Exploring the Role of LDPE in Waste Minimization

LDPE Waste Reduction Background and Objectives

Low-density polyethylene (LDPE) has been a ubiquitous material in packaging and consumer goods since its introduction in the 1930s. As global plastic waste concerns have escalated, the role of LDPE in waste minimization has become a critical focus for environmental sustainability efforts. This technical research report aims to explore the historical context, current challenges, and future objectives in LDPE waste reduction.

The development of LDPE marked a significant milestone in materials science, offering a versatile, lightweight, and cost-effective solution for various applications. However, its widespread use has contributed substantially to the global plastic waste crisis. According to recent studies, LDPE accounts for approximately 17% of all plastic waste generated worldwide, with only a small fraction being recycled effectively.

The primary objective of this research is to investigate innovative approaches to minimize LDPE waste throughout its lifecycle. This encompasses strategies for reducing LDPE production, enhancing recyclability, and developing sustainable alternatives. By examining the entire value chain, from raw material sourcing to end-of-life management, we aim to identify key intervention points for waste reduction.

One of the central challenges in LDPE waste minimization is its persistence in the environment. With a degradation time spanning hundreds of years, LDPE poses long-term ecological risks. This research seeks to explore advanced degradation technologies and bio-based alternatives that could significantly reduce the environmental footprint of LDPE products.

The global market dynamics of LDPE production and consumption play a crucial role in waste generation patterns. As developing economies continue to grow, the demand for LDPE is projected to increase, potentially exacerbating the waste problem. Therefore, this study will also analyze market trends and regulatory landscapes to forecast future challenges and opportunities in LDPE waste reduction.

Technological advancements in recycling processes represent a promising avenue for waste minimization. Current mechanical recycling methods for LDPE face limitations in terms of efficiency and output quality. This research aims to explore cutting-edge chemical recycling technologies and their potential to revolutionize LDPE waste management.

By comprehensively examining these aspects, this technical research report seeks to provide a roadmap for stakeholders in industry, government, and academia to collaboratively address the LDPE waste challenge. The ultimate goal is to pave the way for a circular economy approach to LDPE, where waste is minimized, and resources are conserved through innovative design, efficient recycling, and sustainable consumption patterns.

Market Analysis for LDPE Recycling Solutions

The global market for LDPE recycling solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste management. The demand for recycled LDPE is rising across various industries, including packaging, construction, and agriculture, as companies seek to reduce their environmental footprint and meet sustainability goals.

The market size for LDPE recycling solutions is projected to expand substantially over the next decade. This growth is attributed to the rising awareness of plastic pollution, government initiatives promoting circular economy practices, and the increasing adoption of recycled materials by manufacturers. The packaging industry, in particular, is expected to be a major driver of demand for recycled LDPE, as it seeks alternatives to virgin plastics in response to consumer preferences and regulatory pressures.

Geographically, Europe and North America currently lead the LDPE recycling market, with well-established collection and processing infrastructure. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization, urbanization, and government efforts to address plastic waste challenges. Developing economies in this region are expected to present significant opportunities for market expansion in the coming years.

The competitive landscape of the LDPE recycling market is characterized by a mix of established players and new entrants. Large waste management companies and plastic recyclers are expanding their capabilities in LDPE recycling, while innovative startups are introducing novel technologies to improve recycling efficiency and output quality. Collaborations between recyclers, manufacturers, and brand owners are becoming more common, creating integrated value chains that support the circular economy model.

Key market trends include the development of advanced sorting and processing technologies to improve the quality of recycled LDPE, the integration of artificial intelligence and machine learning in recycling processes, and the emergence of chemical recycling methods as a complement to mechanical recycling. These innovations are addressing longstanding challenges in LDPE recycling, such as contamination and degradation of material properties during the recycling process.

Despite the positive outlook, the LDPE recycling market faces several challenges. These include the volatility of oil prices affecting the competitiveness of recycled materials, the need for significant infrastructure investments, and the complexity of recycling multi-layer and mixed plastic products. Additionally, the COVID-19 pandemic has temporarily disrupted collection and recycling activities, highlighting the need for resilient and adaptable recycling systems.

LDPE Waste Challenges and Current Limitations

Low-density polyethylene (LDPE) waste presents significant challenges in waste minimization efforts due to its widespread use and inherent properties. The current limitations in managing LDPE waste stem from both technical and systemic issues within the recycling and waste management industries.

One of the primary challenges is the difficulty in effectively sorting and separating LDPE from other plastic types in mixed waste streams. LDPE's low density and flexibility make it prone to contamination and entanglement with other materials, complicating automated sorting processes. This often results in lower quality recycled materials and increased costs for recycling facilities.

The chemical structure of LDPE also poses challenges for recycling. Its long, branched polymer chains make it less amenable to mechanical recycling compared to other plastics. When recycled, LDPE often experiences degradation in its physical and mechanical properties, limiting its potential applications in subsequent product cycles. This degradation can lead to downcycling, where the recycled material is used for lower-value applications, rather than maintaining its original quality and value.

Another significant limitation is the lack of widespread infrastructure for collecting and processing LDPE waste. Many municipalities and waste management systems are not equipped to handle LDPE separately, leading to its disposal in landfills or incineration facilities. This gap in infrastructure is particularly pronounced in developing countries, where informal waste collection systems may not prioritize LDPE recycling due to its low value and processing difficulties.

The economic viability of LDPE recycling also presents a substantial challenge. The costs associated with collecting, sorting, and processing LDPE often outweigh the market value of the recycled material. This economic imbalance discourages investment in recycling technologies and infrastructure, perpetuating the cycle of LDPE waste accumulation.

Furthermore, the persistence of LDPE in the environment is a growing concern. Its resistance to degradation means that LDPE waste can remain in ecosystems for hundreds of years, contributing to pollution in terrestrial and marine environments. This long-term environmental impact underscores the urgency of developing more effective waste minimization strategies for LDPE.

The current regulatory landscape also presents limitations in addressing LDPE waste. Many regions lack comprehensive policies or incentives to promote LDPE recycling or reduce its consumption. The absence of standardized labeling and collection systems further complicates efforts to divert LDPE from waste streams effectively.

Addressing these challenges requires a multifaceted approach, involving technological innovation, policy reform, and shifts in consumer behavior. Developing advanced sorting technologies, improving recycling processes, and creating markets for recycled LDPE are crucial steps in overcoming the current limitations in LDPE waste management.

Current LDPE Waste Minimization Strategies

01 Recycling and processing of LDPE waste

Various methods for recycling and processing LDPE waste have been developed. These include mechanical recycling, chemical recycling, and thermal processing. The recycled LDPE can be used to produce new products or as a raw material for other industrial processes, reducing environmental impact and conserving resources.- Recycling and processing of LDPE waste: Various methods for recycling and processing LDPE waste have been developed. These include mechanical recycling, chemical recycling, and thermal processing techniques. The processes aim to convert waste LDPE into reusable materials or energy, reducing environmental impact and promoting circular economy principles.

- LDPE waste as a raw material for new products: LDPE waste can be utilized as a raw material for manufacturing new products. This approach involves incorporating recycled LDPE into the production of various items such as construction materials, packaging, and composite products. The use of LDPE waste in this manner helps to reduce the demand for virgin plastics and promotes sustainable manufacturing practices.

- Biodegradation and composting of LDPE waste: Research has been conducted on enhancing the biodegradability of LDPE waste through various methods. These include the use of additives, microbial treatments, and specialized composting techniques. The goal is to accelerate the decomposition of LDPE waste in natural environments, reducing its long-term environmental impact.

- Energy recovery from LDPE waste: LDPE waste can be used as a source of energy through various thermal processes. These include incineration, pyrolysis, and gasification techniques that convert the plastic waste into usable forms of energy such as heat or fuel. This approach provides an alternative to landfilling while recovering the energy content of the waste material.

- Sorting and separation technologies for LDPE waste: Advanced sorting and separation technologies have been developed to improve the efficiency of LDPE waste recycling. These include optical sorting, density separation, and electrostatic separation methods. These technologies help to isolate LDPE from mixed plastic waste streams, enhancing the quality and value of recycled materials.

02 LDPE waste as a component in composite materials

LDPE waste can be incorporated into composite materials to enhance their properties or reduce costs. These composites may include blends with other polymers, fillers, or reinforcing agents. The resulting materials can be used in various applications, such as construction, automotive parts, or packaging.Expand Specific Solutions03 Biodegradation and environmental impact of LDPE waste

Research has been conducted on improving the biodegradability of LDPE waste and reducing its environmental impact. This includes the development of additives or treatments to enhance degradation, as well as studies on the long-term effects of LDPE waste in various ecosystems.Expand Specific Solutions04 Energy recovery from LDPE waste

Methods for recovering energy from LDPE waste have been explored, including pyrolysis, gasification, and incineration. These processes can convert waste into usable forms of energy, such as fuel or electricity, while reducing the volume of waste sent to landfills.Expand Specific Solutions05 Sorting and separation techniques for LDPE waste

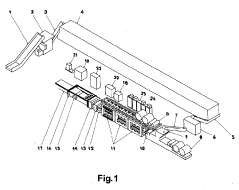

Advanced sorting and separation techniques have been developed to improve the efficiency of LDPE waste recycling. These may include automated systems using optical, infrared, or other sensor technologies to identify and separate LDPE from other materials in mixed waste streams.Expand Specific Solutions

Key Players in LDPE Recycling Industry

The market for LDPE in waste minimization is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, LDPE waste minimization is advancing, with major players like Dow Global Technologies, SABIC, and DuPont leading innovation. These companies are developing more efficient recycling processes and exploring new applications for recycled LDPE. Emerging players such as Beijing Yuantaida Environmental Protection Technology are also contributing to technological advancements. The competitive landscape is characterized by a mix of established petrochemical giants and specialized environmental technology firms, indicating a maturing but still evolving market.

Dow Global Technologies LLC

SABIC Global Technologies BV

Innovative LDPE Recycling Technologies

- Utilization of LDPE as a binding agent for waste materials to create building materials.

- Application of specific temperature and pressure conditions to optimize the binding process of waste materials with LDPE.

- Development of an environmentally friendly waste recycling method that converts waste into useful building materials.

- A biodegradable antimicrobial polymer is developed by mixing Low-Density Polyethylene (LDPE) with waste material of paper tissue (WMPT) and adding cellulose and bentonite nanoparticles, along with antimicrobial agents to enhance mechanical properties and biodegradability, while incorporating nanocomposites for improved performance.

Environmental Impact of LDPE Waste Management

The environmental impact of LDPE waste management is a critical concern in the context of waste minimization efforts. LDPE, or Low-Density Polyethylene, is widely used in packaging and disposable products, contributing significantly to the global plastic waste problem. When improperly managed, LDPE waste can have severe consequences for ecosystems, wildlife, and human health.

One of the primary environmental issues associated with LDPE waste is its persistence in the environment. LDPE can take hundreds of years to decompose naturally, leading to long-term accumulation in landfills and natural habitats. This accumulation can result in soil degradation, reduced land productivity, and the release of harmful chemicals into the surrounding environment.

Marine pollution is another significant concern related to LDPE waste management. A substantial portion of mismanaged plastic waste, including LDPE, ends up in oceans and waterways. This pollution has devastating effects on marine life, with animals often mistaking plastic fragments for food or becoming entangled in larger pieces. The ingestion of LDPE by marine organisms can lead to malnutrition, starvation, and the bioaccumulation of toxins in the food chain.

The production and disposal of LDPE also contribute to greenhouse gas emissions, exacerbating climate change. The manufacturing process of LDPE is energy-intensive and relies heavily on fossil fuels, resulting in significant carbon dioxide emissions. Additionally, when LDPE waste is incinerated, it releases harmful pollutants into the atmosphere, including dioxins and furans, which pose serious health risks to nearby communities.

Improper LDPE waste management can lead to the leaching of toxic additives and chemicals into soil and water systems. These contaminants can disrupt local ecosystems, harm plant and animal life, and potentially enter the human food chain. Furthermore, the accumulation of LDPE waste in urban areas can create breeding grounds for disease-carrying pests, posing public health risks.

However, effective LDPE waste management strategies can mitigate these environmental impacts. Recycling LDPE can significantly reduce the demand for virgin plastic production, thereby decreasing energy consumption and greenhouse gas emissions. Advanced recycling technologies are being developed to improve the efficiency and quality of LDPE recycling, potentially creating a more circular economy for plastic materials.

Biodegradable alternatives to traditional LDPE are also being explored as a means to reduce long-term environmental impact. These materials are designed to break down more rapidly under specific conditions, potentially alleviating the issue of persistent plastic pollution. However, the effectiveness and environmental impact of these alternatives are still subjects of ongoing research and debate.

Circular Economy Potential for LDPE

Low-density polyethylene (LDPE) plays a significant role in the circular economy, offering numerous opportunities for waste minimization and resource efficiency. The circular economy potential for LDPE is substantial, given its widespread use in packaging and other applications.

LDPE's recyclability is a key factor in its circular economy potential. The material can be recycled multiple times without significant loss of quality, making it an ideal candidate for closed-loop systems. This characteristic allows for the creation of a continuous cycle of use, collection, and reprocessing, reducing the need for virgin material production and minimizing waste.

In the context of packaging, LDPE's lightweight nature contributes to resource efficiency and waste reduction. Its ability to provide adequate protection with minimal material use aligns with circular economy principles of doing more with less. Furthermore, innovations in LDPE packaging design are focusing on mono-material solutions, which simplify the recycling process and increase the material's circularity.

The development of advanced recycling technologies is enhancing LDPE's circular economy potential. Chemical recycling methods, such as pyrolysis and depolymerization, are enabling the conversion of LDPE waste into valuable feedstock for new plastic production. These technologies offer a solution for hard-to-recycle LDPE products, further closing the loop in the material's lifecycle.

LDPE's versatility also contributes to its circular economy potential. The material can be repurposed for various applications, from construction materials to energy recovery, providing multiple pathways for waste diversion and resource utilization. This adaptability ensures that even when direct recycling is not feasible, LDPE can still contribute to a circular economy model.

Collaborative efforts across the value chain are crucial for realizing LDPE's full circular economy potential. Initiatives involving manufacturers, retailers, waste management companies, and consumers are driving improvements in collection, sorting, and recycling infrastructure. These partnerships are essential for creating a robust circular economy ecosystem for LDPE.

The circular economy potential of LDPE extends beyond waste minimization to include economic opportunities. The development of markets for recycled LDPE and the creation of new business models based on material circularity are driving innovation and growth in the sector. This economic dimension reinforces the sustainability benefits of LDPE in a circular economy framework.