How GDDR7 Balances PAM3 Advantages With Power And Thermal Constraints?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDDR7 Technology Evolution and Objectives

Graphics Double Data Rate (GDDR) memory has evolved significantly since its inception in the early 2000s, with each generation bringing substantial improvements in bandwidth, power efficiency, and thermal management. GDDR7 represents the latest milestone in this evolutionary journey, building upon the foundations established by its predecessors while introducing revolutionary signaling techniques to meet the ever-increasing demands of high-performance computing applications.

The development of GDDR memory has been driven primarily by the graphics processing industry, where rendering complex 3D environments and processing massive datasets require exceptional memory bandwidth. From GDDR3 to GDDR6, we observed a consistent pattern of doubling bandwidth capabilities approximately every 2-3 years, with GDDR6 reaching speeds of up to 16 Gbps per pin. This progression has been essential in supporting advancements in gaming, artificial intelligence, data centers, and autonomous vehicles.

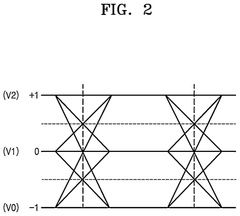

GDDR7 marks a significant departure from conventional binary signaling by adopting Pulse Amplitude Modulation 3-level (PAM3) technology. Unlike traditional Non-Return-to-Zero (NRZ) binary signaling used in previous generations, PAM3 encodes three distinct voltage levels to represent data, enabling the transmission of 1.5 bits per clock cycle instead of just 1 bit. This fundamental shift aims to achieve unprecedented bandwidth of up to 36 Gbps per pin, representing more than a 100% increase over GDDR6X.

The primary objective of GDDR7 development is to balance this remarkable performance enhancement with practical power and thermal constraints. As computational demands grow exponentially across industries, memory subsystems must deliver higher bandwidth without proportionally increasing power consumption or generating excessive heat. This balance is crucial for maintaining system stability and reliability while enabling next-generation applications in AI training, real-time ray tracing, and high-resolution video processing.

Another key goal for GDDR7 is to maintain backward compatibility with existing memory controller designs while introducing new capabilities. This ensures that hardware manufacturers can adopt the technology without completely redesigning their systems, facilitating a smoother transition to the new standard. Additionally, GDDR7 aims to improve signal integrity at higher frequencies through enhanced equalization techniques and more sophisticated error correction mechanisms.

Looking forward, GDDR7 is positioned to support the next wave of technological innovation across multiple industries. Its development objectives include not only raw performance improvements but also enhanced power management features, more granular thermal monitoring capabilities, and optimized data compression algorithms. These advancements collectively aim to extend the practical limits of memory subsystem performance while addressing the critical constraints that have historically limited scaling.

The development of GDDR memory has been driven primarily by the graphics processing industry, where rendering complex 3D environments and processing massive datasets require exceptional memory bandwidth. From GDDR3 to GDDR6, we observed a consistent pattern of doubling bandwidth capabilities approximately every 2-3 years, with GDDR6 reaching speeds of up to 16 Gbps per pin. This progression has been essential in supporting advancements in gaming, artificial intelligence, data centers, and autonomous vehicles.

GDDR7 marks a significant departure from conventional binary signaling by adopting Pulse Amplitude Modulation 3-level (PAM3) technology. Unlike traditional Non-Return-to-Zero (NRZ) binary signaling used in previous generations, PAM3 encodes three distinct voltage levels to represent data, enabling the transmission of 1.5 bits per clock cycle instead of just 1 bit. This fundamental shift aims to achieve unprecedented bandwidth of up to 36 Gbps per pin, representing more than a 100% increase over GDDR6X.

The primary objective of GDDR7 development is to balance this remarkable performance enhancement with practical power and thermal constraints. As computational demands grow exponentially across industries, memory subsystems must deliver higher bandwidth without proportionally increasing power consumption or generating excessive heat. This balance is crucial for maintaining system stability and reliability while enabling next-generation applications in AI training, real-time ray tracing, and high-resolution video processing.

Another key goal for GDDR7 is to maintain backward compatibility with existing memory controller designs while introducing new capabilities. This ensures that hardware manufacturers can adopt the technology without completely redesigning their systems, facilitating a smoother transition to the new standard. Additionally, GDDR7 aims to improve signal integrity at higher frequencies through enhanced equalization techniques and more sophisticated error correction mechanisms.

Looking forward, GDDR7 is positioned to support the next wave of technological innovation across multiple industries. Its development objectives include not only raw performance improvements but also enhanced power management features, more granular thermal monitoring capabilities, and optimized data compression algorithms. These advancements collectively aim to extend the practical limits of memory subsystem performance while addressing the critical constraints that have historically limited scaling.

Market Demand for High-Performance Graphics Memory

The graphics memory market has witnessed unprecedented growth in recent years, primarily driven by the explosive demand for high-performance computing applications. The global graphics DRAM market, valued at approximately $15 billion in 2022, is projected to reach $30 billion by 2027, representing a compound annual growth rate of 14.8%. This remarkable expansion is fueled by several converging factors that collectively create a robust demand environment for next-generation memory solutions like GDDR7.

Artificial intelligence and machine learning applications have emerged as significant drivers of high-performance memory demand. Training large language models and complex neural networks requires massive parallel processing capabilities and extremely high memory bandwidth. Current AI training operations for models with billions of parameters can consume terabytes of memory bandwidth, creating an urgent need for faster, more efficient memory technologies that can keep pace with computational demands.

The gaming industry continues to push the boundaries of graphics processing, with modern AAA game titles requiring increasingly sophisticated rendering techniques. 4K and 8K gaming experiences demand memory bandwidth exceeding 1TB/s, while ray tracing and other advanced rendering technologies further intensify memory requirements. Gaming hardware manufacturers are actively seeking memory solutions that can deliver this performance without excessive power consumption or thermal output.

Data centers represent another critical market segment driving demand for high-performance graphics memory. The shift toward GPU-accelerated computing for big data analytics, scientific simulations, and cloud-based AI services has created substantial demand for memory technologies that can efficiently handle massive parallel workloads. Industry analysts report that data center GPU deployments are growing at 35% annually, with memory bandwidth requirements doubling approximately every two years.

Automotive applications, particularly advanced driver-assistance systems (ADAS) and autonomous driving platforms, are emerging as significant consumers of high-performance graphics memory. These systems process multiple high-resolution sensor inputs simultaneously, requiring memory solutions that combine high bandwidth with reliability under challenging environmental conditions. The automotive ADAS market is expected to grow at 22% annually through 2028, creating sustained demand for advanced memory technologies.

The cryptocurrency mining sector, despite its volatility, continues to influence the high-performance memory market. Mining operations for proof-of-work cryptocurrencies require substantial memory bandwidth, particularly for ASIC-resistant algorithms. This market segment's demand patterns fluctuate significantly but can create periodic surges in memory requirements that impact overall market dynamics.

Artificial intelligence and machine learning applications have emerged as significant drivers of high-performance memory demand. Training large language models and complex neural networks requires massive parallel processing capabilities and extremely high memory bandwidth. Current AI training operations for models with billions of parameters can consume terabytes of memory bandwidth, creating an urgent need for faster, more efficient memory technologies that can keep pace with computational demands.

The gaming industry continues to push the boundaries of graphics processing, with modern AAA game titles requiring increasingly sophisticated rendering techniques. 4K and 8K gaming experiences demand memory bandwidth exceeding 1TB/s, while ray tracing and other advanced rendering technologies further intensify memory requirements. Gaming hardware manufacturers are actively seeking memory solutions that can deliver this performance without excessive power consumption or thermal output.

Data centers represent another critical market segment driving demand for high-performance graphics memory. The shift toward GPU-accelerated computing for big data analytics, scientific simulations, and cloud-based AI services has created substantial demand for memory technologies that can efficiently handle massive parallel workloads. Industry analysts report that data center GPU deployments are growing at 35% annually, with memory bandwidth requirements doubling approximately every two years.

Automotive applications, particularly advanced driver-assistance systems (ADAS) and autonomous driving platforms, are emerging as significant consumers of high-performance graphics memory. These systems process multiple high-resolution sensor inputs simultaneously, requiring memory solutions that combine high bandwidth with reliability under challenging environmental conditions. The automotive ADAS market is expected to grow at 22% annually through 2028, creating sustained demand for advanced memory technologies.

The cryptocurrency mining sector, despite its volatility, continues to influence the high-performance memory market. Mining operations for proof-of-work cryptocurrencies require substantial memory bandwidth, particularly for ASIC-resistant algorithms. This market segment's demand patterns fluctuate significantly but can create periodic surges in memory requirements that impact overall market dynamics.

PAM3 Signaling Challenges and Constraints

PAM3 (Pulse Amplitude Modulation 3-level) signaling represents a significant advancement in memory interface technology, but its implementation in GDDR7 faces substantial technical challenges. Unlike traditional NRZ (Non-Return-to-Zero) signaling that uses two voltage levels to represent binary data, PAM3 employs three distinct voltage levels to encode more information per symbol. This allows GDDR7 to achieve higher data rates without proportionally increasing the operating frequency, theoretically offering 50% more bandwidth per pin compared to binary signaling.

However, the transition to PAM3 introduces several critical signal integrity challenges. The reduced voltage margin between adjacent levels makes the system more susceptible to noise, requiring more sophisticated error detection and correction mechanisms. The signal-to-noise ratio (SNR) becomes a paramount concern as the voltage difference between levels decreases from Vpp in NRZ to approximately Vpp/2 in PAM3, significantly reducing noise immunity.

Intersymbol interference (ISI) presents another major challenge for PAM3 implementation. As data rates increase, the effects of channel loss and reflections become more pronounced, causing symbols to interfere with adjacent bits. This interference is particularly problematic for PAM3 due to its tighter voltage margins, requiring advanced equalization techniques and more complex receiver architectures to mitigate these effects.

Power consumption emerges as a critical constraint in PAM3 signaling for GDDR7. The additional circuitry required for encoding and decoding PAM3 signals, including more complex analog-to-digital converters and digital signal processing components, contributes to increased power draw. Furthermore, the need for more sophisticated equalization and clock recovery circuits adds to the power budget, potentially offsetting some of the efficiency gains promised by the higher data density.

Thermal management represents another significant challenge. The increased power density in GDDR7 memory modules implementing PAM3 signaling can lead to localized hotspots, potentially affecting both performance and reliability. This necessitates advanced cooling solutions and thermal-aware design practices to maintain optimal operating temperatures across the memory subsystem.

Manufacturing and testing considerations also impose constraints on PAM3 implementation. The tighter tolerances required for three-level signaling demand more precise manufacturing processes and more comprehensive testing methodologies. Component variations and process corners must be carefully managed to ensure reliable operation across all environmental conditions and over the product's lifetime.

However, the transition to PAM3 introduces several critical signal integrity challenges. The reduced voltage margin between adjacent levels makes the system more susceptible to noise, requiring more sophisticated error detection and correction mechanisms. The signal-to-noise ratio (SNR) becomes a paramount concern as the voltage difference between levels decreases from Vpp in NRZ to approximately Vpp/2 in PAM3, significantly reducing noise immunity.

Intersymbol interference (ISI) presents another major challenge for PAM3 implementation. As data rates increase, the effects of channel loss and reflections become more pronounced, causing symbols to interfere with adjacent bits. This interference is particularly problematic for PAM3 due to its tighter voltage margins, requiring advanced equalization techniques and more complex receiver architectures to mitigate these effects.

Power consumption emerges as a critical constraint in PAM3 signaling for GDDR7. The additional circuitry required for encoding and decoding PAM3 signals, including more complex analog-to-digital converters and digital signal processing components, contributes to increased power draw. Furthermore, the need for more sophisticated equalization and clock recovery circuits adds to the power budget, potentially offsetting some of the efficiency gains promised by the higher data density.

Thermal management represents another significant challenge. The increased power density in GDDR7 memory modules implementing PAM3 signaling can lead to localized hotspots, potentially affecting both performance and reliability. This necessitates advanced cooling solutions and thermal-aware design practices to maintain optimal operating temperatures across the memory subsystem.

Manufacturing and testing considerations also impose constraints on PAM3 implementation. The tighter tolerances required for three-level signaling demand more precise manufacturing processes and more comprehensive testing methodologies. Component variations and process corners must be carefully managed to ensure reliable operation across all environmental conditions and over the product's lifetime.

Current PAM3 Implementation Approaches

01 Power management techniques for GDDR7 memory

Various power management techniques are implemented in GDDR7 memory systems to address power constraints. These include dynamic voltage and frequency scaling, power gating unused memory components, and implementing low-power states during idle periods. Advanced power controllers monitor and regulate power consumption in real-time, allowing the memory to operate efficiently while staying within thermal limits.- Power management techniques for GDDR7 memory: Various power management techniques are implemented in GDDR7 memory systems to address power constraints. These include dynamic voltage and frequency scaling, power gating unused memory components, and implementing low-power states during idle periods. Advanced power controllers monitor and regulate power consumption in real-time, allowing the memory to operate efficiently while staying within power budgets. These techniques help balance performance requirements with power limitations in high-performance graphics applications.

- Thermal dissipation solutions for GDDR7: Thermal management is critical for GDDR7 memory due to its high operating frequencies and power density. Solutions include advanced heat sink designs, phase-change materials, and integrated cooling systems that efficiently transfer heat away from memory components. Some implementations utilize active cooling methods such as micro-fans or liquid cooling for extreme performance scenarios. Thermal sensors and feedback mechanisms are employed to monitor temperatures and adjust system parameters to prevent thermal throttling while maintaining optimal performance.

- Energy efficiency optimizations in GDDR7 architecture: GDDR7 memory incorporates architectural improvements specifically designed to enhance energy efficiency. These include refined memory cell designs, optimized refresh mechanisms, and improved signal integrity with lower voltage requirements. Advanced power states allow for granular control over different memory sections, enabling parts of the memory to be powered down when not in use. Memory controllers implement intelligent scheduling algorithms that minimize unnecessary operations and reduce overall power consumption while maintaining high bandwidth capabilities.

- Dynamic thermal management systems for GDDR7: Dynamic thermal management systems for GDDR7 employ real-time monitoring and adaptive control mechanisms to maintain optimal operating conditions. These systems utilize distributed temperature sensors throughout the memory subsystem to create thermal profiles and identify hotspots. Based on this data, memory controllers can dynamically adjust refresh rates, access patterns, and voltage levels to reduce thermal stress. Some implementations include predictive algorithms that anticipate thermal issues before they occur, allowing for proactive adjustments to workload distribution and cooling responses.

- System-level integration considerations for GDDR7 power constraints: System-level design considerations are essential for managing GDDR7 power and thermal constraints. These include optimized PCB layouts with enhanced power delivery networks, strategic component placement to improve airflow, and coordinated power management between CPU, GPU, and memory subsystems. System designers implement power budgeting mechanisms that allocate available power resources based on workload requirements and thermal conditions. Advanced system monitoring frameworks provide comprehensive visibility into power and thermal metrics, enabling fine-tuned control strategies that maximize performance within platform constraints.

02 Thermal dissipation solutions for GDDR7

Thermal management is critical for GDDR7 memory due to its high operating speeds. Solutions include advanced heat sink designs, thermal interface materials with improved conductivity, and active cooling systems. Some implementations utilize phase-change materials and vapor chambers to efficiently transfer heat away from memory components, preventing thermal throttling and maintaining performance under load.Expand Specific Solutions03 Power-efficient memory architecture designs

GDDR7 memory architectures incorporate power-efficient design elements to reduce overall consumption. These include optimized memory cell structures, reduced leakage current designs, and improved signal integrity with lower voltage requirements. Memory controllers implement intelligent refresh schemes and bank management to minimize unnecessary power usage while maintaining high bandwidth capabilities.Expand Specific Solutions04 Dynamic thermal management systems

GDDR7 implementations feature dynamic thermal management systems that continuously monitor temperature across memory components. These systems can adjust memory operation parameters in real-time, including bandwidth allocation, refresh rates, and access patterns. When thermal thresholds are approached, the system can implement graduated throttling mechanisms to reduce power consumption while minimizing performance impact.Expand Specific Solutions05 System-level integration for power optimization

System-level approaches to managing GDDR7 power and thermal constraints involve coordinated operation between memory, GPU/CPU, and system firmware. These solutions implement workload-aware power budgeting, predictive thermal modeling, and cross-component optimization. Advanced systems can dynamically allocate power resources between processing units and memory based on application requirements, ensuring optimal performance within thermal design power limits.Expand Specific Solutions

Key GDDR7 Memory Manufacturers and Ecosystem

GDDR7 memory technology is currently in an early growth phase, with the market poised for significant expansion as next-generation graphics and AI applications drive demand. The global GDDR memory market is projected to reach substantial value by 2025-2026, fueled by gaming, data center, and automotive applications. Technologically, GDDR7's implementation of PAM3 signaling represents a critical advancement, though companies are navigating complex power and thermal constraints. Leading players like Samsung, Micron, and SK Hynix are advancing core memory technologies, while NVIDIA, AMD, and Intel are developing compatible GPU architectures. Qualcomm and Rambus contribute significant IP in high-speed signaling. The ecosystem shows varying maturity levels, with established semiconductor manufacturers having more mature implementations than newer entrants, creating a competitive landscape where thermal efficiency innovations will likely determine market leadership.

Intel Corp.

Technical Solution: Intel's approach to GDDR7 implementation focuses on system-level integration that optimizes the balance between PAM3 signaling advantages and power constraints. Their solution incorporates adaptive voltage positioning and dynamic impedance matching to maintain signal integrity while minimizing power consumption. Intel has developed a multi-layered power management architecture for GDDR7 that includes fine-grained clock gating, power-aware memory scheduling, and thermal-adaptive refresh rates. Their memory controllers feature sophisticated power state management with ultra-fast transition times between states to maximize energy efficiency during both active and idle periods. Intel's implementation also includes advanced thermal monitoring with distributed sensors that enable precise thermal management across memory modules, allowing the system to maintain optimal performance while preventing thermal throttling. Their solution achieves up to 32 Gbps data rates while maintaining power efficiency through intelligent voltage scaling that adapts to workload characteristics.

Strengths: Comprehensive system-level integration capabilities; advanced power management architecture; strong expertise in memory controller design. Weaknesses: Less experience with graphics-specific memory optimization compared to dedicated GPU manufacturers; potentially higher implementation complexity requiring more sophisticated platform design.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung's GDDR7 memory solution represents a fundamental advancement in memory technology, with their implementation focusing on semiconductor process optimization to address the PAM3 signaling challenges. Their approach utilizes a refined 10nm-class process technology specifically tailored for GDDR7 requirements, incorporating low-power transistor designs that maintain signal integrity at high speeds while reducing static power consumption. Samsung has developed specialized on-die termination circuits that dynamically adjust impedance based on operating conditions, significantly reducing power consumption during signal transitions. Their GDDR7 modules feature advanced thermal materials with improved thermal conductivity, allowing for more efficient heat dissipation from the memory die to the package surface. Samsung's implementation achieves data rates of up to 36 Gbps while incorporating sophisticated power management features including selective bank activation and temperature-compensated refresh timing to minimize power consumption under varying workloads and environmental conditions.

Strengths: Vertical integration as both memory designer and manufacturer; industry-leading process technology; extensive experience with high-volume memory production. Weaknesses: Potential challenges in customizing solutions for different platform requirements; higher initial production costs during technology ramp-up; dependency on ecosystem partners for complete system optimization.

Core PAM3 Signal Processing Innovations

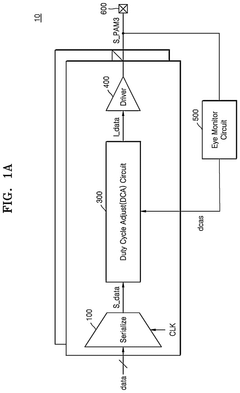

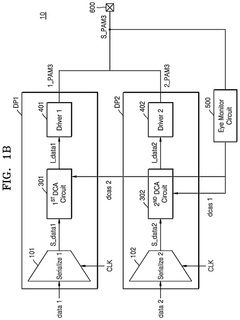

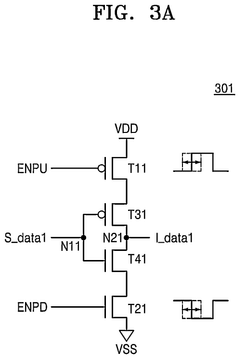

PAM3 transmitter, operating method of PAM3 transmitter and electronic device including the same

PatentPendingUS20250184191A1

Innovation

- A 3 level pulse amplitude modulation (PAM3) transmitter is developed, which includes a driver to convert input data into PAM3 signals, an eye monitor circuit to monitor upper and lower eye patterns, and a duty cycle adjust circuit to adjust the duty cycle of the input data based on feedback from the eye monitor circuit, thereby compensating for signal distortion.

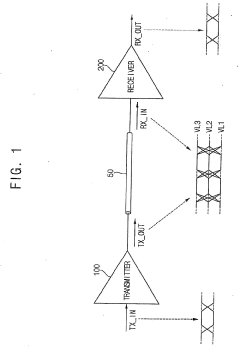

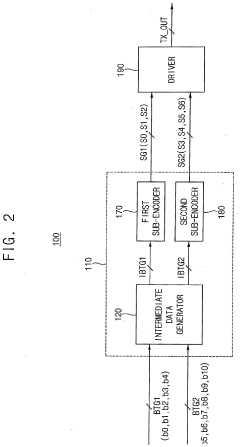

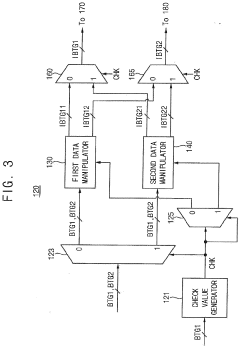

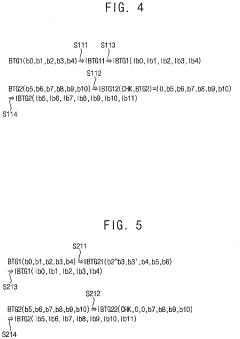

Transmitter and receiver for 3-level pulse amplitude modulation signaling and system including the same

PatentPendingEP4270887A1

Innovation

- A transmitter and receiver system that divides binary input bits into two groups, manipulating and encoding them differently to generate symbol groups with three voltage levels, reducing occupied area and power consumption by encoding in parallel, thereby improving PAM-3 signaling efficiency.

Thermal Management Solutions for GDDR7

The thermal management of GDDR7 memory presents significant challenges due to the increased power density resulting from PAM3 signaling and higher data rates. Traditional cooling methods are becoming insufficient as memory bandwidth demands continue to escalate. GDDR7's thermal envelope requires innovative approaches to maintain optimal operating temperatures while delivering the promised performance improvements.

Advanced heat spreader designs represent a critical advancement for GDDR7 thermal management. These solutions incorporate vapor chambers and phase-change materials that efficiently distribute heat across larger surface areas. Manufacturers have developed composite materials with enhanced thermal conductivity, allowing for more effective heat dissipation without increasing the physical footprint of memory modules.

Active cooling technologies are increasingly being integrated into GDDR7 memory subsystems. Micro-fans and liquid cooling solutions specifically designed for memory components provide targeted thermal relief. These systems can be dynamically controlled based on workload demands, activating only when temperature thresholds are approached, thus balancing cooling performance with energy efficiency.

On-die thermal sensors have become more sophisticated in GDDR7 implementations, enabling real-time temperature monitoring with greater precision. These sensors feed into intelligent thermal management systems that can adjust memory clock speeds, voltage levels, and refresh rates to maintain optimal thermal conditions. The granularity of these adjustments has improved significantly, allowing for minimal performance impact during thermal throttling events.

System-level thermal design considerations have evolved to accommodate GDDR7's thermal profile. Graphics card and computing system manufacturers are implementing holistic cooling approaches that consider the thermal interaction between memory, GPU/CPU, and power delivery components. Airflow patterns are being optimized to ensure adequate cooling for memory modules that may be positioned in thermally challenging locations.

Packaging innovations play a crucial role in GDDR7 thermal management. Advanced substrate materials with lower thermal resistance facilitate better heat transfer from the memory die to external cooling solutions. Additionally, 3D packaging techniques incorporate thermal vias and dedicated heat dissipation layers that channel heat away from critical components more efficiently than previous generations.

Power management features work in tandem with thermal solutions to reduce overall heat generation. GDDR7 implements sophisticated power states that can selectively deactivate portions of the memory when not in active use, significantly reducing idle power consumption and associated heat output while maintaining rapid response capabilities when full bandwidth is required.

Advanced heat spreader designs represent a critical advancement for GDDR7 thermal management. These solutions incorporate vapor chambers and phase-change materials that efficiently distribute heat across larger surface areas. Manufacturers have developed composite materials with enhanced thermal conductivity, allowing for more effective heat dissipation without increasing the physical footprint of memory modules.

Active cooling technologies are increasingly being integrated into GDDR7 memory subsystems. Micro-fans and liquid cooling solutions specifically designed for memory components provide targeted thermal relief. These systems can be dynamically controlled based on workload demands, activating only when temperature thresholds are approached, thus balancing cooling performance with energy efficiency.

On-die thermal sensors have become more sophisticated in GDDR7 implementations, enabling real-time temperature monitoring with greater precision. These sensors feed into intelligent thermal management systems that can adjust memory clock speeds, voltage levels, and refresh rates to maintain optimal thermal conditions. The granularity of these adjustments has improved significantly, allowing for minimal performance impact during thermal throttling events.

System-level thermal design considerations have evolved to accommodate GDDR7's thermal profile. Graphics card and computing system manufacturers are implementing holistic cooling approaches that consider the thermal interaction between memory, GPU/CPU, and power delivery components. Airflow patterns are being optimized to ensure adequate cooling for memory modules that may be positioned in thermally challenging locations.

Packaging innovations play a crucial role in GDDR7 thermal management. Advanced substrate materials with lower thermal resistance facilitate better heat transfer from the memory die to external cooling solutions. Additionally, 3D packaging techniques incorporate thermal vias and dedicated heat dissipation layers that channel heat away from critical components more efficiently than previous generations.

Power management features work in tandem with thermal solutions to reduce overall heat generation. GDDR7 implements sophisticated power states that can selectively deactivate portions of the memory when not in active use, significantly reducing idle power consumption and associated heat output while maintaining rapid response capabilities when full bandwidth is required.

Semiconductor Process Technology Impact

The semiconductor process technology employed in memory manufacturing plays a pivotal role in determining GDDR7's ability to balance PAM3 (Pulse Amplitude Modulation 3-level) advantages with power and thermal constraints. Advanced process nodes, particularly those at 5nm and below, provide the foundation for implementing PAM3 signaling while managing the inherent power challenges.

Current GDDR7 implementations leverage cutting-edge semiconductor processes that enable higher transistor densities and improved power efficiency compared to previous generations. These advanced nodes facilitate the integration of more sophisticated signal processing circuits required for PAM3 encoding and decoding, while simultaneously reducing the power consumption per transistor. The reduced feature sizes allow for more compact designs that can operate at lower voltages, directly addressing thermal concerns.

The transition from planar transistors to FinFET and potentially gate-all-around (GAA) architectures in newer process nodes has significantly improved the electrostatic control of the channel, reducing leakage currents that contribute to static power consumption. This advancement is particularly crucial for GDDR7, as PAM3 signaling requires precise voltage control to distinguish between three signal levels rather than two.

Process technology innovations have also enabled enhanced power management features within GDDR7 memory. Dynamic voltage and frequency scaling (DVFS) capabilities, made possible by advanced process nodes, allow the memory to adjust its operating parameters based on workload demands, optimizing the power-performance balance in real-time. This adaptability is essential for managing the increased power demands associated with PAM3 signaling.

Thermal management has been addressed through process-level innovations such as improved interconnect materials with lower resistance, reducing heat generation during high-speed data transfers. Additionally, advanced packaging technologies like through-silicon vias (TSVs) and interposers facilitate better heat dissipation pathways, allowing GDDR7 to maintain optimal operating temperatures even under high-performance conditions.

The semiconductor process technology also enables the implementation of more sophisticated error correction mechanisms necessary for PAM3 signaling. As signal integrity becomes more challenging with three voltage levels instead of two, robust error detection and correction capabilities are essential to maintain data integrity without requiring excessive power for signal amplification.

Looking forward, emerging process technologies such as 3nm and beyond will further enhance GDDR7's capabilities by providing additional power efficiency improvements and enabling even higher integration densities. These advancements will be crucial for future iterations of GDDR7 that aim to push data rates beyond current limitations while maintaining acceptable power and thermal profiles.

Current GDDR7 implementations leverage cutting-edge semiconductor processes that enable higher transistor densities and improved power efficiency compared to previous generations. These advanced nodes facilitate the integration of more sophisticated signal processing circuits required for PAM3 encoding and decoding, while simultaneously reducing the power consumption per transistor. The reduced feature sizes allow for more compact designs that can operate at lower voltages, directly addressing thermal concerns.

The transition from planar transistors to FinFET and potentially gate-all-around (GAA) architectures in newer process nodes has significantly improved the electrostatic control of the channel, reducing leakage currents that contribute to static power consumption. This advancement is particularly crucial for GDDR7, as PAM3 signaling requires precise voltage control to distinguish between three signal levels rather than two.

Process technology innovations have also enabled enhanced power management features within GDDR7 memory. Dynamic voltage and frequency scaling (DVFS) capabilities, made possible by advanced process nodes, allow the memory to adjust its operating parameters based on workload demands, optimizing the power-performance balance in real-time. This adaptability is essential for managing the increased power demands associated with PAM3 signaling.

Thermal management has been addressed through process-level innovations such as improved interconnect materials with lower resistance, reducing heat generation during high-speed data transfers. Additionally, advanced packaging technologies like through-silicon vias (TSVs) and interposers facilitate better heat dissipation pathways, allowing GDDR7 to maintain optimal operating temperatures even under high-performance conditions.

The semiconductor process technology also enables the implementation of more sophisticated error correction mechanisms necessary for PAM3 signaling. As signal integrity becomes more challenging with three voltage levels instead of two, robust error detection and correction capabilities are essential to maintain data integrity without requiring excessive power for signal amplification.

Looking forward, emerging process technologies such as 3nm and beyond will further enhance GDDR7's capabilities by providing additional power efficiency improvements and enabling even higher integration densities. These advancements will be crucial for future iterations of GDDR7 that aim to push data rates beyond current limitations while maintaining acceptable power and thermal profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!