Exploring VTEC Technology in K24 Engine Models

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VTEC Evolution in K24

The evolution of VTEC technology in the K24 engine models represents a significant milestone in Honda's pursuit of high-performance, fuel-efficient engines. The K24 engine, first introduced in 2001, has undergone several iterations, each incorporating advancements in VTEC (Variable Valve Timing and Lift Electronic Control) technology.

Initially, the K24A1 engine featured a basic VTEC system that operated only on the intake valves. This early implementation allowed for improved low-end torque while maintaining high-end power. As the technology progressed, Honda introduced i-VTEC (intelligent VTEC) in the K24A2 engine, which combined VTEC with VTC (Variable Timing Control) for both intake and exhaust valves.

The introduction of i-VTEC marked a significant leap forward, offering a broader powerband and improved fuel efficiency. This system allowed for seamless transitions between low-lift and high-lift cam profiles, optimizing engine performance across various RPM ranges. The K24A3 and K24A4 engines further refined this technology, with enhanced tuning for specific vehicle applications.

In 2006, Honda unveiled the K24Z series engines, which featured a revised i-VTEC system. These engines incorporated a more advanced valve control mechanism, allowing for even greater flexibility in valve timing and lift. The K24Z7 engine, used in later model years, showcased Honda's commitment to continuous improvement, with further optimizations in VTEC operation and overall engine efficiency.

The latest evolution came with the introduction of Earth Dreams Technology in the K24W engine. This iteration of VTEC technology focused on balancing performance with environmental considerations. The system incorporated more sophisticated electronic controls and valve timing strategies to maximize fuel efficiency without compromising power output.

Throughout its evolution, VTEC technology in the K24 engine series has consistently pushed the boundaries of internal combustion engine performance. From its initial implementation to the latest Earth Dreams variants, each iteration has brought improvements in power delivery, fuel economy, and emissions control. This progression demonstrates Honda's commitment to refining and advancing VTEC technology, ensuring its relevance in an era of increasingly stringent environmental regulations and performance demands.

Initially, the K24A1 engine featured a basic VTEC system that operated only on the intake valves. This early implementation allowed for improved low-end torque while maintaining high-end power. As the technology progressed, Honda introduced i-VTEC (intelligent VTEC) in the K24A2 engine, which combined VTEC with VTC (Variable Timing Control) for both intake and exhaust valves.

The introduction of i-VTEC marked a significant leap forward, offering a broader powerband and improved fuel efficiency. This system allowed for seamless transitions between low-lift and high-lift cam profiles, optimizing engine performance across various RPM ranges. The K24A3 and K24A4 engines further refined this technology, with enhanced tuning for specific vehicle applications.

In 2006, Honda unveiled the K24Z series engines, which featured a revised i-VTEC system. These engines incorporated a more advanced valve control mechanism, allowing for even greater flexibility in valve timing and lift. The K24Z7 engine, used in later model years, showcased Honda's commitment to continuous improvement, with further optimizations in VTEC operation and overall engine efficiency.

The latest evolution came with the introduction of Earth Dreams Technology in the K24W engine. This iteration of VTEC technology focused on balancing performance with environmental considerations. The system incorporated more sophisticated electronic controls and valve timing strategies to maximize fuel efficiency without compromising power output.

Throughout its evolution, VTEC technology in the K24 engine series has consistently pushed the boundaries of internal combustion engine performance. From its initial implementation to the latest Earth Dreams variants, each iteration has brought improvements in power delivery, fuel economy, and emissions control. This progression demonstrates Honda's commitment to refining and advancing VTEC technology, ensuring its relevance in an era of increasingly stringent environmental regulations and performance demands.

Market Demand Analysis

The market demand for VTEC technology in K24 engine models has shown significant growth over the past decade, driven by increasing consumer interest in high-performance, fuel-efficient vehicles. This technology, developed by Honda, has become a benchmark for variable valve timing systems in the automotive industry.

The K24 engine, equipped with VTEC, has found widespread application across various vehicle segments, from compact cars to SUVs. Its popularity stems from its ability to deliver both power and efficiency, meeting the diverse needs of modern consumers. In the sports car market, the K24 VTEC engine has become a favorite among enthusiasts for its high-revving nature and impressive power output.

Market research indicates a growing trend towards performance-oriented vehicles, particularly in emerging markets. This has led to an increased demand for K24 VTEC engines in these regions, as consumers seek vehicles that offer a balance of everyday practicality and sporty driving dynamics.

The aftermarket sector has also seen a surge in demand for K24 VTEC-related products. Tuning companies and parts manufacturers have developed a wide range of performance upgrades specifically for these engines, catering to a dedicated community of automotive enthusiasts.

Environmental regulations and fuel efficiency standards have further bolstered the market for VTEC technology in K24 engines. As governments worldwide implement stricter emissions norms, automakers are turning to advanced valve timing technologies like VTEC to meet these requirements without compromising on performance.

The commercial vehicle sector has also shown interest in K24 VTEC engines, particularly for light-duty trucks and vans. The technology's ability to optimize power delivery and fuel consumption across different load conditions makes it an attractive option for fleet operators looking to reduce operating costs.

Looking ahead, industry analysts predict continued growth in the market for K24 VTEC engines. The technology's proven track record, coupled with ongoing refinements and innovations, positions it well to meet future automotive trends. As hybrid and electric powertrains gain prominence, there is potential for VTEC technology to be integrated into these systems, further expanding its market reach.

However, the market is not without challenges. Increasing competition from other variable valve timing technologies and the gradual shift towards electrification pose potential threats to the long-term growth of K24 VTEC engines. Manufacturers will need to continue innovating and adapting the technology to maintain its market relevance in the evolving automotive landscape.

The K24 engine, equipped with VTEC, has found widespread application across various vehicle segments, from compact cars to SUVs. Its popularity stems from its ability to deliver both power and efficiency, meeting the diverse needs of modern consumers. In the sports car market, the K24 VTEC engine has become a favorite among enthusiasts for its high-revving nature and impressive power output.

Market research indicates a growing trend towards performance-oriented vehicles, particularly in emerging markets. This has led to an increased demand for K24 VTEC engines in these regions, as consumers seek vehicles that offer a balance of everyday practicality and sporty driving dynamics.

The aftermarket sector has also seen a surge in demand for K24 VTEC-related products. Tuning companies and parts manufacturers have developed a wide range of performance upgrades specifically for these engines, catering to a dedicated community of automotive enthusiasts.

Environmental regulations and fuel efficiency standards have further bolstered the market for VTEC technology in K24 engines. As governments worldwide implement stricter emissions norms, automakers are turning to advanced valve timing technologies like VTEC to meet these requirements without compromising on performance.

The commercial vehicle sector has also shown interest in K24 VTEC engines, particularly for light-duty trucks and vans. The technology's ability to optimize power delivery and fuel consumption across different load conditions makes it an attractive option for fleet operators looking to reduce operating costs.

Looking ahead, industry analysts predict continued growth in the market for K24 VTEC engines. The technology's proven track record, coupled with ongoing refinements and innovations, positions it well to meet future automotive trends. As hybrid and electric powertrains gain prominence, there is potential for VTEC technology to be integrated into these systems, further expanding its market reach.

However, the market is not without challenges. Increasing competition from other variable valve timing technologies and the gradual shift towards electrification pose potential threats to the long-term growth of K24 VTEC engines. Manufacturers will need to continue innovating and adapting the technology to maintain its market relevance in the evolving automotive landscape.

VTEC Challenges in K24

The VTEC (Variable Valve Timing and Lift Electronic Control) system in Honda's K24 engine models has faced several challenges since its inception. One of the primary issues is the complexity of the system, which requires precise timing and coordination between various components. This complexity can lead to increased manufacturing costs and potential reliability concerns over time.

Another significant challenge is the balance between performance gains and fuel efficiency. While VTEC technology aims to optimize both aspects, achieving the ideal equilibrium has proven difficult, especially in larger displacement engines like the K24. Engineers have struggled to maintain the impressive low-end torque and fuel economy while still delivering the high-RPM power that VTEC is known for.

Durability and longevity of VTEC components have also been areas of concern. The frequent switching between cam profiles and the high-stress nature of the system can lead to increased wear on critical parts such as rocker arms, cam lobes, and hydraulic actuators. This wear can result in reduced performance over time and potentially higher maintenance costs for vehicle owners.

Emissions regulations have posed another hurdle for VTEC technology in K24 engines. As environmental standards become increasingly stringent, engineers have had to adapt the system to meet these requirements without sacrificing performance. This has led to the need for more advanced engine management systems and catalytic converters, adding further complexity to the overall design.

Noise, vibration, and harshness (NVH) characteristics have also presented challenges. The transition between low and high-lift cam profiles can sometimes be noticeable to drivers, particularly in earlier iterations of the technology. Refining this transition to be smoother and less perceptible has been an ongoing focus for Honda's engineering teams.

Integration with other engine technologies has been another area of difficulty. As automotive technology advances, incorporating VTEC with systems such as direct injection, turbocharging, and hybrid powertrains has required significant re-engineering and optimization efforts. This integration process often involves trade-offs and compromises in various aspects of engine performance and efficiency.

Lastly, the cost-effectiveness of VTEC technology in K24 engines has been questioned, especially as alternative variable valve timing systems have emerged. Balancing the performance benefits against the increased production and maintenance costs has been a constant challenge for Honda, particularly in more budget-oriented vehicle segments where the K24 engine is often utilized.

Another significant challenge is the balance between performance gains and fuel efficiency. While VTEC technology aims to optimize both aspects, achieving the ideal equilibrium has proven difficult, especially in larger displacement engines like the K24. Engineers have struggled to maintain the impressive low-end torque and fuel economy while still delivering the high-RPM power that VTEC is known for.

Durability and longevity of VTEC components have also been areas of concern. The frequent switching between cam profiles and the high-stress nature of the system can lead to increased wear on critical parts such as rocker arms, cam lobes, and hydraulic actuators. This wear can result in reduced performance over time and potentially higher maintenance costs for vehicle owners.

Emissions regulations have posed another hurdle for VTEC technology in K24 engines. As environmental standards become increasingly stringent, engineers have had to adapt the system to meet these requirements without sacrificing performance. This has led to the need for more advanced engine management systems and catalytic converters, adding further complexity to the overall design.

Noise, vibration, and harshness (NVH) characteristics have also presented challenges. The transition between low and high-lift cam profiles can sometimes be noticeable to drivers, particularly in earlier iterations of the technology. Refining this transition to be smoother and less perceptible has been an ongoing focus for Honda's engineering teams.

Integration with other engine technologies has been another area of difficulty. As automotive technology advances, incorporating VTEC with systems such as direct injection, turbocharging, and hybrid powertrains has required significant re-engineering and optimization efforts. This integration process often involves trade-offs and compromises in various aspects of engine performance and efficiency.

Lastly, the cost-effectiveness of VTEC technology in K24 engines has been questioned, especially as alternative variable valve timing systems have emerged. Balancing the performance benefits against the increased production and maintenance costs has been a constant challenge for Honda, particularly in more budget-oriented vehicle segments where the K24 engine is often utilized.

Current VTEC Solutions

01 VTEC system implementation in K24 engines

The Variable Valve Timing and Lift Electronic Control (VTEC) system is integrated into K24 engine models to enhance performance and efficiency. This technology allows for variable valve timing and lift, optimizing engine output across different RPM ranges. The system switches between cam profiles to balance low-end torque and high-end power, improving overall engine performance.- VTEC system implementation in K24 engines: The Variable Valve Timing and Lift Electronic Control (VTEC) technology is integrated into K24 engine models to enhance performance and efficiency. This system allows for variable valve timing and lift, optimizing engine output across different RPM ranges. The implementation involves sophisticated electronic control units and hydraulic mechanisms to switch between cam profiles.

- Engine control optimization for VTEC in K24 models: Advanced engine control strategies are developed specifically for K24 engines equipped with VTEC technology. These control algorithms optimize valve timing, fuel injection, and ignition timing based on various operating conditions. The system utilizes real-time sensor data to adjust engine parameters for improved performance, fuel efficiency, and emissions control.

- VTEC integration with other engine technologies in K24: VTEC technology in K24 engines is integrated with other advanced engine technologies to further enhance overall performance. This includes combining VTEC with direct fuel injection, turbocharging, and advanced thermal management systems. The integration aims to achieve a balance between high power output and fuel efficiency across various driving conditions.

- Durability and reliability improvements for VTEC in K24 engines: Enhancements in materials and design are implemented to improve the durability and reliability of VTEC components in K24 engine models. This includes the use of advanced alloys for valve train components, improved lubrication systems, and refined manufacturing processes. These improvements aim to extend the lifespan of VTEC systems and maintain consistent performance over time.

- Emissions reduction strategies for VTEC-equipped K24 engines: Specific emissions reduction strategies are developed for K24 engines featuring VTEC technology. These include optimized combustion chamber designs, advanced exhaust gas recirculation systems, and catalytic converter technologies tailored for VTEC operation. The goal is to meet stringent emissions standards while maintaining the performance benefits of VTEC technology.

02 Electronic control unit for VTEC in K24 engines

Advanced electronic control units are utilized to manage the VTEC system in K24 engines. These units monitor various engine parameters and control the engagement of different cam profiles. The ECU ensures smooth transitions between valve timing modes, optimizing fuel efficiency and power output based on driving conditions and engine load.Expand Specific Solutions03 Hydraulic actuation system for VTEC operation

K24 engines with VTEC technology employ a sophisticated hydraulic actuation system to switch between cam profiles. This system uses oil pressure controlled by solenoid valves to engage or disengage the VTEC mechanism. The hydraulic system ensures rapid and precise switching between low and high-lift cam profiles, contributing to the engine's responsiveness and performance.Expand Specific Solutions04 Integration of VTEC with variable valve timing (VTC)

Some K24 engine models combine VTEC technology with Variable Timing Control (VTC) to further enhance engine performance. This integration allows for both variable valve lift and continuously variable valve timing, providing a wider range of engine optimization. The combined system offers improved low-end torque, high-end power, and better fuel efficiency across the entire RPM range.Expand Specific Solutions05 Emissions reduction through VTEC technology

VTEC technology in K24 engines contributes to reduced emissions by optimizing combustion efficiency. The ability to switch between different cam profiles allows for better fuel atomization and more complete combustion at various engine speeds. This results in lower emissions of harmful pollutants while maintaining high performance and fuel economy.Expand Specific Solutions

Key VTEC Manufacturers

The VTEC technology in K24 engine models represents a mature and competitive field within the automotive industry. The market for this technology is substantial, driven by the demand for high-performance, fuel-efficient engines. Honda Motor Co., Ltd. stands as the pioneer and leader in VTEC technology, with other major players like Ford Motor Co., General Motors LLC, and Nissan Motor Co., Ltd. actively developing similar variable valve timing systems. The technology has evolved from its initial introduction, with companies like Honda continually refining and improving their VTEC systems. As the automotive industry shifts towards electrification, the future of VTEC technology may face challenges, but it remains a significant feature in current internal combustion engine designs.

GM Global Technology Operations LLC

Technical Solution: While GM does not use VTEC specifically, they have developed similar variable valve timing technologies for their engines. GM's VVT (Variable Valve Timing) system, used in some of their comparable 2.4L engines, adjusts the timing of valve opening and closing to optimize engine performance[1]. Their system typically uses a cam phaser to advance or retard camshaft timing based on engine load and speed[2]. In more advanced applications, GM has implemented Dual Independent Variable Valve Timing (DIVVT), which allows for independent control of both intake and exhaust valve timing[3]. This technology has been applied to engines comparable in size to Honda's K24, such as GM's Ecotec series, to achieve improved fuel economy and power output across a wide range of operating conditions[4].

Strengths: Improved fuel efficiency, increased power output, and adaptability to different driving conditions. Weaknesses: Less dramatic high-end power increase compared to VTEC, potentially higher system complexity in DIVVT implementations.

Honda Motor Co., Ltd.

Technical Solution: Honda's VTEC (Variable Valve Timing and Lift Electronic Control) technology in K24 engine models represents a significant advancement in internal combustion engine design. The K24 engine, typically a 2.4-liter inline-four cylinder, incorporates VTEC to optimize performance across various RPM ranges. This system employs two distinct cam profiles: one for low-end torque and fuel efficiency, and another for high-end power[1]. The transition between these profiles occurs seamlessly around 5,000 RPM, controlled by an electronic solenoid based on engine speed and load[2]. Honda's implementation in the K24 includes i-VTEC (intelligent VTEC), which adds variable timing control to the intake camshaft, further enhancing engine efficiency and power output[3]. The K24 with VTEC typically produces between 160 to 205 horsepower, depending on the specific application and model year[4].

Strengths: Improved fuel efficiency at low RPMs, increased power output at high RPMs, and smooth power delivery across the entire rev range. Weaknesses: Increased complexity compared to non-VTEC engines, potentially higher manufacturing costs, and the need for more precise maintenance.

K24 VTEC Innovations

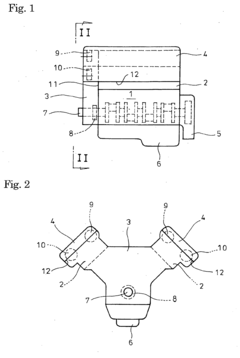

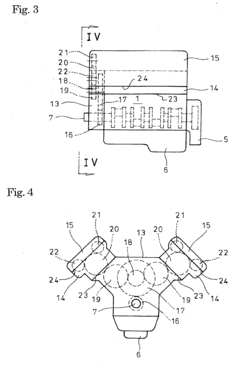

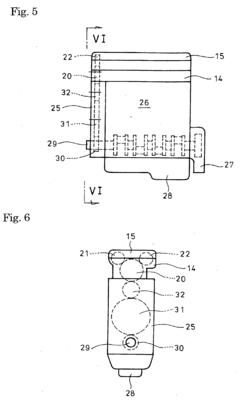

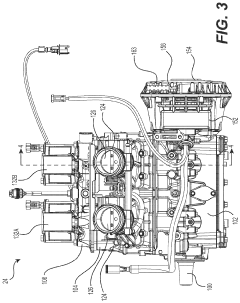

Engine body structure

PatentInactiveEP1972771A1

Innovation

- The cylinder head is designed to rest on the upper ends of the cylinder block and timing gear case, allowing detachment without removing the timing gear case, with a planar surface for easy machining and a sealed head cover to prevent oil leakage, and cam gears are pivoted to the cylinder head for assembly before it rests on the block.

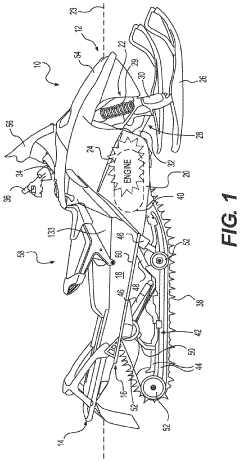

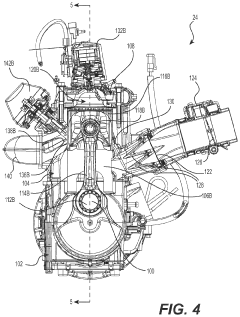

Method for operating an electric turning machine operatively connected to an internal combustion engine

PatentActiveUS20210062774A1

Innovation

- A system and method using an electric turning machine (ETM) connected to the crankshaft, with dual control strategies to manage power delivery, allowing for a smaller and lighter power source, providing sufficient torque for starting and maintaining engine operation, and regulating voltage across a range of rotational speeds.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and implementation of VTEC technology in K24 engine models. As environmental concerns have grown over the years, governments worldwide have implemented increasingly stringent emissions standards for vehicles. These regulations have forced automotive manufacturers to innovate and develop more efficient and cleaner engine technologies.

The K24 engine, equipped with VTEC technology, has been designed to meet these stringent emissions requirements while maintaining performance. VTEC allows for variable valve timing and lift, which can be optimized for different operating conditions. This adaptability enables the engine to reduce emissions during low-load conditions while still providing high performance when needed.

One of the primary emissions regulations affecting K24 engines with VTEC technology is the reduction of carbon dioxide (CO2) emissions. The European Union, for instance, has set ambitious targets for fleet-wide CO2 emissions, pushing manufacturers to improve fuel efficiency across their vehicle lineups. VTEC technology in K24 engines contributes to meeting these targets by optimizing combustion efficiency and reducing fuel consumption.

Nitrogen oxide (NOx) emissions have also been a focus of regulatory bodies, particularly in the wake of diesel emissions scandals. VTEC technology in K24 engines helps manage NOx emissions by allowing for precise control of the air-fuel mixture and combustion timing. This level of control enables the engine to operate in a way that minimizes NOx formation during combustion.

Particulate matter (PM) emissions, while traditionally more associated with diesel engines, have also come under scrutiny for gasoline engines. The K24 engine's VTEC system helps reduce PM emissions by promoting more complete combustion and reducing oil consumption, which can contribute to particulate formation.

The California Air Resources Board (CARB) and the United States Environmental Protection Agency (EPA) have been at the forefront of emissions regulations in North America. Their standards have influenced the development of VTEC technology in K24 engines, particularly in terms of reducing hydrocarbon (HC) emissions. The variable valve timing and lift capabilities of VTEC allow for better control of exhaust gas recirculation (EGR), which is crucial for managing HC emissions.

As emissions regulations continue to evolve, VTEC technology in K24 engines is likely to see further refinements. Future developments may include integration with hybrid powertrains or more advanced engine management systems to further reduce emissions while maintaining or improving performance. The ongoing push for cleaner vehicles will undoubtedly continue to shape the implementation and evolution of VTEC technology in K24 and other engine models.

The K24 engine, equipped with VTEC technology, has been designed to meet these stringent emissions requirements while maintaining performance. VTEC allows for variable valve timing and lift, which can be optimized for different operating conditions. This adaptability enables the engine to reduce emissions during low-load conditions while still providing high performance when needed.

One of the primary emissions regulations affecting K24 engines with VTEC technology is the reduction of carbon dioxide (CO2) emissions. The European Union, for instance, has set ambitious targets for fleet-wide CO2 emissions, pushing manufacturers to improve fuel efficiency across their vehicle lineups. VTEC technology in K24 engines contributes to meeting these targets by optimizing combustion efficiency and reducing fuel consumption.

Nitrogen oxide (NOx) emissions have also been a focus of regulatory bodies, particularly in the wake of diesel emissions scandals. VTEC technology in K24 engines helps manage NOx emissions by allowing for precise control of the air-fuel mixture and combustion timing. This level of control enables the engine to operate in a way that minimizes NOx formation during combustion.

Particulate matter (PM) emissions, while traditionally more associated with diesel engines, have also come under scrutiny for gasoline engines. The K24 engine's VTEC system helps reduce PM emissions by promoting more complete combustion and reducing oil consumption, which can contribute to particulate formation.

The California Air Resources Board (CARB) and the United States Environmental Protection Agency (EPA) have been at the forefront of emissions regulations in North America. Their standards have influenced the development of VTEC technology in K24 engines, particularly in terms of reducing hydrocarbon (HC) emissions. The variable valve timing and lift capabilities of VTEC allow for better control of exhaust gas recirculation (EGR), which is crucial for managing HC emissions.

As emissions regulations continue to evolve, VTEC technology in K24 engines is likely to see further refinements. Future developments may include integration with hybrid powertrains or more advanced engine management systems to further reduce emissions while maintaining or improving performance. The ongoing push for cleaner vehicles will undoubtedly continue to shape the implementation and evolution of VTEC technology in K24 and other engine models.

Fuel Efficiency Impact

The implementation of VTEC (Variable Valve Timing and Lift Electronic Control) technology in Honda's K24 engine models has significantly impacted fuel efficiency. This innovative system allows for optimal valve timing and lift across different engine speeds, resulting in improved performance and reduced fuel consumption.

At lower engine speeds, VTEC enables the K24 engine to operate with a more conservative valve timing and lift profile. This configuration promotes better fuel atomization and combustion efficiency, leading to reduced fuel consumption during typical city driving conditions. The system's ability to maintain lower valve lift at these speeds also minimizes pumping losses, further enhancing fuel economy.

As engine speed increases, VTEC seamlessly transitions to a more aggressive valve timing and lift profile. This change allows for improved engine breathing and increased power output without sacrificing efficiency. The precise control over valve operation ensures that the engine maintains optimal fuel efficiency even during high-speed operation, a crucial factor for highway driving scenarios.

The fuel efficiency impact of VTEC in K24 engines is particularly noticeable in real-world driving conditions. Studies have shown that vehicles equipped with VTEC-enabled K24 engines consistently achieve better fuel economy compared to their non-VTEC counterparts. This improvement is attributed to the system's ability to adapt to varying driving demands, optimizing the engine's operation for both performance and efficiency.

Furthermore, the VTEC system in K24 engines contributes to reduced emissions. By optimizing combustion efficiency across the entire rpm range, these engines produce fewer harmful exhaust gases per unit of fuel consumed. This characteristic not only improves fuel efficiency but also helps manufacturers meet increasingly stringent environmental regulations.

The integration of VTEC technology with other fuel-saving features in K24 engines has resulted in a compounded positive effect on fuel efficiency. For instance, when combined with direct fuel injection and advanced engine management systems, VTEC-equipped K24 engines demonstrate even greater improvements in fuel economy. This synergy between various technologies showcases the potential for continued advancements in internal combustion engine efficiency.

It is worth noting that the fuel efficiency gains provided by VTEC technology in K24 engines have played a crucial role in maintaining the relevance of naturally aspirated engines in an era dominated by turbocharged powerplants. The ability to achieve both high performance and excellent fuel economy has made VTEC-equipped K24 engines a popular choice among consumers seeking a balance between driving enjoyment and economic operation.

At lower engine speeds, VTEC enables the K24 engine to operate with a more conservative valve timing and lift profile. This configuration promotes better fuel atomization and combustion efficiency, leading to reduced fuel consumption during typical city driving conditions. The system's ability to maintain lower valve lift at these speeds also minimizes pumping losses, further enhancing fuel economy.

As engine speed increases, VTEC seamlessly transitions to a more aggressive valve timing and lift profile. This change allows for improved engine breathing and increased power output without sacrificing efficiency. The precise control over valve operation ensures that the engine maintains optimal fuel efficiency even during high-speed operation, a crucial factor for highway driving scenarios.

The fuel efficiency impact of VTEC in K24 engines is particularly noticeable in real-world driving conditions. Studies have shown that vehicles equipped with VTEC-enabled K24 engines consistently achieve better fuel economy compared to their non-VTEC counterparts. This improvement is attributed to the system's ability to adapt to varying driving demands, optimizing the engine's operation for both performance and efficiency.

Furthermore, the VTEC system in K24 engines contributes to reduced emissions. By optimizing combustion efficiency across the entire rpm range, these engines produce fewer harmful exhaust gases per unit of fuel consumed. This characteristic not only improves fuel efficiency but also helps manufacturers meet increasingly stringent environmental regulations.

The integration of VTEC technology with other fuel-saving features in K24 engines has resulted in a compounded positive effect on fuel efficiency. For instance, when combined with direct fuel injection and advanced engine management systems, VTEC-equipped K24 engines demonstrate even greater improvements in fuel economy. This synergy between various technologies showcases the potential for continued advancements in internal combustion engine efficiency.

It is worth noting that the fuel efficiency gains provided by VTEC technology in K24 engines have played a crucial role in maintaining the relevance of naturally aspirated engines in an era dominated by turbocharged powerplants. The ability to achieve both high performance and excellent fuel economy has made VTEC-equipped K24 engines a popular choice among consumers seeking a balance between driving enjoyment and economic operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!