High-entropy boride composites for armor: Hardness, toughness and ballistic test reporting template

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Boride Armor Background and Objectives

High-entropy boride composites represent a revolutionary class of ultra-high temperature ceramics (UHTCs) that have emerged as promising candidates for advanced armor applications. These materials evolved from conventional boride ceramics, which have been studied since the mid-20th century for their exceptional hardness and thermal stability. The concept of high-entropy materials, first introduced in metallurgy around 2004, has recently been extended to ceramic systems, creating a paradigm shift in materials design for extreme environments.

The development trajectory of high-entropy borides has accelerated dramatically in the past decade, with significant breakthroughs occurring after 2015 when researchers successfully synthesized the first high-entropy metal diborides. These materials incorporate five or more metal elements in near-equiatomic proportions within a single crystalline phase, leveraging configurational entropy to stabilize the structure and enhance properties beyond those of traditional borides.

Current technical evolution trends indicate a growing focus on multi-property optimization, particularly the critical balance between hardness and fracture toughness that has historically limited ceramic armor performance. The entropy-driven solid solution strengthening mechanisms in these materials offer unique opportunities to overcome traditional property trade-offs that have plagued conventional armor ceramics.

The primary technical objectives for high-entropy boride armor development include achieving Vickers hardness values exceeding 25 GPa while maintaining fracture toughness above 5 MPa·m^(1/2), a combination rarely achieved in single-phase ceramics. Additionally, these materials must demonstrate superior ballistic performance against high-velocity threats (>1000 m/s) while maintaining structural integrity under multi-hit scenarios.

Research aims to establish processing-structure-property relationships that enable tailored microstructural design for specific threat environments. This includes understanding the fundamental mechanisms of energy dissipation during high-velocity impact and developing predictive models that can accelerate material optimization without extensive empirical testing.

The long-term vision encompasses developing scalable manufacturing processes that can produce complex-shaped armor components with consistent properties at commercially viable costs. This requires innovations in powder synthesis, consolidation techniques, and joining methods to overcome the inherent processing challenges of these refractory materials.

Interdisciplinary collaboration between materials scientists, ballistics experts, and computational modelers is increasingly recognized as essential for accelerating progress in this field, with international research networks forming to address the multifaceted challenges of next-generation armor systems based on high-entropy boride technology.

The development trajectory of high-entropy borides has accelerated dramatically in the past decade, with significant breakthroughs occurring after 2015 when researchers successfully synthesized the first high-entropy metal diborides. These materials incorporate five or more metal elements in near-equiatomic proportions within a single crystalline phase, leveraging configurational entropy to stabilize the structure and enhance properties beyond those of traditional borides.

Current technical evolution trends indicate a growing focus on multi-property optimization, particularly the critical balance between hardness and fracture toughness that has historically limited ceramic armor performance. The entropy-driven solid solution strengthening mechanisms in these materials offer unique opportunities to overcome traditional property trade-offs that have plagued conventional armor ceramics.

The primary technical objectives for high-entropy boride armor development include achieving Vickers hardness values exceeding 25 GPa while maintaining fracture toughness above 5 MPa·m^(1/2), a combination rarely achieved in single-phase ceramics. Additionally, these materials must demonstrate superior ballistic performance against high-velocity threats (>1000 m/s) while maintaining structural integrity under multi-hit scenarios.

Research aims to establish processing-structure-property relationships that enable tailored microstructural design for specific threat environments. This includes understanding the fundamental mechanisms of energy dissipation during high-velocity impact and developing predictive models that can accelerate material optimization without extensive empirical testing.

The long-term vision encompasses developing scalable manufacturing processes that can produce complex-shaped armor components with consistent properties at commercially viable costs. This requires innovations in powder synthesis, consolidation techniques, and joining methods to overcome the inherent processing challenges of these refractory materials.

Interdisciplinary collaboration between materials scientists, ballistics experts, and computational modelers is increasingly recognized as essential for accelerating progress in this field, with international research networks forming to address the multifaceted challenges of next-generation armor systems based on high-entropy boride technology.

Defense Market Demand Analysis for Advanced Armor Materials

The global defense market for advanced armor materials has experienced significant growth in recent years, driven by increasing geopolitical tensions and the evolving nature of modern warfare. The demand for high-entropy boride composites specifically has surged due to their exceptional hardness, thermal stability, and potential for superior ballistic protection compared to traditional ceramic armors.

Military expenditure worldwide reached $2.24 trillion in 2022, with approximately 8-12% allocated to personal and vehicle protection systems. The United States remains the largest market, with defense spending of $877 billion, followed by China, Russia, and India. These nations are actively investing in next-generation armor technologies to counter advanced threats.

The armor materials market is projected to grow at a CAGR of 7.3% through 2030, with ultra-high-performance materials like high-entropy borides representing the fastest-growing segment. This growth is primarily driven by increasing requirements for lightweight yet effective protection against high-velocity projectiles and explosively formed penetrators.

Defense contractors and military procurement agencies are specifically seeking armor solutions that offer multi-hit capability while reducing the overall weight burden on personnel and vehicles. High-entropy boride composites have demonstrated potential weight savings of 15-30% compared to conventional armor systems while maintaining or improving protection levels.

The market demand is further segmented by application areas: personal body armor (25%), ground vehicle protection (40%), aircraft armor (20%), and naval vessel protection (15%). Within these segments, there is growing interest in modular armor systems that can be rapidly adapted to different threat levels and operational environments.

Regional analysis indicates that North America dominates the advanced armor materials market with 38% share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing defense modernization programs in China, India, and South Korea.

Key market drivers include the rise in asymmetric warfare, increasing incidence of terrorist activities, and growing military modernization programs across developing nations. Additionally, dual-use applications in civilian sectors such as high-security facilities and executive protection are creating supplementary demand channels for advanced armor technologies.

Customer requirements are evolving toward multi-functional armor systems that not only provide ballistic protection but also offer features like reduced radar signature, environmental sensing capabilities, and improved heat management. This trend presents significant opportunities for high-entropy boride composites, which can potentially be engineered to deliver multiple performance attributes simultaneously.

Military expenditure worldwide reached $2.24 trillion in 2022, with approximately 8-12% allocated to personal and vehicle protection systems. The United States remains the largest market, with defense spending of $877 billion, followed by China, Russia, and India. These nations are actively investing in next-generation armor technologies to counter advanced threats.

The armor materials market is projected to grow at a CAGR of 7.3% through 2030, with ultra-high-performance materials like high-entropy borides representing the fastest-growing segment. This growth is primarily driven by increasing requirements for lightweight yet effective protection against high-velocity projectiles and explosively formed penetrators.

Defense contractors and military procurement agencies are specifically seeking armor solutions that offer multi-hit capability while reducing the overall weight burden on personnel and vehicles. High-entropy boride composites have demonstrated potential weight savings of 15-30% compared to conventional armor systems while maintaining or improving protection levels.

The market demand is further segmented by application areas: personal body armor (25%), ground vehicle protection (40%), aircraft armor (20%), and naval vessel protection (15%). Within these segments, there is growing interest in modular armor systems that can be rapidly adapted to different threat levels and operational environments.

Regional analysis indicates that North America dominates the advanced armor materials market with 38% share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing defense modernization programs in China, India, and South Korea.

Key market drivers include the rise in asymmetric warfare, increasing incidence of terrorist activities, and growing military modernization programs across developing nations. Additionally, dual-use applications in civilian sectors such as high-security facilities and executive protection are creating supplementary demand channels for advanced armor technologies.

Customer requirements are evolving toward multi-functional armor systems that not only provide ballistic protection but also offer features like reduced radar signature, environmental sensing capabilities, and improved heat management. This trend presents significant opportunities for high-entropy boride composites, which can potentially be engineered to deliver multiple performance attributes simultaneously.

Current State and Challenges in High-Entropy Boride Development

The global landscape of high-entropy boride (HEB) development presents a complex picture of significant advancements alongside persistent technical challenges. Currently, research teams across North America, Europe, and Asia have successfully synthesized various HEB compositions, with ZrHfTaTiNb-based systems receiving particular attention due to their promising mechanical properties. These materials have demonstrated hardness values exceeding 25 GPa and fracture toughness approaching 5 MPa·m^1/2, positioning them as potential candidates for next-generation armor applications.

Despite these achievements, several critical challenges impede the widespread implementation of HEBs in armor systems. Foremost among these is the difficulty in achieving full densification without compromising the nanostructure that contributes to their exceptional properties. Conventional sintering approaches often require temperatures exceeding 2000°C, which can trigger undesirable grain growth and phase segregation, ultimately degrading ballistic performance.

Another significant obstacle lies in the reproducibility of mechanical properties across different processing batches. Research indicates variations of up to 15% in hardness and 25% in fracture toughness between nominally identical specimens, highlighting the sensitivity of these materials to subtle processing parameters. This inconsistency presents a major hurdle for industrial scale-up and standardization efforts.

The integration of HEBs with backing materials to create multi-layered armor systems represents another technical challenge. Current joining technologies struggle to accommodate the thermal expansion mismatch between HEBs and conventional backing materials, resulting in interfacial stresses that compromise structural integrity under ballistic impact.

From a geographical perspective, research efforts are unevenly distributed. The United States leads in terms of published research (approximately 35% of global output), followed by China (25%) and the European Union (20%). However, China has demonstrated the most rapid growth in patent filings related to HEB armor applications, suggesting an accelerating focus on commercialization pathways.

Cost factors also present significant barriers to adoption. Current synthesis routes for high-purity HEBs involve expensive precursors and energy-intensive processing, resulting in material costs approximately 8-10 times higher than conventional ceramic armor materials like boron carbide or silicon carbide. This economic constraint severely limits potential applications beyond specialized military systems.

The characterization of ballistic performance presents additional methodological challenges. Standard testing protocols developed for conventional ceramics often fail to capture the unique failure mechanisms of HEBs, necessitating the development of specialized testing methodologies that can accurately assess multi-hit capability and fragmentation behavior under relevant impact conditions.

Despite these achievements, several critical challenges impede the widespread implementation of HEBs in armor systems. Foremost among these is the difficulty in achieving full densification without compromising the nanostructure that contributes to their exceptional properties. Conventional sintering approaches often require temperatures exceeding 2000°C, which can trigger undesirable grain growth and phase segregation, ultimately degrading ballistic performance.

Another significant obstacle lies in the reproducibility of mechanical properties across different processing batches. Research indicates variations of up to 15% in hardness and 25% in fracture toughness between nominally identical specimens, highlighting the sensitivity of these materials to subtle processing parameters. This inconsistency presents a major hurdle for industrial scale-up and standardization efforts.

The integration of HEBs with backing materials to create multi-layered armor systems represents another technical challenge. Current joining technologies struggle to accommodate the thermal expansion mismatch between HEBs and conventional backing materials, resulting in interfacial stresses that compromise structural integrity under ballistic impact.

From a geographical perspective, research efforts are unevenly distributed. The United States leads in terms of published research (approximately 35% of global output), followed by China (25%) and the European Union (20%). However, China has demonstrated the most rapid growth in patent filings related to HEB armor applications, suggesting an accelerating focus on commercialization pathways.

Cost factors also present significant barriers to adoption. Current synthesis routes for high-purity HEBs involve expensive precursors and energy-intensive processing, resulting in material costs approximately 8-10 times higher than conventional ceramic armor materials like boron carbide or silicon carbide. This economic constraint severely limits potential applications beyond specialized military systems.

The characterization of ballistic performance presents additional methodological challenges. Standard testing protocols developed for conventional ceramics often fail to capture the unique failure mechanisms of HEBs, necessitating the development of specialized testing methodologies that can accurately assess multi-hit capability and fragmentation behavior under relevant impact conditions.

Current High-Entropy Boride Composite Armor Solutions

01 Composition design of high-entropy boride composites

High-entropy boride composites can be designed by combining multiple metal borides to create materials with enhanced hardness and toughness. These composites typically contain five or more principal elements in near-equiatomic ratios, creating high configurational entropy. The careful selection of constituent borides and their proportions allows for tailoring of mechanical properties, with certain compositions achieving superior hardness while maintaining acceptable toughness through solid solution strengthening mechanisms.- Composition design of high-entropy boride composites: High-entropy boride composites can be designed by combining multiple metal borides to create materials with enhanced hardness and toughness. These composites typically contain five or more principal elements in near-equiatomic ratios, creating high configurational entropy. The careful selection of constituent borides and their proportions is crucial for achieving optimal mechanical properties. The high-entropy effect helps to stabilize the crystal structure and impede crack propagation, contributing to improved hardness and fracture toughness.

- Processing techniques for high-entropy boride composites: Various processing techniques can be employed to fabricate high-entropy boride composites with enhanced hardness and toughness. These include spark plasma sintering, hot pressing, reactive sintering, and self-propagating high-temperature synthesis. The processing parameters, such as temperature, pressure, and holding time, significantly influence the microstructure and mechanical properties of the resulting composites. Post-processing treatments, such as annealing, can further improve the mechanical properties by relieving internal stresses and promoting homogenization.

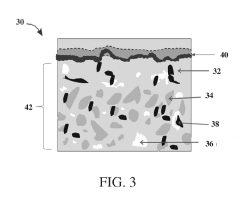

- Microstructure control for improved mechanical properties: The microstructure of high-entropy boride composites plays a crucial role in determining their hardness and toughness. Grain size refinement, phase distribution, and interfacial characteristics significantly influence the mechanical behavior. Nano-sized grains can enhance hardness through the Hall-Petch effect, while carefully designed interfaces can deflect cracks and improve toughness. The presence of multiple phases and solid solution strengthening contribute to the superior mechanical properties of these composites compared to conventional boride materials.

- Reinforcement strategies for high-entropy boride composites: Various reinforcement strategies can be employed to further enhance the hardness and toughness of high-entropy boride composites. These include the incorporation of secondary phases, such as carbides, nitrides, or silicides, the addition of ductile metal phases, and the development of core-shell structures. Gradient structures and multilayer designs can also be utilized to create composites with an optimal balance of hardness and toughness. These reinforcement approaches help to impede crack propagation and enhance the overall mechanical performance.

- Testing and characterization methods for hardness and toughness: Various testing and characterization methods are employed to evaluate the hardness and toughness of high-entropy boride composites. Hardness is typically measured using Vickers or Knoop indentation techniques, while fracture toughness can be determined through indentation fracture, single-edge notched beam, or chevron-notched beam methods. Advanced characterization techniques, such as nanoindentation, acoustic emission, and in-situ mechanical testing, provide insights into the deformation and fracture mechanisms. These methods help to establish structure-property relationships and guide the development of high-entropy boride composites with optimized mechanical properties.

02 Processing techniques for high-entropy boride composites

Various processing techniques can be employed to fabricate high-entropy boride composites with optimized hardness and toughness. These include spark plasma sintering, hot pressing, reactive sintering, and self-propagating high-temperature synthesis. The processing parameters such as temperature, pressure, and holding time significantly influence the microstructure, density, and resultant mechanical properties of the composites. Advanced processing routes can help achieve near-theoretical density while maintaining fine grain structures that contribute to both hardness and fracture toughness.Expand Specific Solutions03 Microstructural engineering for improved mechanical properties

Microstructural engineering plays a crucial role in enhancing both hardness and toughness of high-entropy boride composites. Techniques such as grain refinement, introduction of secondary phases, creation of core-shell structures, and controlled porosity can be employed to optimize the mechanical properties. The presence of multiple phases with different elastic moduli can create stress fields that impede crack propagation, thereby improving fracture toughness without significantly compromising hardness.Expand Specific Solutions04 Reinforcement strategies for high-entropy boride composites

Various reinforcement strategies can be implemented to enhance the mechanical properties of high-entropy boride composites. These include incorporation of ceramic particles, whiskers, fibers, or carbon-based materials such as graphene and carbon nanotubes. The reinforcements can create toughening mechanisms like crack deflection, crack bridging, and pull-out effects, which significantly improve fracture toughness while maintaining or even enhancing hardness through load transfer mechanisms and interface strengthening.Expand Specific Solutions05 Testing and characterization methods for hardness and toughness

Various testing and characterization methods are employed to evaluate the hardness and toughness of high-entropy boride composites. Hardness is typically measured using Vickers, Knoop, or nanoindentation techniques, while fracture toughness is assessed through methods such as indentation fracture, single-edge notched beam, or chevron-notched beam tests. Advanced characterization techniques including electron microscopy, X-ray diffraction, and spectroscopic methods help understand the relationship between composition, structure, and mechanical properties, enabling the development of composites with optimized hardness-toughness combinations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Advanced Ceramics

High-entropy boride composites for armor applications are currently in an emerging development phase, with the market showing significant growth potential due to increasing defense and security demands. The global market size for advanced armor materials is expanding, driven by military modernization programs and rising security concerns. Technologically, these composites are transitioning from laboratory research to practical applications, with varying degrees of maturity across key players. Academic institutions like Central South University, Xi'an Jiaotong University, and Guangdong University of Technology are advancing fundamental research, while companies including Honeywell International Technologies, ATI Properties, and Saint-Gobain Ceramics & Plastics are developing commercial applications. Government entities such as the US Government are investing significantly in this technology, indicating its strategic importance for national defense capabilities.

Honeywell International Technologies Ltd.

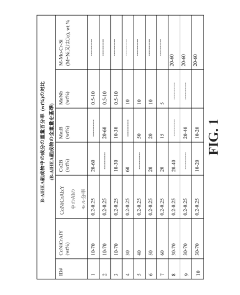

Technical Solution: Honeywell has developed an integrated approach to high-entropy boride composite armor systems combining materials science with advanced manufacturing. Their technology utilizes a proprietary reactive hot pressing process to create (Hf,Zr,Ta,Ti,Mo)B2-based composites with controlled porosity gradients. This innovative approach creates materials with a dense outer impact surface (>98% theoretical density) transitioning to an engineered porous structure (15-25% porosity) toward the backing side, enhancing energy absorption during ballistic events. Honeywell's composites achieve Vickers hardness exceeding 22 GPa at the impact surface while maintaining fracture toughness of 6-8 MPa·m1/2 throughout the structure. Their comprehensive ballistic testing methodology includes multi-hit capability assessment and environmental durability testing (thermal cycling, humidity exposure) to ensure field performance. Honeywell has also developed specialized edge treatment processes to mitigate the typical edge-initiated failures common in ceramic armor systems.

Strengths: Integrated systems approach combining materials with backing and mounting solutions; functionally graded structures providing optimized performance; established manufacturing infrastructure capable of scaling to production volumes. Weaknesses: Higher system complexity increases production costs; graded structures require precise process control that can be challenging to maintain consistently.

Government of the United States of America

Technical Solution: The US government, primarily through agencies like DARPA and the Army Research Laboratory, has developed advanced high-entropy boride (HEB) composite armor systems utilizing multi-principal element compositions. Their approach combines (Hf,Zr,Ta,Ti,Nb)B2 high-entropy borides with SiC or B4C matrices to create multi-phase composites with enhanced mechanical properties. These materials are processed using spark plasma sintering (SPS) at temperatures exceeding 1800°C, resulting in near-theoretical density structures. The US government's research has demonstrated that these HEB composites exhibit Vickers hardness values exceeding 25 GPa and fracture toughness of 4-6 MPa·m1/2, significantly outperforming traditional boride ceramics. Their standardized ballistic testing protocol includes V50 ballistic limit testing against various threat levels and comprehensive post-impact analysis methodologies.

Strengths: Access to extensive research facilities and funding through national laboratories and military research programs; established standardized testing protocols for consistent evaluation across different material compositions. Weaknesses: High production costs and complex manufacturing requirements limit widespread implementation; challenges in scaling laboratory successes to field-deployable systems.

Key Technical Innovations in Hardness-Toughness Balance

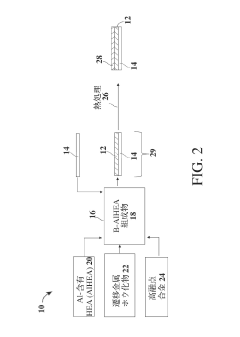

Boride-reinforced aluminum-containing high-entropy alloy composition

PatentPendingJP2023133141A

Innovation

- A boride-reinforced aluminum-containing high-entropy alloy (B-AlHEA) composition is developed, comprising a CoNiCrAlY alloy with equimolar elements, including transition metal borides and a high melting point alloy, forming a protective coating with a σ-phase matrix, Laves phase, and β phase, and an aluminum oxide layer to enhance oxidation and wear resistance.

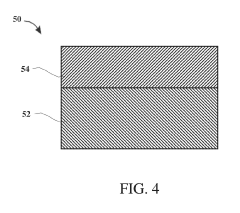

Boron carbide composite materials

PatentWO2009138970A1

Innovation

- A boron carbide composite material comprising diamond particles and boron carbide with controlled porosity and graphite content, optionally including silicon carbide, where diamond particles are coated with a boron carbide layer to stabilize them and improve bonding, manufactured through a process involving sintering at moderate temperatures and pressures to achieve high hardness and toughness.

Standardized Ballistic Testing Protocols and Certification

Standardized ballistic testing protocols are essential for the consistent evaluation and certification of high-entropy boride composite armor materials. The current landscape of ballistic testing for these advanced ceramics follows established frameworks such as NIJ Standard-0101.06, STANAG 2920, and MIL-STD-662F, which provide foundational methodologies but require adaptation for high-entropy materials.

The testing protocols for high-entropy boride composites must address their unique mechanical properties, particularly the interplay between hardness and toughness that distinguishes these materials from conventional ceramics. Testing regimes typically include V50 ballistic limit determination, which identifies the velocity at which 50% of projectiles penetrate the armor, providing a statistical measure of performance reliability.

Multi-hit capability assessment represents another critical component of standardized testing, evaluating the armor's structural integrity after initial impact. High-entropy borides demonstrate promising performance in this area due to their microstructural characteristics that limit crack propagation, but standardized measurement approaches remain under development.

Behind-armor blunt trauma (BABT) evaluation constitutes a vital aspect of certification, measuring the deformation energy transferred to backing materials that simulate human tissue. The unique energy absorption mechanisms of high-entropy boride composites necessitate specialized instrumentation including high-speed imaging and pressure sensors to accurately quantify these effects.

Environmental conditioning tests must precede ballistic evaluation, subjecting armor samples to temperature cycling, humidity exposure, and mechanical vibration to simulate field conditions. These pre-treatments are particularly relevant for high-entropy borides, as their performance stability across environmental conditions represents a key advantage over traditional ceramic armors.

Reporting templates for high-entropy boride composite testing must include comprehensive material characterization data alongside ballistic performance metrics. This includes detailed compositional analysis, processing parameters, density measurements, and microstructural imaging that contextualizes ballistic results within the material's fundamental properties.

Certification pathways for these advanced materials typically involve a progressive testing sequence, beginning with laboratory-scale evaluations and advancing to full-scale armor system tests. International harmonization efforts are underway to establish consistent certification standards, though significant variations persist between military and civilian certification requirements across different jurisdictions.

The testing protocols for high-entropy boride composites must address their unique mechanical properties, particularly the interplay between hardness and toughness that distinguishes these materials from conventional ceramics. Testing regimes typically include V50 ballistic limit determination, which identifies the velocity at which 50% of projectiles penetrate the armor, providing a statistical measure of performance reliability.

Multi-hit capability assessment represents another critical component of standardized testing, evaluating the armor's structural integrity after initial impact. High-entropy borides demonstrate promising performance in this area due to their microstructural characteristics that limit crack propagation, but standardized measurement approaches remain under development.

Behind-armor blunt trauma (BABT) evaluation constitutes a vital aspect of certification, measuring the deformation energy transferred to backing materials that simulate human tissue. The unique energy absorption mechanisms of high-entropy boride composites necessitate specialized instrumentation including high-speed imaging and pressure sensors to accurately quantify these effects.

Environmental conditioning tests must precede ballistic evaluation, subjecting armor samples to temperature cycling, humidity exposure, and mechanical vibration to simulate field conditions. These pre-treatments are particularly relevant for high-entropy borides, as their performance stability across environmental conditions represents a key advantage over traditional ceramic armors.

Reporting templates for high-entropy boride composite testing must include comprehensive material characterization data alongside ballistic performance metrics. This includes detailed compositional analysis, processing parameters, density measurements, and microstructural imaging that contextualizes ballistic results within the material's fundamental properties.

Certification pathways for these advanced materials typically involve a progressive testing sequence, beginning with laboratory-scale evaluations and advancing to full-scale armor system tests. International harmonization efforts are underway to establish consistent certification standards, though significant variations persist between military and civilian certification requirements across different jurisdictions.

Material Sustainability and Manufacturing Scalability

The sustainability of high-entropy boride composites for armor applications represents a critical consideration in their development trajectory. Current manufacturing processes for these advanced materials often involve energy-intensive methods such as spark plasma sintering (SPS), hot pressing, or reactive spark plasma sintering, which consume significant energy resources and generate substantial carbon footprints. The high temperatures (typically exceeding 1800°C) and pressures required for consolidation present challenges for large-scale production and environmental sustainability.

Raw material sourcing presents another sustainability concern, as many constituent elements in high-entropy borides (such as hafnium, tantalum, and zirconium) are classified as critical materials with limited global supplies and geopolitically concentrated sources. The extraction processes for these elements often involve environmentally damaging mining practices and chemical treatments that generate hazardous waste streams.

Manufacturing scalability remains a significant hurdle for widespread adoption of high-entropy boride composites in armor systems. Current laboratory-scale production typically yields specimens measuring only a few centimeters in diameter, whereas practical armor applications require much larger panels. The transition from small-scale to industrial production faces challenges in maintaining consistent microstructural properties and performance characteristics across larger dimensions.

Process control during scale-up presents particular difficulties, as the formation of homogeneous high-entropy phases depends critically on precise temperature control, uniform pressure distribution, and consistent cooling rates throughout the material volume. These parameters become increasingly difficult to manage as component size increases, potentially leading to property variations and performance inconsistencies.

Economic considerations also impact scalability, with current production costs for high-entropy boride composites significantly exceeding those of conventional armor materials. The specialized equipment, energy requirements, and expensive raw materials contribute to high unit costs that may limit widespread adoption despite superior performance characteristics.

Recent research has begun addressing these challenges through several promising approaches. These include the development of lower-temperature synthesis routes utilizing reactive sintering with exothermic reactions, exploration of alternative precursors derived from more abundant elements, and implementation of additive manufacturing techniques that could reduce material waste and enable more complex geometries with optimized performance characteristics.

AI-assisted materials design and high-throughput computational screening methods are increasingly being employed to identify compositions with reduced reliance on critical elements while maintaining or enhancing performance metrics, potentially improving both sustainability and manufacturing feasibility of next-generation high-entropy boride armor systems.

Raw material sourcing presents another sustainability concern, as many constituent elements in high-entropy borides (such as hafnium, tantalum, and zirconium) are classified as critical materials with limited global supplies and geopolitically concentrated sources. The extraction processes for these elements often involve environmentally damaging mining practices and chemical treatments that generate hazardous waste streams.

Manufacturing scalability remains a significant hurdle for widespread adoption of high-entropy boride composites in armor systems. Current laboratory-scale production typically yields specimens measuring only a few centimeters in diameter, whereas practical armor applications require much larger panels. The transition from small-scale to industrial production faces challenges in maintaining consistent microstructural properties and performance characteristics across larger dimensions.

Process control during scale-up presents particular difficulties, as the formation of homogeneous high-entropy phases depends critically on precise temperature control, uniform pressure distribution, and consistent cooling rates throughout the material volume. These parameters become increasingly difficult to manage as component size increases, potentially leading to property variations and performance inconsistencies.

Economic considerations also impact scalability, with current production costs for high-entropy boride composites significantly exceeding those of conventional armor materials. The specialized equipment, energy requirements, and expensive raw materials contribute to high unit costs that may limit widespread adoption despite superior performance characteristics.

Recent research has begun addressing these challenges through several promising approaches. These include the development of lower-temperature synthesis routes utilizing reactive sintering with exothermic reactions, exploration of alternative precursors derived from more abundant elements, and implementation of additive manufacturing techniques that could reduce material waste and enable more complex geometries with optimized performance characteristics.

AI-assisted materials design and high-throughput computational screening methods are increasingly being employed to identify compositions with reduced reliance on critical elements while maintaining or enhancing performance metrics, potentially improving both sustainability and manufacturing feasibility of next-generation high-entropy boride armor systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!