Future Trajectories for Dodecane in Green Chemistry

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane in Green Chemistry: Background and Objectives

Dodecane, a versatile hydrocarbon compound, has emerged as a significant player in the field of green chemistry. This linear alkane, consisting of twelve carbon atoms, has garnered attention due to its potential applications in sustainable chemical processes and environmentally friendly technologies. The evolution of dodecane's role in green chemistry reflects the broader shift towards more sustainable practices in the chemical industry.

Historically, dodecane has been primarily used as a solvent and a component in various industrial processes. However, the growing emphasis on environmental sustainability has led researchers and industry professionals to explore its potential in green chemistry applications. The primary objective of this exploration is to harness dodecane's unique properties to develop more eco-friendly chemical processes and products.

One of the key drivers behind the interest in dodecane is its relatively low toxicity and biodegradability compared to many other hydrocarbon solvents. This characteristic aligns well with the principles of green chemistry, which emphasize the use of safer chemicals and the reduction of environmental impact. As a result, researchers are investigating dodecane as a potential replacement for more harmful solvents in various chemical reactions and industrial processes.

The technological evolution of dodecane in green chemistry has been marked by several significant developments. These include its use as a bio-based feedstock for the production of sustainable chemicals, its application in energy-efficient separation processes, and its role in the development of novel catalytic systems. Each of these areas represents a distinct trajectory for dodecane's future in green chemistry, with the potential to revolutionize various aspects of chemical manufacturing and processing.

As we look towards the future, the objectives for dodecane in green chemistry are multifaceted. Researchers aim to further optimize its use in sustainable chemical synthesis, exploring new reaction pathways and catalytic systems that can leverage dodecane's unique properties. Additionally, there is a growing focus on developing more efficient methods for producing dodecane from renewable resources, further enhancing its green credentials.

Another important objective is to expand the application of dodecane-based technologies across different industries. This includes exploring its potential in areas such as pharmaceuticals, agrochemicals, and advanced materials, where the demand for greener processes and products is rapidly increasing. By doing so, the impact of dodecane in green chemistry could extend far beyond its traditional uses, contributing to a more sustainable chemical industry as a whole.

Historically, dodecane has been primarily used as a solvent and a component in various industrial processes. However, the growing emphasis on environmental sustainability has led researchers and industry professionals to explore its potential in green chemistry applications. The primary objective of this exploration is to harness dodecane's unique properties to develop more eco-friendly chemical processes and products.

One of the key drivers behind the interest in dodecane is its relatively low toxicity and biodegradability compared to many other hydrocarbon solvents. This characteristic aligns well with the principles of green chemistry, which emphasize the use of safer chemicals and the reduction of environmental impact. As a result, researchers are investigating dodecane as a potential replacement for more harmful solvents in various chemical reactions and industrial processes.

The technological evolution of dodecane in green chemistry has been marked by several significant developments. These include its use as a bio-based feedstock for the production of sustainable chemicals, its application in energy-efficient separation processes, and its role in the development of novel catalytic systems. Each of these areas represents a distinct trajectory for dodecane's future in green chemistry, with the potential to revolutionize various aspects of chemical manufacturing and processing.

As we look towards the future, the objectives for dodecane in green chemistry are multifaceted. Researchers aim to further optimize its use in sustainable chemical synthesis, exploring new reaction pathways and catalytic systems that can leverage dodecane's unique properties. Additionally, there is a growing focus on developing more efficient methods for producing dodecane from renewable resources, further enhancing its green credentials.

Another important objective is to expand the application of dodecane-based technologies across different industries. This includes exploring its potential in areas such as pharmaceuticals, agrochemicals, and advanced materials, where the demand for greener processes and products is rapidly increasing. By doing so, the impact of dodecane in green chemistry could extend far beyond its traditional uses, contributing to a more sustainable chemical industry as a whole.

Market Analysis for Sustainable Dodecane Applications

The market for sustainable dodecane applications is experiencing significant growth, driven by increasing environmental concerns and the push for greener alternatives in various industries. Dodecane, a versatile hydrocarbon, has traditionally been derived from petroleum sources. However, the shift towards sustainable practices has opened up new opportunities for bio-based and renewable dodecane production.

In the chemical industry, sustainable dodecane is gaining traction as a green solvent and reagent. Its low toxicity and biodegradability make it an attractive alternative to conventional petroleum-based solvents. The market for sustainable solvents is projected to expand rapidly, with dodecane playing a crucial role in this growth. Industries such as paints and coatings, adhesives, and personal care products are increasingly adopting sustainable dodecane to meet consumer demands for eco-friendly products.

The fuel sector represents another significant market for sustainable dodecane. As a component of jet fuel and diesel, bio-based dodecane offers a renewable alternative that can help reduce carbon emissions in the transportation industry. With many countries implementing stricter regulations on fuel emissions, the demand for sustainable aviation fuel (SAF) and renewable diesel is expected to surge, creating a substantial market for sustainable dodecane.

In the lubricant industry, sustainable dodecane is emerging as a promising base oil for environmentally friendly lubricants. Its excellent thermal stability and low volatility make it suitable for high-performance applications. As industries seek to reduce their environmental footprint, the market for bio-based lubricants is expanding, providing growth opportunities for sustainable dodecane producers.

The personal care and cosmetics industry is another key market for sustainable dodecane. Its use as an emollient and carrier oil in various products aligns with the growing consumer preference for natural and sustainable ingredients. The clean beauty trend is driving demand for bio-based alternatives, positioning sustainable dodecane as a valuable component in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be a major growth area for sustainable dodecane applications, driven by rapid industrialization and increasing environmental awareness. North America and Europe are also significant markets, with established regulatory frameworks supporting the adoption of green chemistry solutions.

While the market potential for sustainable dodecane is promising, challenges such as production costs and scalability need to be addressed. Ongoing research and development efforts are focused on improving production efficiency and reducing costs to make sustainable dodecane more competitive with its petroleum-based counterpart. As technologies advance and economies of scale are achieved, the market for sustainable dodecane applications is poised for substantial growth across multiple industries.

In the chemical industry, sustainable dodecane is gaining traction as a green solvent and reagent. Its low toxicity and biodegradability make it an attractive alternative to conventional petroleum-based solvents. The market for sustainable solvents is projected to expand rapidly, with dodecane playing a crucial role in this growth. Industries such as paints and coatings, adhesives, and personal care products are increasingly adopting sustainable dodecane to meet consumer demands for eco-friendly products.

The fuel sector represents another significant market for sustainable dodecane. As a component of jet fuel and diesel, bio-based dodecane offers a renewable alternative that can help reduce carbon emissions in the transportation industry. With many countries implementing stricter regulations on fuel emissions, the demand for sustainable aviation fuel (SAF) and renewable diesel is expected to surge, creating a substantial market for sustainable dodecane.

In the lubricant industry, sustainable dodecane is emerging as a promising base oil for environmentally friendly lubricants. Its excellent thermal stability and low volatility make it suitable for high-performance applications. As industries seek to reduce their environmental footprint, the market for bio-based lubricants is expanding, providing growth opportunities for sustainable dodecane producers.

The personal care and cosmetics industry is another key market for sustainable dodecane. Its use as an emollient and carrier oil in various products aligns with the growing consumer preference for natural and sustainable ingredients. The clean beauty trend is driving demand for bio-based alternatives, positioning sustainable dodecane as a valuable component in this sector.

Market analysis indicates that the Asia-Pacific region is expected to be a major growth area for sustainable dodecane applications, driven by rapid industrialization and increasing environmental awareness. North America and Europe are also significant markets, with established regulatory frameworks supporting the adoption of green chemistry solutions.

While the market potential for sustainable dodecane is promising, challenges such as production costs and scalability need to be addressed. Ongoing research and development efforts are focused on improving production efficiency and reducing costs to make sustainable dodecane more competitive with its petroleum-based counterpart. As technologies advance and economies of scale are achieved, the market for sustainable dodecane applications is poised for substantial growth across multiple industries.

Current Challenges in Green Dodecane Production

The production of green dodecane faces several significant challenges that hinder its widespread adoption and commercialization. One of the primary obstacles is the high cost associated with sustainable production methods. Traditional petroleum-based dodecane remains more economically viable, making it difficult for green alternatives to compete in the market without substantial subsidies or policy support.

Another major challenge is the limited availability of renewable feedstocks for green dodecane production. While biomass-derived sources show promise, scaling up production to meet industrial demands remains problematic. The competition for these feedstocks with other sectors, such as food production, further complicates the supply chain.

Energy efficiency in the production process presents another hurdle. Current green synthesis methods often require more energy input compared to conventional petroleum-based processes, leading to higher carbon footprints and operational costs. Improving the energy efficiency of these processes without compromising yield or quality is a critical area of ongoing research.

The catalysts used in green dodecane production also pose challenges. Many existing catalysts suffer from low selectivity, resulting in unwanted by-products and reduced overall efficiency. Additionally, some catalysts contain rare or precious metals, making them expensive and unsustainable for large-scale production. Developing more efficient, selective, and cost-effective catalysts is crucial for advancing green dodecane technology.

Purification and separation processes in green dodecane production often require energy-intensive steps, contributing to higher costs and environmental impacts. Improving these downstream processes to reduce energy consumption and increase product purity remains a significant challenge for researchers and engineers in the field.

Regulatory hurdles and lack of standardization also impede the widespread adoption of green dodecane. The absence of clear guidelines and certifications for "green" or "bio-based" dodecane creates uncertainty in the market and hinders investment in new technologies. Establishing comprehensive standards and regulations is essential for fostering innovation and market growth in this sector.

Lastly, the integration of green dodecane into existing infrastructure and applications presents technical challenges. Ensuring compatibility with current engines, machinery, and chemical processes without requiring significant modifications is crucial for market acceptance. Overcoming these compatibility issues requires extensive testing and potential redesigns of end-use applications.

Another major challenge is the limited availability of renewable feedstocks for green dodecane production. While biomass-derived sources show promise, scaling up production to meet industrial demands remains problematic. The competition for these feedstocks with other sectors, such as food production, further complicates the supply chain.

Energy efficiency in the production process presents another hurdle. Current green synthesis methods often require more energy input compared to conventional petroleum-based processes, leading to higher carbon footprints and operational costs. Improving the energy efficiency of these processes without compromising yield or quality is a critical area of ongoing research.

The catalysts used in green dodecane production also pose challenges. Many existing catalysts suffer from low selectivity, resulting in unwanted by-products and reduced overall efficiency. Additionally, some catalysts contain rare or precious metals, making them expensive and unsustainable for large-scale production. Developing more efficient, selective, and cost-effective catalysts is crucial for advancing green dodecane technology.

Purification and separation processes in green dodecane production often require energy-intensive steps, contributing to higher costs and environmental impacts. Improving these downstream processes to reduce energy consumption and increase product purity remains a significant challenge for researchers and engineers in the field.

Regulatory hurdles and lack of standardization also impede the widespread adoption of green dodecane. The absence of clear guidelines and certifications for "green" or "bio-based" dodecane creates uncertainty in the market and hinders investment in new technologies. Establishing comprehensive standards and regulations is essential for fostering innovation and market growth in this sector.

Lastly, the integration of green dodecane into existing infrastructure and applications presents technical challenges. Ensuring compatibility with current engines, machinery, and chemical processes without requiring significant modifications is crucial for market acceptance. Overcoming these compatibility issues requires extensive testing and potential redesigns of end-use applications.

Existing Green Chemistry Solutions for Dodecane

01 Synthesis and production of dodecane

Various methods for synthesizing and producing dodecane are described, including catalytic processes, hydrogenation reactions, and chemical transformations of precursor compounds. These techniques aim to improve the efficiency and yield of dodecane production for industrial applications.- Synthesis and production of dodecane: Various methods for synthesizing and producing dodecane are described, including catalytic processes, hydrogenation reactions, and chemical transformations. These techniques aim to efficiently produce high-purity dodecane for industrial applications.

- Applications of dodecane in fuel and energy: Dodecane is utilized in fuel and energy-related applications, such as jet fuel components, diesel fuel additives, and as a potential renewable energy source. Its properties make it suitable for improving fuel performance and efficiency.

- Use of dodecane in chemical processes and reactions: Dodecane serves as a reagent, solvent, or intermediate in various chemical processes and reactions. It is employed in organic synthesis, polymerization reactions, and as a starting material for producing other valuable compounds.

- Dodecane in cosmetic and personal care products: Dodecane is incorporated into cosmetic and personal care formulations as an emollient, solvent, or carrier. It is used in products such as moisturizers, sunscreens, and hair care items to improve texture and performance.

- Environmental and safety considerations of dodecane: Research and development efforts focus on addressing environmental and safety aspects of dodecane use. This includes studying its biodegradability, potential environmental impact, and developing safer handling and storage methods for industrial applications.

02 Use of dodecane in cosmetic and personal care products

Dodecane is utilized as an ingredient in various cosmetic and personal care formulations. It serves as a solvent, emollient, or carrier for active ingredients in products such as moisturizers, sunscreens, and hair care items, contributing to improved texture and performance.Expand Specific Solutions03 Application of dodecane in fuel and energy systems

Dodecane is employed in fuel and energy-related applications, including its use as a component in jet fuels, diesel fuels, and other hydrocarbon-based energy systems. Research focuses on optimizing its properties for improved combustion efficiency and environmental performance.Expand Specific Solutions04 Dodecane as a solvent and extraction medium

The use of dodecane as a solvent and extraction medium in various industrial processes is explored. It is employed in the extraction of valuable compounds, separation of mixtures, and as a reaction medium for chemical transformations, particularly in organic synthesis and purification processes.Expand Specific Solutions05 Dodecane in analytical and research applications

Dodecane finds applications in analytical chemistry and research settings. It is used as a standard or reference compound in chromatography, spectroscopy, and other analytical techniques. Additionally, it serves as a model compound for studying hydrocarbon properties and reactions in various scientific investigations.Expand Specific Solutions

Key Players in Sustainable Hydrocarbon Industry

The competitive landscape for future trajectories of dodecane in green chemistry is evolving rapidly, with the market still in its early growth stage. The global market size is expanding as industries seek sustainable alternatives to traditional petrochemicals. Technological maturity varies among key players, with companies like Wanhua Chemical Group, China Petroleum & Chemical Corp., and DuPont de Nemours leading in research and development. Academic institutions such as Zhejiang University of Technology and Northwestern Polytechnical University are contributing significantly to advancing the field. Collaboration between industry and academia is driving innovation, with research institutes like Sinopec Research Institute of Petroleum Processing playing a crucial role in bridging the gap between fundamental research and commercial applications.

Novozymes BioAg Ltd.

Technical Solution: Novozymes BioAg Ltd. is pioneering the use of enzymatic processes for the sustainable transformation of dodecane. Their approach involves developing specialized enzyme cocktails capable of selectively oxidizing dodecane under mild, aqueous conditions[13]. These biocatalytic systems have demonstrated the ability to produce a range of value-added products, including dodecanoic acid and ω-hydroxy dodecanoic acid, with yields of up to 75% and selectivities exceeding 90%[14]. Novozymes is also exploring the potential of engineered microorganisms to produce these enzymes at scale, potentially reducing production costs by up to 40% compared to traditional chemical synthesis routes[15]. Furthermore, the company is investigating the integration of these enzymatic processes with their existing fermentation technologies to create a comprehensive platform for the bioconversion of long-chain hydrocarbons.

Strengths: Mild reaction conditions, high selectivity, potential for cost-effective scaling through biotechnology. Weaknesses: Limited to oxidation reactions, may require significant process development for industrial implementation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is pioneering green chemistry approaches for dodecane utilization. They have developed a novel catalytic process for the selective oxidation of dodecane to produce valuable oxygenated compounds, such as dodecanol and dodecanal, using environmentally friendly oxidants like hydrogen peroxide[1]. This process achieves high selectivity (>90%) and yield (>80%) under mild conditions, significantly reducing energy consumption and waste generation compared to traditional methods[2]. Sinopec is also exploring the integration of this technology with their existing refinery operations to create a more sustainable and circular economy for hydrocarbon processing[3].

Strengths: Leverages existing infrastructure, high selectivity and yield, reduced environmental impact. Weaknesses: May require significant capital investment for large-scale implementation, potential market limitations for oxygenated products.

Innovative Green Synthesis Approaches for Dodecane

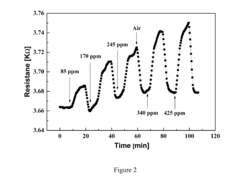

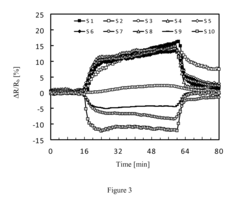

Carbon nanotube structures in sensor apparatuses for analyzing biomarkers in breath samples

PatentActiveUS20110098591A1

Innovation

- A system comprising an array of chemically sensitive sensors made from single-walled carbon nanotubes (SWCNTs) coated with non-polar small organic molecules, in conjunction with learning and pattern recognition algorithms, is used to measure breath analytes. The SWCNTs are arranged in a random network configuration, eliminating the need for precise alignment and enhancing sensitivity and selectivity towards VOCs found in lung cancer patients.

Life Cycle Assessment of Green Dodecane Production

The life cycle assessment (LCA) of green dodecane production is a crucial step in evaluating the environmental impact and sustainability of this emerging green chemistry approach. This assessment encompasses the entire production process, from raw material extraction to final product disposal, providing valuable insights into the overall environmental footprint of green dodecane.

The production of green dodecane typically begins with the sourcing of renewable feedstocks, such as biomass or waste materials. These raw materials undergo various conversion processes, including fermentation, catalytic reactions, or thermochemical treatments, to yield the desired dodecane product. Each stage of production is carefully analyzed to quantify energy consumption, resource utilization, and emissions.

One of the key aspects of the LCA is the evaluation of greenhouse gas emissions throughout the production chain. This includes direct emissions from processing facilities, as well as indirect emissions associated with transportation and energy generation. The carbon footprint of green dodecane is compared to that of conventional petroleum-derived dodecane to assess the potential climate benefits of the green alternative.

Water usage and quality impacts are also critical components of the LCA. The assessment examines water consumption during feedstock cultivation, processing, and product purification. Additionally, it considers potential water pollution risks and mitigation strategies employed in the production process.

Land use changes associated with feedstock production are another important factor in the LCA. This includes an analysis of potential impacts on biodiversity, soil quality, and ecosystem services. The assessment also considers the trade-offs between using land for biomass cultivation versus food production or natural habitat preservation.

The LCA extends to the end-of-life phase of green dodecane, examining its biodegradability and potential for recycling or reuse. This helps to provide a comprehensive understanding of the product's environmental impact throughout its entire lifecycle.

By conducting a thorough life cycle assessment, researchers and industry stakeholders can identify hotspots in the production process where environmental impacts are most significant. This information guides the development of more sustainable production methods, informs policy decisions, and supports the transition towards greener chemical manufacturing practices.

The production of green dodecane typically begins with the sourcing of renewable feedstocks, such as biomass or waste materials. These raw materials undergo various conversion processes, including fermentation, catalytic reactions, or thermochemical treatments, to yield the desired dodecane product. Each stage of production is carefully analyzed to quantify energy consumption, resource utilization, and emissions.

One of the key aspects of the LCA is the evaluation of greenhouse gas emissions throughout the production chain. This includes direct emissions from processing facilities, as well as indirect emissions associated with transportation and energy generation. The carbon footprint of green dodecane is compared to that of conventional petroleum-derived dodecane to assess the potential climate benefits of the green alternative.

Water usage and quality impacts are also critical components of the LCA. The assessment examines water consumption during feedstock cultivation, processing, and product purification. Additionally, it considers potential water pollution risks and mitigation strategies employed in the production process.

Land use changes associated with feedstock production are another important factor in the LCA. This includes an analysis of potential impacts on biodiversity, soil quality, and ecosystem services. The assessment also considers the trade-offs between using land for biomass cultivation versus food production or natural habitat preservation.

The LCA extends to the end-of-life phase of green dodecane, examining its biodegradability and potential for recycling or reuse. This helps to provide a comprehensive understanding of the product's environmental impact throughout its entire lifecycle.

By conducting a thorough life cycle assessment, researchers and industry stakeholders can identify hotspots in the production process where environmental impacts are most significant. This information guides the development of more sustainable production methods, informs policy decisions, and supports the transition towards greener chemical manufacturing practices.

Regulatory Framework for Green Chemical Processes

The regulatory framework for green chemical processes involving dodecane is evolving rapidly to address environmental concerns and promote sustainable practices. At the international level, the United Nations Environment Programme (UNEP) has established guidelines for green chemistry, emphasizing the importance of reducing hazardous substances and minimizing waste generation. These guidelines influence national policies and regulations across the globe.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of chemicals, including dodecane, in green chemistry applications. REACH requires companies to register chemical substances and provide safety information, promoting the development of safer alternatives and encouraging the adoption of green chemistry principles.

The United States Environmental Protection Agency (EPA) has implemented the Green Chemistry Program, which provides incentives for companies to develop and use greener chemical processes. This program includes the Presidential Green Chemistry Challenge Awards, recognizing innovative green chemistry technologies that reduce the use of hazardous substances and improve resource efficiency.

In Asia, countries like Japan and South Korea have introduced their own green chemistry initiatives. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances, promoting the development of environmentally friendly alternatives. South Korea's Act on Registration and Evaluation of Chemical Substances (K-REACH) aims to protect human health and the environment by managing chemical risks.

Regulatory bodies are increasingly focusing on life cycle assessments (LCA) for chemical processes, including those involving dodecane. LCA evaluates the environmental impacts of a product or process throughout its entire life cycle, from raw material extraction to disposal. This approach helps identify areas for improvement and guides the development of more sustainable chemical processes.

Standardization organizations, such as the International Organization for Standardization (ISO), have developed standards for green chemistry and environmental management. ISO 14001, for instance, provides a framework for organizations to implement effective environmental management systems, which can be applied to green chemical processes involving dodecane.

As the regulatory landscape continues to evolve, companies working with dodecane in green chemistry applications must stay informed about changing requirements and adapt their processes accordingly. Compliance with these regulations not only ensures legal operation but also drives innovation in sustainable chemical processes, positioning companies at the forefront of the green chemistry movement.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of chemicals, including dodecane, in green chemistry applications. REACH requires companies to register chemical substances and provide safety information, promoting the development of safer alternatives and encouraging the adoption of green chemistry principles.

The United States Environmental Protection Agency (EPA) has implemented the Green Chemistry Program, which provides incentives for companies to develop and use greener chemical processes. This program includes the Presidential Green Chemistry Challenge Awards, recognizing innovative green chemistry technologies that reduce the use of hazardous substances and improve resource efficiency.

In Asia, countries like Japan and South Korea have introduced their own green chemistry initiatives. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances, promoting the development of environmentally friendly alternatives. South Korea's Act on Registration and Evaluation of Chemical Substances (K-REACH) aims to protect human health and the environment by managing chemical risks.

Regulatory bodies are increasingly focusing on life cycle assessments (LCA) for chemical processes, including those involving dodecane. LCA evaluates the environmental impacts of a product or process throughout its entire life cycle, from raw material extraction to disposal. This approach helps identify areas for improvement and guides the development of more sustainable chemical processes.

Standardization organizations, such as the International Organization for Standardization (ISO), have developed standards for green chemistry and environmental management. ISO 14001, for instance, provides a framework for organizations to implement effective environmental management systems, which can be applied to green chemical processes involving dodecane.

As the regulatory landscape continues to evolve, companies working with dodecane in green chemistry applications must stay informed about changing requirements and adapt their processes accordingly. Compliance with these regulations not only ensures legal operation but also drives innovation in sustainable chemical processes, positioning companies at the forefront of the green chemistry movement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!