Gel Electrophoresis for Assessing Polymeric Materials: State of the Art

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gel Electrophoresis Background and Objectives

Gel electrophoresis has been a cornerstone technique in molecular biology and biochemistry for decades, primarily used for separating and analyzing nucleic acids and proteins. In recent years, this versatile method has found new applications in the field of polymer science, particularly for assessing polymeric materials. The evolution of gel electrophoresis from its initial use in biological sciences to its current role in materials science represents a significant technological advancement.

The primary objective of using gel electrophoresis for polymeric materials is to provide a comprehensive and precise method for characterizing various aspects of polymers, including molecular weight distribution, conformational changes, and structural modifications. This technique offers unique advantages over traditional polymer analysis methods, such as its ability to separate complex mixtures of polymers based on their size, charge, and shape simultaneously.

The development of gel electrophoresis for polymeric materials has been driven by the increasing demand for more sophisticated analytical tools in the polymer industry. As polymers become more complex and their applications more diverse, there is a growing need for techniques that can provide detailed information about their properties and behavior under different conditions. Gel electrophoresis addresses this need by offering high-resolution separation and analysis capabilities.

One of the key trends in this field is the adaptation of existing gel electrophoresis techniques to accommodate the specific requirements of polymeric materials. This includes the development of new gel formulations, buffer systems, and detection methods tailored to different types of polymers. Additionally, researchers are exploring ways to combine gel electrophoresis with other analytical techniques, such as mass spectrometry or spectroscopy, to enhance its capabilities and provide more comprehensive polymer characterization.

The future direction of gel electrophoresis in polymer science is likely to focus on improving sensitivity, resolution, and automation. There is also a growing interest in developing miniaturized and portable gel electrophoresis systems for on-site polymer analysis in industrial settings. These advancements aim to make the technique more accessible and applicable to a wider range of polymeric materials and research questions.

As the field progresses, gel electrophoresis is expected to play an increasingly important role in various aspects of polymer science, including quality control in manufacturing, development of new materials, and environmental monitoring of polymer degradation and pollution. The continued refinement and expansion of this technique will undoubtedly contribute to our understanding of polymeric materials and drive innovation in polymer-based technologies.

The primary objective of using gel electrophoresis for polymeric materials is to provide a comprehensive and precise method for characterizing various aspects of polymers, including molecular weight distribution, conformational changes, and structural modifications. This technique offers unique advantages over traditional polymer analysis methods, such as its ability to separate complex mixtures of polymers based on their size, charge, and shape simultaneously.

The development of gel electrophoresis for polymeric materials has been driven by the increasing demand for more sophisticated analytical tools in the polymer industry. As polymers become more complex and their applications more diverse, there is a growing need for techniques that can provide detailed information about their properties and behavior under different conditions. Gel electrophoresis addresses this need by offering high-resolution separation and analysis capabilities.

One of the key trends in this field is the adaptation of existing gel electrophoresis techniques to accommodate the specific requirements of polymeric materials. This includes the development of new gel formulations, buffer systems, and detection methods tailored to different types of polymers. Additionally, researchers are exploring ways to combine gel electrophoresis with other analytical techniques, such as mass spectrometry or spectroscopy, to enhance its capabilities and provide more comprehensive polymer characterization.

The future direction of gel electrophoresis in polymer science is likely to focus on improving sensitivity, resolution, and automation. There is also a growing interest in developing miniaturized and portable gel electrophoresis systems for on-site polymer analysis in industrial settings. These advancements aim to make the technique more accessible and applicable to a wider range of polymeric materials and research questions.

As the field progresses, gel electrophoresis is expected to play an increasingly important role in various aspects of polymer science, including quality control in manufacturing, development of new materials, and environmental monitoring of polymer degradation and pollution. The continued refinement and expansion of this technique will undoubtedly contribute to our understanding of polymeric materials and drive innovation in polymer-based technologies.

Market Demand Analysis for Polymer Characterization

The market demand for polymer characterization techniques, particularly gel electrophoresis, has been steadily growing due to the increasing complexity and diversity of polymeric materials used across various industries. The global polymer market is experiencing robust growth, driven by advancements in material science and the expanding applications of polymers in sectors such as automotive, packaging, electronics, and healthcare.

Gel electrophoresis, as a powerful analytical tool for assessing polymeric materials, is witnessing heightened demand in research laboratories, quality control departments, and industrial settings. This technique offers unique advantages in separating and analyzing polymer molecules based on their size and charge, providing crucial insights into polymer composition, molecular weight distribution, and purity.

The pharmaceutical and biotechnology sectors are major contributors to the market demand for gel electrophoresis in polymer characterization. As the development of biopolymers and drug delivery systems becomes more sophisticated, there is an increased need for precise analytical methods to ensure product quality and efficacy. Gel electrophoresis plays a vital role in this context, enabling researchers and manufacturers to assess the properties of polymeric drug carriers and biomaterials.

In the plastics industry, the push towards sustainable and biodegradable materials has created new opportunities for gel electrophoresis applications. Manufacturers are seeking reliable methods to characterize novel polymer blends and composites, driving the demand for advanced analytical techniques. Gel electrophoresis offers a cost-effective and versatile solution for evaluating the molecular characteristics of these innovative materials.

The electronics sector is another key driver of market demand for polymer characterization. With the miniaturization of electronic components and the development of flexible electronics, there is a growing need to analyze and optimize polymeric materials used in insulation, coatings, and substrates. Gel electrophoresis provides valuable data on polymer degradation and stability, which is crucial for ensuring the longevity and performance of electronic devices.

Environmental concerns and regulatory pressures are also influencing the market demand for polymer characterization techniques. As governments worldwide implement stricter regulations on plastic waste and environmental impact, industries are investing in analytical tools to develop and validate more eco-friendly polymeric materials. Gel electrophoresis is increasingly used to study the degradation patterns of biodegradable polymers and assess the environmental fate of plastic products.

The academic research community continues to be a significant contributor to the market demand for gel electrophoresis in polymer science. Universities and research institutions are constantly exploring new polymer formulations and applications, necessitating advanced characterization methods. This ongoing research activity not only drives the demand for gel electrophoresis equipment and consumables but also contributes to the refinement and expansion of the technique's capabilities in polymer analysis.

Gel electrophoresis, as a powerful analytical tool for assessing polymeric materials, is witnessing heightened demand in research laboratories, quality control departments, and industrial settings. This technique offers unique advantages in separating and analyzing polymer molecules based on their size and charge, providing crucial insights into polymer composition, molecular weight distribution, and purity.

The pharmaceutical and biotechnology sectors are major contributors to the market demand for gel electrophoresis in polymer characterization. As the development of biopolymers and drug delivery systems becomes more sophisticated, there is an increased need for precise analytical methods to ensure product quality and efficacy. Gel electrophoresis plays a vital role in this context, enabling researchers and manufacturers to assess the properties of polymeric drug carriers and biomaterials.

In the plastics industry, the push towards sustainable and biodegradable materials has created new opportunities for gel electrophoresis applications. Manufacturers are seeking reliable methods to characterize novel polymer blends and composites, driving the demand for advanced analytical techniques. Gel electrophoresis offers a cost-effective and versatile solution for evaluating the molecular characteristics of these innovative materials.

The electronics sector is another key driver of market demand for polymer characterization. With the miniaturization of electronic components and the development of flexible electronics, there is a growing need to analyze and optimize polymeric materials used in insulation, coatings, and substrates. Gel electrophoresis provides valuable data on polymer degradation and stability, which is crucial for ensuring the longevity and performance of electronic devices.

Environmental concerns and regulatory pressures are also influencing the market demand for polymer characterization techniques. As governments worldwide implement stricter regulations on plastic waste and environmental impact, industries are investing in analytical tools to develop and validate more eco-friendly polymeric materials. Gel electrophoresis is increasingly used to study the degradation patterns of biodegradable polymers and assess the environmental fate of plastic products.

The academic research community continues to be a significant contributor to the market demand for gel electrophoresis in polymer science. Universities and research institutions are constantly exploring new polymer formulations and applications, necessitating advanced characterization methods. This ongoing research activity not only drives the demand for gel electrophoresis equipment and consumables but also contributes to the refinement and expansion of the technique's capabilities in polymer analysis.

Current Challenges in Gel Electrophoresis for Polymers

Gel electrophoresis has been a cornerstone technique in polymer analysis for decades, yet it faces several challenges in its application to modern polymeric materials. One of the primary issues is the limited resolution for high molecular weight polymers. As synthetic polymers become increasingly complex and diverse, traditional gel electrophoresis struggles to effectively separate and analyze molecules above certain size thresholds, particularly those exceeding 1 million Daltons.

Another significant challenge is the difficulty in maintaining consistent and reproducible results across different laboratories and experimental setups. Variations in gel composition, buffer systems, and electrophoresis conditions can lead to discrepancies in migration patterns and band resolution, making it challenging to compare results between studies or establish standardized protocols for specific polymer types.

The time-consuming nature of gel electrophoresis poses a substantial hurdle in high-throughput polymer characterization. Sample preparation, gel casting, and running times can be lengthy, limiting the technique's applicability in rapid screening and quality control processes in industrial settings. This becomes particularly problematic when dealing with large sample volumes or time-sensitive analyses.

Quantitative analysis remains a persistent challenge in gel electrophoresis of polymers. While the technique excels in qualitative assessments, accurate quantification of polymer concentrations and molecular weight distributions can be difficult due to factors such as band broadening, non-linear migration, and limitations in staining and detection methods for certain polymer types.

The environmental impact of gel electrophoresis is an emerging concern. The technique often relies on toxic staining agents and generates hazardous waste, which conflicts with growing sustainability initiatives in both academic and industrial research settings. Developing eco-friendly alternatives without compromising analytical performance is a pressing challenge.

Adapting gel electrophoresis for the analysis of novel and complex polymer architectures, such as branched, star-shaped, or block copolymers, presents ongoing difficulties. These structures often exhibit anomalous migration behaviors that do not correlate well with their molecular weights, leading to potential misinterpretations of results.

Lastly, the integration of gel electrophoresis with other analytical techniques for comprehensive polymer characterization remains a challenge. While coupling with mass spectrometry or spectroscopic methods has shown promise, practical implementation often faces obstacles in terms of compatibility, sample preparation, and data integration.

Another significant challenge is the difficulty in maintaining consistent and reproducible results across different laboratories and experimental setups. Variations in gel composition, buffer systems, and electrophoresis conditions can lead to discrepancies in migration patterns and band resolution, making it challenging to compare results between studies or establish standardized protocols for specific polymer types.

The time-consuming nature of gel electrophoresis poses a substantial hurdle in high-throughput polymer characterization. Sample preparation, gel casting, and running times can be lengthy, limiting the technique's applicability in rapid screening and quality control processes in industrial settings. This becomes particularly problematic when dealing with large sample volumes or time-sensitive analyses.

Quantitative analysis remains a persistent challenge in gel electrophoresis of polymers. While the technique excels in qualitative assessments, accurate quantification of polymer concentrations and molecular weight distributions can be difficult due to factors such as band broadening, non-linear migration, and limitations in staining and detection methods for certain polymer types.

The environmental impact of gel electrophoresis is an emerging concern. The technique often relies on toxic staining agents and generates hazardous waste, which conflicts with growing sustainability initiatives in both academic and industrial research settings. Developing eco-friendly alternatives without compromising analytical performance is a pressing challenge.

Adapting gel electrophoresis for the analysis of novel and complex polymer architectures, such as branched, star-shaped, or block copolymers, presents ongoing difficulties. These structures often exhibit anomalous migration behaviors that do not correlate well with their molecular weights, leading to potential misinterpretations of results.

Lastly, the integration of gel electrophoresis with other analytical techniques for comprehensive polymer characterization remains a challenge. While coupling with mass spectrometry or spectroscopic methods has shown promise, practical implementation often faces obstacles in terms of compatibility, sample preparation, and data integration.

State-of-the-Art Gel Electrophoresis Methods

01 Gel composition and preparation

Various gel compositions and preparation methods are used in gel electrophoresis. These include specific formulations of polymers, cross-linking agents, and buffer solutions to create gels with desired properties for different separation applications. The composition and preparation of the gel can significantly impact the resolution and efficiency of the electrophoresis process.- Gel composition and preparation: Various gel compositions and preparation methods are used in gel electrophoresis. These include specific formulations of polymers, cross-linking agents, and buffer solutions to create gels with desired properties for different separation applications. The composition and preparation of the gel can significantly impact the resolution and efficiency of the electrophoresis process.

- Electrophoresis apparatus design: Innovations in electrophoresis apparatus design focus on improving separation efficiency, sample loading, and result visualization. These designs may include features such as multiple gel lanes, integrated cooling systems, and specialized electrodes to enhance performance and ease of use in various electrophoresis applications.

- Detection and analysis methods: Advanced detection and analysis methods are developed to assess gel electrophoresis results more accurately and efficiently. These may include fluorescence-based detection, image analysis software, and automated band identification systems. Such methods aim to improve the sensitivity and reliability of gel electrophoresis assessments.

- Sample preparation techniques: Various sample preparation techniques are employed to optimize gel electrophoresis results. These may include methods for concentrating samples, removing interfering substances, or adding specific markers to aid in analysis. Proper sample preparation is crucial for achieving accurate and reproducible electrophoresis results.

- Specialized electrophoresis applications: Gel electrophoresis techniques are adapted for specialized applications in various fields such as proteomics, genomics, and forensics. These adaptations may involve modifications to gel composition, running conditions, or detection methods to suit specific analytical needs. Specialized applications aim to enhance the resolution and sensitivity of electrophoresis for particular types of molecules or samples.

02 Electrophoresis apparatus design

Innovations in electrophoresis apparatus design focus on improving separation efficiency, sample loading, and result visualization. These designs may include novel electrode configurations, buffer circulation systems, or integrated cooling mechanisms to enhance performance and reproducibility of gel electrophoresis experiments.Expand Specific Solutions03 Detection and analysis methods

Advanced detection and analysis methods are developed to improve the sensitivity and accuracy of gel electrophoresis assessments. These may include fluorescence-based detection, image analysis software, or integration with mass spectrometry for more comprehensive sample characterization.Expand Specific Solutions04 Microfluidic and miniaturized systems

Miniaturized gel electrophoresis systems, often integrated into microfluidic devices, are developed for rapid and high-throughput analysis. These systems can offer advantages in terms of sample volume reduction, faster separation times, and potential for automation in clinical or research settings.Expand Specific Solutions05 Application-specific optimizations

Gel electrophoresis techniques are optimized for specific applications such as DNA sequencing, protein analysis, or clinical diagnostics. These optimizations may involve tailored gel formulations, running conditions, or sample preparation methods to enhance the resolution and accuracy for particular types of biomolecules or diagnostic targets.Expand Specific Solutions

Key Players in Gel Electrophoresis Industry

The gel electrophoresis market for assessing polymeric materials is in a mature growth stage, with a steady increase in market size driven by applications in materials science and polymer research. The global market is estimated to be in the hundreds of millions of dollars, with consistent annual growth. Technologically, gel electrophoresis is well-established, but innovations continue in areas like high-resolution separation and automation. Key players like Life Technologies, Bio-Rad Laboratories, and Beckman Coulter dominate the market with advanced systems, while specialized companies such as Helena Laboratories focus on niche applications. Academic institutions like Shanghai Jiao Tong University and Vanderbilt University contribute to ongoing research and development in this field.

3M Innovative Properties Co.

Technical Solution: 3M has developed innovative gel electrophoresis technologies for assessing polymeric materials, particularly in the field of adhesives and coatings. Their approach includes the use of pulsed-field gel electrophoresis for separating high molecular weight polymers and copolymers[13]. 3M has introduced specialized gel matrices that allow for improved resolution of branched and cross-linked polymers, which are common in adhesive formulations[14]. The company has also developed electrophoresis systems with in-situ polymerization capabilities, enabling the study of polymer formation kinetics[15]. 3M's gel electrophoresis technology incorporates multi-angle light scattering detection for accurate molecular weight determination of separated polymer fractions[16].

Strengths: Specialized solutions for industrial polymers, advanced techniques for complex polymer structures, integration with other analytical methods. Weaknesses: May be less suitable for routine analysis of simple polymers, potentially higher complexity for users.

Beckman Coulter, Inc.

Technical Solution: Beckman Coulter has innovated in gel electrophoresis technology for polymer analysis with their ProteomeLab series. Their systems feature capillary gel electrophoresis, which allows for high-throughput analysis of polymers with minimal sample consumption[5]. The company has developed specialized polymer separation kits that enable rapid characterization of synthetic polymers and biopolymers[6]. Beckman Coulter's gel electrophoresis technology incorporates laser-induced fluorescence detection, providing high sensitivity for trace polymer analysis[7]. They have also introduced automated sample preparation and injection systems, increasing reproducibility and reducing manual handling errors in polymer analysis[8].

Strengths: High-throughput capabilities, minimal sample requirements, automated systems for improved reproducibility. Weaknesses: May be less suitable for very large polymers, higher initial investment compared to traditional gel electrophoresis.

Innovations in Gel Electrophoresis for Polymers

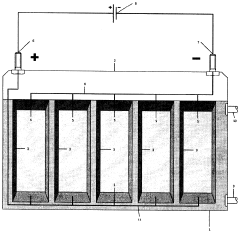

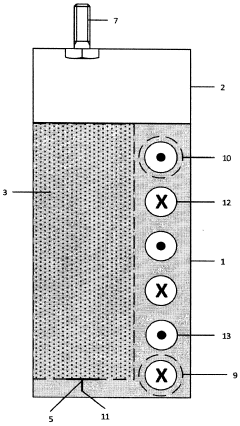

Compartmentalized gel-electrophoresis apparatus

PatentInactiveCA2837319A1

Innovation

- A compartmentalized gel-electrophoresis apparatus with multiple gel cassettes that can be run independently and interchangeably, each with its own buffer solution, and a heat exchanger to manage temperature, enabling real-time electrophoresis and flexible experimentation without requiring additional equipment.

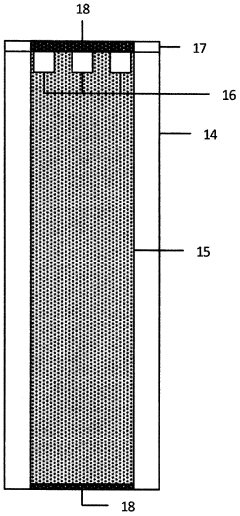

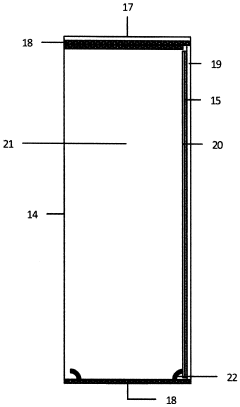

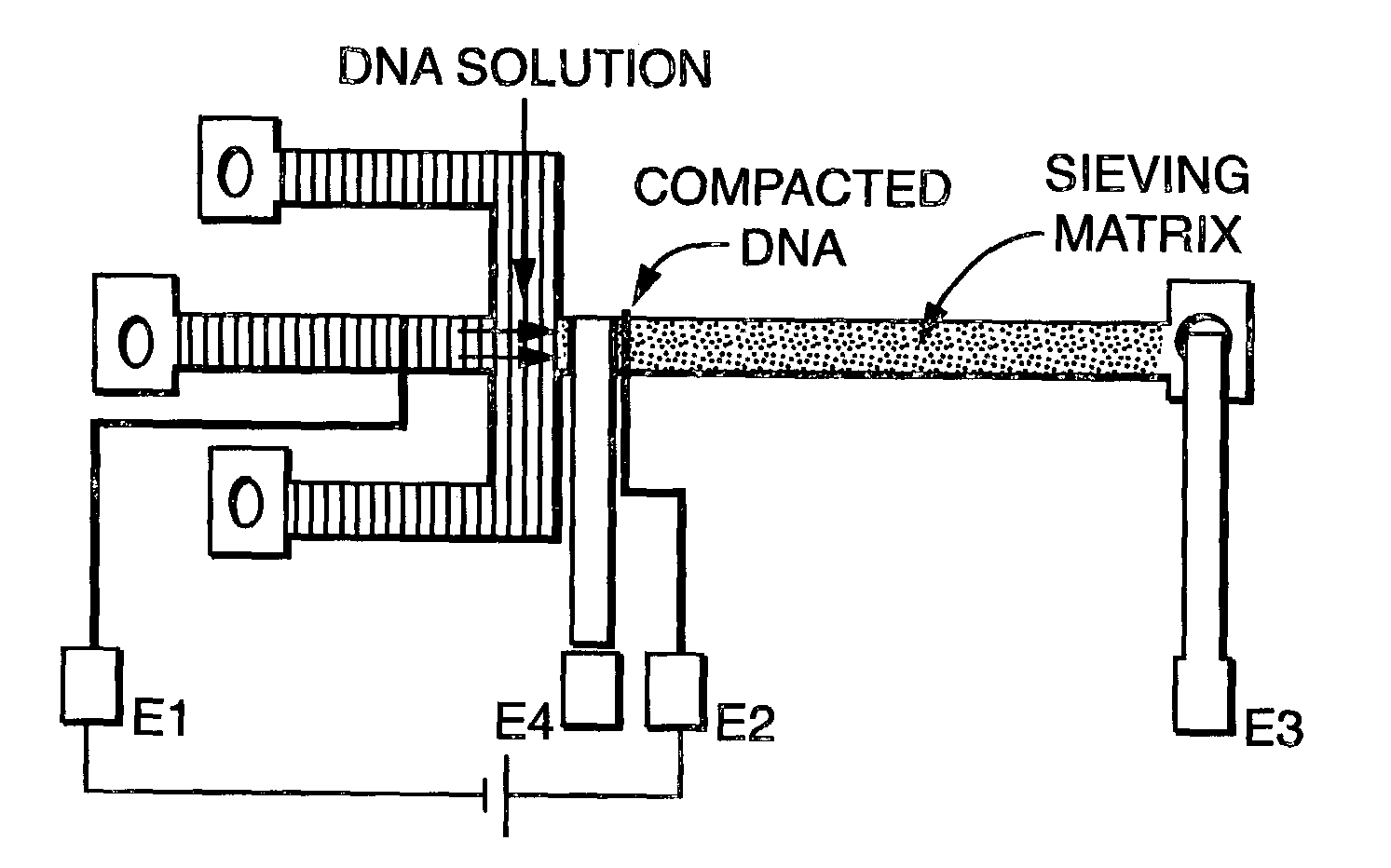

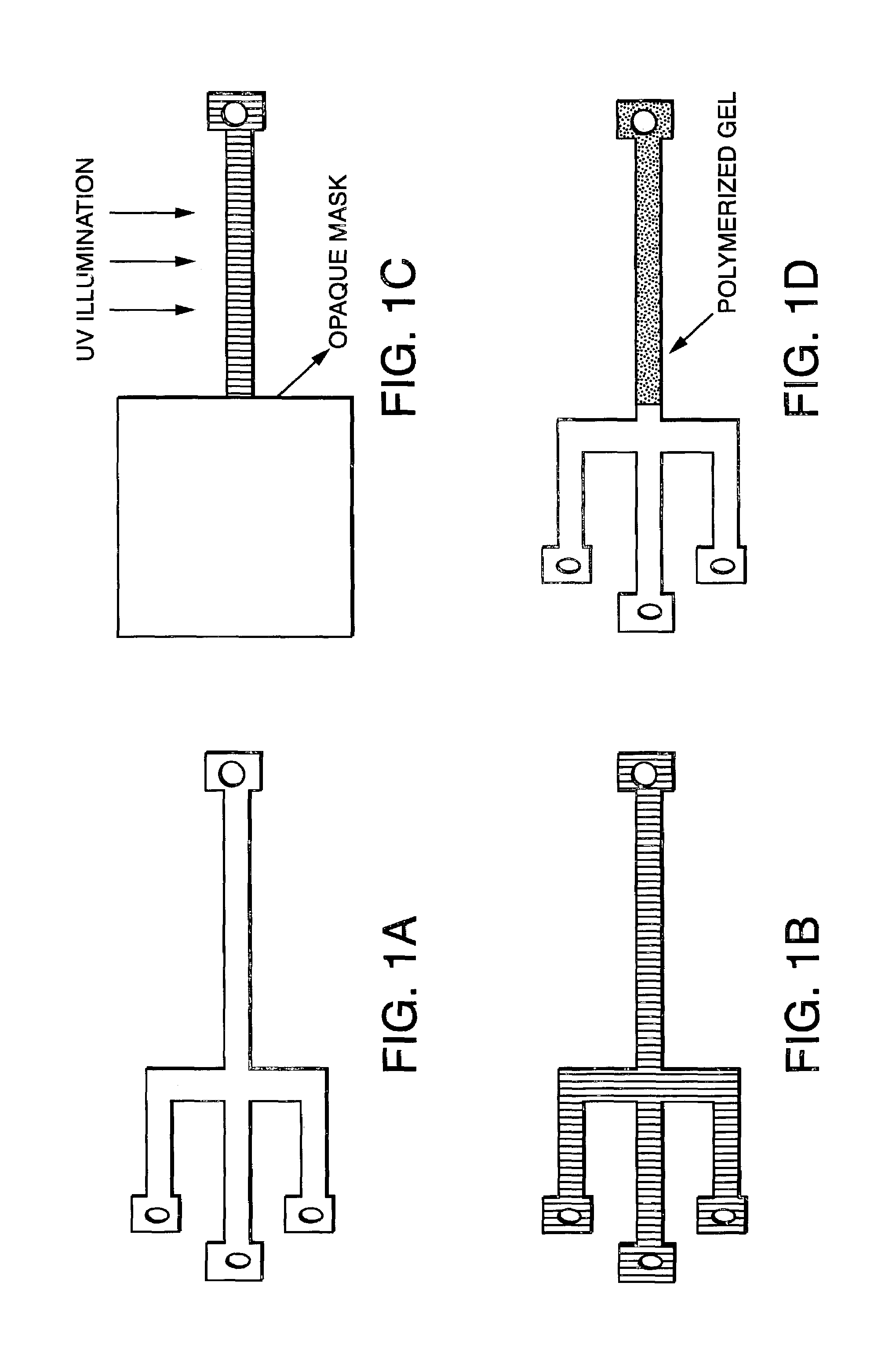

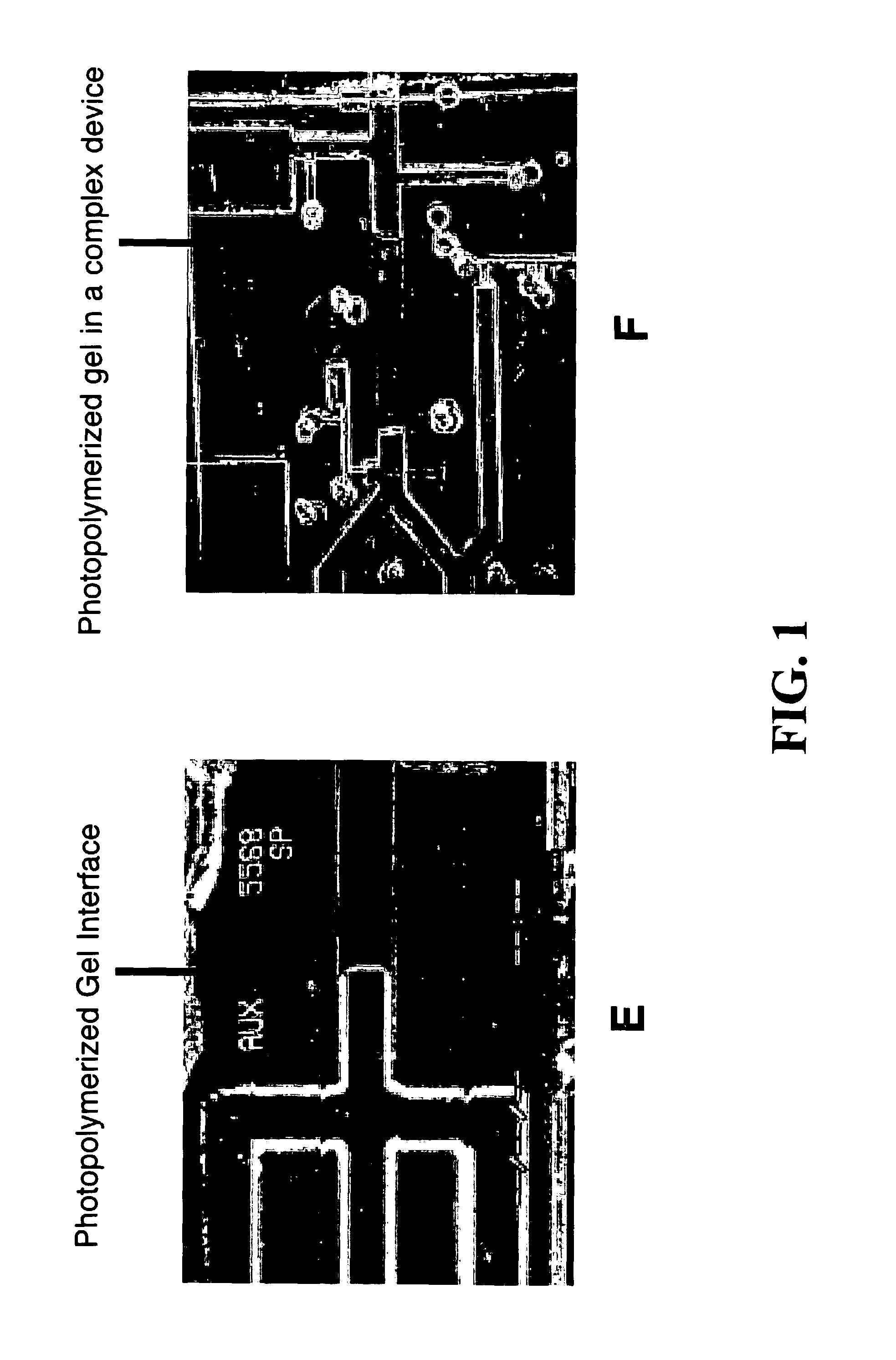

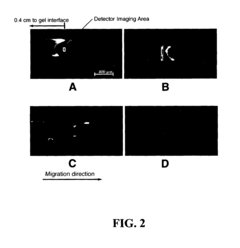

Electrophoresis in microfabricated devices using photopolymerized polyacrylamide gels and electrode-defined sample injection

PatentInactiveUS7005050B2

Innovation

- A novel electrophoretic separation system utilizing photodefined polyacrylamide gels and electrode-defined sample injection, allowing for precise control over the gel interface and sample injection, enabling high-resolution separations over short lengths with reduced power consumption and cost.

Environmental Impact of Gel Electrophoresis

Gel electrophoresis, while a powerful analytical technique for assessing polymeric materials, carries environmental implications that warrant careful consideration. The process involves the use of various chemicals and materials that can potentially impact the environment if not properly managed.

One of the primary environmental concerns associated with gel electrophoresis is the disposal of used gels and buffers. These materials often contain hazardous substances such as ethidium bromide, a common DNA stain known for its mutagenic properties. Improper disposal of these materials can lead to soil and water contamination, posing risks to ecosystems and human health.

The production and use of polyacrylamide gels, a common medium in gel electrophoresis, also raise environmental concerns. Acrylamide, the monomer used to create these gels, is a neurotoxin and potential carcinogen. While polymerized acrylamide is generally considered safe, residual monomers and the potential for gel breakdown over time necessitate careful handling and disposal protocols.

Energy consumption is another environmental factor to consider. Gel electrophoresis equipment, particularly power supplies and cooling systems, can consume significant amounts of electricity during operation. This energy usage contributes to the overall carbon footprint of laboratories and research facilities employing this technique.

Water usage is also a notable environmental aspect of gel electrophoresis. The technique requires substantial amounts of purified water for gel preparation, buffer solutions, and equipment cleaning. In regions facing water scarcity, this consumption can strain local water resources.

The production of single-use plastics associated with gel electrophoresis, such as pipette tips, gel combs, and disposable electrophoresis chambers, contributes to plastic waste. This issue aligns with broader concerns about laboratory plastic waste and its impact on the environment.

To mitigate these environmental impacts, researchers and laboratories are exploring more sustainable practices. These include the development of non-toxic gel stains to replace ethidium bromide, the implementation of recycling programs for gel materials, and the adoption of more energy-efficient electrophoresis equipment.

Additionally, there is a growing trend towards miniaturization and automation in gel electrophoresis systems. These advancements not only improve analytical efficiency but also reduce reagent consumption and waste generation, thereby lessening the environmental footprint of the technique.

One of the primary environmental concerns associated with gel electrophoresis is the disposal of used gels and buffers. These materials often contain hazardous substances such as ethidium bromide, a common DNA stain known for its mutagenic properties. Improper disposal of these materials can lead to soil and water contamination, posing risks to ecosystems and human health.

The production and use of polyacrylamide gels, a common medium in gel electrophoresis, also raise environmental concerns. Acrylamide, the monomer used to create these gels, is a neurotoxin and potential carcinogen. While polymerized acrylamide is generally considered safe, residual monomers and the potential for gel breakdown over time necessitate careful handling and disposal protocols.

Energy consumption is another environmental factor to consider. Gel electrophoresis equipment, particularly power supplies and cooling systems, can consume significant amounts of electricity during operation. This energy usage contributes to the overall carbon footprint of laboratories and research facilities employing this technique.

Water usage is also a notable environmental aspect of gel electrophoresis. The technique requires substantial amounts of purified water for gel preparation, buffer solutions, and equipment cleaning. In regions facing water scarcity, this consumption can strain local water resources.

The production of single-use plastics associated with gel electrophoresis, such as pipette tips, gel combs, and disposable electrophoresis chambers, contributes to plastic waste. This issue aligns with broader concerns about laboratory plastic waste and its impact on the environment.

To mitigate these environmental impacts, researchers and laboratories are exploring more sustainable practices. These include the development of non-toxic gel stains to replace ethidium bromide, the implementation of recycling programs for gel materials, and the adoption of more energy-efficient electrophoresis equipment.

Additionally, there is a growing trend towards miniaturization and automation in gel electrophoresis systems. These advancements not only improve analytical efficiency but also reduce reagent consumption and waste generation, thereby lessening the environmental footprint of the technique.

Standardization and Quality Control Measures

Standardization and quality control measures are crucial for ensuring the reliability and reproducibility of gel electrophoresis techniques in assessing polymeric materials. The development of standardized protocols and quality control procedures has significantly enhanced the accuracy and consistency of results across different laboratories and research institutions.

One of the primary standardization efforts in gel electrophoresis for polymeric materials involves the establishment of uniform sample preparation methods. This includes guidelines for sample concentration, buffer composition, and loading techniques. Standardized sample preparation ensures that results can be compared across different experiments and laboratories, facilitating more robust data analysis and interpretation.

The use of standardized gel compositions and running conditions is another critical aspect of quality control in gel electrophoresis. Researchers have developed specific gel formulations optimized for various types of polymeric materials, taking into account factors such as molecular weight range and charge distribution. These standardized gels, coupled with well-defined running conditions (e.g., voltage, temperature, and duration), contribute to more consistent and reproducible results.

Calibration standards and reference materials play a vital role in quality control measures for gel electrophoresis. The use of well-characterized molecular weight markers and polymer standards allows for accurate size determination and quantification of polymeric materials. These standards are essential for validating the performance of gel electrophoresis systems and ensuring the reliability of experimental results.

To address the challenges of inter-laboratory variability, proficiency testing programs have been established in the field of gel electrophoresis for polymeric materials. These programs involve multiple laboratories analyzing identical samples and comparing their results. This approach helps identify systematic errors, improve measurement techniques, and promote the adoption of best practices across the scientific community.

The development of automated gel imaging and analysis systems has significantly contributed to standardization efforts. These systems provide consistent and objective data acquisition, reducing the potential for human error and subjective interpretation. Advanced software algorithms enable automated lane and band detection, molecular weight calculation, and quantitative analysis, further enhancing the reproducibility and reliability of results.

Quality control measures also extend to the maintenance and calibration of electrophoresis equipment. Regular performance checks, including voltage and current calibration, temperature control verification, and gel casting quality assessments, are essential for ensuring consistent and accurate results. Documentation of these quality control procedures is crucial for maintaining traceability and compliance with regulatory requirements in various industries.

One of the primary standardization efforts in gel electrophoresis for polymeric materials involves the establishment of uniform sample preparation methods. This includes guidelines for sample concentration, buffer composition, and loading techniques. Standardized sample preparation ensures that results can be compared across different experiments and laboratories, facilitating more robust data analysis and interpretation.

The use of standardized gel compositions and running conditions is another critical aspect of quality control in gel electrophoresis. Researchers have developed specific gel formulations optimized for various types of polymeric materials, taking into account factors such as molecular weight range and charge distribution. These standardized gels, coupled with well-defined running conditions (e.g., voltage, temperature, and duration), contribute to more consistent and reproducible results.

Calibration standards and reference materials play a vital role in quality control measures for gel electrophoresis. The use of well-characterized molecular weight markers and polymer standards allows for accurate size determination and quantification of polymeric materials. These standards are essential for validating the performance of gel electrophoresis systems and ensuring the reliability of experimental results.

To address the challenges of inter-laboratory variability, proficiency testing programs have been established in the field of gel electrophoresis for polymeric materials. These programs involve multiple laboratories analyzing identical samples and comparing their results. This approach helps identify systematic errors, improve measurement techniques, and promote the adoption of best practices across the scientific community.

The development of automated gel imaging and analysis systems has significantly contributed to standardization efforts. These systems provide consistent and objective data acquisition, reducing the potential for human error and subjective interpretation. Advanced software algorithms enable automated lane and band detection, molecular weight calculation, and quantitative analysis, further enhancing the reproducibility and reliability of results.

Quality control measures also extend to the maintenance and calibration of electrophoresis equipment. Regular performance checks, including voltage and current calibration, temperature control verification, and gel casting quality assessments, are essential for ensuring consistent and accurate results. Documentation of these quality control procedures is crucial for maintaining traceability and compliance with regulatory requirements in various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!