GDDR7 Thermal Management: Hot-Spot Mapping, TIM Stack And Heatsink Limits

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDDR7 Thermal Evolution and Objectives

Graphics Double Data Rate (GDDR) memory has undergone significant thermal evolution since its inception, with each generation presenting new challenges and solutions in thermal management. The progression from GDDR5 to GDDR6 saw bandwidth increases from 8 Gbps to 16 Gbps, accompanied by corresponding increases in power consumption and thermal output. This evolutionary trend continues with GDDR7, which pushes bandwidth capabilities beyond 24 Gbps while introducing more complex thermal management requirements.

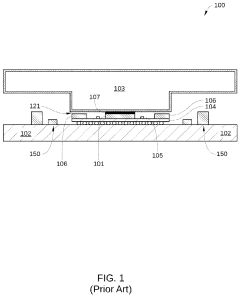

The thermal characteristics of GDDR memory have historically been addressed through conventional cooling methods, including passive heatsinks and thermal interface materials (TIMs). However, as data rates and computational demands have increased, these traditional approaches have reached their practical limits. The transition to GDDR7 represents a critical inflection point where thermal management becomes a primary design consideration rather than a secondary concern.

Industry data indicates that GDDR7 modules can generate thermal densities exceeding 3 W/cm², significantly higher than previous generations. This increased thermal output creates localized hot spots that can reach temperatures above 105°C under peak workloads, potentially compromising both performance and long-term reliability. The thermal gradient across the memory die has also become more pronounced, creating additional challenges for uniform cooling solutions.

The primary objective of GDDR7 thermal management research is to develop comprehensive solutions that address these emerging challenges while maintaining compatibility with existing system architectures. This includes mapping and mitigating hot spots through advanced thermal imaging and simulation techniques, optimizing the thermal interface material stack for improved heat transfer efficiency, and exploring the physical limits of conventional heatsink designs.

Another critical objective is to establish new thermal design power (TDP) guidelines specifically tailored to GDDR7 implementations. These guidelines must account for the unique thermal characteristics of high-bandwidth memory operations, including transient thermal spikes during intensive computational workloads and the cumulative thermal effects of multiple memory modules operating in close proximity.

The evolution of GDDR7 thermal management also aims to balance performance optimization with energy efficiency. As data centers and high-performance computing environments face increasing pressure to reduce power consumption, thermal solutions must not only prevent overheating but also contribute to overall system efficiency by minimizing the energy required for cooling operations.

The thermal characteristics of GDDR memory have historically been addressed through conventional cooling methods, including passive heatsinks and thermal interface materials (TIMs). However, as data rates and computational demands have increased, these traditional approaches have reached their practical limits. The transition to GDDR7 represents a critical inflection point where thermal management becomes a primary design consideration rather than a secondary concern.

Industry data indicates that GDDR7 modules can generate thermal densities exceeding 3 W/cm², significantly higher than previous generations. This increased thermal output creates localized hot spots that can reach temperatures above 105°C under peak workloads, potentially compromising both performance and long-term reliability. The thermal gradient across the memory die has also become more pronounced, creating additional challenges for uniform cooling solutions.

The primary objective of GDDR7 thermal management research is to develop comprehensive solutions that address these emerging challenges while maintaining compatibility with existing system architectures. This includes mapping and mitigating hot spots through advanced thermal imaging and simulation techniques, optimizing the thermal interface material stack for improved heat transfer efficiency, and exploring the physical limits of conventional heatsink designs.

Another critical objective is to establish new thermal design power (TDP) guidelines specifically tailored to GDDR7 implementations. These guidelines must account for the unique thermal characteristics of high-bandwidth memory operations, including transient thermal spikes during intensive computational workloads and the cumulative thermal effects of multiple memory modules operating in close proximity.

The evolution of GDDR7 thermal management also aims to balance performance optimization with energy efficiency. As data centers and high-performance computing environments face increasing pressure to reduce power consumption, thermal solutions must not only prevent overheating but also contribute to overall system efficiency by minimizing the energy required for cooling operations.

Market Demand for Advanced Memory Cooling Solutions

The global market for advanced memory cooling solutions is experiencing unprecedented growth, driven primarily by the escalating thermal challenges in high-performance computing environments. As GDDR7 memory technologies push performance boundaries with higher clock speeds and increased power densities, traditional cooling methods are proving increasingly inadequate. Industry analysts project the specialized thermal management market for graphics memory to reach $3.2 billion by 2026, representing a compound annual growth rate of 14.7% from 2021 levels.

Data center operators constitute a significant demand segment, as they face mounting pressure to optimize cooling efficiency while maintaining reliability in increasingly dense server environments. According to recent surveys, over 68% of enterprise data centers report thermal management as a critical constraint in their GPU acceleration deployments, with memory subsystem cooling cited as a particular pain point.

The gaming and professional graphics sectors represent another substantial market driver. With high-end graphics cards now routinely exceeding 450W total board power, manufacturers are prioritizing sophisticated cooling solutions that can effectively manage memory hot spots without compromising system acoustics or reliability. Consumer demand for quieter yet more powerful systems has created a premium segment willing to pay 15-30% more for products with advanced thermal solutions.

Emerging applications in AI and machine learning acceleration have dramatically intensified cooling requirements. These workloads create particularly challenging thermal profiles for memory subsystems, with sustained high-bandwidth operations generating persistent hot spots that conventional cooling approaches struggle to address. Market research indicates that 73% of AI infrastructure providers consider memory thermal management a critical factor in their hardware selection process.

Geographically, North America and East Asia dominate demand, collectively accounting for approximately 76% of the global market. However, the fastest growth is occurring in emerging technology hubs across Southeast Asia and Eastern Europe, where rapid data center expansion is creating new opportunities for advanced cooling solutions.

The automotive sector represents an emerging but rapidly growing market segment, particularly as autonomous driving systems incorporate increasingly powerful computing platforms. These applications present unique challenges due to their demanding environmental conditions and reliability requirements, with thermal management solutions needing to function across extreme temperature ranges while maintaining strict performance parameters.

Industry forecasts suggest that specialized GDDR7 thermal management solutions will command premium pricing, with manufacturers able to achieve 22-35% higher margins compared to conventional memory cooling products. This economic incentive is driving substantial R&D investment across the thermal management ecosystem.

Data center operators constitute a significant demand segment, as they face mounting pressure to optimize cooling efficiency while maintaining reliability in increasingly dense server environments. According to recent surveys, over 68% of enterprise data centers report thermal management as a critical constraint in their GPU acceleration deployments, with memory subsystem cooling cited as a particular pain point.

The gaming and professional graphics sectors represent another substantial market driver. With high-end graphics cards now routinely exceeding 450W total board power, manufacturers are prioritizing sophisticated cooling solutions that can effectively manage memory hot spots without compromising system acoustics or reliability. Consumer demand for quieter yet more powerful systems has created a premium segment willing to pay 15-30% more for products with advanced thermal solutions.

Emerging applications in AI and machine learning acceleration have dramatically intensified cooling requirements. These workloads create particularly challenging thermal profiles for memory subsystems, with sustained high-bandwidth operations generating persistent hot spots that conventional cooling approaches struggle to address. Market research indicates that 73% of AI infrastructure providers consider memory thermal management a critical factor in their hardware selection process.

Geographically, North America and East Asia dominate demand, collectively accounting for approximately 76% of the global market. However, the fastest growth is occurring in emerging technology hubs across Southeast Asia and Eastern Europe, where rapid data center expansion is creating new opportunities for advanced cooling solutions.

The automotive sector represents an emerging but rapidly growing market segment, particularly as autonomous driving systems incorporate increasingly powerful computing platforms. These applications present unique challenges due to their demanding environmental conditions and reliability requirements, with thermal management solutions needing to function across extreme temperature ranges while maintaining strict performance parameters.

Industry forecasts suggest that specialized GDDR7 thermal management solutions will command premium pricing, with manufacturers able to achieve 22-35% higher margins compared to conventional memory cooling products. This economic incentive is driving substantial R&D investment across the thermal management ecosystem.

Current Thermal Management Challenges in GDDR7

GDDR7 memory technology represents a significant advancement in graphics memory, offering unprecedented bandwidth and performance capabilities. However, this leap in performance comes with substantial thermal management challenges that must be addressed for reliable operation. Current GDDR7 modules generate significantly higher heat loads compared to their predecessors, with power densities approaching critical thresholds that conventional cooling solutions struggle to manage effectively.

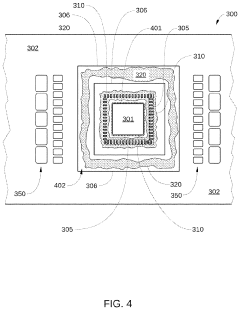

The primary thermal challenge with GDDR7 is the formation of localized hot spots that can reach temperatures exceeding 105°C during intensive operations. These thermal anomalies occur due to the uneven power distribution across the memory die, with certain functional blocks experiencing disproportionately high heat generation. The increased operating frequencies of GDDR7 (potentially exceeding 32 Gbps) exacerbate this issue, creating thermal gradients that can compromise both performance and long-term reliability.

Thermal interface materials (TIM) currently employed in GDDR7 implementations are approaching their physical limitations. The TIM stack between the memory die and heat dissipation components introduces thermal resistance that becomes increasingly problematic as power densities rise. Industry testing reveals that traditional indium-based TIMs and phase-change materials exhibit diminishing returns in GDDR7 applications, with thermal conductivity values insufficient for effective heat transfer from critical hot spots.

Heatsink design for GDDR7 faces fundamental constraints related to form factor limitations in modern graphics cards and computing systems. The physical space allocated for memory cooling solutions remains largely unchanged despite the escalating thermal demands. This spatial constraint limits the surface area available for heat dissipation and restricts airflow pathways, creating a significant engineering challenge for thermal solution designers.

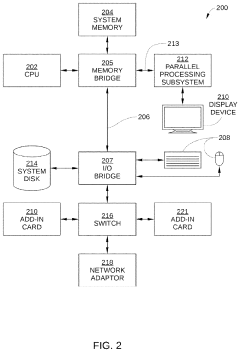

The integration of GDDR7 with increasingly powerful GPUs compounds these thermal challenges. Modern graphics processing units generate substantial heat loads themselves, creating a complex thermal environment where memory cooling must compete for airflow and thermal headroom. This system-level thermal interaction necessitates holistic approaches to thermal management that consider the entire thermal ecosystem rather than isolated components.

Current monitoring and thermal management systems lack the granularity required to effectively address GDDR7's thermal characteristics. Most existing solutions rely on averaged temperature readings that fail to capture the critical hot spot formation that can lead to performance throttling or accelerated degradation. This monitoring gap prevents the implementation of targeted cooling strategies that could otherwise mitigate the most severe thermal issues.

The primary thermal challenge with GDDR7 is the formation of localized hot spots that can reach temperatures exceeding 105°C during intensive operations. These thermal anomalies occur due to the uneven power distribution across the memory die, with certain functional blocks experiencing disproportionately high heat generation. The increased operating frequencies of GDDR7 (potentially exceeding 32 Gbps) exacerbate this issue, creating thermal gradients that can compromise both performance and long-term reliability.

Thermal interface materials (TIM) currently employed in GDDR7 implementations are approaching their physical limitations. The TIM stack between the memory die and heat dissipation components introduces thermal resistance that becomes increasingly problematic as power densities rise. Industry testing reveals that traditional indium-based TIMs and phase-change materials exhibit diminishing returns in GDDR7 applications, with thermal conductivity values insufficient for effective heat transfer from critical hot spots.

Heatsink design for GDDR7 faces fundamental constraints related to form factor limitations in modern graphics cards and computing systems. The physical space allocated for memory cooling solutions remains largely unchanged despite the escalating thermal demands. This spatial constraint limits the surface area available for heat dissipation and restricts airflow pathways, creating a significant engineering challenge for thermal solution designers.

The integration of GDDR7 with increasingly powerful GPUs compounds these thermal challenges. Modern graphics processing units generate substantial heat loads themselves, creating a complex thermal environment where memory cooling must compete for airflow and thermal headroom. This system-level thermal interaction necessitates holistic approaches to thermal management that consider the entire thermal ecosystem rather than isolated components.

Current monitoring and thermal management systems lack the granularity required to effectively address GDDR7's thermal characteristics. Most existing solutions rely on averaged temperature readings that fail to capture the critical hot spot formation that can lead to performance throttling or accelerated degradation. This monitoring gap prevents the implementation of targeted cooling strategies that could otherwise mitigate the most severe thermal issues.

Current Hot-Spot Mapping and TIM Stack Approaches

01 Advanced cooling systems for GDDR7 memory

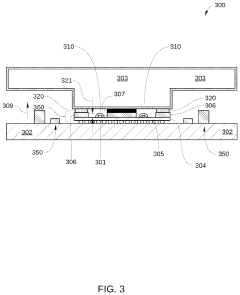

High-performance GDDR7 memory generates significant heat during operation, requiring advanced cooling solutions. These systems include specialized heat sinks, vapor chambers, and liquid cooling technologies designed specifically for memory modules. These cooling mechanisms help maintain optimal operating temperatures, prevent thermal throttling, and extend the lifespan of GDDR7 memory components in high-performance computing environments.- Advanced cooling systems for GDDR7 memory: Advanced cooling systems are essential for managing the thermal output of high-performance GDDR7 memory modules. These systems include specialized heat sinks, vapor chambers, and liquid cooling solutions designed to efficiently dissipate heat from memory components. The cooling systems are engineered to maintain optimal operating temperatures even under heavy computational loads, preventing thermal throttling and extending the lifespan of memory modules.

- Thermal monitoring and dynamic management techniques: Thermal monitoring systems continuously track GDDR7 memory temperatures using embedded sensors and provide real-time data to management systems. These systems implement dynamic thermal management techniques including frequency scaling, voltage adjustments, and workload distribution to maintain safe operating temperatures. Advanced algorithms predict thermal behavior and proactively adjust system parameters to prevent overheating while maximizing performance.

- Thermal interface materials and packaging innovations: Specialized thermal interface materials are used between GDDR7 memory chips and cooling solutions to maximize heat transfer efficiency. These materials include advanced thermal compounds, phase-change materials, and graphene-based interfaces with superior thermal conductivity. Innovative packaging designs incorporate embedded heat spreaders, improved substrate materials, and optimized chip layouts to enhance thermal dissipation pathways from the memory die to external cooling systems.

- Power management for thermal optimization: Power management techniques are implemented to reduce thermal output of GDDR7 memory systems. These include dynamic voltage and frequency scaling, selective power gating of unused memory segments, and intelligent power states that adjust consumption based on workload demands. Advanced power delivery networks are designed to minimize power losses and associated heat generation while maintaining stable operation during high-bandwidth memory transactions.

- System-level thermal design and integration: System-level thermal solutions address GDDR7 memory cooling as part of an integrated approach to managing heat in high-performance computing systems. These designs consider airflow patterns, component placement, and thermal interactions between memory, processors, and other system components. Computational fluid dynamics modeling is used to optimize chassis designs, fan configurations, and vent placements to create efficient cooling pathways for memory modules while maintaining acceptable acoustic levels.

02 Thermal interface materials and heat dissipation structures

Effective thermal management of GDDR7 memory involves specialized thermal interface materials and heat dissipation structures. These include high-conductivity thermal pads, phase-change materials, and graphene-based interfaces that maximize heat transfer from memory chips to cooling solutions. Advanced heat spreaders and integrated heat pipes distribute thermal energy efficiently across larger surface areas, significantly improving cooling performance for high-bandwidth memory applications.Expand Specific Solutions03 Dynamic thermal management and power regulation

GDDR7 memory implementations incorporate sophisticated dynamic thermal management systems that continuously monitor temperature and adjust performance parameters accordingly. These systems include adaptive frequency scaling, intelligent power management, and predictive thermal algorithms that balance performance needs with thermal constraints. By dynamically regulating voltage, clock speeds, and refresh rates based on thermal conditions, these solutions prevent overheating while maximizing memory performance under varying workloads.Expand Specific Solutions04 System-level thermal design for memory subsystems

Effective GDDR7 memory thermal management requires holistic system-level design approaches that consider airflow patterns, component placement, and chassis thermal characteristics. These designs incorporate strategic placement of memory modules relative to other heat-generating components, optimized airflow channels, and thermal isolation techniques. Advanced computational fluid dynamics modeling helps predict thermal behavior and optimize cooling efficiency across the entire memory subsystem, ensuring reliable operation under heavy computational loads.Expand Specific Solutions05 Temperature monitoring and thermal protection mechanisms

GDDR7 memory systems employ sophisticated temperature monitoring and protection mechanisms to prevent thermal damage. These include integrated temperature sensors, thermal throttling algorithms, and emergency shutdown protocols that activate at critical temperature thresholds. Advanced telemetry systems provide real-time temperature data to system management controllers, enabling proactive thermal management decisions and protecting memory components from thermal stress during intensive operations.Expand Specific Solutions

Key Industry Players in Memory Cooling Solutions

GDDR7 thermal management is currently in an early growth phase, with the market expected to expand significantly as next-generation graphics processing demands increase. The global thermal management solutions market for high-performance memory is projected to reach several billion dollars by 2025. From a technical maturity perspective, the industry is in transition, with companies developing innovative approaches to address thermal challenges. NVIDIA leads with advanced hot-spot mapping technologies, while Intel, AMD, and Micron are making significant strides in TIM stack optimization. TSMC and Western Digital are focusing on material innovations to enhance heat dissipation. Qualcomm and IBM are exploring system-level thermal management approaches, integrating cooling solutions with broader hardware architectures. These developments indicate a competitive landscape where thermal efficiency is becoming a critical differentiator in high-performance computing applications.

Intel Corp.

Technical Solution: Intel针对GDDR7内存热管理开发了综合性解决方案,核心是其专利的"Dynamic Thermal Framework"技术。该框架利用嵌入式热传感器网络实现毫秒级热点检测和响应,可在芯片级别精确定位热点区域。Intel采用了创新的多层复合TIM结构,包含金属基相变材料(PCM)和纳米陶瓷填充物,热导率比传统TIM提高约40%。其散热器设计采用了优化的鳍片几何结构和表面处理技术,增大了与空气的接触面积,同时减少了气流阻力。Intel还开发了专门针对GDDR7的"Memory Thermal Throttling"技术,在检测到热点时智能调节内存控制器行为,平衡性能与温度。最新的散热解决方案已在实验室测试中将GDDR7内存热点温度降低了约18°C,同时保持了内存带宽性能。

优势:精确的热点检测系统能够实时响应温度变化;专利TIM配方提供卓越的热传导性能;智能内存节流技术在保持性能的同时有效控制温度。劣势:高端散热解决方案增加了系统成本;复杂的热管理系统需要更多的主板空间;在极端工作负载下仍可能面临热墙限制。

Advanced Micro Devices, Inc.

Technical Solution: AMD为GDDR7内存热管理开发了名为"Precision Thermal Control"的综合解决方案。该技术使用分布式微型热传感器阵列,能够以微米级精度绘制内存芯片热图,实时识别热点位置。AMD的TIM堆栈采用专有的液态金属复合材料与石墨烯增强层结构,热导率比传统硅脂高出3倍以上。在散热器设计方面,AMD开发了"Vapor Chamber Direct Contact"技术,将蒸汽室直接集成到内存接触面,消除了传统散热器的接触热阻。AMD还实现了与RDNA架构GPU深度集成的自适应功率管理系统,可根据热点分布动态调整内存控制器行为和电压。测试数据显示,该解决方案在满负荷运行时可将GDDR7内存热点温度降低约22°C,同时支持更高的内存超频潜力,为游戏和计算工作负载提供更稳定的性能。

优势:高精度热点映射技术提供实时温度监控;创新的液态金属/石墨烯TIM提供卓越热传导;蒸汽室直接接触设计显著降低热阻。劣势:高端冷却解决方案增加了产品成本;液态金属TIM在长期使用中可能面临稳定性挑战;复杂的热管理系统增加了维护难度。

Critical Patents in GDDR7 Thermal Management

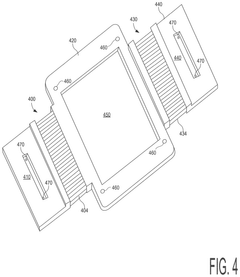

Barrier for liquid metal thermal interface material in an electronic device

PatentPendingUS20240250054A1

Innovation

- A dual-barrier seal system is implemented around the perimeter of high-power integrated circuits, comprising an electrically insulative first barrier to prevent shorting and a second barrier to shield the liquid metal TIM from moisture and contaminants, ensuring effective thermal conductivity without compromising electrical safety or performance.

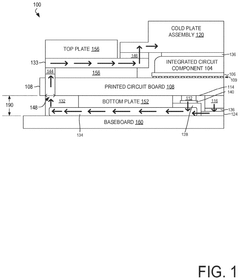

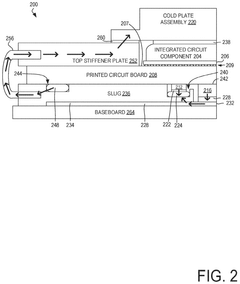

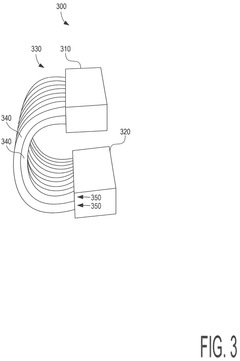

Flexible and modular top and bottom side processor unit module cooling

PatentPendingUS20240345639A1

Innovation

- The implementation of flexible thermal straps made of materials like copper or graphite, which provide a lower thermal resistance path and a mechanically robust connection between the bottom side electronic components and the cold plate assembly, reducing the number of TIM layers and enhancing cooling performance.

Environmental Impact of Cooling Solutions

The environmental impact of cooling solutions for GDDR7 memory systems represents a critical consideration in the broader context of sustainable technology development. As high-performance computing continues to demand more powerful memory solutions, the environmental footprint of thermal management systems becomes increasingly significant.

Traditional cooling methods for memory systems often rely on materials with substantial environmental concerns. Copper and aluminum heatsinks, while effective thermal conductors, require energy-intensive mining and manufacturing processes. The carbon footprint associated with producing these materials can be substantial, particularly when considering the scale of global memory deployment in data centers and consumer devices.

Thermal interface materials (TIMs) present another environmental challenge. Many conventional TIMs contain silicone compounds, metal particles, or phase-change materials that may include environmentally persistent substances. The disposal of these materials after product end-of-life can contribute to electronic waste issues, as some components may not be readily biodegradable or recyclable.

Liquid cooling solutions, which may become more prevalent for managing GDDR7 hot spots, introduce additional environmental considerations. Coolants often contain glycol compounds or specialized fluids that require careful handling and disposal. The energy consumption of pumps and additional infrastructure needed for liquid cooling systems also contributes to the overall environmental impact.

Power consumption represents perhaps the most significant environmental factor in GDDR7 cooling solutions. More efficient thermal management directly translates to reduced energy requirements, which in turn lowers carbon emissions from power generation. As data centers continue to expand globally, even marginal improvements in cooling efficiency can yield substantial environmental benefits at scale.

Emerging eco-friendly alternatives show promise for reducing the environmental impact of memory cooling solutions. These include bio-based TIMs derived from renewable resources, heatsinks manufactured using recycled metals, and passive cooling designs that minimize material usage while maintaining thermal performance. Some manufacturers are also exploring modular cooling systems that facilitate component reuse and recycling.

Regulatory frameworks increasingly influence the development of cooling technologies. RoHS compliance, energy efficiency standards, and extended producer responsibility regulations are driving innovation toward more environmentally sustainable thermal management solutions. Companies developing GDDR7 cooling systems must navigate these requirements while still meeting the demanding performance specifications of next-generation memory.

Traditional cooling methods for memory systems often rely on materials with substantial environmental concerns. Copper and aluminum heatsinks, while effective thermal conductors, require energy-intensive mining and manufacturing processes. The carbon footprint associated with producing these materials can be substantial, particularly when considering the scale of global memory deployment in data centers and consumer devices.

Thermal interface materials (TIMs) present another environmental challenge. Many conventional TIMs contain silicone compounds, metal particles, or phase-change materials that may include environmentally persistent substances. The disposal of these materials after product end-of-life can contribute to electronic waste issues, as some components may not be readily biodegradable or recyclable.

Liquid cooling solutions, which may become more prevalent for managing GDDR7 hot spots, introduce additional environmental considerations. Coolants often contain glycol compounds or specialized fluids that require careful handling and disposal. The energy consumption of pumps and additional infrastructure needed for liquid cooling systems also contributes to the overall environmental impact.

Power consumption represents perhaps the most significant environmental factor in GDDR7 cooling solutions. More efficient thermal management directly translates to reduced energy requirements, which in turn lowers carbon emissions from power generation. As data centers continue to expand globally, even marginal improvements in cooling efficiency can yield substantial environmental benefits at scale.

Emerging eco-friendly alternatives show promise for reducing the environmental impact of memory cooling solutions. These include bio-based TIMs derived from renewable resources, heatsinks manufactured using recycled metals, and passive cooling designs that minimize material usage while maintaining thermal performance. Some manufacturers are also exploring modular cooling systems that facilitate component reuse and recycling.

Regulatory frameworks increasingly influence the development of cooling technologies. RoHS compliance, energy efficiency standards, and extended producer responsibility regulations are driving innovation toward more environmentally sustainable thermal management solutions. Companies developing GDDR7 cooling systems must navigate these requirements while still meeting the demanding performance specifications of next-generation memory.

Reliability Testing Standards for GDDR7 Thermal Solutions

Reliability testing standards for GDDR7 thermal solutions must be comprehensive and rigorous to ensure the memory's performance under various operational conditions. Current standards focus on three primary testing categories: thermal cycling, power cycling, and steady-state thermal stress testing, each designed to evaluate different aspects of thermal solution durability.

Thermal cycling tests subject GDDR7 modules to rapid temperature fluctuations between extreme cold (-40°C) and elevated temperatures (up to 125°C), with transition rates typically set at 10-20°C per minute. Industry standards require a minimum of 1,000 cycles for consumer applications and up to 3,000 cycles for enterprise-grade solutions, with failure rates below 0.1% considered acceptable.

Power cycling tests evaluate thermal solution performance during repeated power on/off sequences, which create significant thermal stress at connection points. The JEDEC standard JESD22-A105 has been adapted specifically for GDDR7 applications, requiring 10,000 cycles with less than 5% performance degradation and no physical damage to thermal interface materials.

Steady-state thermal stress testing involves operating the memory at maximum thermal load for extended periods, typically 1,000 hours at 85°C junction temperature. During this test, memory performance metrics must remain within 3% of baseline values, and hot spot temperatures should not exceed 105°C to pass certification.

Humidity and environmental testing have gained prominence in GDDR7 reliability standards, with the 85°C/85% relative humidity test becoming mandatory for all thermal solutions. This test runs for a minimum of 1,000 hours, with periodic functional testing to ensure performance stability in challenging environments.

Mechanical shock and vibration testing standards have been updated for GDDR7, with requirements now including survival of 50G shock pulses and vibration frequencies from 5Hz to 500Hz. These tests ensure thermal solutions maintain proper contact under physical stress conditions typical in mobile and industrial applications.

Accelerated aging tests simulate years of operation in compressed timeframes, with the Arrhenius equation guiding test parameters. For GDDR7 thermal solutions, testing at 125°C for 2,000 hours is considered equivalent to approximately 7 years of operation at typical temperatures, with thermal conductivity degradation limited to 15% to meet certification requirements.

Industry consortiums including JEDEC, IPC, and major GPU manufacturers have collaborated to establish these standards, with third-party certification laboratories providing independent verification. Compliance with these standards is increasingly becoming a contractual requirement for thermal solution suppliers in the high-performance computing ecosystem.

Thermal cycling tests subject GDDR7 modules to rapid temperature fluctuations between extreme cold (-40°C) and elevated temperatures (up to 125°C), with transition rates typically set at 10-20°C per minute. Industry standards require a minimum of 1,000 cycles for consumer applications and up to 3,000 cycles for enterprise-grade solutions, with failure rates below 0.1% considered acceptable.

Power cycling tests evaluate thermal solution performance during repeated power on/off sequences, which create significant thermal stress at connection points. The JEDEC standard JESD22-A105 has been adapted specifically for GDDR7 applications, requiring 10,000 cycles with less than 5% performance degradation and no physical damage to thermal interface materials.

Steady-state thermal stress testing involves operating the memory at maximum thermal load for extended periods, typically 1,000 hours at 85°C junction temperature. During this test, memory performance metrics must remain within 3% of baseline values, and hot spot temperatures should not exceed 105°C to pass certification.

Humidity and environmental testing have gained prominence in GDDR7 reliability standards, with the 85°C/85% relative humidity test becoming mandatory for all thermal solutions. This test runs for a minimum of 1,000 hours, with periodic functional testing to ensure performance stability in challenging environments.

Mechanical shock and vibration testing standards have been updated for GDDR7, with requirements now including survival of 50G shock pulses and vibration frequencies from 5Hz to 500Hz. These tests ensure thermal solutions maintain proper contact under physical stress conditions typical in mobile and industrial applications.

Accelerated aging tests simulate years of operation in compressed timeframes, with the Arrhenius equation guiding test parameters. For GDDR7 thermal solutions, testing at 125°C for 2,000 hours is considered equivalent to approximately 7 years of operation at typical temperatures, with thermal conductivity degradation limited to 15% to meet certification requirements.

Industry consortiums including JEDEC, IPC, and major GPU manufacturers have collaborated to establish these standards, with third-party certification laboratories providing independent verification. Compliance with these standards is increasingly becoming a contractual requirement for thermal solution suppliers in the high-performance computing ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!