HE ceramic microstructure tuning to control fracture toughness — practical recipes and metrics

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Ceramic Microstructure Development Background and Objectives

High-entropy (HE) ceramics represent a revolutionary frontier in materials science, emerging from the successful application of high-entropy concepts to ceramic systems. The evolution of these materials began in the early 2010s, following the development of high-entropy alloys, and has rapidly expanded into a diverse field encompassing oxides, carbides, borides, and nitrides. This technological progression has been driven by the unique properties that emerge from combining multiple elements in near-equimolar ratios within a single crystallographic structure.

The fundamental principle behind HE ceramics lies in maximizing configurational entropy through the incorporation of five or more principal elements, creating systems with enhanced stability through entropy effects. This approach has yielded materials with exceptional combinations of hardness, thermal stability, and oxidation resistance that often surpass traditional ceramics. However, one persistent challenge has been controlling fracture toughness—a critical property for structural applications that has traditionally been a limitation for ceramic materials.

Current research trajectories indicate growing interest in microstructure engineering as a key strategy for enhancing fracture toughness in HE ceramics. Historical approaches to toughening conventional ceramics through microstructural control—including grain size manipulation, secondary phase incorporation, and controlled porosity—provide valuable frameworks, but require significant adaptation for the complex compositional landscape of HE systems.

The primary technical objective of this research direction is to establish systematic methodologies for tuning HE ceramic microstructures specifically to enhance fracture toughness. This includes developing reproducible processing routes that can reliably control grain morphology, phase distribution, and interfacial characteristics in multi-component ceramic systems. Additionally, there is a critical need to establish standardized metrics for evaluating toughening mechanisms in these complex materials, as traditional fracture mechanics approaches may not fully capture the unique deformation behaviors in high-entropy systems.

Recent advances in characterization techniques, particularly in situ TEM mechanical testing and 3D tomographic methods, have begun to reveal the complex crack propagation behaviors in HE ceramics. These insights suggest that compositional gradients and local structural heterogeneities may offer novel pathways for toughening that are uniquely available in high-entropy systems. The field is now moving toward establishing predictive models that can guide compositional and processing decisions to achieve targeted microstructural features.

The ultimate goal is to develop a comprehensive "recipe book" approach that connects processing parameters, resulting microstructures, and mechanical performance—particularly fracture toughness—in HE ceramic systems. This would transform the current largely empirical development process into a more systematic engineering approach, accelerating the practical implementation of these promising materials in extreme environment applications.

The fundamental principle behind HE ceramics lies in maximizing configurational entropy through the incorporation of five or more principal elements, creating systems with enhanced stability through entropy effects. This approach has yielded materials with exceptional combinations of hardness, thermal stability, and oxidation resistance that often surpass traditional ceramics. However, one persistent challenge has been controlling fracture toughness—a critical property for structural applications that has traditionally been a limitation for ceramic materials.

Current research trajectories indicate growing interest in microstructure engineering as a key strategy for enhancing fracture toughness in HE ceramics. Historical approaches to toughening conventional ceramics through microstructural control—including grain size manipulation, secondary phase incorporation, and controlled porosity—provide valuable frameworks, but require significant adaptation for the complex compositional landscape of HE systems.

The primary technical objective of this research direction is to establish systematic methodologies for tuning HE ceramic microstructures specifically to enhance fracture toughness. This includes developing reproducible processing routes that can reliably control grain morphology, phase distribution, and interfacial characteristics in multi-component ceramic systems. Additionally, there is a critical need to establish standardized metrics for evaluating toughening mechanisms in these complex materials, as traditional fracture mechanics approaches may not fully capture the unique deformation behaviors in high-entropy systems.

Recent advances in characterization techniques, particularly in situ TEM mechanical testing and 3D tomographic methods, have begun to reveal the complex crack propagation behaviors in HE ceramics. These insights suggest that compositional gradients and local structural heterogeneities may offer novel pathways for toughening that are uniquely available in high-entropy systems. The field is now moving toward establishing predictive models that can guide compositional and processing decisions to achieve targeted microstructural features.

The ultimate goal is to develop a comprehensive "recipe book" approach that connects processing parameters, resulting microstructures, and mechanical performance—particularly fracture toughness—in HE ceramic systems. This would transform the current largely empirical development process into a more systematic engineering approach, accelerating the practical implementation of these promising materials in extreme environment applications.

Market Applications and Demand for Tough Ceramics

The global market for high-performance ceramics with enhanced fracture toughness continues to expand rapidly, driven by increasing demands across multiple industrial sectors. Aerospace and defense industries represent primary markets, where tough ceramics are essential for components exposed to extreme temperatures, pressures, and mechanical stresses. These materials are critical for jet engine components, thermal protection systems, and ballistic armor, where failure can have catastrophic consequences.

In the energy sector, particularly in power generation and oil and gas extraction, tough ceramics play a vital role in extending equipment lifespan under harsh operating conditions. The transition toward renewable energy sources has further accelerated demand for ceramics that can withstand thermal cycling and mechanical loads in solar thermal systems and fuel cells.

The biomedical industry represents another significant growth area, with increasing utilization of tough ceramics in dental implants, joint replacements, and surgical instruments. The market values ceramics with controlled microstructures that can provide both biocompatibility and mechanical reliability over decades of use in the human body.

Electronics and semiconductor manufacturing equipment rely heavily on ceramics with precisely tuned fracture toughness properties. As device miniaturization continues, the need for ceramics that can maintain structural integrity while providing electrical insulation or thermal management becomes increasingly critical.

Automotive applications represent an emerging market segment, particularly with the growth of electric vehicles and more efficient combustion engines. Ceramic components in turbochargers, exhaust systems, and braking systems require carefully engineered microstructures to withstand thermal shock and mechanical loading.

Market analysis indicates that industries are willing to pay premium prices for ceramics with demonstrably superior fracture toughness, particularly when accompanied by reliable metrics and testing protocols that predict in-service performance. The ability to customize ceramic microstructures for specific applications represents a significant competitive advantage for manufacturers.

Recent market surveys suggest that end-users prioritize consistency and reliability over absolute performance values, highlighting the importance of manufacturing processes that can deliver predictable microstructural characteristics. This trend underscores the value of practical recipes and standardized metrics for controlling fracture toughness through microstructure tuning.

The global push toward sustainable manufacturing has also created demand for ceramic processing techniques that minimize energy consumption while maintaining precise microstructural control. Companies that can develop energy-efficient methods for tuning ceramic microstructures stand to capture significant market share in this evolving landscape.

In the energy sector, particularly in power generation and oil and gas extraction, tough ceramics play a vital role in extending equipment lifespan under harsh operating conditions. The transition toward renewable energy sources has further accelerated demand for ceramics that can withstand thermal cycling and mechanical loads in solar thermal systems and fuel cells.

The biomedical industry represents another significant growth area, with increasing utilization of tough ceramics in dental implants, joint replacements, and surgical instruments. The market values ceramics with controlled microstructures that can provide both biocompatibility and mechanical reliability over decades of use in the human body.

Electronics and semiconductor manufacturing equipment rely heavily on ceramics with precisely tuned fracture toughness properties. As device miniaturization continues, the need for ceramics that can maintain structural integrity while providing electrical insulation or thermal management becomes increasingly critical.

Automotive applications represent an emerging market segment, particularly with the growth of electric vehicles and more efficient combustion engines. Ceramic components in turbochargers, exhaust systems, and braking systems require carefully engineered microstructures to withstand thermal shock and mechanical loading.

Market analysis indicates that industries are willing to pay premium prices for ceramics with demonstrably superior fracture toughness, particularly when accompanied by reliable metrics and testing protocols that predict in-service performance. The ability to customize ceramic microstructures for specific applications represents a significant competitive advantage for manufacturers.

Recent market surveys suggest that end-users prioritize consistency and reliability over absolute performance values, highlighting the importance of manufacturing processes that can deliver predictable microstructural characteristics. This trend underscores the value of practical recipes and standardized metrics for controlling fracture toughness through microstructure tuning.

The global push toward sustainable manufacturing has also created demand for ceramic processing techniques that minimize energy consumption while maintaining precise microstructural control. Companies that can develop energy-efficient methods for tuning ceramic microstructures stand to capture significant market share in this evolving landscape.

Current Challenges in HE Ceramic Microstructure Control

Despite significant advancements in high-entropy (HE) ceramic materials, controlling their microstructure to achieve optimal fracture toughness remains a formidable challenge. The inherent complexity of multi-principal element systems creates unpredictable phase formations and grain boundary characteristics that directly impact mechanical properties. Current manufacturing processes struggle to consistently produce HE ceramics with tailored microstructures due to the complex thermodynamic interactions between five or more principal elements.

Temperature control during sintering presents a critical challenge, as the multi-element composition of HE ceramics results in varied melting points and diffusion rates. This heterogeneity leads to inconsistent grain growth and densification, making it difficult to establish standardized processing parameters. Additionally, the formation of secondary phases at grain boundaries, while potentially beneficial for toughening mechanisms, remains largely unpredictable and difficult to control systematically.

The lack of comprehensive computational models that can accurately predict microstructural evolution in HE ceramics significantly hampers progress. Existing models developed for conventional ceramics fail to account for the complex entropic contributions and elemental interactions in high-entropy systems. This modeling gap creates a heavy reliance on empirical approaches, which are both time-consuming and resource-intensive.

Characterization techniques also present limitations when applied to HE ceramics. Traditional methods often struggle to provide accurate compositional mapping at grain boundaries and to identify nanoscale features that influence fracture behavior. The multi-element nature of these materials complicates spectroscopic analysis, making it challenging to correlate specific microstructural features with mechanical properties.

Scalability represents another significant hurdle. Laboratory-scale successes in microstructure control often fail to translate to industrial production environments due to variations in heating rates, cooling profiles, and atmospheric conditions. This scale-up challenge severely limits the commercial viability of HE ceramics with engineered fracture toughness.

Furthermore, there exists a fundamental knowledge gap regarding the relationship between specific microstructural features and toughening mechanisms in HE ceramics. While crack deflection, bridging, and transformation toughening are well-understood in conventional ceramics, their manifestation and optimization in high-entropy systems remain poorly defined. This lack of understanding prevents the development of targeted microstructure tuning strategies.

The absence of standardized metrics for evaluating microstructure-property relationships in HE ceramics further complicates development efforts. Without consistent evaluation frameworks, comparing results across different research groups becomes problematic, hindering collaborative progress in the field.

Temperature control during sintering presents a critical challenge, as the multi-element composition of HE ceramics results in varied melting points and diffusion rates. This heterogeneity leads to inconsistent grain growth and densification, making it difficult to establish standardized processing parameters. Additionally, the formation of secondary phases at grain boundaries, while potentially beneficial for toughening mechanisms, remains largely unpredictable and difficult to control systematically.

The lack of comprehensive computational models that can accurately predict microstructural evolution in HE ceramics significantly hampers progress. Existing models developed for conventional ceramics fail to account for the complex entropic contributions and elemental interactions in high-entropy systems. This modeling gap creates a heavy reliance on empirical approaches, which are both time-consuming and resource-intensive.

Characterization techniques also present limitations when applied to HE ceramics. Traditional methods often struggle to provide accurate compositional mapping at grain boundaries and to identify nanoscale features that influence fracture behavior. The multi-element nature of these materials complicates spectroscopic analysis, making it challenging to correlate specific microstructural features with mechanical properties.

Scalability represents another significant hurdle. Laboratory-scale successes in microstructure control often fail to translate to industrial production environments due to variations in heating rates, cooling profiles, and atmospheric conditions. This scale-up challenge severely limits the commercial viability of HE ceramics with engineered fracture toughness.

Furthermore, there exists a fundamental knowledge gap regarding the relationship between specific microstructural features and toughening mechanisms in HE ceramics. While crack deflection, bridging, and transformation toughening are well-understood in conventional ceramics, their manifestation and optimization in high-entropy systems remain poorly defined. This lack of understanding prevents the development of targeted microstructure tuning strategies.

The absence of standardized metrics for evaluating microstructure-property relationships in HE ceramics further complicates development efforts. Without consistent evaluation frameworks, comparing results across different research groups becomes problematic, hindering collaborative progress in the field.

Practical Processing Recipes for Microstructure Tuning

01 Microstructural design for enhanced fracture toughness

The microstructural design of high-entropy (HE) ceramics plays a crucial role in enhancing fracture toughness. By controlling grain size, phase distribution, and boundary characteristics, the crack propagation paths can be manipulated to increase energy absorption during fracture. Specific microstructural features such as interlocking grains, nano-sized domains, and controlled porosity can significantly improve the mechanical properties of HE ceramics, making them more resistant to crack initiation and propagation.- Microstructural design for enhanced fracture toughness: High-entropy (HE) ceramics can achieve improved fracture toughness through specific microstructural designs. These include creating multi-phase structures, controlling grain size and distribution, and introducing controlled porosity. The microstructural features create crack deflection mechanisms and energy dissipation pathways that enhance the material's resistance to fracture propagation, resulting in ceramics with superior mechanical properties.

- Addition of secondary phases and reinforcements: Incorporating secondary phases and reinforcements into high-entropy ceramic matrices significantly improves fracture toughness. These additions include whiskers, particles, fibers, or platelets that create toughening mechanisms such as crack bridging, crack deflection, and energy absorption. The interfaces between the matrix and reinforcements play a crucial role in determining the overall fracture behavior and mechanical properties of the composite ceramic system.

- Grain boundary engineering and dopant effects: Controlling grain boundary characteristics through dopants and processing techniques is essential for optimizing fracture toughness in high-entropy ceramics. Strategic addition of specific elements can modify grain boundary energy, cohesion, and sliding behavior. This engineering approach creates more tortuous crack paths, enhances grain boundary strength, and activates toughening mechanisms like intergranular fracture and crack bridging, resulting in ceramics with superior resistance to crack propagation.

- Novel processing techniques for optimized microstructure: Advanced processing methods significantly impact the microstructure and fracture toughness of high-entropy ceramics. Techniques such as spark plasma sintering, hot isostatic pressing, and controlled cooling rates enable precise control over grain growth, phase distribution, and defect concentration. These processing approaches can create unique microstructural features like core-shell structures, gradient compositions, or metastable phases that contribute to enhanced fracture toughness through multiple toughening mechanisms.

- Compositional design strategies for toughness enhancement: The specific elemental composition and stoichiometry of high-entropy ceramics significantly influence their microstructure and fracture toughness. By carefully selecting constituent elements with appropriate atomic size differences, electronegativity, and valence electron concentration, researchers can induce solid solution strengthening, lattice distortion, and entropy stabilization effects. These compositional strategies create intrinsic toughening mechanisms at the atomic scale that complement microstructural toughening approaches.

02 Compositional effects on HE ceramic toughness

The composition of high-entropy ceramics significantly influences their fracture toughness. Multi-component systems with five or more principal elements in near-equiatomic proportions create lattice distortion and solid solution strengthening that enhance mechanical properties. The selection of elements with varying atomic radii and electronegativity can create local stress fields that impede crack propagation. Additionally, the incorporation of specific dopants or secondary phases can further improve the fracture toughness through various toughening mechanisms.Expand Specific Solutions03 Processing techniques for optimized microstructure

Various processing techniques can be employed to optimize the microstructure of high-entropy ceramics for improved fracture toughness. These include specialized sintering methods such as spark plasma sintering, hot isostatic pressing, and microwave sintering that allow for precise control of grain growth and densification. Post-processing treatments like annealing and surface modification can further enhance the mechanical properties by relieving internal stresses and creating compressive surface layers that resist crack initiation.Expand Specific Solutions04 Toughening mechanisms in HE ceramics

High-entropy ceramics exhibit various toughening mechanisms that contribute to their enhanced fracture toughness. These include crack deflection, crack bridging, transformation toughening, and microcrack toughening. The complex crystal structure and chemical disorder in HE ceramics create energy dissipation pathways during crack propagation. Additionally, the presence of multiple phases with different elastic properties can induce stress fields that shield the crack tip, thereby increasing the energy required for crack propagation.Expand Specific Solutions05 Characterization and testing of fracture toughness

Various methods are employed to characterize and test the fracture toughness of high-entropy ceramics. These include indentation techniques, single-edge notched beam tests, double cantilever beam tests, and chevron notch methods. Advanced microscopy techniques such as scanning electron microscopy and transmission electron microscopy are used to analyze the microstructure and fracture surfaces. Computational methods, including finite element analysis and molecular dynamics simulations, provide insights into the relationship between microstructure and fracture behavior, guiding the design of ceramics with optimized toughness.Expand Specific Solutions

Leading Research Groups and Industrial Players

The ceramic microstructure tuning for fracture toughness control market is in a growth phase, with increasing applications in aerospace, energy, and electronics sectors. The global technical ceramics market is projected to reach approximately $10 billion by 2025, with high-performance engineering ceramics representing a significant segment. Technology maturity varies across players, with established companies like NGK Insulators and ExxonMobil Technology & Engineering demonstrating advanced capabilities in ceramic microstructure optimization. Research institutions including King Abdullah University of Science & Technology and Forschungszentrum Jülich are driving innovation through fundamental research. Industrial leaders such as JFE Steel, IBIDEN, and Siemens Energy are applying these technologies in commercial applications, focusing on performance-critical components where controlled fracture toughness provides competitive advantages.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed advanced ceramic microstructure tuning techniques focusing on controlling fracture toughness in high-temperature ceramic components. Their approach involves precise manipulation of grain size, porosity, and phase distribution through controlled sintering processes. NGK employs a multi-phase ceramic system where secondary phases are strategically distributed at grain boundaries to impede crack propagation. Their proprietary process includes the addition of specific dopants (such as yttria and alumina) in controlled quantities to promote toughening mechanisms like transformation toughening and crack deflection. NGK has established quantitative metrics for fracture toughness evaluation, including R-curve behavior analysis and in-situ crack propagation monitoring under thermal cycling conditions. Their manufacturing protocol incorporates hot isostatic pressing followed by controlled cooling rates to optimize residual stress distributions that enhance fracture resistance.

Strengths: Superior control over microstructural features at nanoscale levels, resulting in exceptional thermal shock resistance and mechanical reliability. Established manufacturing infrastructure allows for consistent quality at industrial scale. Weaknesses: Higher production costs compared to conventional ceramics, and limited flexibility in geometric design due to processing constraints.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed innovative approaches to HE ceramic microstructure tuning focused on fundamental understanding of toughening mechanisms. Their research employs advanced in-situ characterization techniques to directly observe crack propagation and arrest mechanisms at multiple length scales. KAUST's methodology incorporates precise control of grain boundary chemistry through segregation engineering, utilizing specific dopants to modify interfacial energies and cohesive strength. Their practical recipes include tailored thermal processing routes with controlled heating/cooling rates to achieve desired grain size distributions and phase assemblages. The university has established novel metrics for fracture toughness evaluation that incorporate both intrinsic and extrinsic toughening contributions. KAUST's approach includes the development of bio-inspired microstructural designs that mimic natural materials with exceptional damage tolerance. Their research has established quantitative relationships between processing parameters, resultant microstructures, and mechanical properties through integrated computational and experimental approaches.

Strengths: Cutting-edge fundamental understanding of toughening mechanisms with innovative bio-inspired design approaches. Access to world-class characterization facilities enables precise structure-property correlations. Weaknesses: Less emphasis on industrial scalability and manufacturing considerations compared to commercial entities, and solutions may require further development for commercial implementation.

Critical Analysis of Toughness Measurement Metrics

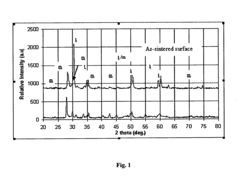

Method of making high toughness high strength zirconia bodies

PatentInactiveUS20140011661A1

Innovation

- Simultaneously adding yttria, ceria, and chromia to partially stabilized zirconia in specific proportions to create a microstructure with high tetragonal phase content, resulting in a ceramic with bending strength over 1150 MPa and fracture toughness over 15 MPa.m1/2, achieved through a process involving mixing, compacting, and sintering with controlled temperature and time.

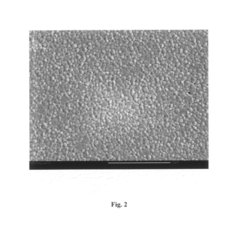

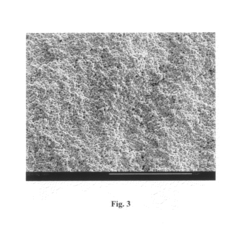

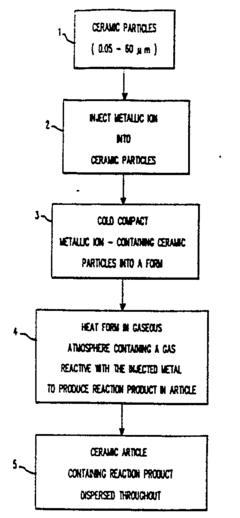

Method to improve the fracture toughness and strength of ceramic materials

PatentInactiveEP0308708A3

Innovation

- A powder metallurgical process involving the injection of fine ceramic particles with metallic ions, followed by compaction and heating in a reactive gas atmosphere to form a uniformly dispersed metal-gas reaction product, enhancing fracture toughness through mechanisms like transformation toughening and dispersion strengthening.

Materials Sustainability and Environmental Impact

The sustainability implications of high-entropy (HE) ceramic materials represent a critical dimension in their development and application. These advanced materials offer significant potential for reducing environmental footprints across multiple industries due to their exceptional durability and performance characteristics under extreme conditions.

When considering the environmental impact of HE ceramics with tuned microstructures for fracture toughness, their extended service life becomes a primary sustainability advantage. Conventional ceramics often require frequent replacement due to brittle failure, generating substantial waste and resource consumption. By contrast, HE ceramics with optimized fracture toughness can significantly reduce replacement frequency, minimizing the material throughput in high-stress applications.

The manufacturing processes for microstructure-tuned HE ceramics present both challenges and opportunities from a sustainability perspective. Current synthesis methods often involve high-temperature processing, which demands considerable energy input. However, emerging research indicates that precise microstructural control may enable lower processing temperatures while maintaining desired mechanical properties, potentially reducing the carbon footprint associated with production.

Resource efficiency represents another critical sustainability factor. HE ceramics typically incorporate multiple elements in near-equiatomic proportions, which can diversify resource dependencies away from critical or rare materials. This compositional flexibility allows for the substitution of environmentally problematic elements with more abundant and less harmful alternatives while maintaining performance characteristics.

End-of-life considerations for HE ceramics must also be addressed in sustainability assessments. Their complex compositions can complicate recycling efforts, though their exceptional durability means this concern is offset by significantly extended service lifetimes. Research into recovery methods for constituent elements from spent HE ceramics is emerging as an important area for future development.

Life cycle assessment (LCA) studies specifically focused on microstructure-tuned HE ceramics remain limited, representing a significant knowledge gap. Preliminary analyses suggest that despite energy-intensive production, the total environmental impact over the full product lifetime may be substantially lower than conventional alternatives due to superior performance and longevity. Quantitative metrics linking microstructural features to both performance and environmental impact are needed to guide sustainable material design.

The potential for HE ceramics to enable more efficient energy systems further enhances their sustainability profile. Their exceptional thermal stability and mechanical properties at high temperatures make them ideal candidates for next-generation energy conversion systems, potentially contributing to broader decarbonization efforts beyond the direct impacts of the materials themselves.

When considering the environmental impact of HE ceramics with tuned microstructures for fracture toughness, their extended service life becomes a primary sustainability advantage. Conventional ceramics often require frequent replacement due to brittle failure, generating substantial waste and resource consumption. By contrast, HE ceramics with optimized fracture toughness can significantly reduce replacement frequency, minimizing the material throughput in high-stress applications.

The manufacturing processes for microstructure-tuned HE ceramics present both challenges and opportunities from a sustainability perspective. Current synthesis methods often involve high-temperature processing, which demands considerable energy input. However, emerging research indicates that precise microstructural control may enable lower processing temperatures while maintaining desired mechanical properties, potentially reducing the carbon footprint associated with production.

Resource efficiency represents another critical sustainability factor. HE ceramics typically incorporate multiple elements in near-equiatomic proportions, which can diversify resource dependencies away from critical or rare materials. This compositional flexibility allows for the substitution of environmentally problematic elements with more abundant and less harmful alternatives while maintaining performance characteristics.

End-of-life considerations for HE ceramics must also be addressed in sustainability assessments. Their complex compositions can complicate recycling efforts, though their exceptional durability means this concern is offset by significantly extended service lifetimes. Research into recovery methods for constituent elements from spent HE ceramics is emerging as an important area for future development.

Life cycle assessment (LCA) studies specifically focused on microstructure-tuned HE ceramics remain limited, representing a significant knowledge gap. Preliminary analyses suggest that despite energy-intensive production, the total environmental impact over the full product lifetime may be substantially lower than conventional alternatives due to superior performance and longevity. Quantitative metrics linking microstructural features to both performance and environmental impact are needed to guide sustainable material design.

The potential for HE ceramics to enable more efficient energy systems further enhances their sustainability profile. Their exceptional thermal stability and mechanical properties at high temperatures make them ideal candidates for next-generation energy conversion systems, potentially contributing to broader decarbonization efforts beyond the direct impacts of the materials themselves.

Scale-up Considerations for Industrial Implementation

Scaling up the laboratory-developed HE ceramic microstructure tuning techniques to industrial implementation presents several critical challenges that must be addressed systematically. The transition from small-scale experimental setups to mass production environments requires careful consideration of process parameters, equipment capabilities, and quality control mechanisms.

Manufacturing equipment selection represents a primary consideration, as industrial-scale production demands specialized high-temperature furnaces with precise temperature control capabilities across larger volumes. These systems must maintain uniform heating profiles throughout the ceramic body to ensure consistent microstructural development. Variations in temperature gradients can lead to heterogeneous microstructures and unpredictable fracture toughness properties in the final products.

Raw material sourcing and consistency become increasingly important at industrial scales. Manufacturers must establish robust supply chains for high-purity precursor materials with consistent particle size distributions and chemical compositions. Even minor variations in starting materials can significantly impact the final microstructural characteristics and mechanical properties of HE ceramics.

Process parameter optimization requires extensive validation studies to determine how laboratory-established parameters translate to larger production volumes. This includes sintering time-temperature profiles, atmospheric conditions, cooling rates, and post-processing treatments. Computer modeling and simulation tools can help predict how these parameters will affect microstructure development in larger ceramic components.

Quality control protocols must be implemented at multiple production stages to ensure consistent fracture toughness properties. This includes in-line monitoring techniques such as ultrasonic testing, X-ray diffraction analysis, and mechanical testing of representative samples from each production batch. Statistical process control methodologies should be employed to identify and correct deviations before they affect product quality.

Cost-benefit analysis is essential when evaluating industrial implementation feasibility. While enhanced fracture toughness provides significant value, the additional processing steps and specialized equipment required for microstructure tuning must be economically justified. Manufacturers should consider both capital investment requirements and ongoing operational costs against the performance benefits and potential market premium for improved products.

Environmental and safety considerations also factor into scale-up planning. Industrial-scale ceramic processing typically involves energy-intensive heating operations and potentially hazardous materials. Implementing energy recovery systems, optimizing furnace loading patterns, and establishing appropriate handling protocols for raw materials are necessary components of responsible scale-up strategies.

Manufacturing equipment selection represents a primary consideration, as industrial-scale production demands specialized high-temperature furnaces with precise temperature control capabilities across larger volumes. These systems must maintain uniform heating profiles throughout the ceramic body to ensure consistent microstructural development. Variations in temperature gradients can lead to heterogeneous microstructures and unpredictable fracture toughness properties in the final products.

Raw material sourcing and consistency become increasingly important at industrial scales. Manufacturers must establish robust supply chains for high-purity precursor materials with consistent particle size distributions and chemical compositions. Even minor variations in starting materials can significantly impact the final microstructural characteristics and mechanical properties of HE ceramics.

Process parameter optimization requires extensive validation studies to determine how laboratory-established parameters translate to larger production volumes. This includes sintering time-temperature profiles, atmospheric conditions, cooling rates, and post-processing treatments. Computer modeling and simulation tools can help predict how these parameters will affect microstructure development in larger ceramic components.

Quality control protocols must be implemented at multiple production stages to ensure consistent fracture toughness properties. This includes in-line monitoring techniques such as ultrasonic testing, X-ray diffraction analysis, and mechanical testing of representative samples from each production batch. Statistical process control methodologies should be employed to identify and correct deviations before they affect product quality.

Cost-benefit analysis is essential when evaluating industrial implementation feasibility. While enhanced fracture toughness provides significant value, the additional processing steps and specialized equipment required for microstructure tuning must be economically justified. Manufacturers should consider both capital investment requirements and ongoing operational costs against the performance benefits and potential market premium for improved products.

Environmental and safety considerations also factor into scale-up planning. Industrial-scale ceramic processing typically involves energy-intensive heating operations and potentially hazardous materials. Implementing energy recovery systems, optimizing furnace loading patterns, and establishing appropriate handling protocols for raw materials are necessary components of responsible scale-up strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!