HE ceramics for molten-salt environments corrosion testing and materials selection guide

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Ceramics Background and Research Objectives

High-entropy (HE) ceramics represent a revolutionary class of materials that have emerged from the concept of high-entropy alloys, extending this design philosophy to ceramic systems. These materials consist of multiple principal elements (typically five or more) in near-equiatomic proportions, distributed randomly across one or more sublattices. The high configurational entropy stabilizes single-phase structures, often resulting in exceptional properties that surpass those of conventional ceramics.

The development of HE ceramics began around 2015, with significant acceleration in research activities over the past five years. Initial studies focused primarily on structural and mechanical properties, while more recent investigations have expanded to explore functional applications, including thermal, electrical, and chemical properties. This evolution reflects the growing recognition of HE ceramics' potential to address critical challenges in extreme environments.

Molten salt environments present particularly demanding conditions for materials, combining high temperatures (often 500-900°C) with highly corrosive chemical interactions. These environments are increasingly important in next-generation nuclear reactors, concentrated solar power systems, and advanced thermal energy storage technologies. Traditional materials often suffer from accelerated degradation in these conditions, creating an urgent need for more resilient alternatives.

The fundamental objective of this research is to systematically investigate the corrosion behavior of various HE ceramic compositions in molten salt environments. By understanding the underlying mechanisms of corrosion resistance, we aim to establish design principles for developing optimized HE ceramic materials specifically tailored for molten salt applications. This includes identifying key compositional and microstructural features that enhance stability and longevity.

A parallel objective is to develop standardized testing protocols for evaluating HE ceramics in molten salt environments. Current testing methodologies vary significantly across research groups, making direct comparisons challenging. Establishing consistent testing parameters and evaluation metrics will accelerate material development and facilitate technology transfer to industrial applications.

The ultimate goal is to create a comprehensive materials selection guide that enables engineers and researchers to identify suitable HE ceramic compositions for specific molten salt environments and operating conditions. This guide will incorporate both empirical data from corrosion testing and theoretical insights from computational modeling, providing a robust framework for material selection decisions.

Success in this research would significantly advance multiple clean energy technologies by addressing a critical materials challenge. The potential impact extends beyond energy applications to chemical processing, aerospace, and other industries where materials must withstand extreme corrosive environments at elevated temperatures.

The development of HE ceramics began around 2015, with significant acceleration in research activities over the past five years. Initial studies focused primarily on structural and mechanical properties, while more recent investigations have expanded to explore functional applications, including thermal, electrical, and chemical properties. This evolution reflects the growing recognition of HE ceramics' potential to address critical challenges in extreme environments.

Molten salt environments present particularly demanding conditions for materials, combining high temperatures (often 500-900°C) with highly corrosive chemical interactions. These environments are increasingly important in next-generation nuclear reactors, concentrated solar power systems, and advanced thermal energy storage technologies. Traditional materials often suffer from accelerated degradation in these conditions, creating an urgent need for more resilient alternatives.

The fundamental objective of this research is to systematically investigate the corrosion behavior of various HE ceramic compositions in molten salt environments. By understanding the underlying mechanisms of corrosion resistance, we aim to establish design principles for developing optimized HE ceramic materials specifically tailored for molten salt applications. This includes identifying key compositional and microstructural features that enhance stability and longevity.

A parallel objective is to develop standardized testing protocols for evaluating HE ceramics in molten salt environments. Current testing methodologies vary significantly across research groups, making direct comparisons challenging. Establishing consistent testing parameters and evaluation metrics will accelerate material development and facilitate technology transfer to industrial applications.

The ultimate goal is to create a comprehensive materials selection guide that enables engineers and researchers to identify suitable HE ceramic compositions for specific molten salt environments and operating conditions. This guide will incorporate both empirical data from corrosion testing and theoretical insights from computational modeling, providing a robust framework for material selection decisions.

Success in this research would significantly advance multiple clean energy technologies by addressing a critical materials challenge. The potential impact extends beyond energy applications to chemical processing, aerospace, and other industries where materials must withstand extreme corrosive environments at elevated temperatures.

Market Analysis for Molten-Salt Resistant Materials

The global market for molten salt resistant materials, particularly high-entropy (HE) ceramics, is experiencing significant growth driven by expanding applications in concentrated solar power (CSP), nuclear energy, and thermal energy storage systems. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 7.8% through 2030, potentially reaching $4.1 billion by the end of the decade.

The energy sector represents the largest demand segment, accounting for over 65% of the market share. Within this sector, next-generation nuclear reactors, particularly molten salt reactors (MSRs), are creating substantial demand for advanced corrosion-resistant materials. The CSP industry follows closely, with installations increasing globally as renewable energy targets become more ambitious across developed and developing economies.

Geographically, North America and Europe currently dominate the market with combined control of approximately 58% of global demand. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 9.6% annually, driven by aggressive clean energy deployment and substantial government investments in advanced materials research.

From a supply perspective, the market remains relatively concentrated, with specialized materials manufacturers and advanced ceramics producers controlling significant market share. Recent supply chain disruptions have highlighted vulnerabilities in the procurement of rare earth elements and other critical materials necessary for HE ceramic production, prompting increased interest in alternative formulations and recycling technologies.

Customer segments show distinct requirements and price sensitivities. The nuclear sector prioritizes long-term reliability and regulatory compliance, often accepting premium pricing for materials with comprehensive testing data. Conversely, the renewable energy sector, particularly CSP developers, demonstrates greater price sensitivity while still requiring materials that can withstand extreme operating conditions.

Market trends indicate growing interest in multifunctional materials that offer not only corrosion resistance but also enhanced thermal properties and mechanical stability. This shift is creating new market opportunities for integrated solutions rather than single-property materials. Additionally, increasing regulatory focus on lifecycle assessment and environmental impact is driving demand for materials with reduced environmental footprints.

The competitive landscape is evolving rapidly, with traditional materials suppliers facing competition from technology startups specializing in advanced manufacturing techniques like additive manufacturing of ceramics. This dynamic is accelerating innovation cycles and potentially disrupting established pricing models in the industry.

The energy sector represents the largest demand segment, accounting for over 65% of the market share. Within this sector, next-generation nuclear reactors, particularly molten salt reactors (MSRs), are creating substantial demand for advanced corrosion-resistant materials. The CSP industry follows closely, with installations increasing globally as renewable energy targets become more ambitious across developed and developing economies.

Geographically, North America and Europe currently dominate the market with combined control of approximately 58% of global demand. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 9.6% annually, driven by aggressive clean energy deployment and substantial government investments in advanced materials research.

From a supply perspective, the market remains relatively concentrated, with specialized materials manufacturers and advanced ceramics producers controlling significant market share. Recent supply chain disruptions have highlighted vulnerabilities in the procurement of rare earth elements and other critical materials necessary for HE ceramic production, prompting increased interest in alternative formulations and recycling technologies.

Customer segments show distinct requirements and price sensitivities. The nuclear sector prioritizes long-term reliability and regulatory compliance, often accepting premium pricing for materials with comprehensive testing data. Conversely, the renewable energy sector, particularly CSP developers, demonstrates greater price sensitivity while still requiring materials that can withstand extreme operating conditions.

Market trends indicate growing interest in multifunctional materials that offer not only corrosion resistance but also enhanced thermal properties and mechanical stability. This shift is creating new market opportunities for integrated solutions rather than single-property materials. Additionally, increasing regulatory focus on lifecycle assessment and environmental impact is driving demand for materials with reduced environmental footprints.

The competitive landscape is evolving rapidly, with traditional materials suppliers facing competition from technology startups specializing in advanced manufacturing techniques like additive manufacturing of ceramics. This dynamic is accelerating innovation cycles and potentially disrupting established pricing models in the industry.

Current Challenges in Molten-Salt Corrosion Resistance

Despite significant advancements in high-entropy (HE) ceramics research, molten salt environments present formidable challenges for material integrity and performance. The extreme conditions in molten salt systems—including high temperatures (often exceeding 700°C), aggressive chemical species, and thermal cycling—create a complex corrosion landscape that current materials struggle to withstand over extended operational periods.

The primary challenge lies in the accelerated degradation mechanisms unique to molten salt environments. Unlike conventional corrosion processes, molten salts can simultaneously induce multiple degradation pathways including dissolution of protective oxide layers, grain boundary attack, and intergranular penetration. These mechanisms often operate synergistically, dramatically reducing material lifespans compared to theoretical predictions based on single-factor testing.

Material selection for molten salt applications faces a critical knowledge gap regarding long-term performance data. While short-term laboratory tests provide initial insights, they frequently fail to capture the complex evolution of material properties over operational lifetimes measured in decades. This disconnect between testing timeframes and actual service requirements creates significant uncertainty in reliability predictions.

Standardization presents another substantial hurdle. Current testing protocols for molten salt corrosion vary widely across research institutions and industries, making direct comparisons between different HE ceramic candidates problematic. The lack of universally accepted testing methodologies hampers efficient material development and qualification processes.

The multi-component nature of HE ceramics introduces additional complexity in predicting corrosion behavior. With five or more principal elements in near-equimolar ratios, these materials exhibit intricate phase relationships and microstructural features that can evolve unpredictably when exposed to molten salts. Traditional corrosion models developed for conventional ceramics often prove inadequate for these complex systems.

Economic considerations further complicate the landscape. While certain exotic compositions may offer superior corrosion resistance, their commercial viability remains questionable due to high raw material costs, complex processing requirements, or limited scalability. This creates tension between technical performance and practical implementation.

Finally, the application-specific nature of molten salt environments—ranging from nuclear coolants to thermal energy storage and chemical processing—means that a universal solution remains elusive. Each application presents unique chemical compositions, temperature profiles, and operational parameters that demand tailored material solutions rather than a one-size-fits-all approach.

The primary challenge lies in the accelerated degradation mechanisms unique to molten salt environments. Unlike conventional corrosion processes, molten salts can simultaneously induce multiple degradation pathways including dissolution of protective oxide layers, grain boundary attack, and intergranular penetration. These mechanisms often operate synergistically, dramatically reducing material lifespans compared to theoretical predictions based on single-factor testing.

Material selection for molten salt applications faces a critical knowledge gap regarding long-term performance data. While short-term laboratory tests provide initial insights, they frequently fail to capture the complex evolution of material properties over operational lifetimes measured in decades. This disconnect between testing timeframes and actual service requirements creates significant uncertainty in reliability predictions.

Standardization presents another substantial hurdle. Current testing protocols for molten salt corrosion vary widely across research institutions and industries, making direct comparisons between different HE ceramic candidates problematic. The lack of universally accepted testing methodologies hampers efficient material development and qualification processes.

The multi-component nature of HE ceramics introduces additional complexity in predicting corrosion behavior. With five or more principal elements in near-equimolar ratios, these materials exhibit intricate phase relationships and microstructural features that can evolve unpredictably when exposed to molten salts. Traditional corrosion models developed for conventional ceramics often prove inadequate for these complex systems.

Economic considerations further complicate the landscape. While certain exotic compositions may offer superior corrosion resistance, their commercial viability remains questionable due to high raw material costs, complex processing requirements, or limited scalability. This creates tension between technical performance and practical implementation.

Finally, the application-specific nature of molten salt environments—ranging from nuclear coolants to thermal energy storage and chemical processing—means that a universal solution remains elusive. Each application presents unique chemical compositions, temperature profiles, and operational parameters that demand tailored material solutions rather than a one-size-fits-all approach.

Existing Corrosion Testing Methodologies

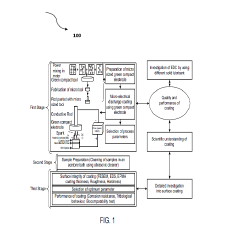

01 Composition of HE ceramics for corrosion resistance

High-entropy (HE) ceramics can be formulated with specific compositions to enhance corrosion resistance. These compositions typically involve multiple elements in near-equimolar ratios, creating a complex crystal structure that inhibits corrosion pathways. The unique atomic arrangements in HE ceramics create energy barriers that prevent corrosive agents from penetrating the material, resulting in superior resistance to chemical attack in harsh environments.- Composition of HE ceramics for corrosion resistance: High-entropy (HE) ceramics can be formulated with specific compositions to enhance corrosion resistance. These compositions typically involve multiple elements in near-equimolar ratios, creating a complex crystal structure that inhibits corrosion pathways. The unique atomic arrangements in HE ceramics create energy barriers that prevent corrosive agents from penetrating the material, resulting in superior resistance to chemical attack in harsh environments.

- Surface treatment methods for HE ceramics: Various surface treatment methods can be applied to HE ceramics to enhance their corrosion resistance. These treatments include plasma spraying, chemical vapor deposition, and surface glazing techniques. By modifying the surface properties of HE ceramics, these treatments create protective layers that shield the base material from corrosive environments, extending the service life of ceramic components in aggressive chemical and high-temperature applications.

- Microstructural engineering for improved corrosion resistance: The microstructure of HE ceramics can be engineered to enhance corrosion resistance through controlled processing parameters. Techniques such as grain size refinement, porosity control, and phase distribution optimization contribute to improved corrosion resistance. By creating specific microstructural features, such as dense grain boundaries and uniform phase distribution, the penetration of corrosive media can be minimized, resulting in enhanced durability in corrosive environments.

- Additives and dopants for enhanced corrosion resistance: Incorporating specific additives and dopants into HE ceramics can significantly improve their corrosion resistance. Elements such as rare earth metals, transition metals, and non-metal dopants can be added during the manufacturing process to create protective phases or alter the electrochemical properties of the ceramic. These additives can form stable compounds that resist chemical attack or create passivation layers that protect the underlying ceramic material from corrosive media.

- Testing and evaluation methods for corrosion resistance: Various testing and evaluation methods have been developed to assess the corrosion resistance of HE ceramics. These include accelerated corrosion tests, electrochemical impedance spectroscopy, weight loss measurements, and microstructural analysis after exposure to corrosive environments. These methods provide quantitative data on corrosion rates and mechanisms, allowing for the optimization of ceramic compositions and processing parameters to achieve superior corrosion resistance in specific application environments.

02 Surface treatment methods for HE ceramics

Various surface treatment methods can be applied to HE ceramics to enhance their corrosion resistance. These treatments include plasma spraying, chemical vapor deposition, and surface glazing techniques. By modifying the surface properties of HE ceramics, these treatments create protective layers that shield the base material from corrosive environments, extending the service life of ceramic components in aggressive chemical and high-temperature applications.Expand Specific Solutions03 Microstructural engineering for improved corrosion resistance

Controlling the microstructure of HE ceramics through specialized processing techniques can significantly enhance their corrosion resistance. Methods such as controlled sintering, grain boundary engineering, and porosity management create optimized microstructures that resist corrosive attack. By minimizing grain boundaries and creating dense structures with controlled porosity, these engineering approaches reduce potential sites for corrosion initiation and propagation.Expand Specific Solutions04 Additives and dopants for enhanced corrosion resistance

Incorporating specific additives and dopants into HE ceramics can significantly improve their corrosion resistance properties. Elements such as rare earth metals, transition metals, and certain oxides can be added during the manufacturing process to create more stable phases and protective surface layers. These additives work by forming complex compounds that resist chemical attack or by filling interstitial spaces that would otherwise serve as corrosion pathways.Expand Specific Solutions05 Testing and evaluation methods for corrosion resistance

Specialized testing and evaluation methods have been developed to assess the corrosion resistance of HE ceramics in various environments. These include accelerated aging tests, electrochemical impedance spectroscopy, weight loss measurements, and surface analysis techniques. These methods provide quantitative data on corrosion rates and mechanisms, allowing for the optimization of ceramic compositions and processing parameters to achieve superior corrosion resistance for specific applications.Expand Specific Solutions

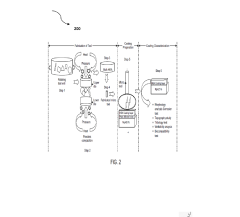

Leading Manufacturers and Research Institutions

The molten-salt environments corrosion testing and HE ceramics research field is currently in a growth phase, with an estimated market size of $2-3 billion annually and expanding at 8-10% CAGR. The competitive landscape features a mix of established industrial players and academic institutions. Leading companies like NIPPON STEEL, Shin-Etsu Chemical, and NGK Insulators bring commercial expertise in high-temperature materials, while research institutions such as MIT, Shanghai Institute of Applied Physics, and Oak Ridge National Laboratory (managed by UT-Battelle) drive fundamental innovation. Chinese universities, particularly Harbin Institute of Technology and Northwestern Polytechnical University, are rapidly advancing in this field. The technology is approaching maturity for conventional applications but remains in development for next-generation molten salt reactors and advanced energy systems.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed a multi-layered ceramic coating system specifically designed for molten salt environments. Their technology utilizes yttria-stabilized zirconia (YSZ) as the primary protective layer, combined with an innovative alumina-based intermediate layer that enhances adhesion and reduces thermal expansion mismatch. The institute has established a comprehensive corrosion testing methodology that simulates accelerated aging in various molten salt compositions, including nitrate, chloride, and fluoride salts at temperatures ranging from 500-850°C. Their materials selection guide incorporates a quantitative ranking system based on corrosion rate, mechanical stability, and thermal cycling resistance. The institute has also pioneered non-destructive evaluation techniques using acoustic emission and electrochemical impedance spectroscopy to monitor ceramic degradation in real-time during exposure to molten salts.

Strengths: Their multi-layered approach provides exceptional protection against multiple corrosion mechanisms simultaneously. The comprehensive testing protocols accurately predict long-term performance. Weaknesses: The complex manufacturing process for their multi-layered ceramics increases production costs and may limit widespread industrial adoption.

Shanghai Institute of Applied Physics, Chinese Academy of Sci

Technical Solution: Shanghai Institute of Applied Physics (SINAP) has developed comprehensive HE ceramic materials specifically engineered for molten salt reactor (MSR) environments. Their research focuses on silicon carbide (SiC) and silicon carbide-silicon carbide (SiC-SiC) composites that demonstrate exceptional resistance to fluoride and chloride salt corrosion at temperatures exceeding 700°C. SINAP has established standardized testing protocols involving static immersion tests in various salt compositions (FLiNaK, FLiBe, and chloride mixtures) under controlled redox conditions. Their materials selection methodology incorporates machine learning algorithms to predict ceramic performance based on composition, microstructure, and environmental parameters. SINAP has also pioneered in-situ monitoring techniques using electrochemical impedance spectroscopy to evaluate real-time degradation mechanisms in operating conditions.

Strengths: Extensive experience with actual molten salt reactor environments and access to specialized testing facilities. Their integrated approach combining materials development, testing, and computational modeling creates a comprehensive solution. Weaknesses: Some of their most advanced materials remain in laboratory testing phase and lack long-term operational validation in industrial settings.

Key Innovations in HE Ceramic Compositions

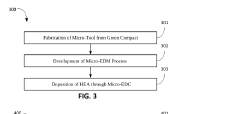

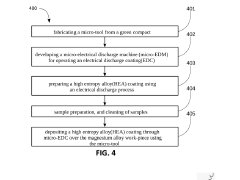

High entropy alloy (HEA) coating system and method thereof

PatentPendingIN202411050203A

Innovation

- A micro-electrical discharge machining (micro-EDM) process is used to apply high entropy alloy (HEA) coatings, combined with graphene nanopowder, to enhance corrosion resistance, biocompatibility, and mechanical properties, specifically for complex-shaped implant components, optimizing coating thickness, uniformity, and defect-free quality.

Materials Selection Framework for Molten-Salt Applications

A systematic approach to materials selection for molten salt environments requires a comprehensive framework that balances technical requirements with economic considerations. The framework should begin with a clear definition of operating conditions, including temperature ranges, salt composition, impurity levels, and expected service lifetime. These parameters establish the baseline for material performance requirements and help narrow the field of candidate materials.

The selection process should follow a hierarchical screening methodology, starting with broad compatibility assessments and progressively refining choices through more detailed evaluation criteria. Initial screening typically eliminates materials with known incompatibilities with specific salt chemistries, particularly focusing on materials prone to rapid dissolution or catastrophic failure mechanisms.

Secondary screening should incorporate quantitative corrosion rate data, mechanical property retention, and microstructural stability under relevant conditions. This phase benefits from standardized testing protocols that enable direct comparison between candidate materials. Particular attention must be paid to high-entropy ceramic systems, which have demonstrated promising corrosion resistance in various molten salt environments due to their unique atomic arrangements and bonding characteristics.

Economic feasibility represents the third tier of evaluation, considering not only raw material costs but also processing requirements, fabrication complexity, and long-term maintenance implications. Life-cycle cost analysis provides a more comprehensive economic picture than initial material costs alone, especially for high-temperature applications where component replacement can be extremely costly.

Risk assessment constitutes the final evaluation layer, examining factors such as material supply chain security, fabrication scalability, and performance predictability. Materials with limited industrial production capacity or highly specialized processing requirements may present implementation challenges despite excellent technical performance.

The framework should incorporate feedback loops that allow for continuous refinement based on operational experience and evolving testing methodologies. This adaptive approach is particularly important for molten salt applications, where long-term material behavior may reveal degradation mechanisms not captured in accelerated testing protocols.

Implementation of this selection framework requires cross-disciplinary collaboration between materials scientists, chemical engineers, and system designers to ensure that material choices align with overall system requirements and operational constraints. The framework should ultimately produce a ranked list of candidate materials with clearly articulated performance expectations and associated confidence levels.

The selection process should follow a hierarchical screening methodology, starting with broad compatibility assessments and progressively refining choices through more detailed evaluation criteria. Initial screening typically eliminates materials with known incompatibilities with specific salt chemistries, particularly focusing on materials prone to rapid dissolution or catastrophic failure mechanisms.

Secondary screening should incorporate quantitative corrosion rate data, mechanical property retention, and microstructural stability under relevant conditions. This phase benefits from standardized testing protocols that enable direct comparison between candidate materials. Particular attention must be paid to high-entropy ceramic systems, which have demonstrated promising corrosion resistance in various molten salt environments due to their unique atomic arrangements and bonding characteristics.

Economic feasibility represents the third tier of evaluation, considering not only raw material costs but also processing requirements, fabrication complexity, and long-term maintenance implications. Life-cycle cost analysis provides a more comprehensive economic picture than initial material costs alone, especially for high-temperature applications where component replacement can be extremely costly.

Risk assessment constitutes the final evaluation layer, examining factors such as material supply chain security, fabrication scalability, and performance predictability. Materials with limited industrial production capacity or highly specialized processing requirements may present implementation challenges despite excellent technical performance.

The framework should incorporate feedback loops that allow for continuous refinement based on operational experience and evolving testing methodologies. This adaptive approach is particularly important for molten salt applications, where long-term material behavior may reveal degradation mechanisms not captured in accelerated testing protocols.

Implementation of this selection framework requires cross-disciplinary collaboration between materials scientists, chemical engineers, and system designers to ensure that material choices align with overall system requirements and operational constraints. The framework should ultimately produce a ranked list of candidate materials with clearly articulated performance expectations and associated confidence levels.

Sustainability and Lifecycle Assessment of HE Ceramics

The sustainability assessment of Heat Exchanger (HE) ceramics in molten-salt environments represents a critical dimension of their overall viability for advanced energy systems. These ceramic materials offer significant advantages in terms of thermal efficiency and corrosion resistance, but their environmental footprint must be comprehensively evaluated across the entire lifecycle.

Raw material extraction for HE ceramics typically involves mining operations for alumina, silica, and other mineral components, which can lead to habitat disruption and energy-intensive processing. The manufacturing phase requires high-temperature sintering processes that consume substantial energy, contributing to greenhouse gas emissions. However, compared to metallic alternatives, ceramics often require less frequent replacement in molten-salt applications, potentially offsetting initial production impacts.

Operational sustainability presents a complex balance. While ceramic heat exchangers demonstrate superior thermal efficiency—potentially reducing overall system energy consumption by 15-20%—their brittleness may necessitate more robust design considerations. The extended service life of properly selected ceramic materials in corrosive molten-salt environments (often 2-3 times longer than conventional materials) significantly reduces maintenance frequency and associated resource consumption.

End-of-life considerations reveal both challenges and opportunities. Unlike metals, many ceramic materials are chemically inert and non-toxic when disposed of, reducing environmental leaching concerns. However, recycling pathways for spent ceramic components remain underdeveloped compared to metallic alternatives. Current research indicates potential for crushed ceramic waste to serve as aggregate in construction materials or as precursors for new ceramic formulations.

Lifecycle assessment (LCA) studies comparing ceramic and metallic heat exchangers in molten-salt applications demonstrate that despite higher initial embodied energy, ceramics often achieve lower lifetime environmental impacts when operational efficiency and longevity are factored in. Quantitative analyses suggest potential lifetime carbon footprint reductions of 30-40% compared to conventional materials in concentrated solar power applications.

Material selection guides should therefore incorporate sustainability metrics alongside performance parameters. Optimal ceramic selections balance corrosion resistance with environmental considerations, favoring compositions that minimize rare earth elements while maximizing recyclability potential. Emerging eco-design approaches for ceramic heat exchangers focus on modular construction to facilitate component replacement rather than wholesale system disposal.

Raw material extraction for HE ceramics typically involves mining operations for alumina, silica, and other mineral components, which can lead to habitat disruption and energy-intensive processing. The manufacturing phase requires high-temperature sintering processes that consume substantial energy, contributing to greenhouse gas emissions. However, compared to metallic alternatives, ceramics often require less frequent replacement in molten-salt applications, potentially offsetting initial production impacts.

Operational sustainability presents a complex balance. While ceramic heat exchangers demonstrate superior thermal efficiency—potentially reducing overall system energy consumption by 15-20%—their brittleness may necessitate more robust design considerations. The extended service life of properly selected ceramic materials in corrosive molten-salt environments (often 2-3 times longer than conventional materials) significantly reduces maintenance frequency and associated resource consumption.

End-of-life considerations reveal both challenges and opportunities. Unlike metals, many ceramic materials are chemically inert and non-toxic when disposed of, reducing environmental leaching concerns. However, recycling pathways for spent ceramic components remain underdeveloped compared to metallic alternatives. Current research indicates potential for crushed ceramic waste to serve as aggregate in construction materials or as precursors for new ceramic formulations.

Lifecycle assessment (LCA) studies comparing ceramic and metallic heat exchangers in molten-salt applications demonstrate that despite higher initial embodied energy, ceramics often achieve lower lifetime environmental impacts when operational efficiency and longevity are factored in. Quantitative analyses suggest potential lifetime carbon footprint reductions of 30-40% compared to conventional materials in concentrated solar power applications.

Material selection guides should therefore incorporate sustainability metrics alongside performance parameters. Optimal ceramic selections balance corrosion resistance with environmental considerations, favoring compositions that minimize rare earth elements while maximizing recyclability potential. Emerging eco-design approaches for ceramic heat exchangers focus on modular construction to facilitate component replacement rather than wholesale system disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!