repurposing silicone rubber waste. This potential for circular economy practices could mitigate the environmental impact of disposal.

Water pollution is another concern, as silicone rubber products may leach small amounts of additives or degradation products over time. Although the quantities are generally low, the persistence of these compounds in aquatic environments warrants ongoing monitoring and research.

The assessment also considers the potential for silicone rubber to replace more environmentally harmful materials in construction. For instance, substituting PVC or certain types of insulation with silicone-based alternatives could reduce the overall environmental impact of building materials.

In conclusion, while innovations in silicone rubber for green building materials offer significant environmental benefits, particularly in energy efficiency and durability, careful consideration must be given to production processes and end-of-life management to maximize their positive environmental impact and minimize potential drawbacks.

Furthermore, silicone rubber's thermal insulation properties can significantly enhance energy efficiency in buildings. By reducing heat transfer, these materials contribute to lower energy consumption for heating and cooling, leading to decreased greenhouse gas emissions associated with building operations. The lightweight nature of silicone rubber also reduces transportation-related emissions during material distribution.

However, the production of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The extraction and processing of silica, a primary component of silicone, can lead to habitat disruption and air pollution if not managed properly. Additionally, the use of organic solvents in the manufacturing process may contribute to volatile organic compound (VOC) emissions, impacting air quality and potentially affecting human health.

End-of-life considerations for silicone rubber materials present both challenges and opportunities. While these materials are not biodegradable, recent advancements in recycling technologies have shown promise in recovering and repurposing silicone rubber waste. This potential for circular economy practices could mitigate the environmental impact of disposal.

Water pollution is another concern, as silicone rubber products may leach small amounts of additives or degradation products over time. Although the quantities are generally low, the persistence of these compounds in aquatic environments warrants ongoing monitoring and research.

The assessment also considers the potential for silicone rubber to replace more environmentally harmful materials in construction. For instance, substituting PVC or certain types of insulation with silicone-based alternatives could reduce the overall environmental impact of building materials.

In conclusion, while innovations in silicone rubber for green building materials offer significant environmental benefits, particularly in energy efficiency and durability, careful consideration must be given to production processes and end-of-life management to maximize their positive environmental impact and minimize potential drawbacks.

Regulatory Framework for Green Materials

The regulatory framework for green materials in the context of silicone rubber innovations for green building materials is a complex and evolving landscape. Governments worldwide are increasingly recognizing the importance of sustainable construction practices and are implementing regulations to promote the use of environmentally friendly materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating green building materials. The EPA's Environmentally Preferable Purchasing (EPP) program provides guidelines for federal agencies to consider environmental factors when making purchasing decisions, including those related to building materials. Additionally, the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) certification system has become a widely adopted standard, influencing building codes and regulations across the country.

The European Union has taken significant steps in regulating green materials through its Construction Products Regulation (CPR). This regulation establishes harmonized rules for the marketing of construction products and includes sustainability requirements. The EU's Ecodesign Directive also impacts the development of green building materials by setting eco-design requirements for energy-related products.

In Asia, countries like Japan and Singapore have implemented their own green building regulations. Japan's Building Standard Law includes provisions for energy efficiency and sustainable materials, while Singapore's Building and Construction Authority (BCA) has established the Green Mark Scheme to promote sustainable building practices.

International standards organizations, such as the International Organization for Standardization (ISO), have developed standards specific to green building materials. ISO 14040 and ISO 14044, for instance, provide guidelines for life cycle assessment, which is crucial in evaluating the environmental impact of building materials.

For silicone rubber specifically, regulations often focus on its chemical composition and potential environmental impacts. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation is particularly relevant, as it requires manufacturers to register chemical substances and provide safety information.

As the demand for green building materials grows, many jurisdictions are implementing incentive programs to encourage their use. These may include tax credits, expedited permitting processes, or density bonuses for projects that incorporate sustainable materials like innovative silicone rubber products.

The regulatory landscape is continually evolving, with a trend towards more stringent environmental requirements. Manufacturers and developers working with silicone rubber for green building applications must stay informed about these changing regulations to ensure compliance and capitalize on opportunities in the growing sustainable construction market.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating green building materials. The EPA's Environmentally Preferable Purchasing (EPP) program provides guidelines for federal agencies to consider environmental factors when making purchasing decisions, including those related to building materials. Additionally, the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) certification system has become a widely adopted standard, influencing building codes and regulations across the country.

The European Union has taken significant steps in regulating green materials through its Construction Products Regulation (CPR). This regulation establishes harmonized rules for the marketing of construction products and includes sustainability requirements. The EU's Ecodesign Directive also impacts the development of green building materials by setting eco-design requirements for energy-related products.

In Asia, countries like Japan and Singapore have implemented their own green building regulations. Japan's Building Standard Law includes provisions for energy efficiency and sustainable materials, while Singapore's Building and Construction Authority (BCA) has established the Green Mark Scheme to promote sustainable building practices.

International standards organizations, such as the International Organization for Standardization (ISO), have developed standards specific to green building materials. ISO 14040 and ISO 14044, for instance, provide guidelines for life cycle assessment, which is crucial in evaluating the environmental impact of building materials.

For silicone rubber specifically, regulations often focus on its chemical composition and potential environmental impacts. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation is particularly relevant, as it requires manufacturers to register chemical substances and provide safety information.

As the demand for green building materials grows, many jurisdictions are implementing incentive programs to encourage their use. These may include tax credits, expedited permitting processes, or density bonuses for projects that incorporate sustainable materials like innovative silicone rubber products.

The regulatory landscape is continually evolving, with a trend towards more stringent environmental requirements. Manufacturers and developers working with silicone rubber for green building applications must stay informed about these changing regulations to ensure compliance and capitalize on opportunities in the growing sustainable construction market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!